Emerson Network Power LCU+ Series User manual

LCU+ Series Controller

User Manual

Version

V1.0

Revision date

March 30, 2010

BOM

31011833

Emerson Network Power provides customers with technical support. Users may contact the nearest

Emerson local sales office or service center.

Copyright © 2010 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Safety Instructions

Authorization

User/Operator

A user/operator who has no training for the equipment in question is authorized only to handle the equipment

under normal operation, and to take the first measures in case of alarm according to the MAINTENANCE

INSTRUCTIONS of the equipment.

Trained User/Operator

A user/operator who has been trained for the equipment in question is authorized to have the responsibility for

this equipment, to perform tests, fault tracing, exchange of units and repairs of the said equipment. Intervention

in live equipment may be performed by a trained user/operator only.

Installer

The installation personnel shall be responsible for the installation and the test of the equipment in question

according to the installation and test documents in force.

The installer is also liable for using the correct cable to and from the equipment and for protecting it with the

adequate fuses or circuit breakers.

Local authorization regulations for work with electric equipment shall always be observed.

Basic Guidelines

Danger

Danger

Contact the site operations manager or other responsible local personnel before commencing work. Inform all

personnel near the equipment that work is in progress and the equipment is under power.

Reduce the risk of accidents and increase the operation reliability by keeping the power or cooling room clean

and clear of any unauthorized material.

While work is in progress, the equipment also must be protected against damages and unauthorized intervention.

Busbars, live cabinets, etc., shall be protected during work using protective sheeting.

Never work alone in the power or cooling room. Do not leave equipment with unprotected parts under power

unattended.

Inform the site operations manager or other responsible local personnel when the work is complete.

Thunderstorms

Danger

Danger

Avoid working with electrical installations or being close to towers during thunderstorms.

Thunderstorms generate strong electric fields that may result in lightning strokes. It is essential that equipment

and facilities be properly earthed to minimize the risks of personal injury and equipment damage.

Contents

Chapter 1 Introduction.........................................................................................................................................................1

1.1 Overview...............................................................................................................................................................1

1.1.1 General......................................................................................................................................................1

1.1.2 Models Of LCU+........................................................................................................................................1

1.2 Technical Specifications .......................................................................................................................................2

1.2.1 Operating Conditions.................................................................................................................................2

1.2.2 EMC Requirements ...................................................................................................................................2

1.2.3 RoHS Compliance.....................................................................................................................................2

1.2.4 Safety Requirement:..................................................................................................................................2

1.2.5 Protective Level.........................................................................................................................................2

1.2.6 Mechanical Data........................................................................................................................................2

1.3 Main Functions......................................................................................................................................................3

1.3.1 Measurement Functions:...........................................................................................................................3

1.3.2 Display And Indicating Functions...............................................................................................................3

1.3.3 Communication Functions.........................................................................................................................4

1.3.4 Alarm Functions.........................................................................................................................................4

1.3.5 Battery Management Functions:................................................................................................................4

1.3.6 Low Voltage Disconnect............................................................................................................................5

1.4 Hardware Interfaces..............................................................................................................................................6

1.4.1 I/O Connector Of Motherboard..................................................................................................................6

1.4.2 RS232 Interface.........................................................................................................................................6

1.4.3 Ethernet Port .............................................................................................................................................6

Chapter 2 Installation, Replacement And Power-On...........................................................................................................7

2.1 Installation And Replacement ...............................................................................................................................7

2.1.1 Pre-Steps...................................................................................................................................................7

2.1.2 Controller Removal....................................................................................................................................7

2.1.3 Controller Installation/Replacement...........................................................................................................8

2.1.4 Post-Steps.................................................................................................................................................8

2.2 Initially Starting, Configuring, And Checking Controller Operation........................................................................8

2.2.1 Controller Initialization ...............................................................................................................................8

2.2.2 Checking System Status............................................................................................................................9

Chapter 3 Operation..........................................................................................................................................................10

3.1 Local Controls And Indicators.............................................................................................................................10

3.1.1 Front Panel..............................................................................................................................................10

3.1.2 Functions Of Indicators............................................................................................................................11

3.1.3 Functions Of Controls..............................................................................................................................11

3.2 LCD Menu Tree ..................................................................................................................................................11

3.2.1 Status ......................................................................................................................................................12

3.2.2 Settings....................................................................................................................................................12

3.2.3 Manual.....................................................................................................................................................20

3.2.4 ECO.........................................................................................................................................................20

3.2.5 Quick Setting...........................................................................................................................................20

3.2.6 Controller Setting.....................................................................................................................................21

3.3 WEB Interface Operation....................................................................................................................................22

3.3.1 Setting Up The Internet Explorer Web Browser.......................................................................................22

3.3.2 Logging Into The Controller.....................................................................................................................23

3.3.3 Homepage Introduction ...........................................................................................................................24

3.4 WEB Bootloader Interface Operation..................................................................................................................28

3.5 Serial Bootloader Interface Operation.................................................................................................................29

Appendix 1 Hardware Interfaces.......................................................................................................................................33

Chapter 1 Introduction 1

LCU+ Series Controller User Manual

Chapter 1 Introduction

1.1 Overview

1.1.1 General

LCU+ is the next generation DC power controller developed by Emerson Network Power. The LCU+ offers power

supply management function, and a user-friendly and easy-to-use interface. Refer to Figure 1-1 for an image of the

LCU+.

