EMPERO EMP.9IG010 User manual

1

GAS GRILLS

CONTENTS

A GENERAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 3

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 7

F TROUBLESHOOTING Page 8

G INJECTOR CHANGE AND GAS SETTING Page 9

H GAS CONNECTION IMAGES Page 10

I SPARE PART LIST- EXPLODING DRAWING Page 12

2

GAS GRILLS

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

GAS GRILLS

A1 PRODUCT DESCRIPTION

*The Professional Gas Grills,that provides high efficiency has been designed to be used in

industrial kitchens.

Product Code

Dimensions (mm)

Weight (kg)

Packaging

Dimensions (mm)

EMP.9IG010

400x900x285

65

430x1000x590

EMP.9IG020

800x900x285

106

830x1000X590

EMP.9IG022

800x900x285

108

830x1000X590

EMP.7IG010

400X730X285

40

480X800X590

EMP.7IG020

800X730X285

60

830X800X590

EMP.7IG022

800X730X285

60

830X800X590

A2 TECHNICAL INFORMATION

Product

Code

Model

Power

(KW)

Gas

Consumption

(NG)

Gas

Consumption

(LPG)

EMP.9IG010

Gas Grill-Smooth-Cabinet

7

1,0 m³/h

0,7 kg/h

EMP.9IG020

Gas Grill-Smooth-Cabinet

14

1,9 m³/h

1,4 kg/h

EMP.9IG022

Gas Grill-Smooth+Ribbed-

Cabinet

14

1,9 m³/h

1,4 kg/h

EMP.7IG010

Gas Grill-Smooth-Cabinet

6

0,8 m³/h

0,6 kg/h

EMP.7IG020

Gas Grill-Smooth-Cabinet

12

1,5 m³/h

1,1 kg/h

EMP.7IG022

Gas Grill-Smooth+Ribbed-

Cabinet

12

1,5 m³/h

1,1 kg/h

4

GAS GRILLS

A3 TRANSPORTATION

* This appliance can not be moved by hand from area to area. Therefore Use a hauling truck

(forklift or pallet jack) to move the appliance. ( The lifting arms of the of forklift or pallet jack

must reach up to more than half part of t appliance underneath.)

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shipping.

B MONTAJ

*Please place the product to straight and sturdy ground,please take necessary steps against

possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Gas Fitment or any amendment process must be done by authorized person.

*The area where the appliance is must have enough ventilation and vent-hole.

*The appliance must be connected correctly according to local and national gas standards of

your country.

*The appliance gas entrances are indicated with ‘’G’’ label on the body.

*Connection to gas fitment must be done with suitable diameter metal flex pipe and spheric

valve.The spheric valve must be immobilized to a place that is far away from heat and

accessible during the danger.After gas entrance connection done,gas leakages must be

checked.

*According to the datas on appliance information plate,gas and pressure must be adjusted.If

the gas type that is adjusted is not the suitable with gas type that is at installation place,apply

the instructions that is about adjustment of different gas type. (Event :G)

*If the location where gas grills placed is covered with nonflammable heat insulation

material,the distance between them must be 5 cm.Otherwise it should be at least 20 cm.The

appliance shouldn’t be operated under chimney hood.

5

GAS GRILLS

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*If there is gas leakage where the appliance is, .do not fire absolutely and do not use

electric .

*Definitely do not allow to check the sealing with flame.

!

!

!

!

!

!

!

!

6

GAS GRILLS

D OPERATION

*Control Panel;

A : Off Position

B : Lighter Position

C : Full Flame

D: Half Flame

E: Spyhole

F: Lighter

G : Oil Drawer

*Operating;

•According to type of use,make gas entrance connection from behınd the grill.Because the

machine is operated with LPG and NG.

•Turn on the gas valves.

•Press the button at Pilot position before firing to remove the air from gas fitment during

first operation.

•Press the gas grill button and provide pilot position.Fire the pilot with suitable lighter.

•In order to heat thermocouple’s end keep pressing to button after the pilot is fired.

•For desired temperature switch to half or full flame position.

