Instruction Manual

IM-106-340AC-1, Rev. 1.0

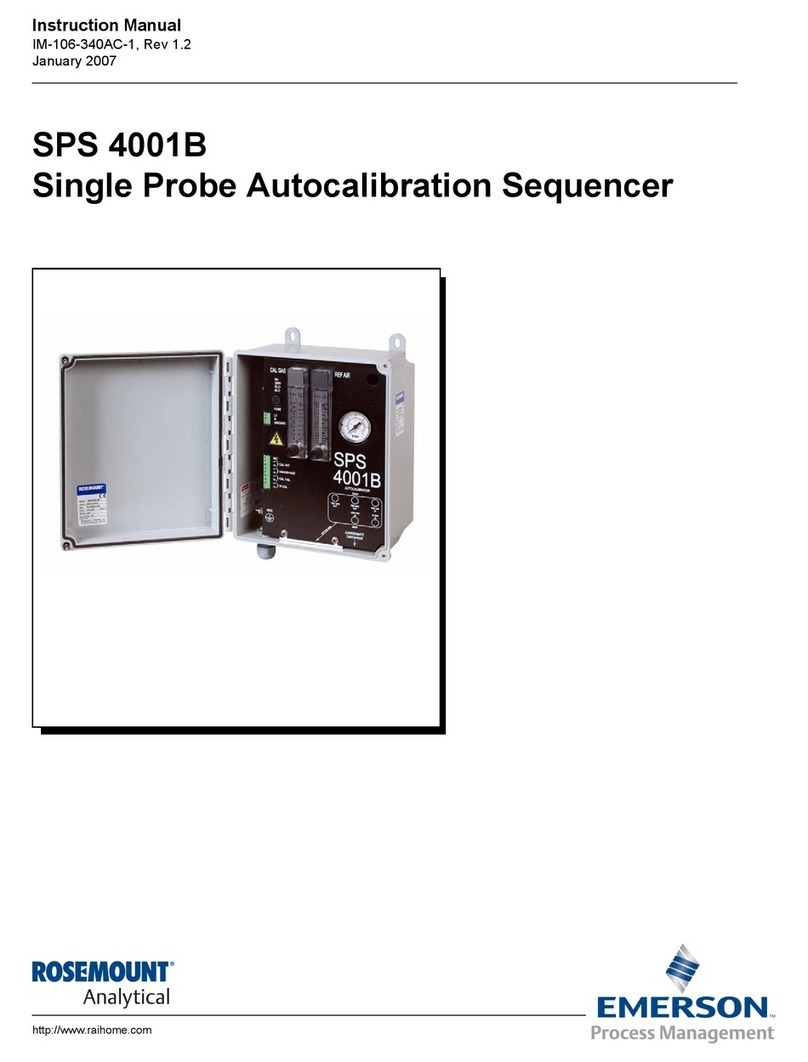

April 2005 SPS 4001B

http://www.raihome.com

SPS 4001B Single Probe

Autocalibration Sequencer

ESSENTIAL

INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet

many national and international standards. Because these instruments are

sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal

specifications. The following instructions MUST be adhered to and integrated

into your safety program when installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper instructions may cause any

one of the following situations to occur: Loss of life; personal injury; property

damage; damage to this instrument; and warranty invalidation.

•Read all instructions prior to installing, operating, and servicing the

product.

• If you do not understand any of the instructions, contact your

Rosemount Analytical representative for clarification.

•Follow all warnings, cautions, and instructions marked on and

supplied with the product.

•Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

•Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and per applicable local and

national codes.Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel to install,

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and

procedures can affect the product's performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or

improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without

notice.

Get other manuals https://www.bkmanuals.com