Figure 1-1 LCU+

1.1.2 Models Of LCU+

The LCU+ is available in four different models as listed in Table 1-1.

Table 1-1 Models of LCU+

Models

Configuration

M221S

M222S

M223S

M224S

Display

128 × 128 LCD

No LCD

Communication port

RS232,Ethernet

RS232

RS232,Ethernet

RS232

Protocol

HTTP,

SNMP

HTTP,SNMP

-

HTTP,SNMP

-

YDN23

YDN23

YDN23

Input

Analog

signal

One battery current input, one bus voltage input, two temperature inputs, four battery mid-voltage

inputs

Digital

signal

Two load fuse status inputs, four battery fuse status inputs, one bi-stable contactor sampling signal

input, four digital signal inputs

Load fuse status input and battery fuse status input circuits can be changed into battery fuse status

input, load fuse status input or battery mid-voltage input circuits

Output

One mono-stable contactor or bi-stable contactor, one mono-stable contactor, eight dry contact

outputs (configurable, realized by external board)

2 Chapter 1 Introduction

LCU+ Series Controller User Manual

1.2 Technical Specifications

1.2.1 Operating Conditions

Table 1-2 Operating Conditions

Item

Range

Input voltage

19V ~ 60V

Operating temperature range

(ambient temperature)

-10C ~ +55C*

Storage temperature

-40C ~ +75C

Relative humidity

≤ 90%RH

Elevation

≤ 3000m

*: The LCD display may become difficult to display at the temperature above 50C or below -10C, and user may

need to adjust contrast of the LCD at these temperatures for easy reading.

1.2.2 EMC Requirements

Table 1-3 EMC Requirements

Item

Test Item

Standard

Requirement

Criterion

Remarks

EMI

Radiated Emission

EN55022

Class B

--

--

Conducted Emission

EN55022

Class B

--

--

EMS

Immunity to ESD

IEC61000-4-2

8kV contact discharge,

15kV air discharge

A

To enclosure, RS232,

Ethernet Port, LCD

Panel, and Keys

Immunity to Radiated

Magnetic Field

IEC61000-4-3

10V/m, 80MHz-1GHz

1.4 - 2 GHz

A

--

Immunity to EFT

IEC61000-4-4

2kV for DC Power Input

Port, 1kV for

Communication Port

B

CAN, RS232,

Ethernet

Communication Port

Immunity to Surge

IEC61000-4-5

800V Common Mode for

DC Power Port, 12ohm

Internal Resistance; 500V

Differential Mode, 2ohm

Internal Resistance; 1kV

for Signal Port, Common

Mode, 42ohm Internal

Resistance

B

Signal Ports include

CAN, RS232,

Ethernet

Immunity to Conducted

Magnetic Field

IEC61000-4-6

10Vrms

A

Power Supply, CAN,

RS232, Ethernet

1.2.3 RoHS Compliance

Complies with RoHS R6 standard.

1.2.4 Safety Requirement:

CE,UL: Certification by third party.

1.2.5 Protective Level

IP20

1.2.6 Mechanical Data

Dimensions: 202 × 86.8 × 42 (mm, excluding golden finger),

211.5 × 86.6 × 42 (mm, including golden finger)

Chapter 1 Introduction 3

LCU+ Series Controller User Manual

Weight: <1kg

1.3 Main Functions

1.3.1 Measurement Functions:

Analog value measurement

Table 1-4 Analog value measurement

Item

Quantity

Measurement range

Resolution

Battery Current

1

Differential Voltage Signal of Battery Shunt:

-100mV ~ 100mV

Error is less than ±1% of full measurement

range

Bus Voltage

1

-48V System: 10Vdc ~ 65Vdc.

+24V System: -10Vdc ~ -30Vdc

± 0.1V, absolute value is 19V to 60V

Temperature

2

233uA to 373uA (-40C ~ 100C)

± 2C (sensor error is not considered)

Battery String Voltage

4

-48V System: 10Vdc ~ 65Vdc.

+24V System: -10Vdc ~ -30Vdc

± 0.2V, absolute value is 19V to 60V

Note: The applicable scope of all the measurement resolution is 15C ~ 30C

Digital value measurement

Table 1-5 Digital value measurement

Item

Quantity

Parameter

Load Fuse

2

Absolute Value: 15V ~ 60V fault, 0 to 1V normal.

Battery Fuse

4

Absolute Value: < 400mV - 50mV normal, > 400mV + 50mV fault.

DI for Status of bi-stable contactor

1

Absolute Value: 15V ~ 60V open, 0V ~ 1V close.

