Emerald K3 User manual

1

Emerald K3

Engine management system

Operating manual

Draft v0.51

2

•TheECUcanstoreup tothree completelyseparatemaps.

•IfsettodosotheECUwill allowyoutofreelyswitchbetweenmapson-the-

fly.

•Themapping softwarealsoholdsthree mapsinmemoryandwill switchmaps

insyncwiththeECU.

•Themapping softwareusesanewfileformatthatallowsthree mapsbeto

storedwithintheonefile.

•A0-5voltsignalviaananalogueinputcanbeusedtoinstructtheECUwhich

maptouse.Asimpletwopositionon-offswitchcanbeusedtoprovidea

high-lowsignalthatwillenableyoutoswitchbetweentwomaps. Toswitch

betweenthree mapsarotarymulti-positionorpotentiometercanbeused.

Mapswitching

3

Mapswitching–software

TheK3ECUhastheabilitytoretainthree totallyseparatemapswithintheECU. The

laptoporPCalsohasthree mapscreensavailable. ForaslongasthePCis

communicatingwiththeECUitwillautomaticallyswitchthemapsdisplayedtostay

insync. Ifyouwanttoworkonamapthatisnotcurrentlyselectedwithoutusingthe

ECUtoswitchmapsyoucanpowerdowntheECU(orunplug thecommunications

lead)andselect‘Switchtomap’fromthe‘File’menu.

Thereisashortcuttothismapselectionscreenbyclicking thePCmapboxatthe

bottomofthemainscreen.

Note: Topreventconfusion thePCwill notallowyou toswitchmapswhenlinkedto

theECU.

Forexample:ifmapping onarolling roadyoucanalterthefuelandignitionsettings

onmap1(greenmap)viathelivemappingpage(F8)andthen, viaaswitchonthe

dash, switchtomap2(redmap). ThePCwill bring theredmaptothefrontofthe

screenandyoucanalterfuelandignitiontiming againviathelivemapping screen

exactlyasbefore. SwitchtheECUtomap3(yellowmap)andrepeatthemapping

process.

4

Mapswitching-configuration

Therearevariouswaysofsettingup theECUtoreadtheswitching signal. Beloware

twoexamples.

Example1

TheECUistoswitchbetweentwomapsaccording toauseractivatedswitch. Inthis

particularcaseAuxIn35 isunusedsoitisavailableasaninputsource forthemap

switchingfunction. Byenabling theinternalpull-up resistorontheAuxIn35 inputwe

canchangemapsusing asimpleswitchtoearth.

AuxIn35

ECU

Mapswitch

+5v

Withtheswitchintheopenpositiontheinternalpull-up resistorresultsintheECU

reading5vattheAuxIn35 input. WiththeswitchintheclosedpositiontheECUwill

read0vattheAuxIn35 input. Theinternalpull-upto+5vforAuxIn35 mustbe

enabledinthe‘Inputchannels’sectionofthe‘ECUconfiguration’asshownbelow.

5

Toconfigurethemapswitching functionselect‘Mapswitching’fromthe‘ECU

configuration’menu.

Inthisexamplewehavetwovoltagelevels, 0vand5v, atAuxIn35 depending onthe

positionofaswitch.

TheinputsourcehasbeensettoAuxIn35. Twovoltagelevelsareusedtodetermine

whichmaptheECUshouldbeusing. Map1isselectedifthevoltageis below a

certainthresholdandMap3isselectedifthevoltageis above acertainthreshold.

Map2isselectediftheinputvoltageliesbetweenthe above andthe below thresholds.

Forthisexamplethemid-pointvoltageof2.51 voltsisusedastheaboveandbelow

thresholds. Map1isselectedifthevoltageatAuxIn35 isbelow2.51 volts(switchis

intheclosedposition)andMap3isselectedifthevoltageatAuxIn35 isabove2.51

volts(switchisintheopenposition). Map2isnotusedandcannotbeactivated.

WhentheECUisconnectedthelivereadingspanelshowsthereal-timeinputvoltage

usedforthemapswitchingfunction. Thebargraph hasaverticalscalethatpresents0

to5voltsandisalsocolourcodedtoshowthevoltagetomapselectionrelationship.

Theverticalcolourcodingofthebargraphiscolourcodedaccordingtothemap

switchingsettings.

6

Example2

TheECUistoswitchbetweenthethree mapsaccordingtoa3-wayrotaryposition

switchmountedonthedashboard.

