Model: GT

00

PN: 752103 12V

752104 24V

Introduction

Feature

Line lifting: 998 kg / 2,200 lb wire rope first layer

Wire rope: 6.3 mm × 30.5 m (1/4" × 100′) galvanized aircraft A7 × 19

Brake:

Both Mechanical cone brake and permanent motor dynamic

brakes

Control: Handheld pendant switch powers the hoist

Unpacking

.Hoist assembly…………………………………………………………… 1 pc

.Control box……………………………………..……………………….... 1 pc

.Remote control……………………………………..…………..………… 1 pc

.Wire rope with clevis hook………………………..………..…………….1 pc

Read this manual carefully

You should carefully read and understand this manual before operating it.

Careless hoist operation may result in personal injury hazards or property

damage.

Information requesting or parts ordering

Please specify the following information:

.Hoist PN .Part description

.Serial number .Replacement part number

.Quantity for each part

Installation

Before using the hoist, make sure all electrical components have no corrosion

or damaged; the environment should be clear and dry.

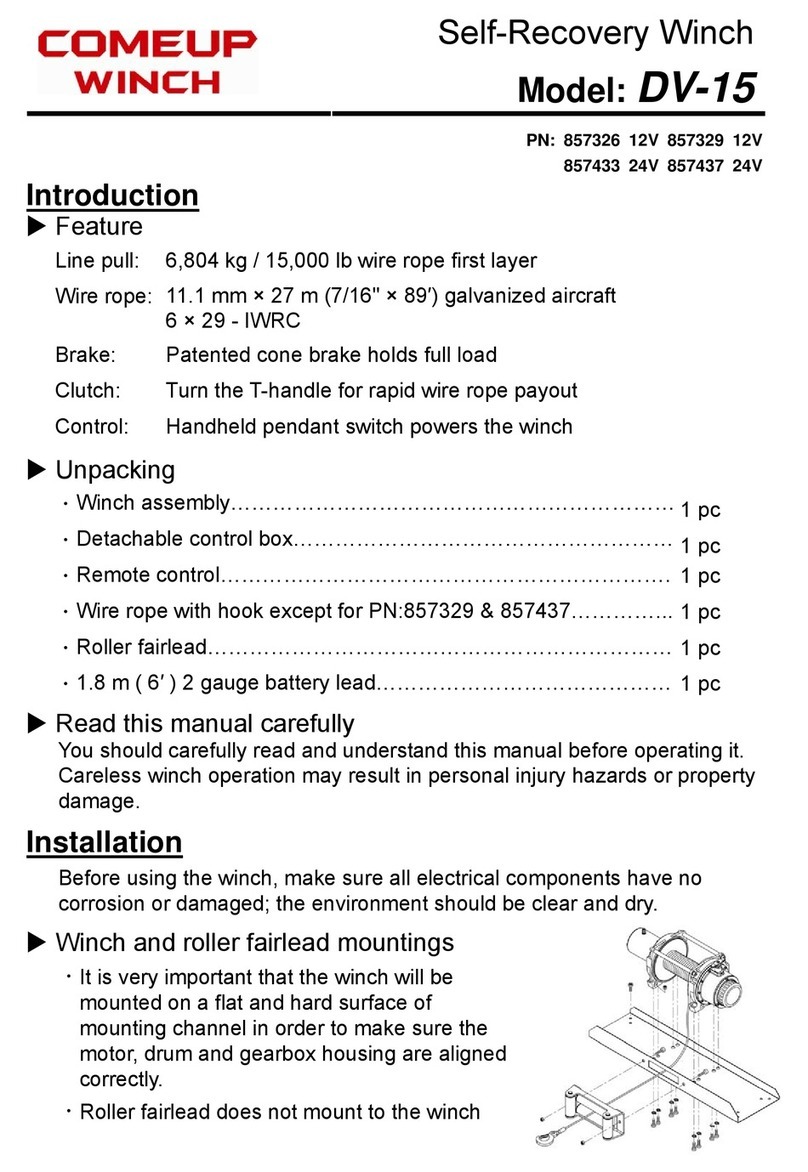

Hoist mounting

Eight(8) M10 x 35L 8.8 grade with 44 N-m torque settings (maximum) high

tensile steel bolts must be used in order to sustain the loads imposed on the

winch mounting.