DI for Auxiliary Contact of SPD

1

--

Extended User DI

4

Expansion board needs to be connected

Digital output

Table 1-6 Digital output

Item

Quantity

Parameter

Extended User DO

8

Capacity of Contact: 1A / 30Vdc or 125Vac, expansion board is needed

Power output

Table 1-7 Power Output

Item

Parameter

Power Out of External Interface Board

5VDC, 300mA

Power Out of Temperature Sensor

10V ~ 12V, 10mA

LVD drive

The controller has 2 LVD drive outputs that can drive two bi-stable / mono-stable contactors.

1. Bi-stable Contactor: 2A maximum drive current with drive pulse width of 500ms ~ 1s.

2. Mono-stable Contactor: 3A maximum starting current and 1Amaximum holding current.

1.3.2 Display And Indicating Functions

The controller has a green LED for indicating operating status, a yellow LED for indicating observation alarm, and a

red LED for indicating major and critical alarms. It also provides a drive output for alarm LED on a system cabinet.

The controller LCD can display theAC parameters, DC parameters, rectifier and battery parameters, operating status,

alarm status, settings, and control parameters.

4 Chapter 1 Introduction

LCU+ Series Controller User Manual

1.3.3 Communication Functions

The controller can communicate with the host computer in three modes: RS232, Modem, and Ethernet (WEB and

SNMP). It can communicate with the rectifiers in CAN-bus mode.

1.3.4 Alarm Functions

When the DC power system is in alarm status, the controller generates an alarm automatically and reports the alarm

to higher level controller according to actual requirements. The controller records the history alarm and a user can

query history alarm through the controller.

The alarm contents include communication failure, SPD fault, DC over/under voltage, load disconnection, battery

disconnection, BLVD, battery/ambient temperature abnormal, and rectifier alarm. The controller has four different

alarm categories.

1. CA, Critical Alarm

2. MA, Major Alarm

3. OA, Observation Alarm

4. None

User can set the alarm category for each alarm. User can also block all outgoing alarms from reporting to remote

computer and affecting any relay. This function can be programmed to reset automatically after 24 hours. When

outgoing alarms are blocked, an ‘Outgoing Alarms Blocked’ alarm is generated.

1.3.5 Battery Management Functions:

Battery test

The purpose of a battery test is to check the condition of the battery. This test discharges the battery and monitors

battery voltage and current.

During a battery test, the controller reduces rectifier output to a predefined value and the battery supplies the load

and begins to discharge. The controller monitors the battery and saves the result in a battery test log.

The controller has two separate battery tests: full load current test and stable current test.

Below are the requirements of the full load current test and stable current test.

The test can be programmed to start under the following conditions.

1. Manual start

2. Cyclic start after a predefined time schedule

Starting a full load battery test or stable current is determined by the discharge current parameter of the stable current

test, as illustrated in Figure 1-2.

Figure 1-2 The Principle of Battery Test

Battery boost charge

When the batteries have been discharged, the controller can raise system voltage to recharge the batteries quicker,

as illustrated in Figure 1-3. The boost charge function can also be used to equalize the difference between the

different battery blocks/cells.

Chapter 1 Introduction 5

LCU+ Series Controller User Manual

Figure 1-3 The Principle of Battery Boost Charge

The boost charge function can be programmed to start under the following conditions.

1. Automatic start after Commercial AC Fault (programmed to start after low battery capacity or high battery charging

current is detected) or Battery Test

2. Manual start

3. Cyclic start after a predefined time schedule

Temperature compensated battery charge

In order to extend battery life, the controller can automatically adjust system voltage as battery ambient temperature

changes. Battery temperature compensated charging is a function that lowers system voltage when battery

temperature increases and raises system voltage when battery temperature decreases.

System voltage follows the characteristics as shown in Figure 1-4.

Figure 1-4 The Principle of Temperature Compensation

Battery current limitation

The controller can limit the current to the batteries by adjusting the current limit of the rectifiers. If battery current

exceeds the alarm setting of Battery Over Current, a Battery Over Current alarm is issued.

Battery prediction

The controller can calculate the remaining capacity and the remaining time of the battery while charging or

discharging.

1.3.6 Low Voltage Disconnect

The controller can disconnect the load or battery in case of under voltage or after a predefined time from when a

Commercial AC Fault occurs, in order to prevent the batteries from deep discharge. Deep discharge can result in

permanently damaged batteries.

The load or battery can be disconnected through the two internal LVD drive outputs. The features of the LVD function

are:

The controller can manage a maximum of 2 LVDs, which are internal LVD drive outputs. The controller

disconnects these LVDs during an under voltage condition. The disconnection level for each LVD can be set

6 Chapter 1 Introduction

LCU+ Series Controller User Manual

individually. There is one reconnection level for all LVDs. These LVDs can be used for load disconnection

and/or battery disconnection.

LVD Disconnection Setting Precautions

(1) The disconnection level for load contactor should be set higher than the battery contactor so that the load

contactor can always be disconnected before the battery contactor.

(2) Maximum 1 LVD is used for battery disconnection to protect from the large current difference between

batteries (using the internal LVD2 of the controller is suggested). When Commercial AC returns, the batteries

can be close to complete discharge and the voltage difference can generate a large current. Therefore, the

current of rectifiers should be limited before the battery reconnection.

