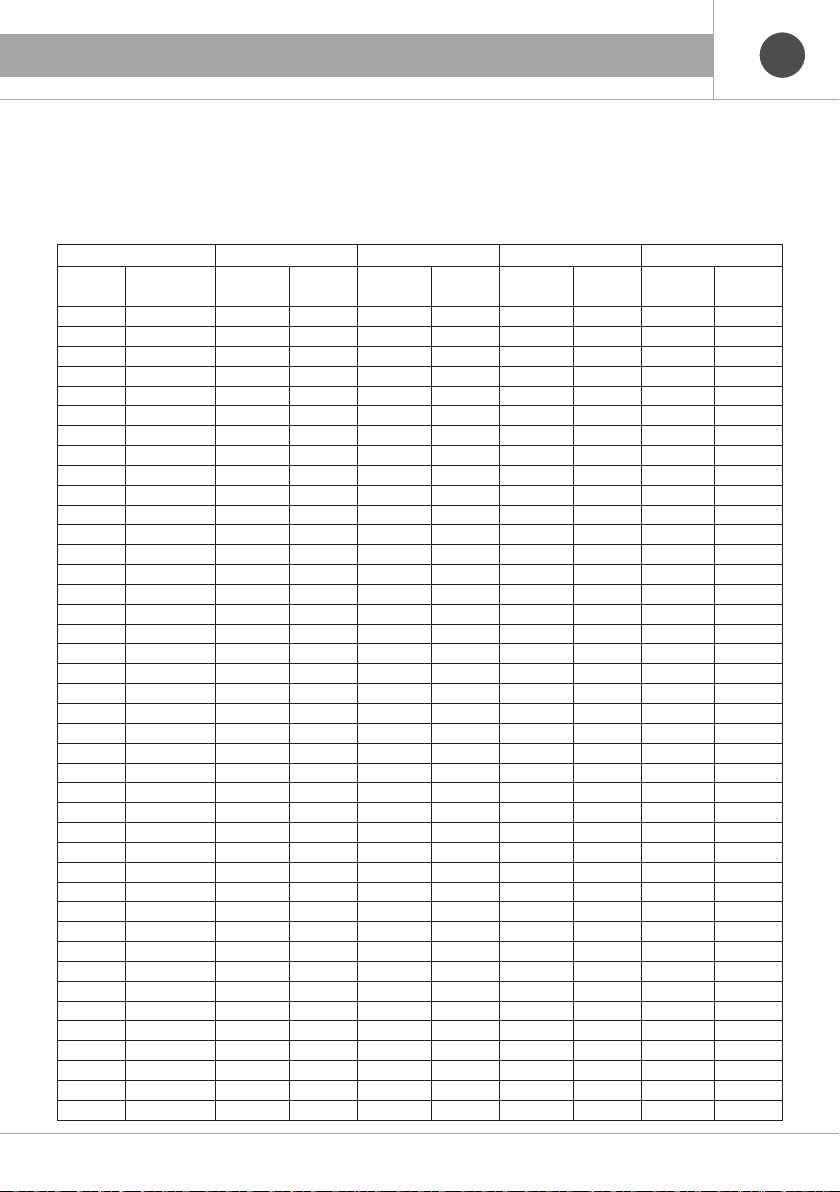

– Temperature: 15 °C

– Pressure: 1013.25 mbar – LPG density: 1.864 kg/m³

– Lower calorific LPG value: 27000 kcal/m³

LPG 16 20 26 32

Power

(kW)

Flow Rate

(m³/h)

Δp

(mbar/m)

Speed

(m/s)

Δp

(mbar/m)

Speed

(m/s)

Δp

(mbar/m)

Speed

(m/s)

Δp

(mbar/m)

Speed

(m/s)

