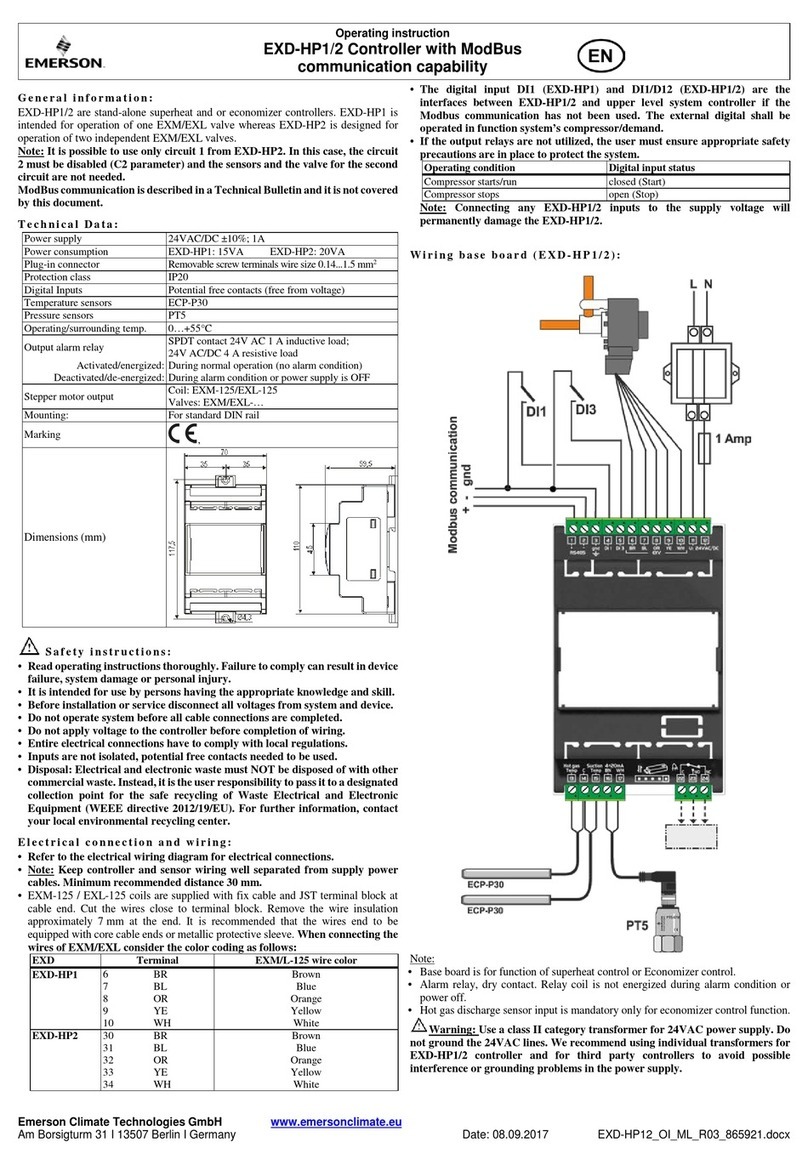

Emerson Biffi Morin Series User manual

Other Emerson Controllers manuals

Emerson

Emerson Fisher 912N Series User manual

Emerson

Emerson Branson 2000X User manual

Emerson

Emerson PACSystems RX3i User manual

Emerson

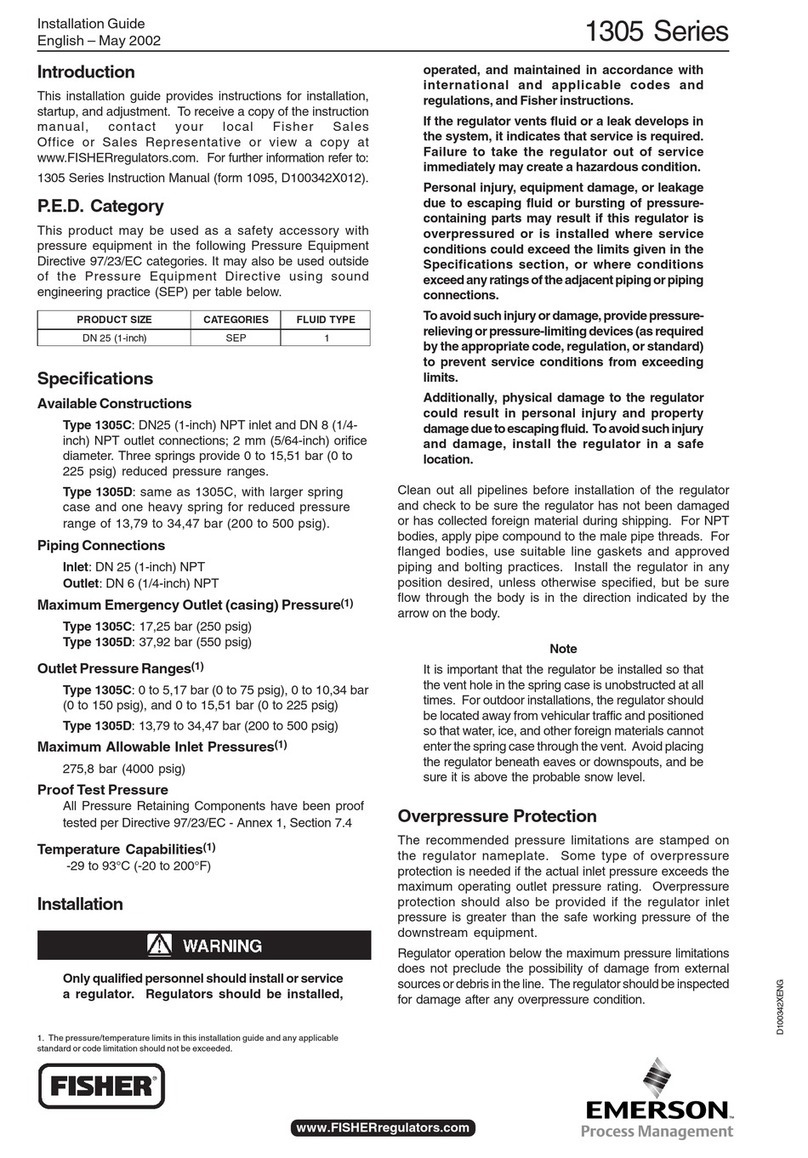

Emerson Fisher 67D Series User manual

Emerson

Emerson Fisher FIELDVUE DVC6200 SIS User manual

Emerson

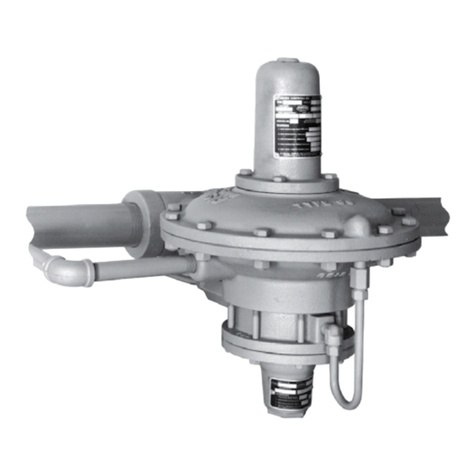

Emerson VAREC Series Manual

Emerson

Emerson Shafer ECAT User manual

Emerson

Emerson Bettis RGS Q Series User manual

Emerson

