TOC − 2

Table of Contents

Section Title Page Number

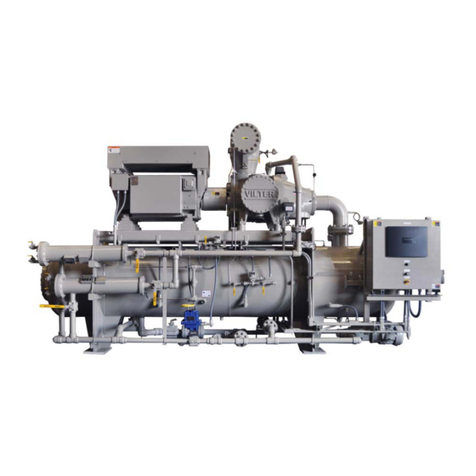

VSG & VSSG Single Screw Compressor • Installation, Operation and Service Manual • Emerson • 35391SB

Section 4 • Operation

Notice on Using Non-Vilter Oils .............................................................................................................. 4-1

Safety Setpoints.....................................................................................................................................4-1

Control System .....................................................................................................................................4-2

Calibration .................................................................................................................................4-2

Starting, Stopping and Restarting The Compressor ....................................................................4-2

Emergency Shutdown ................................................................................................................4-2

Slide Valve Actuator Calibration (25972XP)............................................................................................4-3

Slide Calibration Screen Overview ..............................................................................................4-3

Calibrate Slide Valve Actuators (25972XP)..................................................................................4-3

Slide Valve Actuators Calibration (For VPN 25972D Only).......................................................................4-6

Section 5 • Maintenance/Service

Maintenance and Service Schedule ........................................................................................................5-1

Additional Notes ........................................................................................................................5-2

Recommendations When Servicing........................................................................................................5-2

Preparation of Unit For Servicing............................................................................................................5-2

Compressor Inspection ..........................................................................................................................5-3

Bearing Check ............................................................................................................................5-3

Gaterotor Assembly Replacement ..........................................................................................................5-5

Removal (All VSG Models) ..........................................................................................................5-5

Removal (All VSG 301-701 Models)............................................................................................. 5-6

Installation (All VSG Models) ......................................................................................................5-8

Installation (All VSG 301-701 Models).........................................................................................5-10

Gate Rotor Blade Removal ..........................................................................................................5-11

Gate Rotor Blade Installation ......................................................................................................5-11

Gate Rotor Thrust Bearing Removal ............................................................................................5-11

Gate Rotor Thrust Bearing Installation ........................................................................................5-11

Gate Rotor Roller Bearing Removal .............................................................................................5-12

Gate Rotor Roller Bearing Installation .........................................................................................5-12

Compressor Shaft Seal Replacement ......................................................................................................5-13

Compressor Shaft Seal Removal .................................................................................................5-13

Compressor Shaft Seal Installation .............................................................................................5-13

Maintenance Suggestion............................................................................................................5-13

Inspection of Slide Valve Assemblies In The Compressor ........................................................................5-15

Prepare The Compressor For Servicing .......................................................................................5-15

Removal of Slide Valve Carriage Assemblies...............................................................................5-15

Installation of Slide Valve Carriage Assemblies............................................................................5-16

Slide Valve Actuator Assembly Replacement ..........................................................................................5-17

Removal.....................................................................................................................................5-17

Installation.................................................................................................................................5-17

Actuator Installation Using Anti-Rotation Bolts...........................................................................5-18

Slide Valve Command Shaft Assembly Replacement...............................................................................5-19

Removal.....................................................................................................................................5-19

Installation.................................................................................................................................5-19

Slide Valve Command Shaft Assembly Replacement (For the Design Before June 2006)..........................5-20

Removal.....................................................................................................................................5-20

Installation.................................................................................................................................5-20

Slide Valve Command Shaft Bearing and O-Ring Seal Replacement (For the Design Before June 2006) ... 5-20

Removal.....................................................................................................................................5-20

Reassembly ................................................................................................................................5-21