Aswiththepreviousexample, usingananalogueinputthathasaninternalpull-up

resistorsimplifiesthemapswitchwiring. Usingsuchaninputgivesustwovoltage

levelswithaswitchtoearth(open=5volts, closed=0volts).Byswitching this

inputtoearthviaaresistorwecreateapotentialdividercircuitwhichwillresultina

thirdvoltagelevelofbetween0voltsand5volts(depending onthevalueofthe

resistorused).AstheECUuses1K internalpull-up resistorswecanswitchthe

inputtoearthviaanother1K resistortogiveamid-pointvoltagelevelof2.5volts.

ECU

1

2

3

1K

Ω

Aux7b

+5v 1K

Ω

InthisexampleAux7bisfree sowillbeassignedtothemapswitching function.

Aux7b, Aux8bandAux9bhavefixedinternal1K pull-up resistors.

Withtherotarypositionswitchatposition1Aux7bisconnectedtoearthwhich

resultsinaninputvoltageof0volts.

Atposition2Aux7bisconnectedtoearthviaa1K resistorresultingin2.5voltsat

Aux7b.

Atposition3Aux7bisunconnectedsowillbeat5voltsduetotheinternalpull-up

resistor.

7

TheECUconfigurationforthisexampleisshownbelow.

Herethemapswitchthresholdshavebeensetsothattheboundariesarespacedevenly

givemorethanenoughroomforerror.

Themapswitching functionmonitors theinputvoltageapproximately5timesper

second. Beforechanging mapstheECUwill re-evaluatethenewmapaccordingto

thecurrentrunning conditionstoensurethechangeisseamless. Thisprocess takes

approximately1-2mS.

TheECUwill switchmapson-the-flyregardless ofenginerpmorload.

8

Thisfunctionisusedtointerrupt/reduce enginepowersothatafastgearchangecan

bemadewithoutlifting thethrottle. Enginepowerisreducedbyretardingtheignition

toasetposition. Thisignitiontiming canbenegative(AfterTDC).Ifturbo-charged,

thisretardedignitiontiming duringagearchangecanprovideaformofanti-lag.

Theflatshiftfunctionwillbeactivatedifcertainuseradjustableconditionsaremet

andauserassignedinputisactivated.

Thisflatshiftfunctioncanbeconfiguredaccording tothegearboxtypeused.

•Sequentialgearbox.

Theuserassignedinputcanbewiredagearlevermovementswitchorclutch

switch. Theflatshiftfunctioncanbeconfiguredtointerruptpowerfora

specificamountoftimeaccordingtothegearselected.

•H-patterngearbox.

Theuserassignedinputcanbewiredtoaclutchpositionorpressureswitch.

Theflatshiftfunctioncanbeconfiguredtointerruptpowerforaslongasthe

inputisactivated, i.e. untiltheclutchpedalisreleased.

Select‘fullthrottlegearshift’fromthe‘Additionalmaps’menutoaccess thesettings

pageforthisfunction. Thesettingsaregroupedinto3areas onthescreen; Activation

conditions, Enginecontrolsettings and Powercuttable.

Full throttlegearshift(Flat shift)

9

Activationconditions

Theactivationconditionsdeterminehowandwhenthegearshiftfunctioncanbe

activated.

•Flatshiftenabled:Setswhetherthisfunctionisenabledornot.

•Clutchinput:Showsthecurrentclutchswitchstatus .

•Throttepositionatorabove:Throttlepositionmustbeabovethisbeforethe

flatshiftfunctionwillactivate.

•Enginespeedatorabove:Theflatshiftfunctionwillonlyactivateabove

thisrpm.

•Re-activatedelay:HowlongtheECUwillwaitbeforeallowing

thisfunctiontoactivateagain.

Enginecontrolsettings

Thisenginecontrolsettingsdeterminehowtheenginepoweriscutandhowlowthe

enginerpmisallowedtodrop.

•Retardignitionto:Sets thefixedignitiontiming duringthegear

change. Youcanretardasfaras-30 °BTDC(30

°ATDC).

•Powercuttype:Continuousforapowercutforaslongasthe

inputswitchisactivateorTimedforatimedcut

accordingtothegeartable.

•Minimumenginespeed:Whenactivatethisfunctionwillnotallowthe

enginerpmtofallbelowthissetting.

