2

RULES FOR SAFERULES FOR SAFE

RULES FOR SAFERULES FOR SAFE

RULES FOR SAFE

INSTALLATION AND OPERATIONINSTALLATION AND OPERATION

INSTALLATION AND OPERATIONINSTALLATION AND OPERATION

INSTALLATION AND OPERATION

Please read instructions before installing and using the

Electronic Air Cleaner. This will help you obtain the full

benefit from the Electronic Air Cleaner you have selected.

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of the air cleaner

or unsatisfactory service.

▲

!WARNINGWARNING

WARNINGWARNING

WARNING

Do not attempt installation of this unit unless youDo not attempt installation of this unit unless you

Do not attempt installation of this unit unless youDo not attempt installation of this unit unless you

Do not attempt installation of this unit unless you

are familiar with the necessary tools, equipment,are familiar with the necessary tools, equipment,

are familiar with the necessary tools, equipment,are familiar with the necessary tools, equipment,

are familiar with the necessary tools, equipment,

utility connections and potential hazards.utility connections and potential hazards.

utility connections and potential hazards.utility connections and potential hazards.

utility connections and potential hazards.

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

Installation should be performed only by a qualified

service provider.service provider.

service provider.service provider.

service provider.

Failure to do so could result in reduced perfor-Failure to do so could result in reduced perfor-

Failure to do so could result in reduced perfor-Failure to do so could result in reduced perfor-

Failure to do so could result in reduced perfor-

mance of the unit, serious personal injury or death.mance of the unit, serious personal injury or death.

mance of the unit, serious personal injury or death.mance of the unit, serious personal injury or death.

mance of the unit, serious personal injury or death.

▲

!WARNINGWARNING

WARNINGWARNING

WARNING

Installation of this unit must comply with localInstallation of this unit must comply with local

Installation of this unit must comply with localInstallation of this unit must comply with local

Installation of this unit must comply with local

electric codes or other applicable codes.electric codes or other applicable codes.

electric codes or other applicable codes.electric codes or other applicable codes.

electric codes or other applicable codes.

Review and understand local codes prior toReview and understand local codes prior to

Review and understand local codes prior toReview and understand local codes prior to

Review and understand local codes prior to

installation.installation.

installation.installation.

installation.

Do not use this apparatus in an explosiveDo not use this apparatus in an explosive

Do not use this apparatus in an explosiveDo not use this apparatus in an explosive

Do not use this apparatus in an explosive

atmosphere.atmosphere.

atmosphere.atmosphere.

atmosphere.

Failure to do so could result in serious personalFailure to do so could result in serious personal

Failure to do so could result in serious personalFailure to do so could result in serious personal

Failure to do so could result in serious personal

injury or death.injury or death.

injury or death.injury or death.

injury or death.

2. Follow a regular service and maintenance schedule

for efficient operation.

3. Unit must run for one full hour after installation. This will

allow the collecting cells to reach peak efficiency.

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

Rules for Safe Installation and Operation......2

Introduction ....................................................2

How Your Air Cleaner Works.........................3

Unpacking and Inspection .............................3

Preinstallation ................................................4

Installation .....................................................6

Operation .......................................................9

Maintenance ..................................................9

Service Hints ...............................................11

Repair Parts.................................................12

Wash Reminder ...........................................14

AIR CLEANER SIZINGAIR CLEANER SIZING

AIR CLEANER SIZINGAIR CLEANER SIZING

AIR CLEANER SIZING

The units are available in three models:

Model TTW1000Model TTW1000

Model TTW1000Model TTW1000

Model TTW1000

designed for an air volume of up to 1,000 CFM

Model TTW1400Model TTW1400

Model TTW1400Model TTW1400

Model TTW1400

designed for an air volume of up to 1,400 CFM

Model TTW2000Model TTW2000

Model TTW2000Model TTW2000

Model TTW2000

designed for an air volume of up to 2,000 CFM

Shut off power at fuse panel beforeShut off power at fuse panel before

Shut off power at fuse panel beforeShut off power at fuse panel before

Shut off power at fuse panel before

servicing. Failure to do so could resultservicing. Failure to do so could result

servicing. Failure to do so could resultservicing. Failure to do so could result

servicing. Failure to do so could result

in serious personal injury or death.in serious personal injury or death.

in serious personal injury or death.in serious personal injury or death.

in serious personal injury or death.