Emerson EC3-X32 User manual

Emerson

Emerson DL8000 Quick guide

Emerson

Emerson Dixell XR64CX Wiring diagram

Emerson

Emerson Fisher 2052 User manual

Emerson

Emerson Dixell XRB06CH Wiring diagram

Emerson

Emerson E2 Enhanced RX Service manual

Emerson

Emerson Dixell XR40CX Wiring diagram

Emerson

Emerson Fisher Type 99 User manual

Emerson

Emerson Bettis SCE300 User manual

Emerson

Emerson Fisher 299H User manual

Emerson

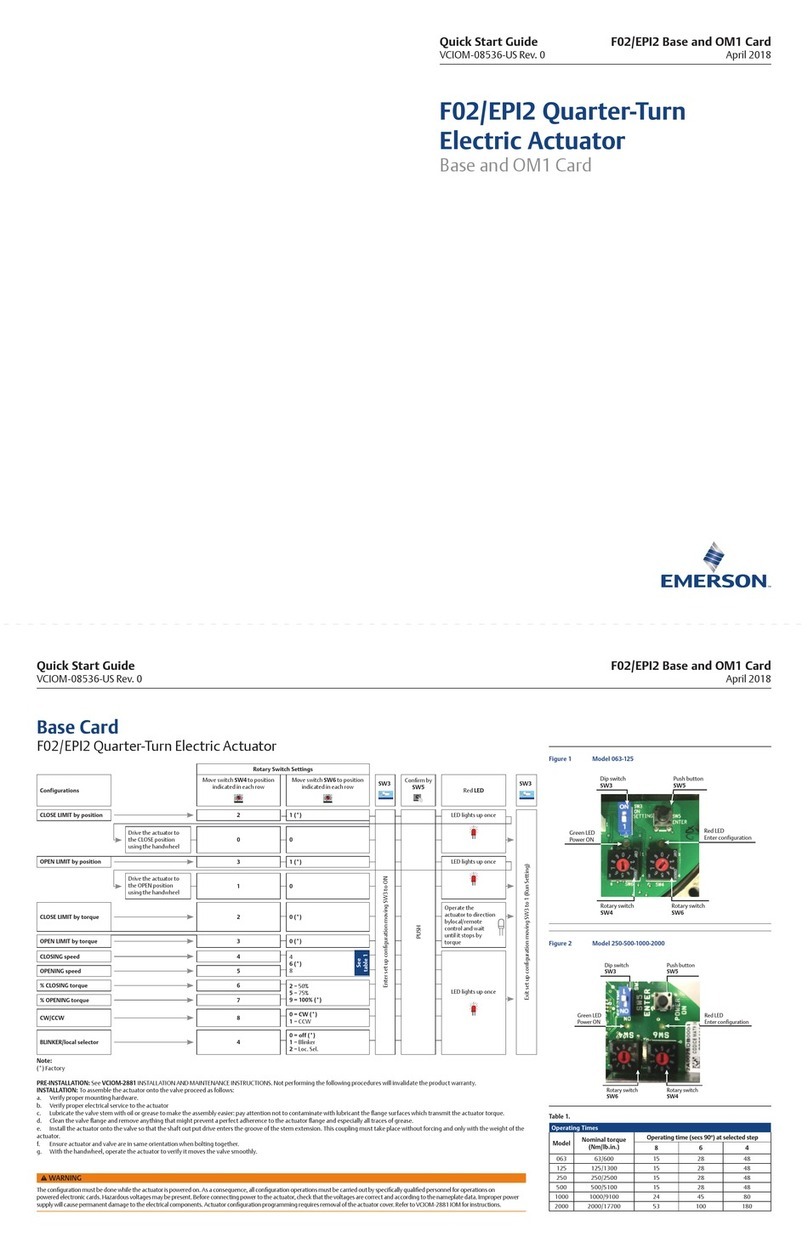

Emerson F02/EPI2 User manual

Emerson

Emerson AXIMA 2000 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions