EMH metering DIZ User manual

Table of contents

Other EMH metering Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

hf sensor

hf sensor MOIST 350 B Operation manual

TSI Instruments

TSI Instruments 9535A Operation and service manual

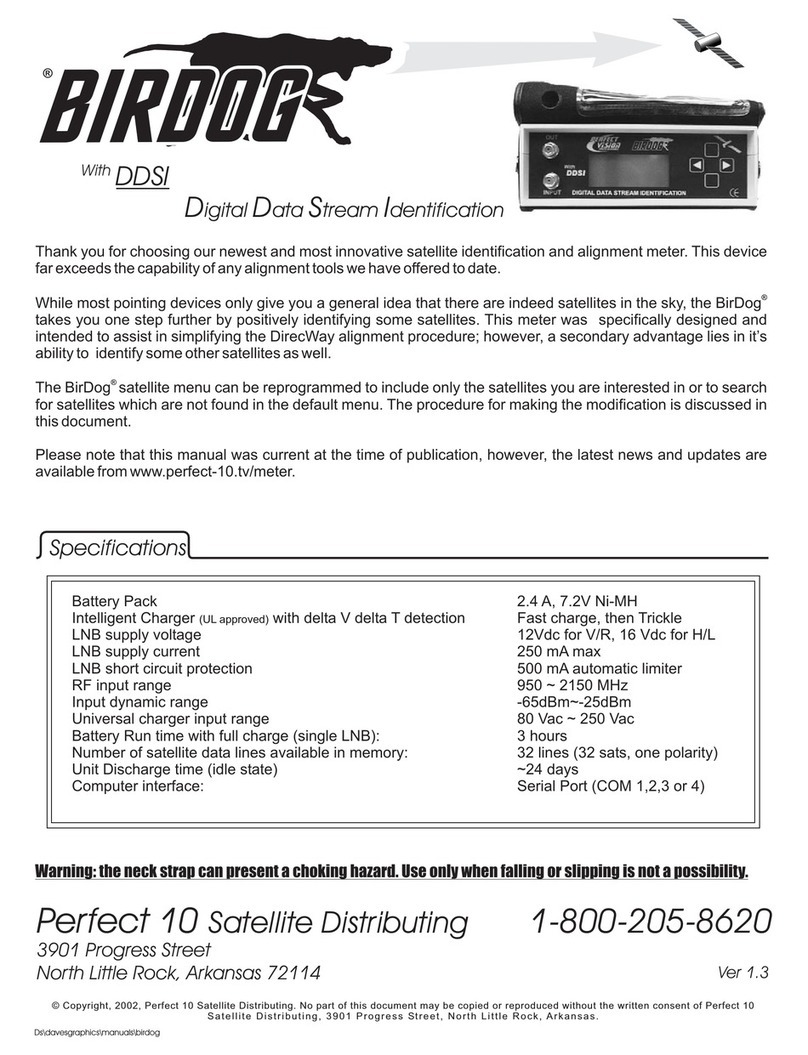

Perfect 10 Satellite Distributing

Perfect 10 Satellite Distributing Birdog manual

Endress+Hauser

Endress+Hauser Proline Promag H 200 operating instructions

PCB Piezotronics

PCB Piezotronics 356A14 Installation and operating manual

techem

techem MOC Series installation instructions

Keysight Technologies

Keysight Technologies N5221A Service guide

Agilent Technologies

Agilent Technologies 4286A user guide

IFM Electronic

IFM Electronic efector300 SD5000 operating instructions

ILLKO

ILLKO MDtest user manual

socomec

socomec DIRIS A14 user manual

CORNING

CORNING ONE GX Quick installation sheet