The controller can individually disable LVD1 and LVD2, preventing the contactor from opening during an LVD

condition.

The controller can reconnect the LVDs when the Commercial AC Fault alarm is inactive and system voltage is

higher than the reconnection level.

An LVD alarm is issued when the controller automatically or a User through the controller manually activates an

LVD. An LVD Detection Fault alarm is also issued when the controller detects the auxiliary input status is not

identical with the LVD operation.

1.4 Hardware Interfaces

1.4.1 I/O Connector Of Motherboard

This connector is located at the lower rear part of the controller. It is a 50 PIN PCB golden finger connector. For

connector pin-outs, refer to Appendix 1 Hardware Interfaces.

1.4.2 RS232 Interface

This connector is located in the left lower part on the controller front panel and it is an RJ45 connector.

Table 1-8 RS232 Connector

Pin

Name

Definition

1

RTS232

Request for Sending

2

DTR232

Terminal is Ready

3

TXD232

Data Transmit

4

GND

Communication Ground

5

GND

Communication Ground

6

RXD232

Data Receiving

7

DCD232

Carrier Wave Checking

8

--

No connection

1.4.3 Ethernet Port

This connector is located in the left upper part on the controller front panel and it is an RJ45 connector.

Table 1-9 Definition of Ethernet Port

Pin

Name

Definition

1

TX+

Write Signal +

2

TX-

Write Signal -

3

RX+

Read Signal +

4

--

no connection

5

--

no connection

6

RX-

Read Signal -

7

--

no connection

8

--

no connection

Chapter 2 Installation, Replacement And Power-On 7

LCU+ Series Controller User Manual

Chapter 2 Installation, Replacement And Power-On

2.1 Installation And Replacement

The controller is hot swappable. It can be removed and installed with the system operating.

2.1.1 Pre-Steps

1. Performing this procedure may activate external alarms. Do one of the following: 1) If possible, disable these

alarms. 2) If these alarms cannot be easily disabled, notify the appropriate personnel to disregard any future alarms

associated with this system.

2. Connect an approved grounding strap to your wrist. Attach the other end to a suitable ground.

2.1.2 Controller Removal

1. Loosen the captive fastener securing the top of the latch mechanism to the front of the controller. Pull the top of the

latch mechanism away from the controller (this will retract the latch mechanism located on the underside of the

controller). This unlocks the controller from the shelf. Refer to Figure 2-1.

Handle is opened

Handle is closed

Figure 2-1 Latch Mechanism on the controller

2. Slide the controller completely from the shelf.

8 Chapter 2 Installation, Replacement And Power-On

LCU+ Series Controller User Manual

2.1.3 Controller Installation/Replacement

1. Loosen the captive fastener securing the top of the latch mechanism to the front of the controller to be installed.

Pull the top of the latch mechanism away from the controller (this will retract the latch mechanism located on the

underside of the controller).

2. Slide the controller completely into its mounting position.

3. Push the top of the latch mechanism into the front panel of the controller, and secure by tightening the captive

fastener. This locks the controller securely to the shelf.

2.1.4 Post-Steps

1. Perform the next procedure, ‘Initially Starting, Configuring, and Checking Controller Operation’.

2. Enable the external alarms, or notify appropriate personnel that this procedure is finished.

3. Ensure that there are no local or remote alarms active on the system.

2.2 Initially Starting, Configuring, And Checking Controller Operation

2.2.1 Controller Initialization

After power is first applied to the controller, the following initialization routine is performed.

Procedure

1. After the controller is powered on, the language screen appears.

英语

English

Figure 2-2 Language screen

Press the ▲, or ▼ key to select the desired language. Press ENT key to confirm the selection. If no key is pressed

within 10 seconds, the controller selects the displayed language automatically.

Wait….

Figure 2-3 Wait screen

2. The controller displays ‘Wait...’ as it performs an initialization routine. The controller has a ‘System Type’ parameter

that was pre-programmed for your specific system. This setting determines the initial configuration of the controller

parameters such as output voltage and alarm levels.

3. Once initialized, the Main screen is displayed. Note that at the top of the screen the date and time are alternately

displayed.

18:15:10

Float

53.5V 7.8A

Auto Alarm

18:15:10

Float

53.5V 7.8A

Auto Alarm

or

2009-07-28

Float

53.5V 7.8A

Auto Alarm

2009-07-28

Float

53.5V 7.8A

Auto Alarm

Figure 2-4 Main screen

Chapter 2 Installation, Replacement And Power-On 9

LCU+ Series Controller User Manual

4. From the Main screen, press ENT key to go to the ‘Main Menu’ screen.

MAIN MENU

Settings

Quick Settings

Status

ECO

Manual

Figure 2-5 Main Menu screen

5. From the Main Menu, select a submenu by repetitively pressing the ▲ or ▼ key on the screen. The selected

submenu will be indicated by the cursor. Press ENT key to open the submenu.

Note

Repeatedly press the ESC key to return in reverse order level by level from any submenu until the Main screen

appears.