10

Powercuttable

Thistableisonlyusedwhenthepowercuttypeissetto‘timed’. Atimedpowercut

isusuallyonlyusedifyouhaveasequentialgearbox.

Setthecuttimeaccordingtotheselectedgear.Ifthecut-timeissettozero, the

functionwillnotactivate.

11

Clutchswitchwiringexample

AuxIn10(pin10)

ECU

Clutchswitch

Anyspareanalogueinputcanbeusedtoactivatethefullthrottlegearshiftfunction.

ThisexampleusesECUpin10 (AuxIn10), withtheinternalpull-up enabled, wiredto

aswitchontheclutchpedal.

Whentheclutchpedalisup (notpressed)theclutchswitchcontactsareopen. The

internalpull-up resistorsets theinputlevel‘high’. Whentheclutchpedalisdownthe

switchcontactsareclosed,theAuxIn10 inputisconnectedtoearthwhichsetsthe

input‘low’.

Inthisexampletheclutchinputisactivelow,i.e.thesignalatAuxIn10 islowwhen

theclutchispressed. TheECUshouldbeconfiguredtoreadAuxIn10 astheclutch

signalandalsosettorecognisethattheclutchisdown/pressedwhenthesignallevel

islow.

Select‘Inputchannels’fromthe‘ECUconfiguration’menu. Asshownbelow, the

clutchswitchchannelhasbeensetto AuxIn10,theinputactivehasbeensetto Low

andthe internal1Kpull-up to5v hasbeenenabled.ECUinputsAuxIn10 and

AuxIn35 haveswitchableinternalpull-up resistors.Ifanotherinputconnectionwhere

tobeusedinstead, e.g.AuxIn34 orAuxIn36, anexternalpull-up resistorwouldneed

tobefitted.TheAuxIn7b, AuxIn8bandAuxIn9binputshaveinternalpull-ups.

exampleclutchswitchconfigurationsettings

12

TheECUisabletocalculatetheselectedgearbyusingenginerpm, roadspeedanda

gearpositionlook-uptable.

Select‘Gearposition’fromthe‘ECUconfiguration’menutoaccess thegearposition

calculationsettings…

Gearcalculationfunction

•Enabled:Setswhetherthisfunctionisenabledornot.

•Matcherror:SetshowclosetheECU’scalculationsmustbetothe

figuressetinthegearpos table.

Gearpostable

Foreachoftheforwardgearssetthespeed(mph/kmh)per1,000rpminthetable.

TheeasiestmethodtodeterminethesevaluesistosetthePCdataloggertorecord

enginerpmandroadspeed.Driveforashortamountoftimeineachgearandthen

usethedataloggertrace todeterminethetablesettings.

Forexamplein3rd gear, ataroadspeedof38.0mph, withanenginespeedof

3,193rpm:-

Mphper1,000rpm=__38.0__ x1000 = 11.9

3193

Note:gearpositioncalculationsaresuspendedwhiletheclutchswitchinputisactive

(clutch=down).Ifaclutchswitchisnotfittedensurethatinputisdisabled.

Gearposition

13

TheECUhas4wheelspeed(frequencymeasurement)inputchannelsviaAuxportB.

Theseinputchannelscanbewireddirectlytoinductivewheelspeedsensorsora

digitalspeedsignal.

Forspeedmeasurementonlyonewheelspeedsignalisneeded. Ifthismeasurement

isusedtocalculatetheselectedgearthesignalmustbefromadrivenwheel.

Select‘WheelSpeedSensors’fromthe‘ECUconfiguration’menutoaccess the

wheelspeedsensorsettings.

Thefourwheelspeedinputchannelsareidentifiedasfollows

Input Label AuxPortBpinnumber

Channel1 LF(Left Front) 2

Channel2 RF(Right Front) 3

Channel3 LR(Left Rear) 4

Channel4 RR (Right Rear) 5

Roadspeedmeasurement

14

LF,RF, LR, RR sensorsettings

Eachchannelisenabledandconfiguredindependentlyfromtheotherchannels. This

flexibilityallowsdiffering wheelsizesand/orsensorsetups oneachofthefour

wheels.

Clickthelabelbutton(LF, RF, LR, RR)toaccess thesettingsforthatinputchannel.

Eachchannelhasthefollowingsettings:

•Enabled:Ticktheenableboxifthischannelisused.

•Wheelroll:Distance travelledforonerotationofthewheel.