•Operate the grill when it is empty to remove protective oil and place the foods that will be

cooked on the grill.

•Be sure that the oil flows to oil drawer.

•After the operation is completed,switch the gas valve to (0) position.

7

GAS GRILLS

E CLEANING & MAINTENANCE

➢CLEANING AND MAINTENANCE AFTER EVERY USE

•Turn off the gas connection before cleaning.

•Clean the outer surface of the appliance with a wet cloth and chrome shiner.

•Do not use abrasive cleaning chemicals as these can leave harmful residues.

•Do not wash the appliance with pressure water.

•Do not clena the appliance with a materials that may damage chrome material.

•Clean the grills with suitable spatula.

➢PERIODIC CLEANING AND MAINTENANCE

•Maintenance should be done by qualified person.

•These parts ; Gas storage,pilot,thermocouples,taps,burner,lighter and spark plug

cable are not maintained so they need to be changed when they have error.

•Check the gas connection hoses in periodic time.If there is slit,hole..etc,change the

hoses.

•Ventilate the area where the device is in periodic times.

8

GAS GRILLS

F TROUBLESHOOTING

THE APPLIANCE DOESN’T OPERATE

1. Check if the gas connection is done or

not.

2. If there is no gas entrance to pilot,the

appliance is not operated.

3. Check if the injector holes are opened

or not.

4. If the hoses that have gas entrance

lose gas due to slit,hole.etc.,the

appliance is not operated.

THE APPLIANCE DOESN’T COOK WELL

1. Check if it is operated at suitable gas

setting or not.

THE APPLIANCE STOPPED

1. Gas flow is stopped automatically when

the flame is off due to having gas tap

that has safety valve.In this situation

the appliance is not operated.

2. When there is gas leakage,if there is

solenoid gas stopper alarm,gas flow is

stopped and the appliance is not

operated.Ventilate the area through the

agency of vent-hole.

•If cooking at gas grills is not done at suitable quality

•If any function of security doesn’t work

➢Do not use the appliance.

*If these problems are still going on,contact with our authorized services.

9

GAS GRILLS

G INJECTOR CHANGE AND GAS SETTING

GAS GRILL BURNER - INJECTOR CHANGE CHART

Gas Group

Gas

9IG-7IG

Pilot

Injector mm

Injector mm

2

G20

2,15

0,41

G25

2,15

0,41

3

G30

30 mbar

1,35

0,22

50 mbar

1,6

0,20

G31

37 mbar

1,35

0,22

30 mbar

1,3

0,20

Change of Burner Injector;

1. Rip off the injector at the entrance of burner with a suitable tool.

2. Change A injector by paying attention to the datas at chart with suitable injector.

(Image 1)

3. Adjust the burner entrance setting (F) by loosening ‘B’ bolt and moving the valve to

forward-back. (Image 2)

4. Change C injector by paying attention to the datas at chart with suitable injector.For

this it is enough to take off ‘D’ fitting and pull the gas pipe to down. (Image 3)

Setting of Half Flame;

1. Remove the tap button and set by turning tap half flame screw (K) with suitable

screwdriver.(Image 4) Turn it to left for transformation from LPG to N.G,turn it right for

transformation from N.G to LPG.