6. Verify and set the controller as required for your application. Refer to Chapter 3 Operation for procedures.

2.2.2 Checking System Status

Procedure

1. Observe the status of the indicators located on the controller. If the system is operating normally, the status is

shown in Table 2-1.

Table 2-1 Status and Alarm Indicators

Indicator

Color

Normal State

Status

Green

On

Minor Alarm

Yellow

Off

Major Alarm

Red

Off

10 Chapter 3 Operation

LCU+ Series Controller User Manual

Chapter 3 Operation

3.1 Local Controls And Indicators

3.1.1 Front Panel

The controller is offered in four different Models. Each Model provides different features. Refer to Figure 3-1 to Figure

3-4 for a front view of each Model.

Figure 3-1 Front Panel of Controller Model M221S

Figure 3-2 Front Panel of Controller Model M222S

Figure 3-3 Front Panel of Controller Model M223S

Figure 3-4 Front Panel of Controller Model M224S

Chapter 3 Operation 11

LCU+ Series Controller User Manual

3.1.2 Functions Of Indicators

Table 3-1 Functions of Indicators

Indicator

Normal State

Fault State

Fault Cause

Status (green)

On

Off

If this LED is on, this means the system is operating normally

Observation Alarm

(yellow)

Off

On

The power system has one or more active observation alarms.

Alarm conditions are programmable. Refer to Table 3-3 for defaults

Major Alarm (red)*

Off

On

The power system has one or more active major alarms (Major and

Critical Alarms). Alarm conditions are programmable. Refer to

Table 3-3 for defaults

Note: A Major Alarm initiates an alarm report if alarm report is enabled

3.1.3 Functions Of Controls

Table 3-2 Function of Keys on the Panel

Key Symbol

Key Name

Function

ENT

Enter

Confirm or Execute

▲

Up

Move Up Cursor or Select the Previous Screen

▼

Down

Move Down Cursor or Select the Next Screen

ESC

Escape

Escape or Cancel

3.2 LCD Menu Tree

The overall menu structure is shown in Figure 3-5.

09:20:20

Float

53.4V 404A

Manual Normal

08 -11 -03

Float

53.4V 404A

Manual Normal

ENT MAIN MENU

Status

Settings

ECO

Manual

Quick Settings

ENT STATUS

Active Alarm

Rectifiers

History Alarm

SETTINGS

Alarm

Rectifier

Battery

AC

DC

Controller

Communication

Disable

CycPeriod: 168h

RectWork: 80%

MANUAL

Sys Mode: Auto

In Manual▼

System Type:

48V / set

Capacity: 300Ah

ECO

▼

Rect Limit: 1

LCD Rotation: On

Figure 3-5 Main menu screen

12 Chapter 3 Operation

LCU+ Series Controller User Manual

3.2.1 Status

In the screen of MAINMENU, when cursor is at ‘Status’, press ‘ENT’ to go to the status screen:

Active Alarm

Rectifiers

History Alarm

ENT ALARM: 1/2

Batt Discharge

Observation Alarm

Start Time:

081104 15:52:53

RECTIFIER 1/3

ID: 02070801232

R48800B00

DC Volt: 53.4V

DC Curr

CurrLimit: 109%

AC Volt: 201V

AC Status: On

DC Status: On

AC Derated: N

Temp Derated : N

ALARM 001

SPD Fault

08-07-10 11:35:22

08-07-10 12:35:22

ENT ALARM: 2/2

Batt Volt Low

Critical Alarm

Start Time:

081104 15:52:55

ALARM 002

DC Volt Low

08-07-10 11:35:25

08-07-10 12:35:25

ENT

Status

: 0.0A

Figure 3-6 Status screen

In the status screen, you can move the cursor to ‘Active Alarm’, ‘Rectifiers’, and ‘History Alarm’ respectively and press

‘ENT’ to check the information of active alarm, rectifiers, and history alarm. The rectifier screen shows the information

of first rectifier, if you want see the information of next rectifier, just press ‘ENT’. In screen of ‘Active Alarm’, ‘Alarm

1/2’, ‘1/2’ means there are 2 active alarms and this screen is displaying the first active alarm. The alarm level and

alarm start time are displayed in the screen

In the screen of ‘History Alarm’, the ‘ALARM 001’ means this screen is displaying the first history alarm. The alarm

start time and end time are displayed in the screen.

3.2.2 Settings

In the Main Menu screen, move the cursor to the item of ‘Setting’ and press ‘ENT’ to enter the Setting menus. Before

you access the Setting menu, the system will require you to enter the password first. Method of entering password:

For example, to enter the password of ‘640275’: Press ‘ENT’, and the bit will be highlighted, now you can press ▲ or

▼ continuously to enter the numbers from 0 to 9, or enter the letters from ‘a’ to ‘z’ or from capital letter ‘A’ to ‘Z’. After

entering ‘6’, press ‘ENT’ and the cursor will move to the next bit, and in the same way, press ▲ or ▼ continuously to

enter ‘4’, and you can enter the rest bits ‘0275’ in the same way.