•Triggerpoints:Numberofpulsesperwheelrotation

Thetriggerpointssettingcanbedeterminedbycountingthenumberofteeth/points

thatwillpassthewheelspeedsensorinonerevolutionofthewheel.

Aquick/simplemethodtodeterminethewheelroll settingistoputachalkmarkat

thebottomofthetyre(atthe6o’clockposition)and markthegroundatthesame

point.Rollthecarforwardssothewheelrotates once andmarkthegroundinline

withthetyremark. Thedistance betweenthetwogroundchalkmarks,inmm,isthe

‘wheelroll’. Arolling roadcanbeusedtocompareactualandmeasuredroadspeeds

-adjustthewheelrollvalueifnecessary.

Options

•Drivetrain:Thissettingisnotcurrentlyused.

•Roadspeedsource:Settothechannelyouwishtomeasureroadspeedfrom

•Sensortype:Globalsettingforwheelspeedsensors, inductiveor

digital. Opencollectordigitalsensorswillrequirea

pull-up resistor.

15

3

2

1

TheEmeraldK3isabletoreadEGT viaanexternalsignalconditioning unit. To

ensurethebestaccuracytheexhaustgas temperaturereadingistransmitteddigitally

betweenthesignalconditioning unitandtheECU.

TheVAG G235 exhaustgastemperatureinterface combinesathermocoupleprobe,

suitableforpre-turbogas temperaturemeasurements, alongwithacombined

amplifierandserialdataoutput.TheserialdataoutputlinefromtheG235 shouldbe

wiredtoECUpin13.

pin13

ECU

EGTinterface

+12vsupply

pin28

pin29

1

2

3

VAG

G235

thermocouple

probe

VAGG235 toEmeraldK3connectiondiagram

WiresideofG235 loomconnector

Exhaust GasTemperature

16

TosettheECUtoreadtheG235 exhaustgas temperatureserialdatathe‘EGT

interface’settinginthe‘Inputchannels’sectionoftheECUconfigurationshouldbe

to‘[2]VAGG235’asshownbelow..

Once configuredtoreadEGT fromtheG235

thisEGT measurementcanbedisplayedonthe

‘liveadjustments’screen. ThisEGT reading

canalsoberecorded,alongwithother

readings,intothedata-logger.

TheEGT canbeused,inconjunctionwiththefeedbacktable, toadjustthefuelling

and/orboostpressure.

17

TheK3ECUcanbeconfiguredtosettransmitdatatoexternaldevices, suchas

dashboards, usingit’s Controller Area Networkinterface.

TheCANwasoriginallydevelopedbyBoschGmbhasarobustserial

communicationsprotocoltopass informationbetweencontrollersonanautomotive

network.Communicationspeedscanbeup to1Mbit/sbetweenmultipledevices

sharingthesame2-wireCANbus.

TheCANbuswiring shouldbeatwisted-paircableand,ifrequired, shielded. The

CAN busmustbeterminatedateachendbya120 resistor.TheK3ECU, withit’s

internal120 terminationresistor,providesoneend oftheCANbus. When

connectinganotherdevice/syoumustensurethattheCANbusiscorrectlyterminated

withanother120 resistor.Thisterminationresistormustbeattheotherendofthe

CAN bus. Somedevices(e.g.theAIMMXLdashlogger) alsohaveaninternal

terminationresistorsoanexternalresistorisnotrequired.

AIMdashloggerconnection

ECU

COMMS

AIM

CAN_L

CAN_H

1

2

Refertothe‘Communicationsport’sectionofthemanualforfurtherdetailsofthe

communicationsport.

CANdata-link

18

K3CANconfiguration

Select‘CANdata-link’fromthe‘ECUconfiguration’menu.

Fromthe‘Device’dropdownmenuselect‘AIMdashboard’. ToenablethisK3to

AIMdata-linkensurethe‘data-link’checkboxisticked.

BeforeconfigurationchangescantakeeffecttheECUmustbeupdated, select

‘UpdateECUconfiguration’fromthe‘ECU’menu.

AIMMXLconfiguration

UsingtheAIMRace Studio2softwareselect‘Systemmanager’.

RetrievethecurrentconfigurationfromtheAIMdashbyclicking the‘Receive’

button.Clickthe‘ECUmanufacturer’entryforthecurrentconfigurationandsetto

‘AIM’. Clickthe‘ECUmodel’entryforthecurrentconfigurationandsetto

‘PROT_CAN’.

