Endress+Hauser RIA452 User manual

Other Endress+Hauser Measuring Instrument manuals

Endress+Hauser

Endress+Hauser gammapilot FTG 671 Manual

Endress+Hauser

Endress+Hauser Nivocompact FTC 131 Manual

Endress+Hauser

Endress+Hauser Deltabar FMD71 User manual

Endress+Hauser

Endress+Hauser Proline t-mass 65 User manual

Endress+Hauser

Endress+Hauser Proline Promass S 300 User manual

Endress+Hauser

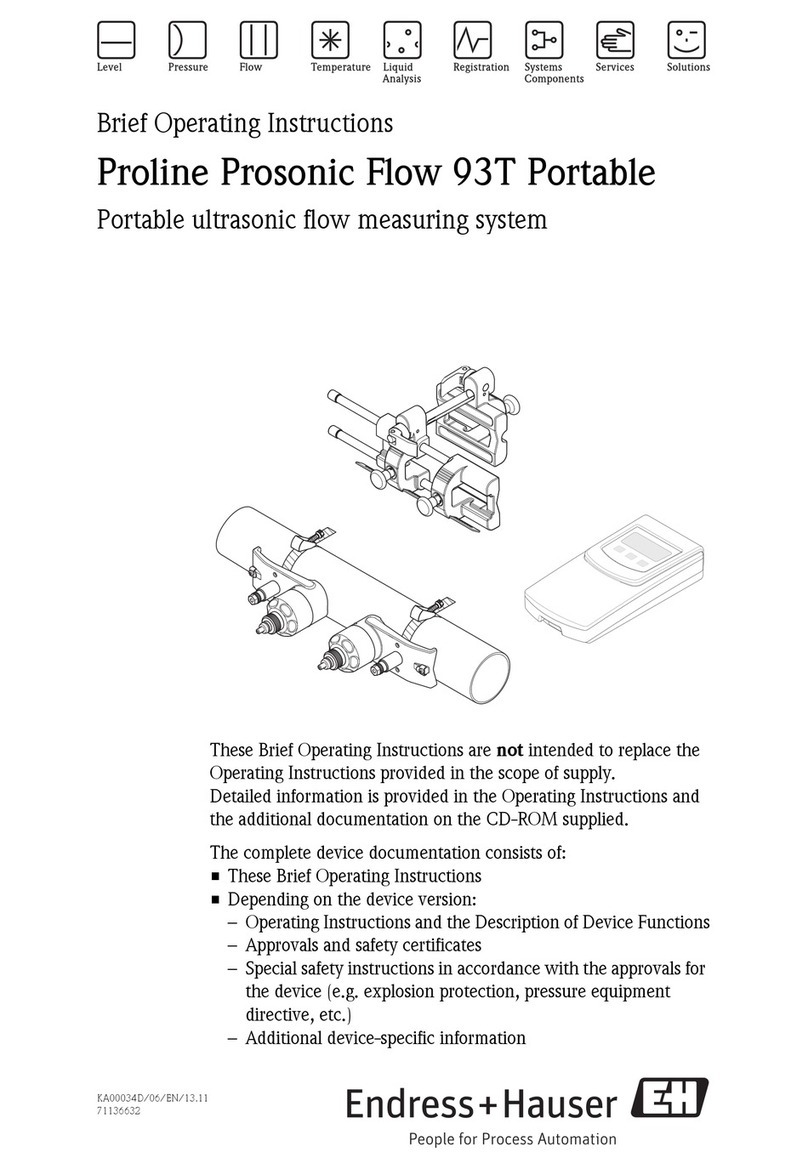

Endress+Hauser Proline Prosonic Flow 93T Portable User manual

Endress+Hauser

Endress+Hauser Memograph M RSG40 Manual

Endress+Hauser

Endress+Hauser RID14 Technical specifications

Endress+Hauser

Endress+Hauser magphant User manual

Endress+Hauser

Endress+Hauser Gammapilot M FMG60 User manual