2. After this process,operate the appliance and set it not to be deflated during transition

from full flame to half flame

10

GAS GRILLS

H GAS CONNECTION IMAGES

Image-1

Image-2

Image-1

11

GAS GRILLS

H GAS CONNECTION IMAGES

Image-3

Image -4

12

GAS GRILLS

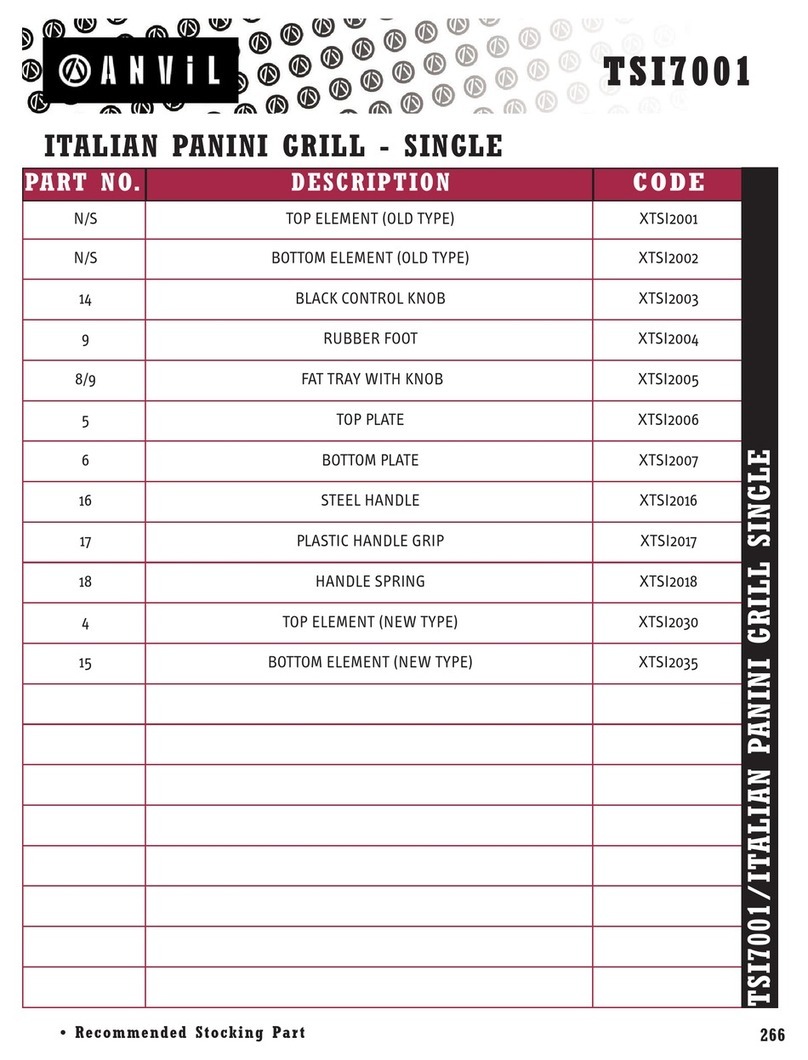

I SPARE PART LIST-EXPLODING DRAWING

EMP.9IG010-7IG010

13

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.7IG010

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.7IG010.001

2

FEET

Y.EMP.7IG010.002

3

SPARKING PLUG+CABLE

Y.EMP.7IG010.003

4

DRAWER

Y.EMP.7IG010.004

5

INJECTOR GROUP

Y.EMP.7IG010.005

6

BUTTON BUFFER

Y.EMP.7IG010.006

7

PILOT

Y.EMP.7IG010.007

8

GAS TANK

Y.EMP.7IG010.008

9

BUTTON

Y.EMP.7IG010.009

10

LIGHTER

Y.EMP.7IG010.010

11

GAS TAP

Y.EMP.7IG010.011

12

TOP PLATINE

Y.EMP.7IG010.012

13

BURNER

Y.EMP.7IG010.013

14

THERMO PART

Y.EMP.7IG010.014

15

BURNER BRACKET

Y.EMP.7IG010.015

16

FLAME SPREADER

Y.EMP.7IG010.016

17

FLEX HOSE 60CM

Y.EMP.7IG010.017

14

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.9IG010

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.9IG010.001

2

FEET

Y.EMP.9IG010.002

3

SPARKING PLUG+CABLE

Y.EMP.9IG010.003

4

DRAWER

Y.EMP.9IG010.004

5

INJECTOR GROUP

Y.EMP.9IG010.005

6

BUTTON BUFFER

Y.EMP.9IG010.006

7

PILOT

Y.EMP.9IG010.007

8

GAS TANK

Y.EMP.9IG010.008

9

BUTTON

Y.EMP.9IG010.009

10

LIGHTER

Y.EMP.9IG010.010

11

GAS TAP

Y.EMP.9IG010.011

12

TOP PLATINE

Y.EMP.9IG010.012

13

BURNER

Y.EMP.9IG010.013

14

THERMO PART

Y.EMP.9IG010.014

15

BURNER BRACKET

Y.EMP.9IG010.015

16

FLAME SPREADER

Y.EMP.9IG010.016

17

FLEX HOSE 80CM