Ifyouwishtochangehow/whatdatafromtheECUisdisplayedontheAIMdash

clickthe‘Systemconfiguration’tabandsetaccordingly. Once youarehappywith

yourchannel/displaysettingsupdatetheAIMdashbyclicking the‘Transmit’button.

RefertoyourAIMmanualfordetailedinformation.

19

AlthoughtheK3cannotdirectlycontrolawideband lambdasensoritcanreada0-5v

analoguesignalthatrelatestoAFR/lambda. Many widebandlambdasensor

controllersproduce a0-5vsignalforusewithECU’sordata-loggers.

ThisAFRdatacanberecordedintheEmeralddata-logger, displayedinthelive

adjustmentsscreenandusedbytheECUforclosedloopand/oradaptivefuelling

functions.

The0-5vsignalisconvertedtoAFRbyauseradjustablelook-uptableintheECU

configuration. ThistablemustbesettomatchtheAFR/voltageofyourlambdasignal

conditioning unit.

EmeraldK3toInnovate LC-1 connectionexample

AnInnovateLC-1isusedinthisexamplebuttheprinciplescanbeappliedtomany

otherwidebandlambdacontrollers.

TheInnovateLC-1manualshouldbereadcarefullybeforeinstallation.

Itisabsolutelyessentialthatthecorrectsensorcalibrationroutineisfollowed-thisis

detailedintheInnovatemanual.

Wiring

LC-1 Function Wireto..

Red +12vsupply Ignitioncontrolled+12v

Blue Heaterground Goodchassisgroundorbattery(-) terminal

White Systemground Join withGreenwiretoECUpin30

Yellow

Analogueout1

(narrowbandlambdasignal) ECUpin7viainlineresistor.

See note 1

Brown Analogueout2

(AFRsignal) AnyspareanalogueECUinputviaan

inlineresistor.(see note2).AuxIn35

(ECUpin35)isusedinthisexample.

Green Analogueground Join withWhitewiretoECUpin30

Black Calibrationwire Calibrationbutton

Connectiontoawidebandlambda

20

30

35

Earth

Switched+12vsupply

Tocalibrationswitch

7

Emerald

K3

LC-1

100Ω

100Ω

Note1:

Narrowbandlambdasignal. Thisconnectionisoptional. IfusedensuretheLC-1is

settooutputa0-1vnarrowbandsimulatedsignalonanalogue1. TheLC-1is

normallysettodothisbydefault. A100 resistor*shouldbefittedinlinebetween

theyellowanalogueout1wireandtheECUpin7.

Note2:

WidebandAFRsignal. A100 resistor*shouldbefittedinlinebetweenthebrown

analogueout2wireandtheECUanalogueinputpin(AuxIn35, pin35 inthis

example)

*TheLC-1outputsarequitesensitiveandcanbecomeunstableifconnectedtoa

capacitiveload. TheinlineresistorbufferstheLC-1fromtheECUinputsignal

filters.