Chapter 3 Operation 13

LCU+ Series Controller User Manual

SETTINGS

Alarm

Rectifier

Battery

AC

DC

Controller

Communication

ALARM

Alarm Level

Alarm Control

DI Setting

COMMUNICATION

Address: 1

CommMode: RS232

Protocol: YDN23

BaudRate: 9600

IP/Subnet/Gate:

10.163.210.91

255.255.255.0

10.163.210.1

CallbackTime: 3

PhoneNumber:

86010677

86010808

RECTIFIER

Position: Disabl

R-Posi: 1-1

HVSD: 59.0V

Default V: 53.5V

Walk-in On: N

Walk-in T: 8s

Interval T: 0s

AC OverV On: N

ACCurrLim : 30A

BATTERY

Basic

Charge

Test

Temp Comp

AC

Over Volt: 280V

Under Volt: 180V

PH Fail: 80V

AC Input: N

AC PH: 3-PH

DC

Over Volt2: 58.2V

Over Volt1: 58.5V

Under V1: 45.0V

Under V2: 45.0V

Amb High: 40C

Amb Low: -5C

CONTROLLER

Lang: English

Tzone: GMT + 08:00

Date: 2009-03-23

Time: 22:17:18

System Type:

48V/1000A

DownloadMode:N

Reset PWD: N

Reset Para: N

Oper1PWD: ******

Oper2PWD: ******

AdminPWD: ******

LVD

Figure 3-7 Settings screen

In the Setting menu, there are 7 items that are ‘Alarm’, ‘Rectifier’, ‘LVD’, ‘AC’, ‘DC’, ‘Controller’ and ‘Communication’

respectively.

Move the cursor to ‘Rectifier’ and press ENT, you can configure the following rectifier parameters:

Position: Enable or disable the shelf setting.

R-Posi: rectifier position in shelf.

HVSD: high voltage shut down, rectifier will shut down when its output voltage exceeds this HVSD point.

Default V: rectifier default output voltage.

Walk-in ON: rectifier walk-in function (soft start) is enabled.

Walk-in T: rectifier walk-in time (soft start time).

Interval T: rectifier sequential startup interval.

AC OverV on: rectifier will shutdown when AC input exceeds AC over voltage point.

ACCurrLim: rectifier current limiting value during startup process.

Move the cursor to ‘AC’ and press ENT, you can configure the following AC parameters:

Over Volt: set the over voltage protection point.

Under Volt: set the under voltage protection point.

PH Fail: set the phase failure voltage point.

14 Chapter 3 Operation

LCU+ Series Controller User Manual

AC PH: can set the AC input to 3-phase or single phase (‘1-PH’).

Move the cursor to ‘DC’ and press ENT, you can configure the following DC parameters:

Over Volt2: set the over voltage protection point2.

Over Volt1: set the over voltage protection point1.

Under V1: set the DC output under voltage point 1.

Under V2: set the DC output under voltage point 2.

AmbHigh: set the high ambient temperature.

AmbLow: set the low ambient temperature.

Move the cursor to ‘Controller’ and press ENT, you can configure the following controller parameters:

Lang: set the display language of LCD, you can select English or your local language.

Tzone: set the time zone.

Date: set the current date.

Time: set the current time.

System Type: set the system type.

DownloadMode: enter the download mode through serial port.

Reset PWD: Reset the password to default.

Reset Para: Reset parameters to default.

Oper1PWD: set the password of operator 1.

Oper2PWD: set the password of operator 2.

AdminPWD: set the password of administrator.

There are three levels password. Default passwords: 1 for operator1, 2 for operator2, and 640275 for administrator.

Only administrator can transfer to serial and web download mode and reset the password. Operator2 can change the

system type and reset the parameters.

Move the cursor to ‘Alarm’ and press ENT, you can enter the alarm menus:

Alarm

Alarm Level

Alarm Control

DI Setting

ALARM LEVEL

Alarm Block

Severity:

Observation Alarm

Out Relay: 0

ALARM LEVEL

SPD fault

Severity:

Major Alarm

Out Relay: 0

ALARM LEVEL

LFuse Alarm

Severity:

Critical Alarm

Out Relay: 6

ENT ENT ENT

ALARM CONTROL

Alm Voice: Open

Clear: History

DI SETTINGS

DI NO.: 1

Digital1 Alarm

Active: High

Figure 3-8 Alarm screen

Alarm level setting

In the submenu of alarm level setting, move cursor before ‘Alarm Block’, press ‘ENT’, then you can set the alarm

levels of other alarms such as ‘SPD fault’, ‘LFuse Alarm’, ‘Digital3 Alarm’, etc.

In the submenu of alarm level setting, you can set the alarm level of each alarm to observe alarm, major alarm, or

critical alarm. You can also set the output relay number that outputs the alarm signal.

