Enduraplas SWIFT BLENDER User manual

OWNER’S MANUAL

SWIFT BLENDER™

Version 1.0 Copyright © Enduraplas. All Rights Reserved.

Product Codes:

CHSSB001

SWIFT BLENDER

CHSSB001

2Swift Blender™

English

CONTENTS

INTRODUCTION 3

WARNINGS 4 - 7

GETTING STARTED 8 - 11

STORING/WINTERIZING 12

TROUBLESHOOTING 13

WARRANTY 14 - 17

PARTS BREAKDOWNS 18 - 27

!

3Version 1.0

English

INTRODUCTION

Congratulations! You now own an Enduraplas chemical mixing

station. Durable design and construction assure you a lifetime of

extreme performance.

Take a look through this owner’s manual to learn how the pros

use their Enduraplas chemical mixing station.

Discover More Helpful Tips:

blog.enduraplas.com/liquid-storage-transport

Watch Instruction Videos:

www.youtube.com/enduraplas

4Swift Blender™

English

WARNINGS

1. To ensure your own safety and that of others, you must

comply with all relevant environmental, work place health,

safety legislation and codes of practice.

2. Select and wear appropriate Personal Protection Equipment in

accordance with the label of the product you intend to use.

3. Once the mixing operation has been completed,

decontaminate the spray tank and spray accessories. Dispose

of tank rinsing’s in compliance with current environmental,

work place health and safety regulations.

4. Personal Protection Equipment must still be worn while

decontaminating your sprayer as per warning 3 above.

5. Improper or careless use of this mixing station can cause

serious injury. Minors should never be allowed to use

this sprayer. This mixing station should not be used when

bystanders or animals are in the area. This mixing station

should never be used while children are in the area.

6. Never leave the mixing station unattended without turning off

the pump, relieving the line pressure, and flushing the mixing

station of any harmful chemicals.

!

5Version 1.0

English

Discover More Helpful Tips:

blog.enduraplas.com/liquid-storage-transport

Watch Instruction Videos:

www.youtube.com/enduraplas

7. You must be in good mental health to operate this mixing

station and not be under the influence of alcohol or any drugs

that could impair your vision, physical strength, dexterity,

judgment, or other mental capacity.

8. No modifications and/or alterations may be made to this

mixing station. Any such modifications not only void the

warranty but can make the unit dangerous to anyone

operating the pump.

9. Always inspect hoses and piping to avoid burst injuries.

10. Clean out and fully flush the tank between switching

chemicals.

6Swift Blender™

English

WARNINGS !

Safety and Operating Instructions

SAFETY INSTRUCTIONS

DUE TO RISK OF SEVERE PERSONAL INJURY, DO NOT USE THIS EQUIPMENT UNTIL YOU

HAVE COMPLETELY READ AND FULLY UNDERSTAND HOW TO FOLLOW ALL OF THESE

WARNINGS AND INSTRUCTIONS.

SHARP POINT AND BLADES POSE A RISK OF PUNCTURE AND LACERATION. USE

GLOVES AND EXTREME CAUTION WHEN POSITIONING HANDS AND ARMS TO AVOID

COMING IN CONTACT WITH THE BLADE. MAKE SURE FOOTING IS STABLE AND

BALANCED BEFORE OPERATION.

HIGH PRESSURE WATER USED WITH CHEMICALS POSES A RISK OF SPLASH WITH

CHE

MICAL RESIDUE. ALWAYS WEAR SAFETY GLASSES TO REDUCE THE RISK THAT WATER

AND CHEMICAL COULD COME IN CONTACT WITH YOUR EYES.

AGRICULTURAL CHEMICALS POSE NUMEROUS HAZARDS. BE SURE TO READ,

UNDERSTAND AND FOLLOW ALL WARNINGS AND INSTRUCTIONS BY THE CHEMICAL

MANUFACTURER OR SUPPLIER REGARDING THE USE OF EACH CHEMICAL.