Table of contents

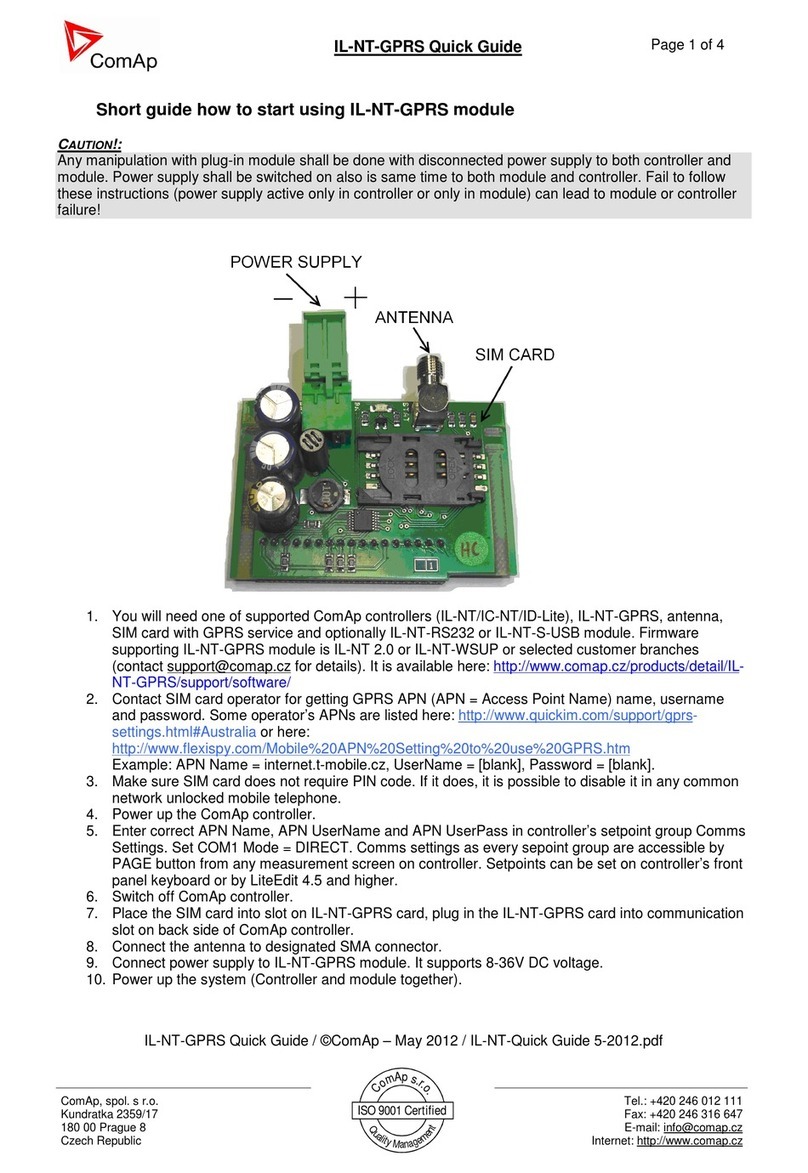

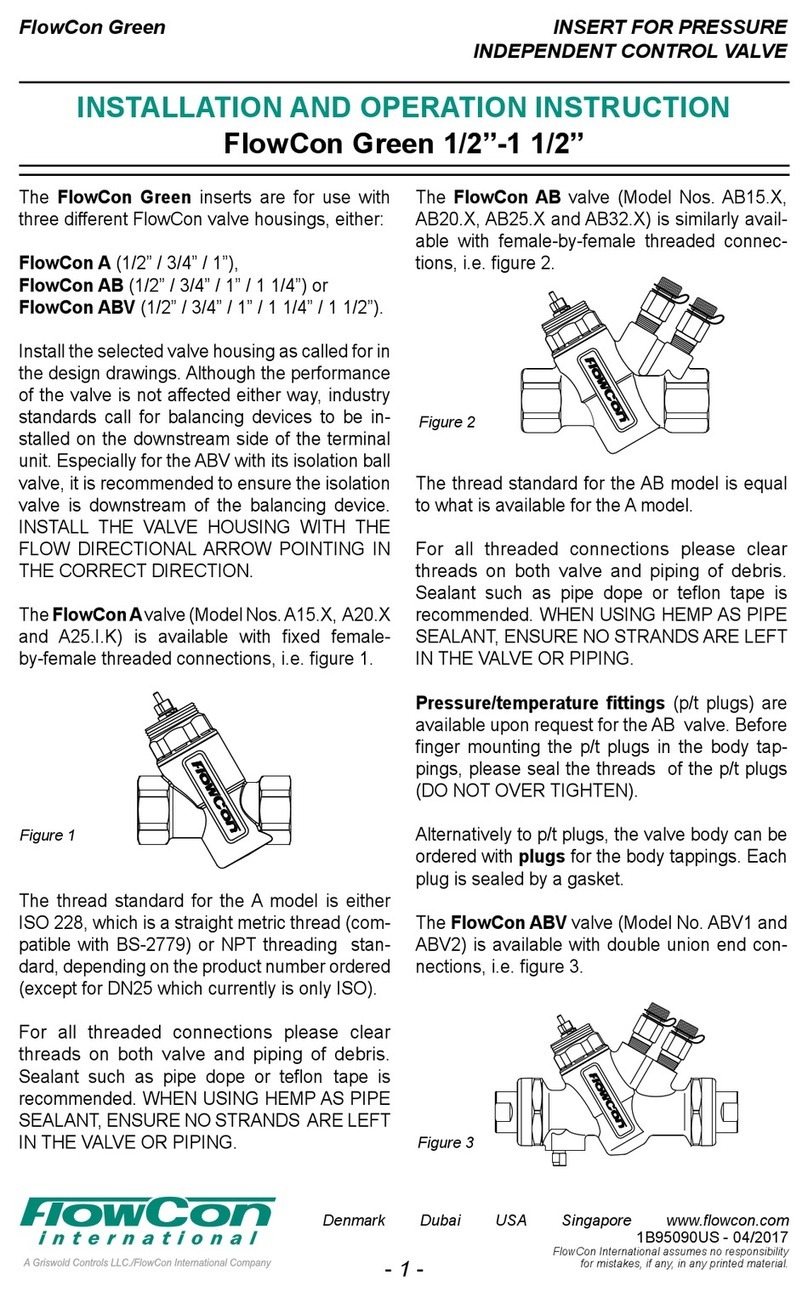

Popular Control Unit manuals by other brands

ICP DAS USA

ICP DAS USA I-7080 user manual

Aqualisa

Aqualisa AQ150 installation guide

Watts

Watts LF25AUB-Z3 Series Installation instructions and instructions for use

Control Techniques

Control Techniques FM-3 Reference manual

Sentiotec

Sentiotec K Series Instructions for installation and use

FlowCon