Wire Rope Replacement

.Feed the end of the wire rope into No. 1 anchor hole in the

drum and wind about 1/4 wrap of rope on the drum. Insert

the wire rope into No. 2 hole and tighten the set screw

securely.

.Make sure the first layer of wire rope is tight and maintain a

freeboard at least 1.5 x rope diameter.

.

Wire rope shall be wound in an under-wound orientation only.

.To compensate for uneven spooling and the decrease in line

pull capacity as the drum fills up, use as short a wire rope as

practical.

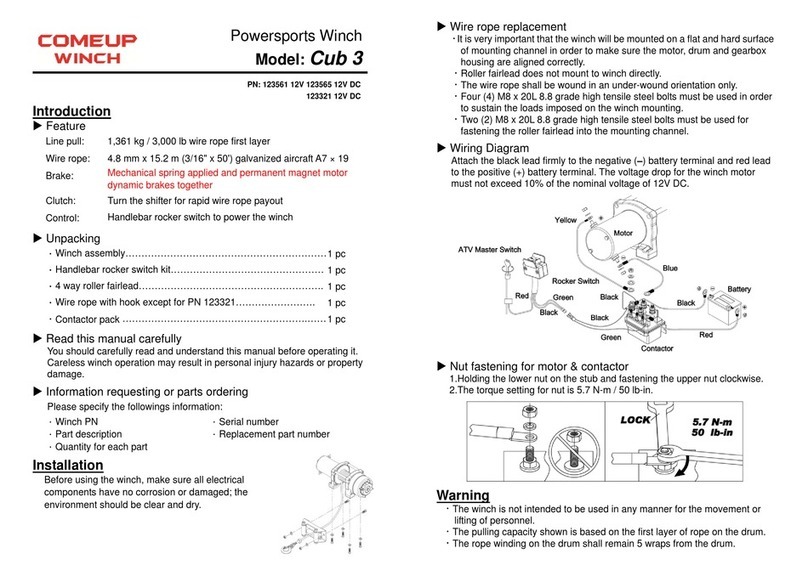

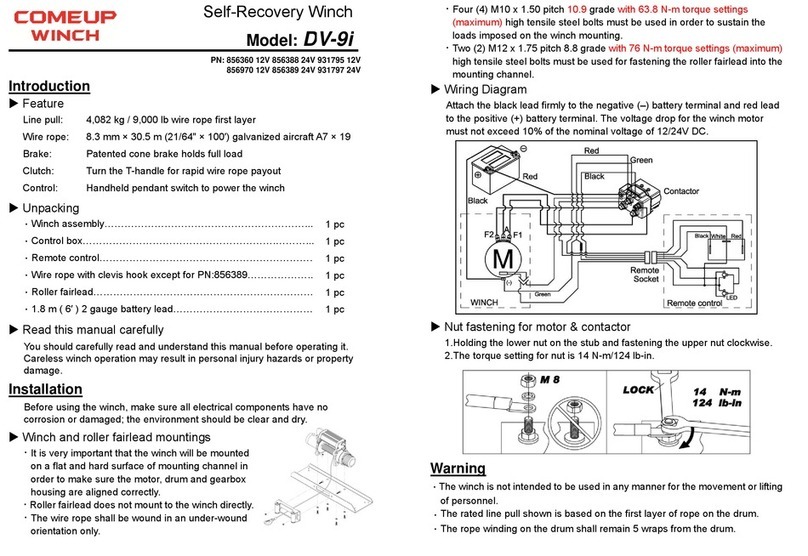

Wiring Diagram

•Connect positive/negative terminal cables to the winch motor.

•Attach the ground lead firmly to the negative (–) battery terminal and power

lead to the positive (+) battery terminal. The voltage drop for the winch

motor must not exceed 10% of the nominal voltage of 12/24V DC.

Nut fastening for motor & contactor

•Holding the lower nut on the stub and fastening the upper nut clockwise.

•The torque setting for nut is 6 N-m / 58 lb-in. (Terminal material copper)

Warning

.The operator shall always work in compliance with the operating instructions.

.Overload shall be forbidden and overload protection shall be required.

.Ban on transporting persons and excessive inching shall be avoided.