Chapter 3 Operation 15

LCU+ Series Controller User Manual

The characteristics of 4 alarm categories are given in the following table:

Table 3-3 characteristics of 4 alarm categories

Alarm levels

Red alarm

indicator of

controller and

system

Yellow alarm

indicator of

controller and

system

Alarm buzzer

Alarm report

Remark

CA (critical

alarm)

On

On

Yes

Alarm report is

enabled

MA (major

alarm)

On

On

Yes

Alarm report is

enabled

OA (observation

alarm)

On

Off

No

No alarm

Off

Off

Off

No

Note:

1. The alarm levels of temperature sensor disconnected alarm and temperature sensor failure alarm, and the

corresponding relay output cannot be set through the LCD. The alarm levels of these two alarms and the

corresponding relay are the same with those of the high temperature alarm setting.

2. If the analog alarm has two levels of alarm thresholds, and if these two alarm thresholds are set to the same value,

then the second level will be cancelled and the first level of the alarm will be displayed in LCD. For example: If the

alarm threshold of ‘high temperature 1’ is set to the same with the threshold of ‘high temperature 2’, and if this

threshold is set to 40 deg C, then when the temperature exceeds 40 deg C, the system will only issue ‘high

temperature 1 alarm’, and will not issue the ‘high temperature 2 alarm’.

In the alarm level setting submenu, you can also set the output relay no. for the corresponding alarm.

Alarm control menu

For the submenu of ‘AlmVoice’ of alarm control menu, you can set it to ‘Open’(audible alarm is enabled) or ‘Close’ (no

audible alarm), and you can also set the time of audible alarm and the time can be ‘3min’, ‘10min’, ‘1h’ and ‘4h’.

For the submenu of ‘Block Alarm’, you can set ‘Y’ or ‘N’ to select whether the alarm should be blocked or not.

For the submenu of ‘Clear’, you can select ‘History’, ‘ECOFail’, ‘Maintain’, ‘ShortTest’, ‘TestFail’ ,’Rect Lost’ ‘Rect

Commb’and ‘Rect Not respond’ to clear corresponding alarm.

16 Chapter 3 Operation

LCU+ Series Controller User Manual

DI SETTINGS

All the alarms can be configured with No.1 to No.8 alarm contacts. ‘0’ means no alarm dry contacts. All the alarm dry

contacts provide NC (normally closed) or NO (normally opened) output and the default alarm dry contacts are given in

the following table.

Table 3-4 Default alarm dry contact setting

Dry contact No.

Default alarm

Dry contact 1

Mains Failure

Dry contact 2

DC Under Volt or DC Over Volt

Dry contact 3

Rectifier alarm

Dry contact 4

LVD2

Dry contact 5

LVD1

Dry contact 6

None

Dry contact 7

None

Dry contact 8

None

Table 3-5 lists the alarms that you can scroll through in the ALARM SETTINGS/ALARM LEVEL menu, and also

shows their factory default ‘Alarm Level’ and ‘Mapped Output Relay’ settings.