Endress+Hauser

Endress+Hauser Liquiline System CA80AM Technical specifications

Endress+Hauser

Endress+Hauser Proline 500 Technical specifications

Endress+Hauser

Endress+Hauser PROFIBUS PA Proline Promass 80 User manual

Endress+Hauser

Endress+Hauser Prosonic M FMU40 Technical specifications

Endress+Hauser

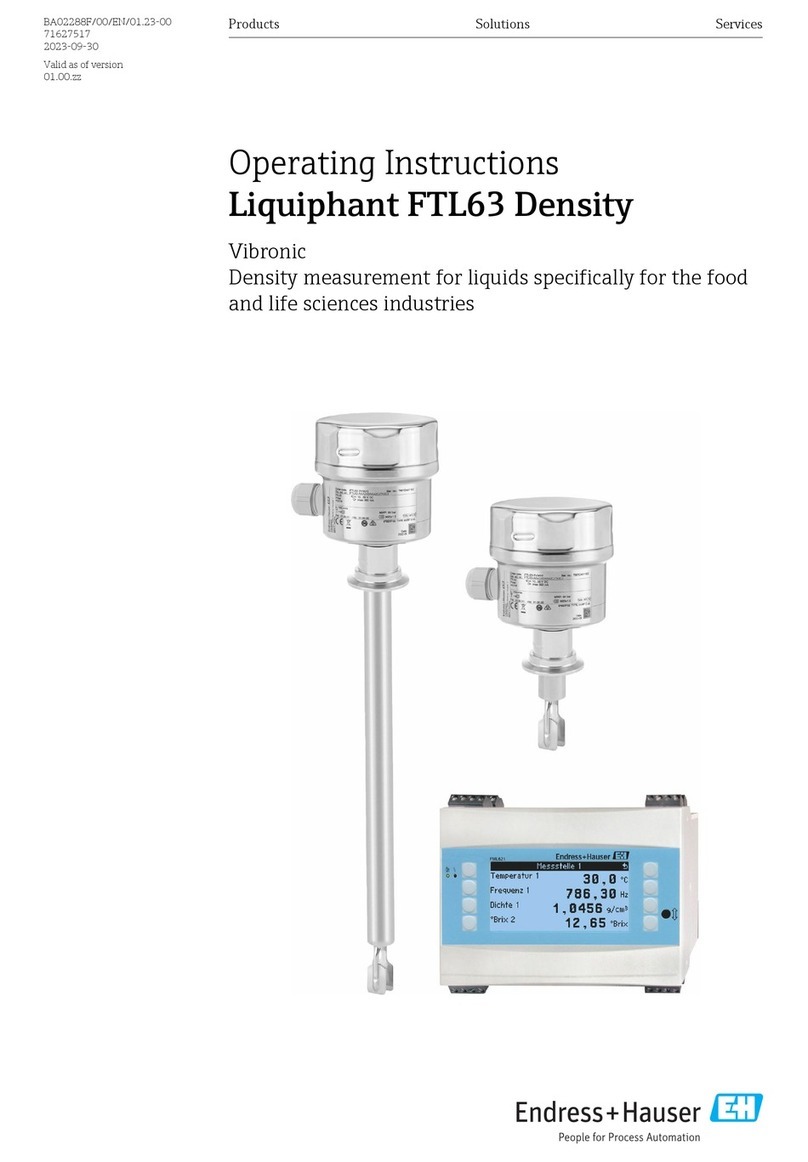

Endress+Hauser Liquiphant FTL63 User manual

Endress+Hauser

Endress+Hauser Gammapilot FMG50 User manual

Endress+Hauser

Endress+Hauser SpectraSensors SS2100 User manual

Endress+Hauser

Endress+Hauser PROline promag 53 User manual

Endress+Hauser

Endress+Hauser StamoLys CA 71 HY User manual

Endress+Hauser

Endress+Hauser Proline Prosonic Flow 93T Portable User manual