MR95 Series

Installation Guide

D103587X014

July 2017

Introduction

This Installation Guide provides instructions for installation, startup

and adjustment. To receive a copy of the Instruction Manual, contact

your local Sales Office or view a copy at www.fisher.com. For further

information refer to MR95 Series Instruction Manual, D103587X012.

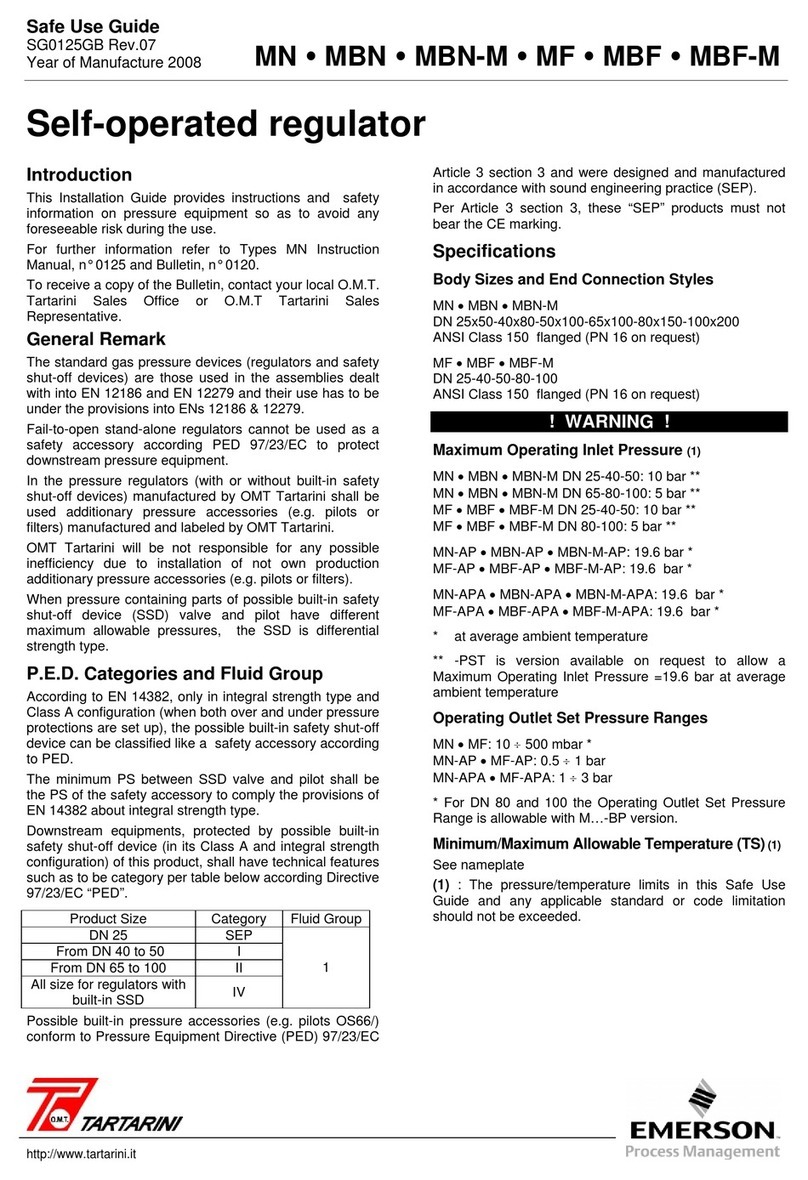

PED Category

This product may be used as a safety accessory with pressure

equipment in the following Pressure Equipment Directive. It may

also be used outside of the Pressure Equipment Directive using

Sound Engineering Practice (SEP) per table below. For information

on the current PED revision see Bulletin: D103053X012.

TYPE PRODUCT SIZE BODY MATERIAL CATEGORY

MR95L/

MR95LD

1/4 NPT, DN 15 to 25 /

1/2 to 1 in. All SEP

MR95H/

MR95HD

1/4 NPT, DN 15 to 25 /

1/2 to 1 in. All SEP

DN 40 and 50 /

1-1/2 and 2 in.

Cast iron I

Steel and

Stainless steel II

MR95HP/

MR95HT/

MR95HDP

1/4 NPT, DN 15 to 25 /

1/2 to 1 in. All SEP

DN 40 and 50 /

1-1/2 and 2 in.