FlowCon FlowCon Green Series Installation and operation instruction

Beckhoff

Beckhoff EP31 Series Documentation

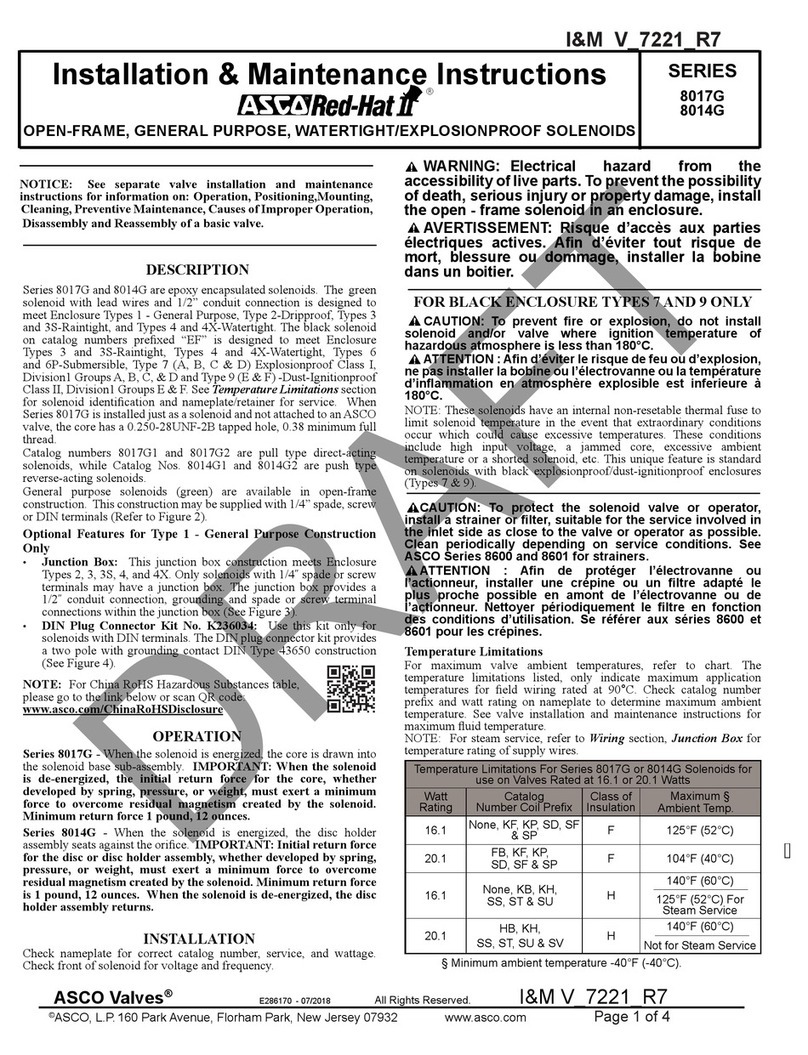

ASCO Valves

ASCO Valves Red-Hat II 8017G Series Installation & maintenance instructions

American Standard

American Standard R127 installation instructions

Veripos

Veripos LD6 installation manual

Flowserve

Flowserve Nordstrom Series Repair manual

Emerson

Emerson White-Rodgers 36C01 installation instructions