Y.EMP.9IG010.017

15

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

EMP.9IG020-7IG020

16

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.9IG020

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.9IG020.001

2

FEET

Y.EMP.9IG020.002

3

SPARKING PLUG+CABLE

Y.EMP.9IG020.003

4

DRAWER

Y.EMP.9IG020.004

5

INJECTOR GROUP

Y.EMP.9IG020.005

6

BUTTON BUFFER

Y.EMP.9IG020.006

7

PILOT

Y.EMP.9IG020.007

8

GAS TANK

Y.EMP.9IG020.008

9

BUTTON

Y.EMP.9IG020.009

10

LIGHTER

Y.EMP.9IG020.010

11

GAS TAP

Y.EMP.9IG020.011

12

TOP PLATINE

Y.EMP.9IG020.012

13

BURNER

Y.EMP.9IG020.013

14

THERMO PART

Y.EMP.9IG020.014

15

BURNER BRACKET

Y.EMP.9IG020.015

16

FLAME SPREADER

Y.EMP.9IG020.016

17

FLEX HOSE 80CM

Y.EMP.9IG020.017

17

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.7IG020

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.7IG020.001

2

FEET

Y.EMP.7IG020.002

3

SPARKING PLUG+CABLE

Y.EMP.7IG020.003

4

DRAWER

Y.EMP.7IG020.004

5

INJECTOR GROUP

Y.EMP.7IG020.005

6

BUTTON BUFFER

Y.EMP.7IG020.006

7

PILOT

Y.EMP.7IG020.007

8

GAS TANK

Y.EMP.7IG020.008

9

BUTTON

Y.EMP.7IG020.009

10

LIGHTER

Y.EMP.7IG020.010

11

GAS TAP

Y.EMP.7IG020.011

12

TOP PLATINE

Y.EMP.7IG020.012

13

BURNER

Y.EMP.7IG020.013

14

THERMO PART

Y.EMP.7IG020.014

15

BURNER BRACKET

Y.EMP.7IG020.015

16

FLAME SPREADER

Y.EMP.7IG020.016

17

FLEX HOSE 60CM

Y.EMP.7IG020.017

18

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

EMP.9IG022-7IG022

19

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.9IG022

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.9IG022.001

2

FEET

Y.EMP.9IG022.002

3

SPARKING PLUG+CABLE