Steel and

Stainless steel II

Specications

Available Constructions

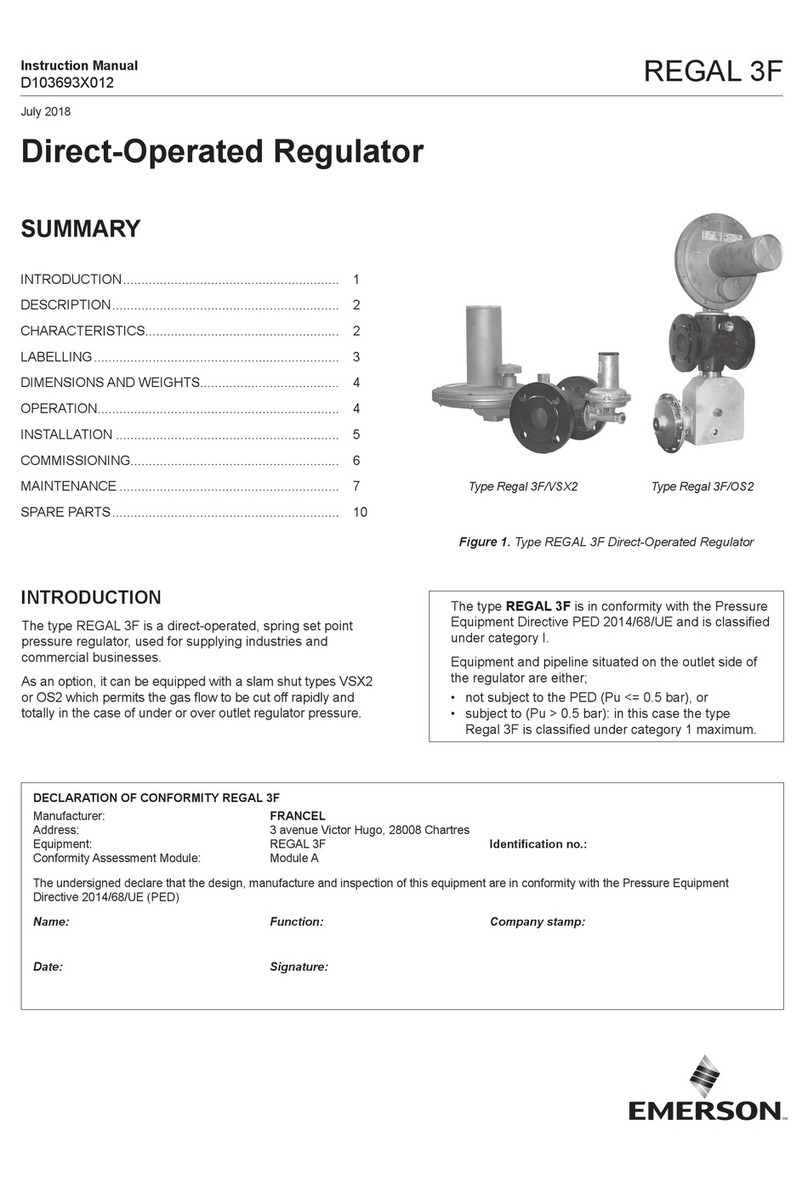

Type MR95L: Pressure reducing regulator for outlet pressures

from 0.14 to 2.1 bar / 2 to 30 psig. 1/4 to 1 in. body sizes only.

Type MR95H: Pressure reducing regulator for outlet pressures

from 0.34 to 10.3 bar / 5 to 150 psig.

Type MR95HP: Pressure reducing regulator for outlet

pressures from 1.0 to 27.6 bar / 15 to 400 psig (soft-seated).

Type MR95HT: High temperature pressure reducing regulator

for outlet pressures from 1.0 to 20.7 bar / 15 to 300 psig

(metal seat) and up to 343°C / 650°F.

Type MR95LD: Pressure reducing differential regulator for

differential set pressures from 0.14 to 2.1 bar / 2 to 30 psi with

maximum inlet pressure up to 20.7 bar / 300 psi and maximum

outlet pressure up to 8.6 bar / 125 psi. 1/4 to 1 in. body

sizes only.

Type MR95HD: Pressure reducing differential regulator for

differential set pressures from 0.34 to 10.3 bar / 5 to 150 psi

with maximum inlet/outlet pressures up to 20.7 bar / 300 psig.

Type MR95HDP: Pressure reducing differential regulator for

differential set pressures from 0.34 to 10.3 bar / 5 to 150 psi

with maximum inlet/outlet pressures up to 41.4 bar / 600 psi.

Body and Orifice Sizes

1/4 NPT body: 7.22 mm / 0.284 in. orifice

DN 15 / 1/2 in. body: 10.56 mm / 0.416 in. orifice

DN 20 and 25 / 3/4 and 1 in. bodies: 16.02 mm / 0.631 in. orifice

DN 40 and 50 / 1-1/2 and 2 in. bodies (not available for

Types MR95L and MR95LD): 29 mm / 1.142 in. orifice

1. The pressure/temperature limits in this Installation Guide and any applicable standard or code limitation should not be exceeded.

2. The pressure limits given are based on the body size and body materials only. Actual pressure limits of the assembled regulator may decrease

and vary depending on the temperature, body end connection, diaphragm, seat and/or trim material of the regulator.

End Connection Styles

NPT, SWE, Welded and Integral CL150 RF, CL300 RF,

CL600 RF and PN 16/25/40 RF; all sizes are fabricated with

slip-on flanges (for welded end connections) and are EN

flanged 356 mm face-to-face (14 in. face-to-face)

Outlet and Differential Pressure Ranges(1)

See Table 1

Maximum Spring Case Loading Pressure for

Types MR95LD, MR95HD and MR95HDP

See Table 2

Maximum Cold Working Pressures of

Body Size and Materials(1)(2)

See Table 2

Pressure Registration

Internal or External

Maximum Temperature Ranges of

Diaphragm and Seat Materials(1)(2)

See Table 3

Shutoff Classification Per ANSI/FCI 70-3-2004

Metal Seats: Class IV

PTFE: Class IV

Elastomer Seats: Class VI or better

API 614 Compliant

Steel or Stainless steel constructions with Stainless steel trim

meet API 614 Requirements.

Sour Gas Service Capability

Optional materials are available for applications handling sour

gases. These constructions comply with the recommendations

of NACE International Standards MR0175-2002 and MR0103.

Optional materials are available to meet ANSI/NACE

MR0175/ISO 15156.

Installation

!

WARNING

Only qualified personnel shall install or service

a regulator. Regulators should be installed,

operated and maintained in accordance with

international and applicable codes and regulations

and Emerson Process Management Regulator

Technologies, Inc. instructions.

If the regulator vents fluid or a leak develops in the

system, it indicates that service is required. Failure

to take the regulator out of service immediately

may create a hazardous condition.

Personal injury, equipment damage or leakage

due to escaping fluid or bursting of pressure

containing parts may result if this regulator

is overpressured or is installed where service

conditions could exceed the limits given in

the Specifications section or where conditions

exceed any ratings of the adjacent piping or

piping connections.