D7.8.4/0112-0415/E 1/17

Date of last update: Apr-15

Application Engineering Europe

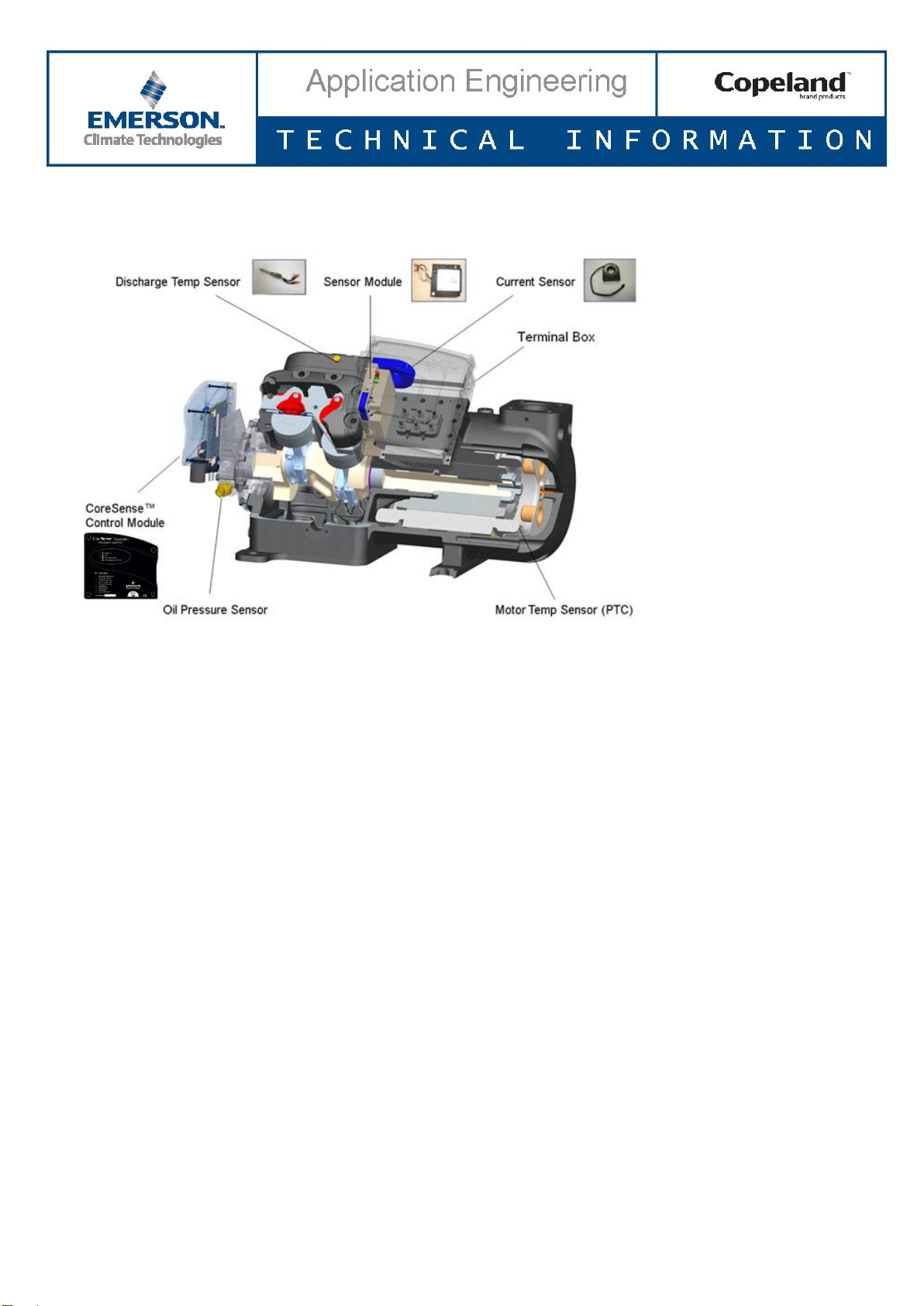

CORESENSE™ DIAGNOSTICS FOR STREAM REFRIGERATION COMPRESSORS

CoreSense™Diagnostics for Stream Refrigeration Compressors................................................................................1

1 Introduction..........................................................................................................................................................2

2 Specifications........................................................................................................................................................2

3 CoreSense Diagnostics features ...........................................................................................................................2

3.1 Insufficient oil pressure protection ..............................................................................................................3

3.2 Motor overheat protection ..........................................................................................................................3

3.3 High discharge temperature protection.......................................................................................................3

3.4 Locked rotor protection................................................................................................................................4

3.5 Missing phase protection .............................................................................................................................4

3.6 Low voltage protection.................................................................................................................................4

3.7 Voltage imbalance protection ......................................................................................................................4

3.8 “Jog” feature.................................................................................................................................................5

3.9 Crankcase heater (CCH) control....................................................................................................................5

3.10 Flash memory information ...........................................................................................................................5

3.11 Modbus® communication.............................................................................................................................6

3.12 Reset .............................................................................................................................................................7

3.13 Alarm history and running conditions ..........................................................................................................7

3.14 Compressor status codes..............................................................................................................................7

3.15 LEDs on the module to display the failure alarms........................................................................................7

3.16 Oil functionality self-test option...................................................................................................................9

4 Electrical connections...........................................................................................................................................9

4.1 System wiring diagram .................................................................................................................................9

4.2 Terminal box and current sensing transformer connections .....................................................................11

4.2.1 Installation of current sensing module...............................................................................................11

4.2.2 CoreSense Diagnostics with Υ/Δmotors ............................................................................................11

4.2.3 CoreSense Diagnostics with part winding ..........................................................................................12

5 CoreSense Diagnostics jumper settings..............................................................................................................13

6 CoreSense Diagnostics DIP-switch settings ........................................................................................................14

7 Troubleshooting..................................................................................................................................................15