Endress+Hauser

CYR52

Table of contents

1 Basic safety instructions . . . . . . 4

1.1 Requirements for personnel . . . . . . . . . . . 4

1.2 Designated use . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Workplace safety . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational safety . . . . . . . . . . . . . . . . . . . 4

1.5 Product safety . . . . . . . . . . . . . . . . . . . . . . 5

2 Incoming acceptance and

product identification . . . . . . . . 6

2.1 Incoming acceptance . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . 6

2.3 Product identification . . . . . . . . . . . . . . . . 7

2.4 Certificates and approvals . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . 8

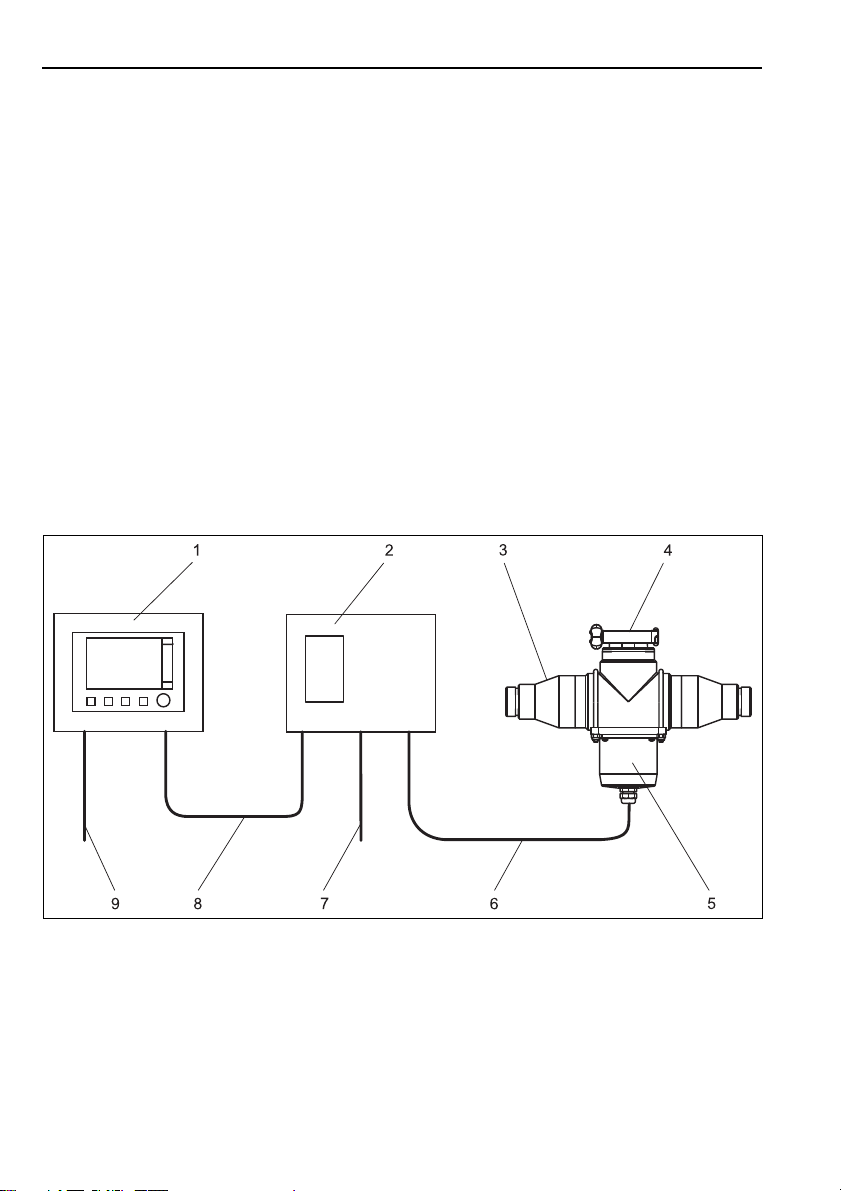

3.1 Quick installation guide . . . . . . . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . 13

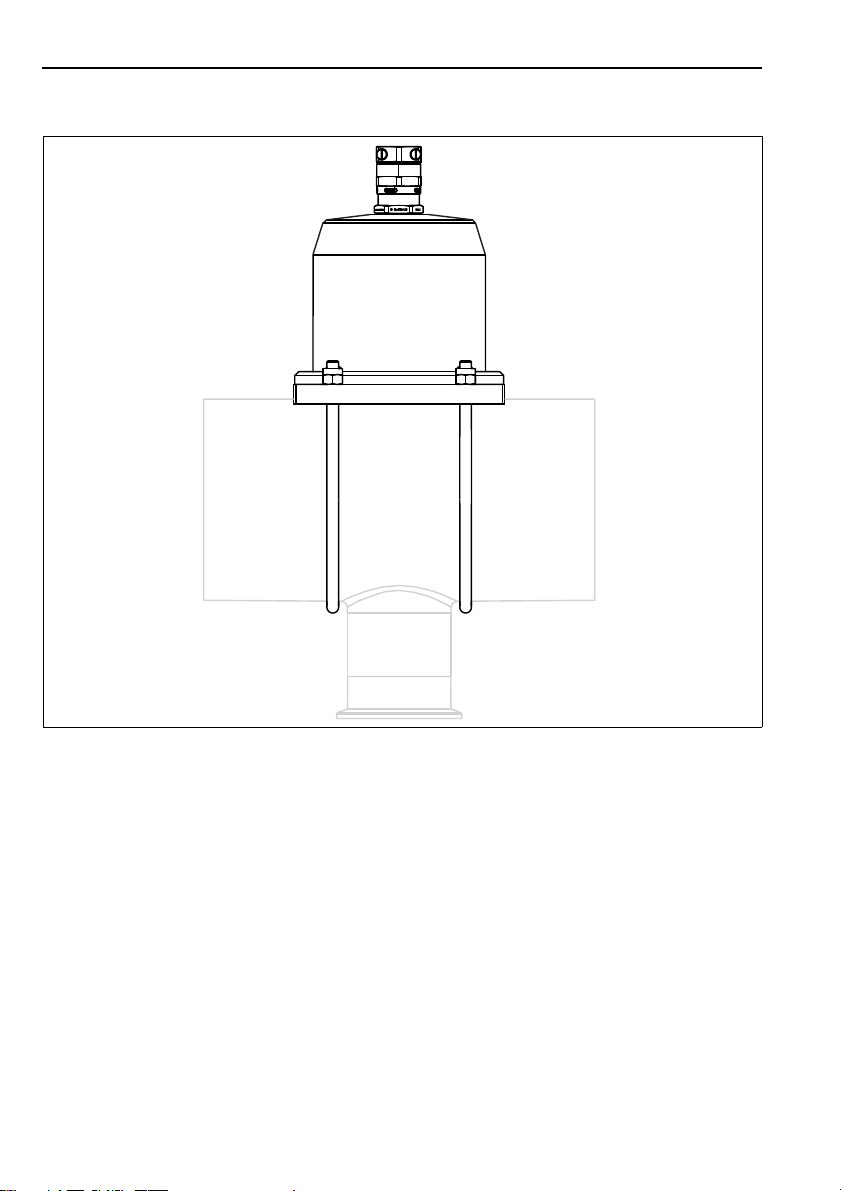

3.3 Mounting the ultrasonic transducer . . . 17

3.4 Mounting the ultrasonic generator . . . . 18

3.5 Post-installation check . . . . . . . . . . . . . . 21

4 Electrical connection . . . . . . . . 22

4.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Post-connection check . . . . . . . . . . . . . . 23

5 Commissioning. . . . . . . . . . . . . 24

5.1 Function check . . . . . . . . . . . . . . . . . . . . . 24

5.2 Configuration . . . . . . . . . . . . . . . . . . . . . . 24

6 Diagnostics and troubleshooting

25

7 Maintenance. . . . . . . . . . . . . . . 26

7.1 Cleaning the transmitter, ultrasonic

transducer and ultrasonic generator . . . 26

8 Repair. . . . . . . . . . . . . . . . . . . . . 27

8.1 Spare part kits . . . . . . . . . . . . . . . . . . . . . 27

8.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Accessories . . . . . . . . . . . . . . . . 28

10 Technical data. . . . . . . . . . . . . . 29

10.1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . 29

10.3 Environment . . . . . . . . . . . . . . . . . . . . . . . 29

10.4 Mechanical construction . . . . . . . . . . . . . 30

Index. . . . . . . . . . . . . . . . . . . . . . 31