Cerabar PMC11, PMC21, PMP11, PMP21

2 Endress+Hauser

Table of contents

Document information ....................... 4

Document function ............................ 4

Symbols used ................................ 4

Documentation ............................... 5

Terms and abbreviations ........................ 6

Turn down calculation .......................... 7

Function and system design ................... 8

Measuring principle - process pressure measurement ..... 8

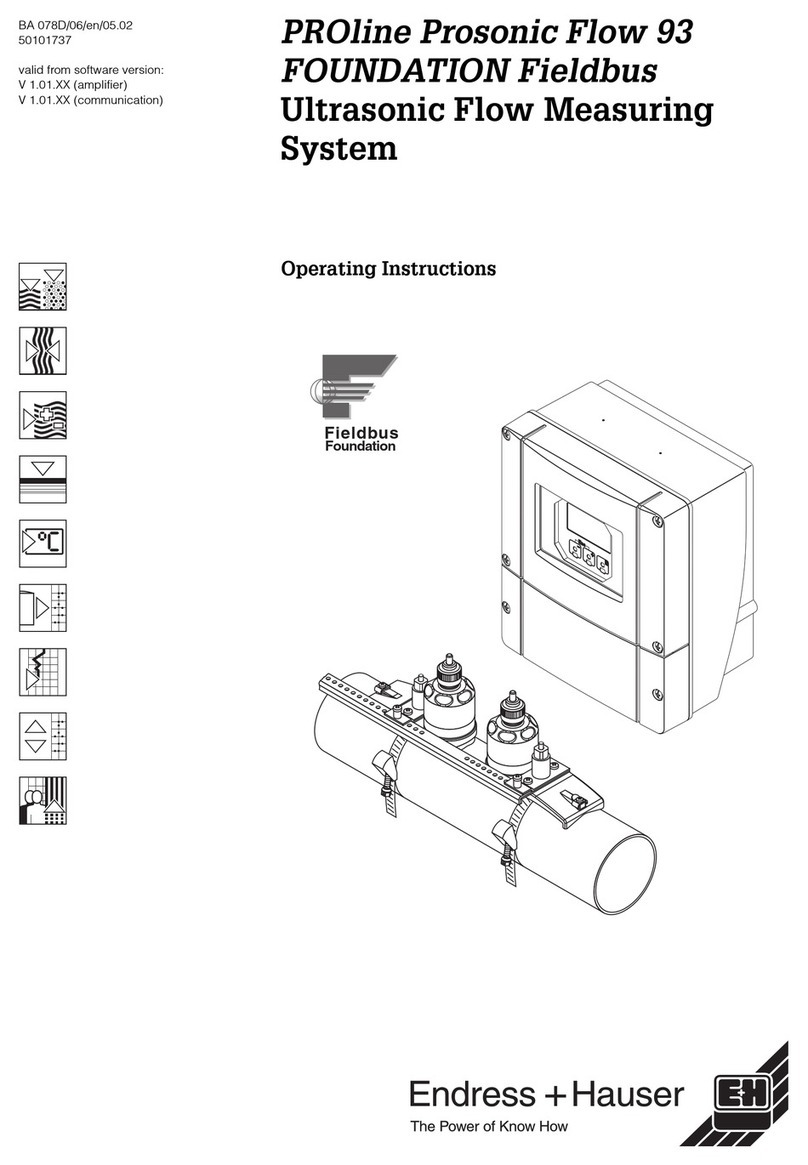

Measuring system ............................. 8

Device features ............................... 9

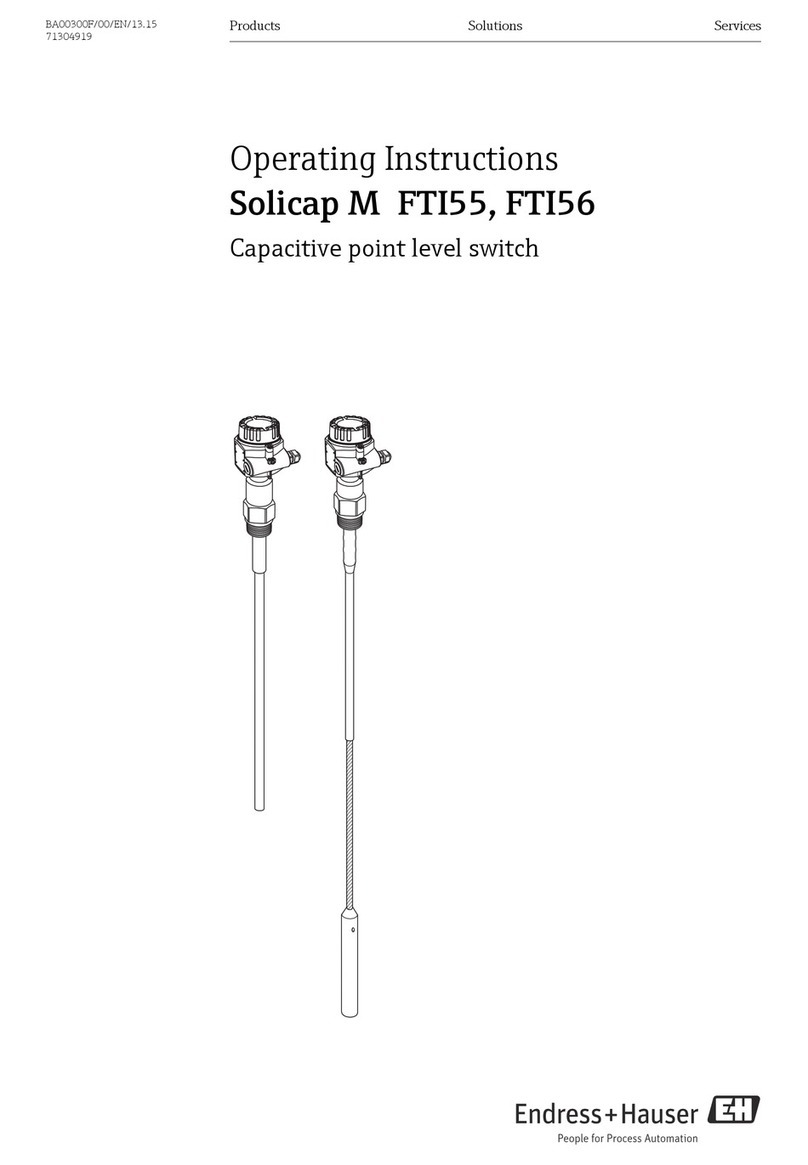

Product design .............................. 11

System integration ........................... 12

Input .................................... 13

Measured variable ............................ 13

Measuring range ............................ 13

Output .................................. 16

Output signal ............................... 16

Signal range 4 to 20 mA ........................ 16

Load (for 4 to 20 mA devices ) .................... 16

Load resistance (for 0 to 10 V devices) .............. 16

Signal on alarm 4 to 20 mA ...................... 16

Dead time, time constant ....................... 16

Dynamic behavior ............................ 17

Power supply ............................. 18

Terminal assignment .......................... 18

Supply voltage .............................. 18

Current consumption and alarm signal .............. 18

Power supply fault ............................ 19

Electrical connection .......................... 19

Cable specification ............................ 19

Residual ripple .............................. 19

Influence of power supply ....................... 19

Overvoltage protection ........................ 19

Performance characteristics of ceramic process

isolating diaphragm ........................ 20

Reference operating conditions ................... 20

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 20

Influence of the installation position ................ 20

Resolution ................................. 20

Reference accuracy ........................... 20

Thermal change of the zero output and the output span ... 20

Long-term stability ........................... 21

Switch-on time .............................. 21

Performance characteristics of metal process

isolating diaphragm ........................ 22

Reference operating conditions ................... 22

Measuring uncertainty for small absolute pressure

measuring ranges ............................ 22

