MN yMBN yMBN-M yMF yMBF yMBF-M Safe Use Guide

SG0125GB Rev.07

Year of Manufacture 2008

2

Marking

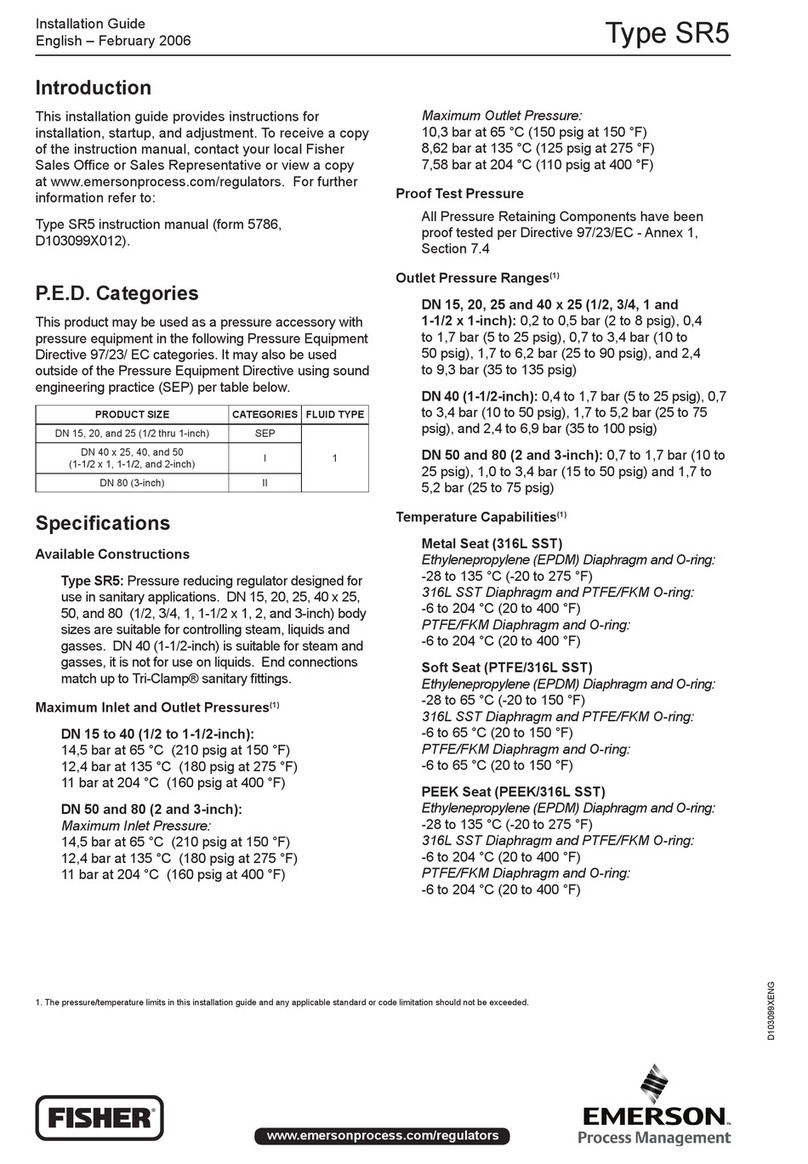

Note 1: See “Specifications” paragraph

Note 2: See page header

Note 3: Class 1: -10/+60 °C

Note 4: PN 16 PS = 16 bar

ANSI 150 PS = 19,3 bar

Note 5: 1,5 bar for M…N-BP/80-100

4 bar for all other models

Overpressure Protection

The recommended maximum allowable pressures are

stamped on the regulator nameplate.

If actual version hasn’t a built-in safety shut-off device,

some type of overpressure protection is needed if the

actual outlet pressure exceeds the actual maximum

operating outlet pressure rating.

Overpressure protection should also be provided if the

regulator inlet pressure is greater than the maximum

operating inlet pressure.

Downstream side pressure after possible built-in SSD’s

intervention shall stay within the actual maximum

operating set-up range to avoid anomalous back

pressures that can damage the SSD’s pilot.

Downstream overpressure protection shall be also

provided if the SSD outlet pressure can be greater than

the PS of the SSD pilot (differential strength type).

Regulator operation below the maximum pressure

limitations does not preclude the possibility of damage

from external sources or debris in the line.

The regulator should be inspected for damage after any

overpressure condition.

Transport and Handling

Established transport and handling procedures shall be

followed to avoid any damage on the pressure containing

parts by shocks or anomalous stresses.

Ringbolts are designed just for handling of equipment

weight.

Built-up sensing lines and pressure accessories shall to

be protected by shocks or anomalous stresses.

Installation

! WARNING !

Only qualified personnel should install or service a

regulator.

Regulators should be installed, operated, and

maintained in accordance with international and

applicable codes and regulations, and O.M.T. Tartarini

instructions.

If the regulator vents fluid or a leak develops in the

system, it indicates that service is required.

Failure to take the regulator out of service

immediately may create a hazardous condition.

Personal injury, equipment damage, or leakage due to

escaping fluid or bursting of pressure-containing

parts may result if this regulator is over pressured or

is installed where service conditions could exceed the

limits given in the Specifications section, or where

conditions exceed any ratings of the adjacent piping

or piping connections.

To avoid such injury or damage, provide pressure-

relieving or pressure-limiting devices (as required by

the appropriate code, regulation, or standard) to

prevent service conditions from exceeding limits.

Additionally, physical damage to the regulator could

result in personal injury and property damage due to

escaping fluid.

To avoid such injury and damage, install the regulator

in a safe location.

Before installation, check shall be done if service

conditions are consistent with use limitations and if

pilot set-up of possible built-in safety shut-off device

are in accordance with service conditions of protected

equipment.

All means for venting have to be provided in the

assemblies where the pressure equipment are

installed (ENs 12186 & 12279).

All means for draining have to be provided in the

equipment installed before regulators & shut-off

devices (ENs 12186 & 12279).

Further the ENs 12186 & 12279, where this product is used :

−provide the cathodic protection and electrical

isolation to avoid any corrosion and

−in accordance with clause 7.3/7.2 of aforesaid

standards, the gas shall be cleaned by proper

filters/separators/scrubbers to avoid any technical

& reasonable hazard of erosion or abrasion for

pressure containing parts.

Pressure equipment in subject shall be installed in non-

seismic area and hasn’t to undergo fire and thunderbolt

action.

Clean out all pipelines before installation of the regulator

and check to be sure the regulator has not been damaged

or has collected foreign material during shipping.

Use suitable line gaskets and approved piping and bolting

practices.