Y.EMP.9IG022.003

4

DRAWER

Y.EMP.9IG022.004

5

INJECTOR GROUP

Y.EMP.9IG022.005

6

BUTTON BUFFER

Y.EMP.9IG022.006

7

PILOT

Y.EMP.9IG022.007

8

GAS TANK

Y.EMP.9IG022.008

9

BUTTON

Y.EMP.9IG022.009

10

LIGHTER

Y.EMP.9IG022.010

11

GAS TAP

Y.EMP.9IG022.011

12

TOP PLATINE

Y.EMP.9IG022.012

13

BURNER

Y.EMP.9IG022.013

14

THERMO PART

Y.EMP.9IG022.014

15

BURNER BRACKET

Y.EMP.9IG022.015

16

FLAME SPREADER

Y.EMP.9IG022.016

17

FLEX HOSE 80CM

Y.EMP.9IG022.017

20

GAS GRILLS

I SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.7IG022

NO

PRODUCT NAME

P.CODE

1

BASE FRAME

Y.EMP.7IG022.001

2

FEET

Y.EMP.7IG022.002

3

SPARKING PLUG+CABLE

Y.EMP.7IG022.003

4

DRAWER

Y.EMP.7IG022.004

5

INJECTOR GROUP

Y.EMP.7IG022.005

6

BUTTON BUFFER

Y.EMP.7IG022.006

7

PILOT

Y.EMP.7IG022.007

8

GAS TANK

Y.EMP.7IG022.008

9

BUTTON

Y.EMP.7IG022.009

10

LIGHTER

Y.EMP.7IG022.010

11

GAS TAP

Y.EMP.7IG022.011

12

TOP PLATINE

Y.EMP.7IG022.012

13

BURNER

Y.EMP.7IG022.013

14

THERMO PART

Y.EMP.7IG022.014

15

BURNER BRACKET

Y.EMP.7IG022.015

16

FLAME SPREADER

Y.EMP.7IG022.016

17

FLEX HOSE 60CM

Y.EMP.7IG022.017

This manual suits for next models

5

Table of contents

Other EMPERO Grill manuals

Popular Grill manuals by other brands

Thermos

Thermos 461644304 use and care manual

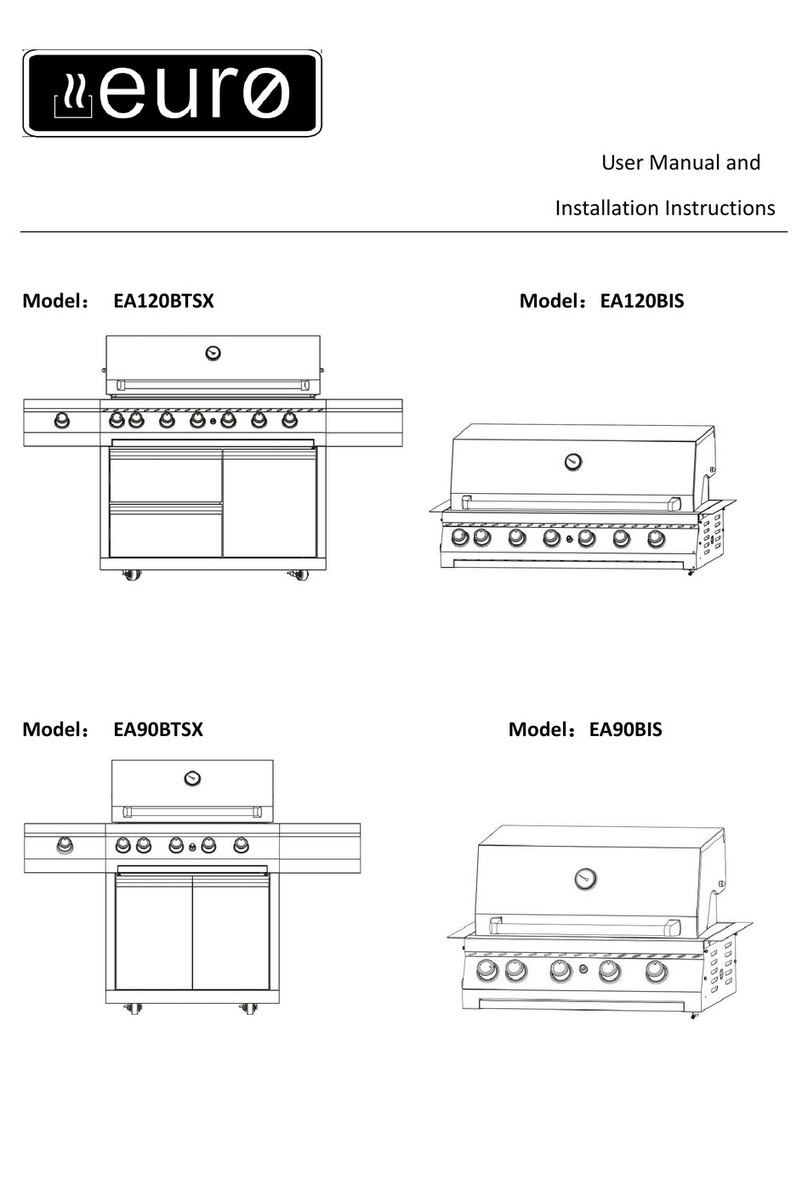

EURO

EURO EA120BTSX User manual and installation instructions

Char-Broil

Char-Broil Heatwave 2218932 Guide

Jackson Grills

Jackson Grills Classic PG-50403SRL Assembly, care & use manual

Texsport

Texsport 15100 instructions

Broil King

Broil King Imperial XLS 9578-84 Assembly manual & parts list