Influence of the installation position ................ 22

Resolution ................................. 22

Reference accuracy ........................... 22

Thermal change of the zero output and the output span ... 22

Long-term stability ........................... 22

Switch-on time .............................. 22

Installation ............................... 23

Installation conditions ......................... 23

Influence of the installation position ................ 23

Mounting location ............................ 23

Mounting instructions for oxygen applications ......... 24

Environment .............................. 26

Ambient temperature range ..................... 26

Storage temperature range ...................... 26

Climate class ............................... 26

Degree of protection .......................... 26

Vibration resistance ........................... 26

Electromagnetic compatibility .................... 26

Process .................................. 27

Process temperature range for devices with ceramic

process isolating diaphragm ..................... 27

Process temperature range for devices with metallic

process isolating diaphragm ..................... 27

Pressure specifications ......................... 28

Mechanical construction .................... 29

Design, dimensions ........................... 29

Electrical connection .......................... 29

Housing ................................... 30

Process connections with internal, ceramic process

isolating diaphragm ........................... 32

Process connections with internal, ceramic process

isolating diaphragm ........................... 33

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, ceramic process

isolating diaphragm ........................... 34

Process connections with internal, metal process isolating

diaphragm ................................. 35

Process connections with internal, metal process isolating

diaphragm ................................. 36

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with internal, metal process isolating

diaphragm ................................. 37

Process connections with flush-mounted, metal process

isolating diaphragm ........................... 38

Materials in contact with process .................. 39

Materials not in contact with process ............... 40

Cleaning .................................. 41

Operability ............................... 42

Plug-on display PHX20 (optional) .................. 42

Certificates and approvals ................... 43

CE mark ................................... 43