5 0,154 0,010 0,379 0,021 0,213 0,002 0,137 0,0002 0,081

6 0,185 0,013 0,455 0,029 0,256 0,003 0,164 0,0003 0,097

7 0,216 0,018 0,531 0,000 0,299 0,000 0,191 0,0004 0,113

8 0,247 0,023 0,607 0,048 0,341 0,005 0,218 0,0006 0,129

9 0,278 0,028 0,683 0,059 0,384 0,007 0,246 0,0007 0,145

10 0,309 0,034 0,758 0,072 0,427 0,008 0,273 0,0008 0,162

11 0,340 0,040 0,834 0,085 0,469 0,009 0,300 0,0010 0,178

12 0,370 0,047 0,910 0,100 0,512 0,011 0,328 0,0011 0,194

13 0,401 0,054 0,986 0,115 0,555 0,013 0,355 0,0013 0,210

14 0,432 0,062 1,062 0,132 0,597 0,015 0,382 0,0015 0,226

15 0,463 0,070 1,138 0,149 0,640 0,016 0,410 0,0017 0,242

16 0,494 0,079 1,214 0,167 0,683 0,018 0,437 0,0019 0,258

17 0,525 0,088 1,289 0,187 0,725 0,021 0,464 0,0021 0,275

18 0,556 0,097 1,365 0,207 0,768 0,023 0,491 0,0024 0,291

19 0,586 0,107 1,441 0,228 0,811 0,025 0,519 0,0026 0,307

20 0,617 0,118 1,517 0,250 0,853 0,028 0,546 0,0029 0,323

21 0,648 0,129 1,593 0,273 0,896 0,030 0,573 0,0031 0,339

22 0,679 0,140 1,669 0,297 0,939 0,033 0,601 0,0034 0,355

23 0,710 0,152 1,744 0,322 0,981 0,035 0,628 0,0037 0,372

24 0,741 0,164 1,820 0,347 1,024 0,038 0,655 0,0040 0,388

25 0,772 0,176 1,896 0,374 1,067 0,041 0,683 0,0043 0,404

26 0,802 0,189 1,972 0,401 1,109 0,044 0,710 0,0046 0,420

27 0,833 0,202 2,048 0,429 1,152 0,047 0,737 0,0049 0,436

28 0,864 0,216 2,124 0,459 1,195 0,051 0,765 0,0053 0,452

29 0,895 0,230 2,199 0,488 1,237 0,054 0,792 0,0056 0,469

30 0,926 0,244 2,275 0,519 1,280 0,057 0,819 0,0060 0,485

31 0,957 0,259 2,351 0,551 1,323 0,061 0,846 0,0063 0,501

32 0,988 0,275 2,427 0,583 1,365 0,064 0,874 0,0067 0,517

33 1,019 0,290 2,503 0,616 1,408 0,068 0,901 0,0071 0,533

34 1,049 0,306 2,579 0,650 1,451 0,072 0,928 0,0075 0,549

35 1,080 0,323 2,655 0,685 1,493 0,076 0,956 0,0079 0,565

40 1,235 0,410 3,034 0,871 1,706 0,096 1,092 0,0100 0,646

45 1,389 0,507 3,413 1,077 1,920 0,119 1,229 0,0124 0,727

50 1,543 0,613 3,792 1,302 2,133 0,144 1,365 0,0150 0,808

60 1,852 0,851 4,551 1,808 2,560 0,199 1,638 0,0208 0,969

70 2,160 1,123 5,309 2,386 2,986 0,263 1,911 0,0275 1,131

80 2,469 1,429 6,068 3,034 3,413 0,335 2,184 0,0349 1,292

90 2,778 1,766 6,826 3,751 3,840 0,414 2,457 0,0432 1,454

100 3,086 2,135 7,584 4,534 4,266 0,500 2,730 0,0522 1,616

110 3,395 2,534 8,343 5,382 4,693 0,594 3,003 0,0619 1,777

120 3,704 2,964 9,101 6,295 5,119 0,694 3,276 0,0725 1,939

Reference values for LPG gas:

7

GB

3. INSTALLATION