Table 3-5 Controller Alarms and Factory Default Settings

Alarm name

Alarm description

Condition

Default alarm level

Default mapped

output relay

Alarm Block

Alarm Block

Alarms are blocked by the LCU+

Observation

Batt

Imbalance

Batt Imbalance

Battery middle voltage out of the range of ( bus

voltage /2) ± 0.6

Major

SavePowerF

ault

SavePowerFault

Into and out of save power status for 5 times in one

hour

Major

Save Power

Save Power Function

System is in save power status

Observation

AC High

AC Voltage High

Input phase voltage higher than AC High point

Observation

AC Low

AC Voltage Low

Input phase voltage lower than AC Low point

Observation

AC PH Fail

AC Phase Fail

Input phase fails

Observation

Temp High2

Temperature High 2

Ambient/ Battery temperature higher than

Temperature High 2

Major

Temp High1

Temperature High1

Ambient/ Battery temperature higher than normal

operation range

Major

Temp Low

Temperature Low

Ambient/ Battery temperature lower than normal

operation range

Observation

Batt Over

Chg

Battery Over Charge

The charging current over the maximum value

Observation

DC Volt

High+

DC Voltage High+

System output voltage much higher than float

charge voltage

Critical

2

DC Volt High

DC Voltage High

System output voltage higher than float charge

voltage

Critical

2

DC Volt Low

DC Voltage Low

System output voltage slightly lower than float

charge voltage

Critical

2

DC Volt Low-

DC Voltage Low-

System output voltage is much lower than float

charge voltage

Critical

2

Rect HVSD

Rectifier HVSD

Rectifier HVSD circuit activated

Major

3

Rect

LoadShare

Rectifier LoadShare

The difference between rectifier output current and

average output current larger than 8A (+/-4A), and

the load of the rectifier greater than 10% of its

capacity

Observation

3

Rect Derated

Rectifier Derated

The output power of at least one rectifier is derated

because of AC undervoltage or overtemperature

Observation

3

Rect Fan

Fails

Rectifier Fan Fails

Fan of at least one rectifier fails

Major

3

Rect Protect

Rectifier Protect

AC input voltage out of the range of 85Vac to

295Vac results in at least one rectifier protected

Observation

3

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

Multi Channel Systems

Multi Channel Systems TC02 user manual

Sofar solar

Sofar solar 4-12KTL-X Quick installation guide

KEPCO

KEPCO TP564 user manual

Ebmpapst

Ebmpapst VTD-60 K5SB Series Translation of the original operating instructions

WindowMaster

WindowMaster WMU 936-n installation instructions

FEB

FEB 9322 quick start guide

Midwest

Midwest TeeJet Mid-Tech ARC 6000 manual

One Remote

One Remote MultyMedia TS1e Operation instructions

WindowMaster

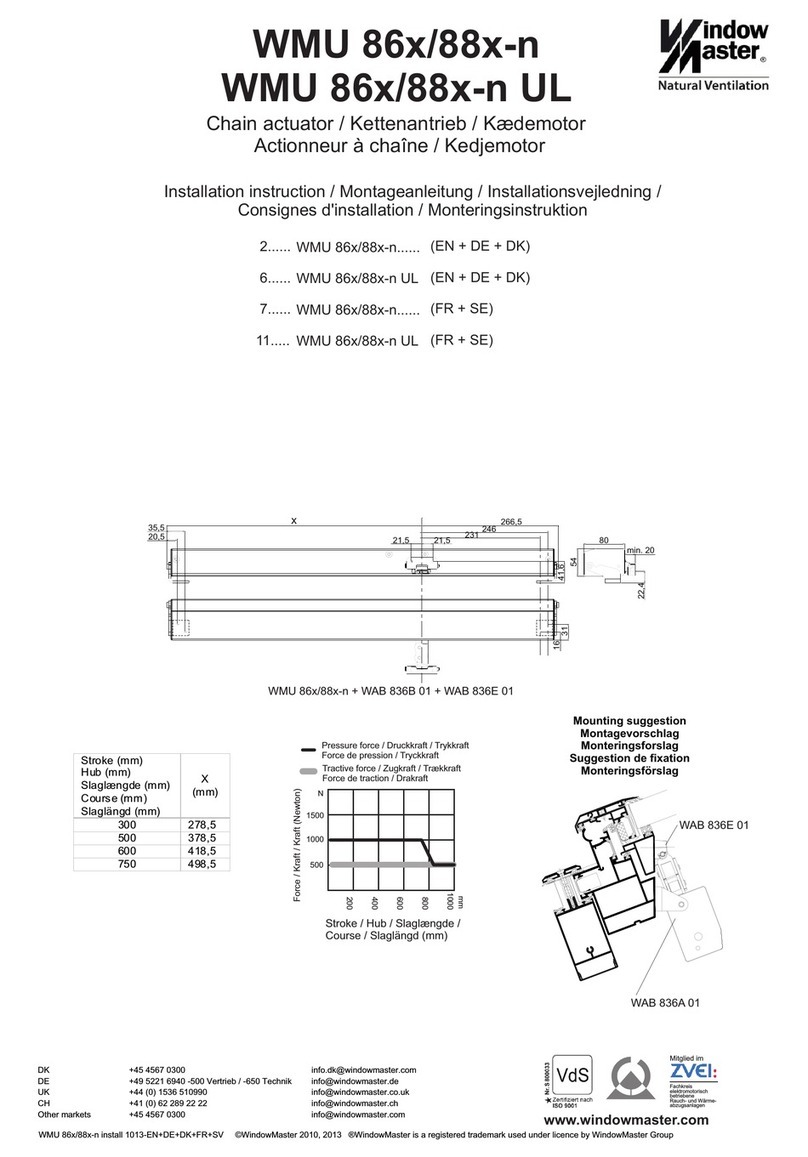

WindowMaster WMU 86x/88x-n Installation instruction

Alto-Shaam

Alto-Shaam Prodigi 6-10E installation manual

DGFLOW

DGFLOW STEADYPRES 2.0 M/M 8.5 manual

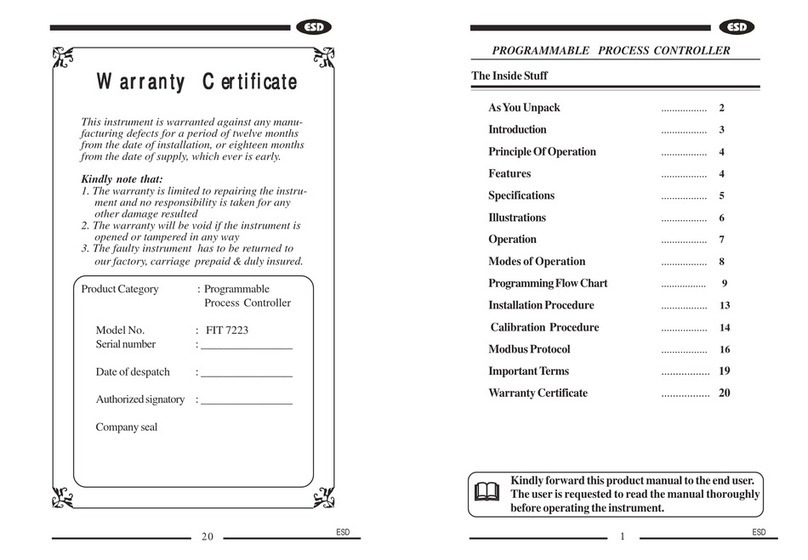

Electronics

Electronics FIT 7223 manual