ELECTROCUTION HAZARDELECTROCUTION HAZARD

ELECTROCUTION HAZARDELECTROCUTION HAZARD

ELECTROCUTION HAZARD

▲

!WARNINGWARNING

WARNINGWARNING

WARNING

▲

!CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAIN

SHARP EDGES.SHARP EDGES.

SHARP EDGES.SHARP EDGES.

SHARP EDGES.

Use care when servicing unit or handl-Use care when servicing unit or handl-

Use care when servicing unit or handl-Use care when servicing unit or handl-

Use care when servicing unit or handl-

ing cells. Failure to do so could result ining cells. Failure to do so could result in

ing cells. Failure to do so could result ining cells. Failure to do so could result in

ing cells. Failure to do so could result in

minor personal injury.minor personal injury.

minor personal injury.minor personal injury.

minor personal injury.

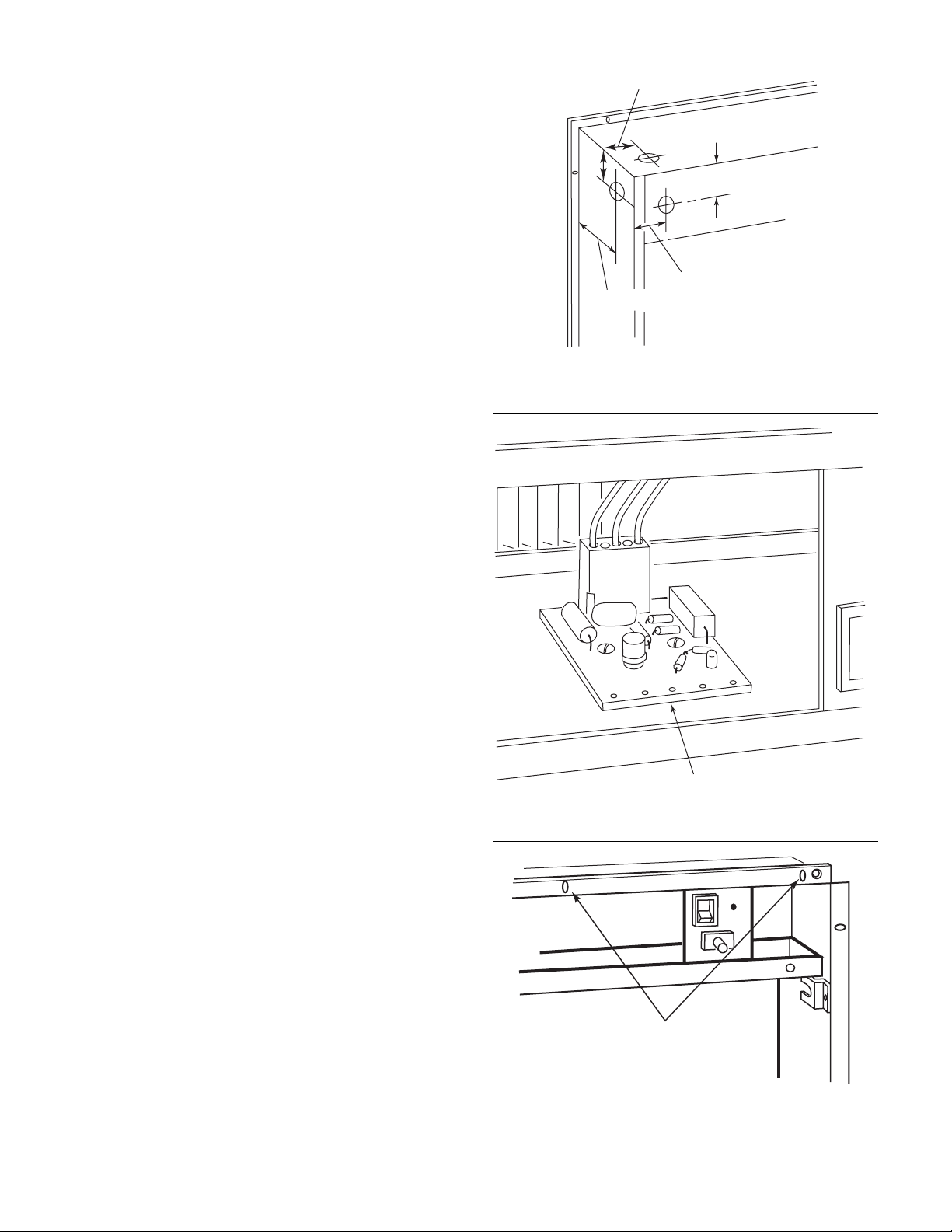

TTW Thru-The-Wall Electronic Air CleanerTTW Thru-The-Wall Electronic Air Cleaner

TTW Thru-The-Wall Electronic Air CleanerTTW Thru-The-Wall Electronic Air Cleaner

TTW Thru-The-Wall Electronic Air Cleaner

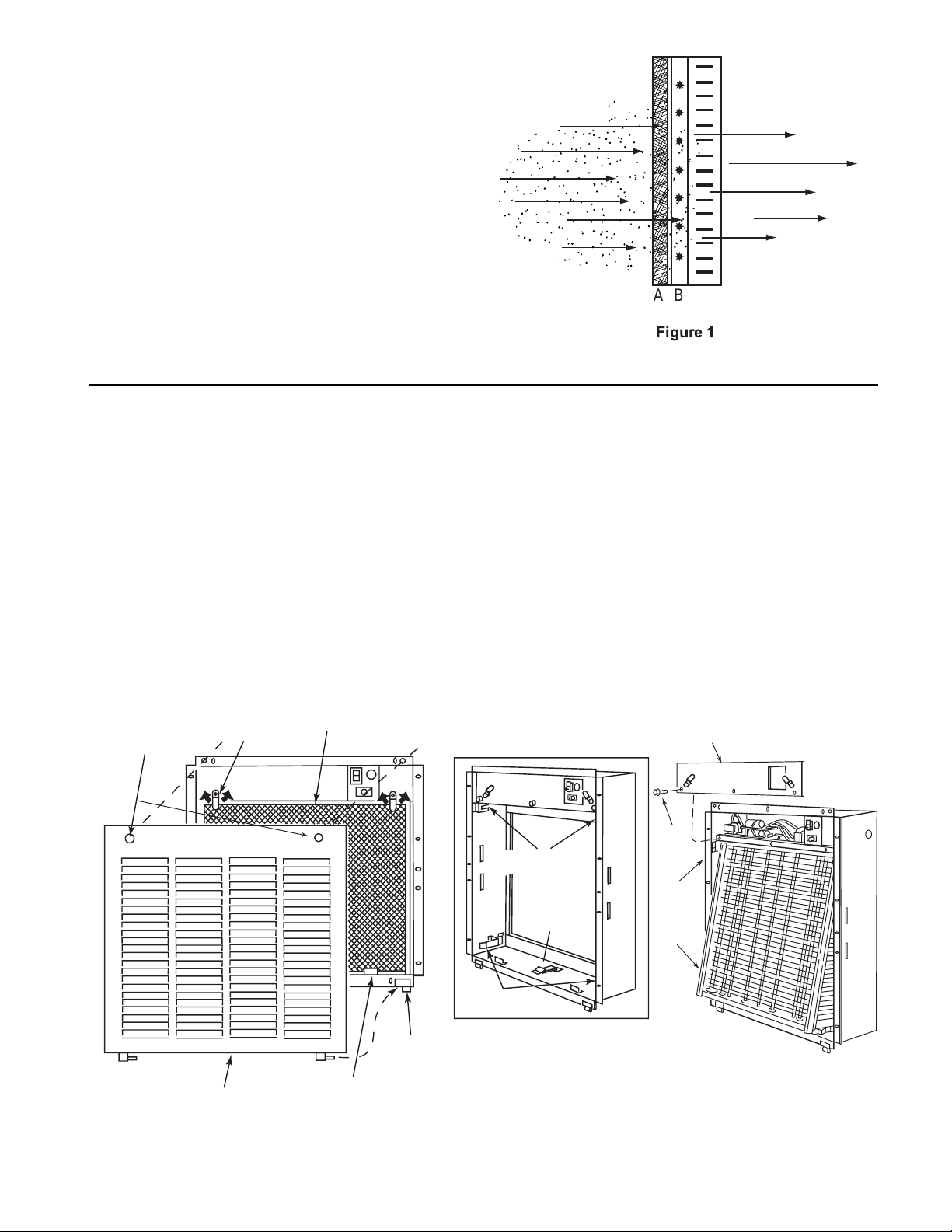

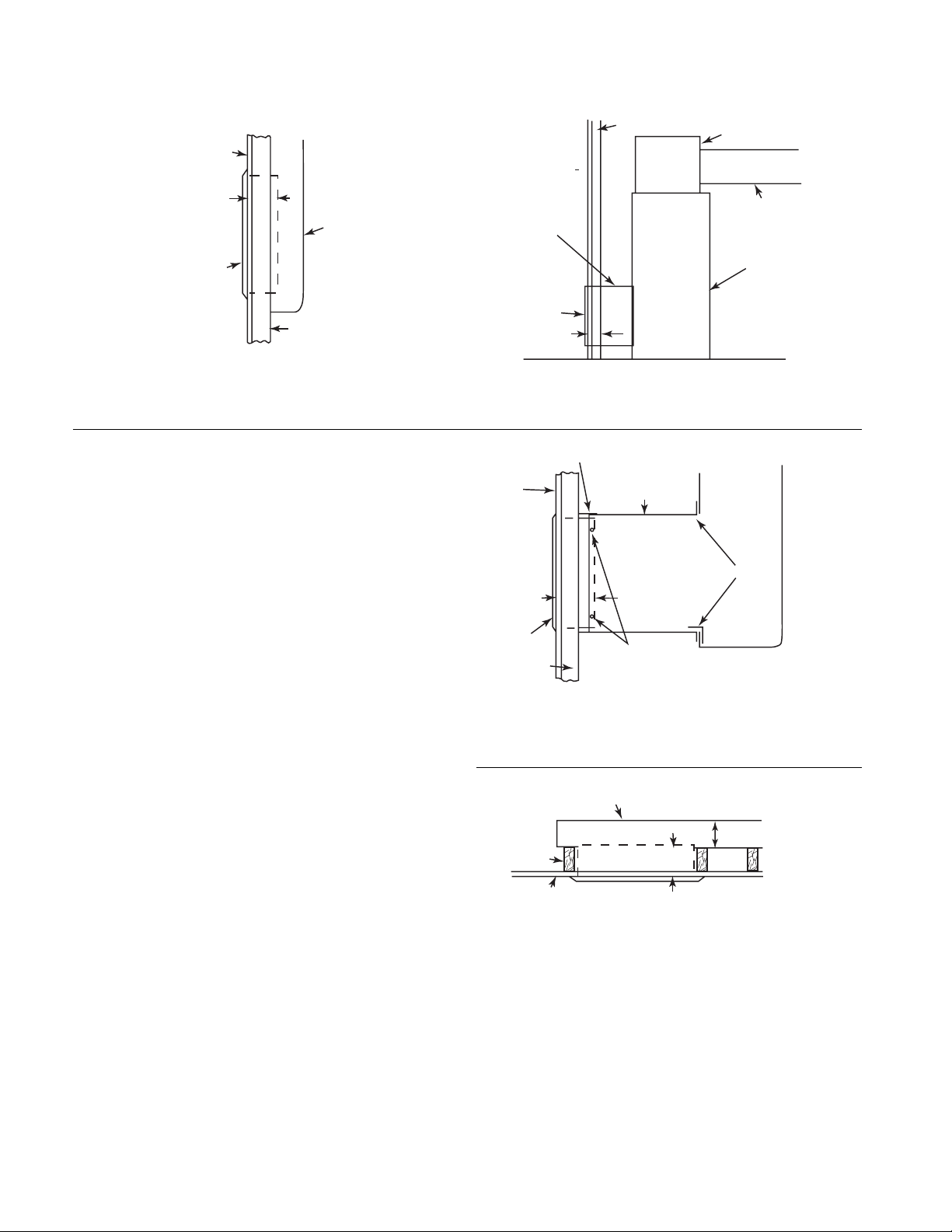

Thru-The-Wall electronic air cleaners are designed to

provide maximum air cleaning in applications where a

single central return air duct is employed, or where the

central heating or air conditioning is in a limited access

area. The Thru-The-Wall units may be installed in the wall

such as in closet installations or in the ceiling with attic type

installations.

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

This manual contains essential information for locating,

installing, operating and servicing your electronic air

cleaner. Before installing and using your air cleaner, be

sure to read these instructions carefully and observe them

in order to derive the maximum benefits from the superior

performance built into the unit and help to avoid needless

service costs that result from causes the manufacturer

cannot control and cannot be covered in the warranty.