ALWAYS USE ALL PERSONAL PROTECTIVE EQUIPMENT SPECIFIED BY THE CHEMICAL

MANUFACTURER OR SUPPLIER WHICH MAY INCLUDE BUT NOT BE LIMITED TO CHEMICAL

PROTECTIVE GLOVES, EYE PROTECTION, PROTECTIVE FOOTWEAR AND CLOTHING, AND

NIOSH APPROVED RESPIRATORY PROTECTION.

ALWAYS POSITION THE HANDLE AND LID OPENING OF THE CHEMICAL CONTAINER IN

THE VERTICAL AND UPRIGHT POSITION WHEN OPERATING THE BLADE IN ORDER TO BE

ABLE TO HAVE A FIRM GRIP ON THE CONTAINER.

SLOWLY OPEN RINSE SUPPLY VALVE TO MAKE SURE ONLY ENOUGH WATER PRESSURE

IS APPLIED AND NOT TO OVER PRESSURE. TOO MUCH WATER PRESSURE COULD CAUSE

YOU TO LOSE GRIP ON THE CHEMICAL CONTAINER, SPLASH CHEMICAL OR CAUSE THE

RINSE HEAD TO FAIL

. ONLY PARTIAL OPENING OF THE RINSE VALVE MAY BE NECESSARY.

NEVER OPERATE THE RINSE HEAD WITH THE TANK LID OPEN AND WITHOUT THE

LIQUID CHEMICAL CONTAINER POSITIONED OVER THE RINSE HEAD TO AVOID SPRAY OF

WATER OR CHEMICAL OUT OF THE TANK.

7Version 1.0

English

THE BLADE IS DESIGNED FOR USE WITH 2.5 GALLON JUGS AND LARGER. DO NOT

USE WITH SMALLER JUGS THAN 2.5 GALLON AND USE EXTREME CAUTION WITH

SMALLER CONTAINERS TO AVOID HANDS AND ARMS COMING IN CONTACT WITH SHARP

POINT AND BLADES.

THE BLADE'S SHARP EDGES ARE DESIGNED TO LAST A LONG TIME WITHOUT

SHARPENING. IN CASE BLADES NEED TO BE SHARPENED, USE GLOVES AND EXTREME

CAUTION WHEN HANDLING AND REMOVING BLADE ASSEMBLY TO AVOID LACERATION

AND PUNCTURE WOUND. CONTACT ECK FABRICATION FOR NEW BLADE ASSEMBLY.

TO AVOID THE RISK OF SEVERE INJURY, INCLUDING LACERATION AND PUNCTURE

WOUND, NEVER REACH INTO THE TANK TO RETRIEVE ANY OBJECT OR CONTAMINATE

WITHOUT FIRST SAFELY REMOVING THE BLADE.

Steps of Operation

TO AVOID SERIOUS PERSONAL INJURY, BE SURE TO READ, UNDERSTAND AND FOLLOW ALL

SAFETY INSTRUCTION LISTED ABOVE AND ALL STEPS LISTED BELOW.

1. Firmly grab liquid chemical jug with one hand on the handle and one hand on the lid of the jug; for bags

of dry chemical firmly hold two corners of the bag with two hands.

2. Suspend jug or bag centered vertically straight up from the tip of the Blade.

3. With speed Press container down onto Blade until container is half way down blades or until sufficient

puncture has occurred so contents can empty. Use care not to push too far to avoid hands and arms

coming in contact with the sharp point and edges of the Blade.

4. Once liquid chemical has emptied from the container, while keeping firm hold of the container, open

rinse supply valve slowly and introduce only enough water pressure to apply rinse. Do not use rinse

for dry product application. chemical.

5. After running the rinse system for the time specified by the chemical manufacturer or supplier, turn off

rinse supply valve and allow container to drain completely as directed by the chemical manufacturer or

supplier.

6. Pull straight up on container and remove it from the Blade and discard as directed by the chemical

manufacturer or supplier.

7. Successful Operation!

8Swift Blender™

English

2) Fill your engine with oil.

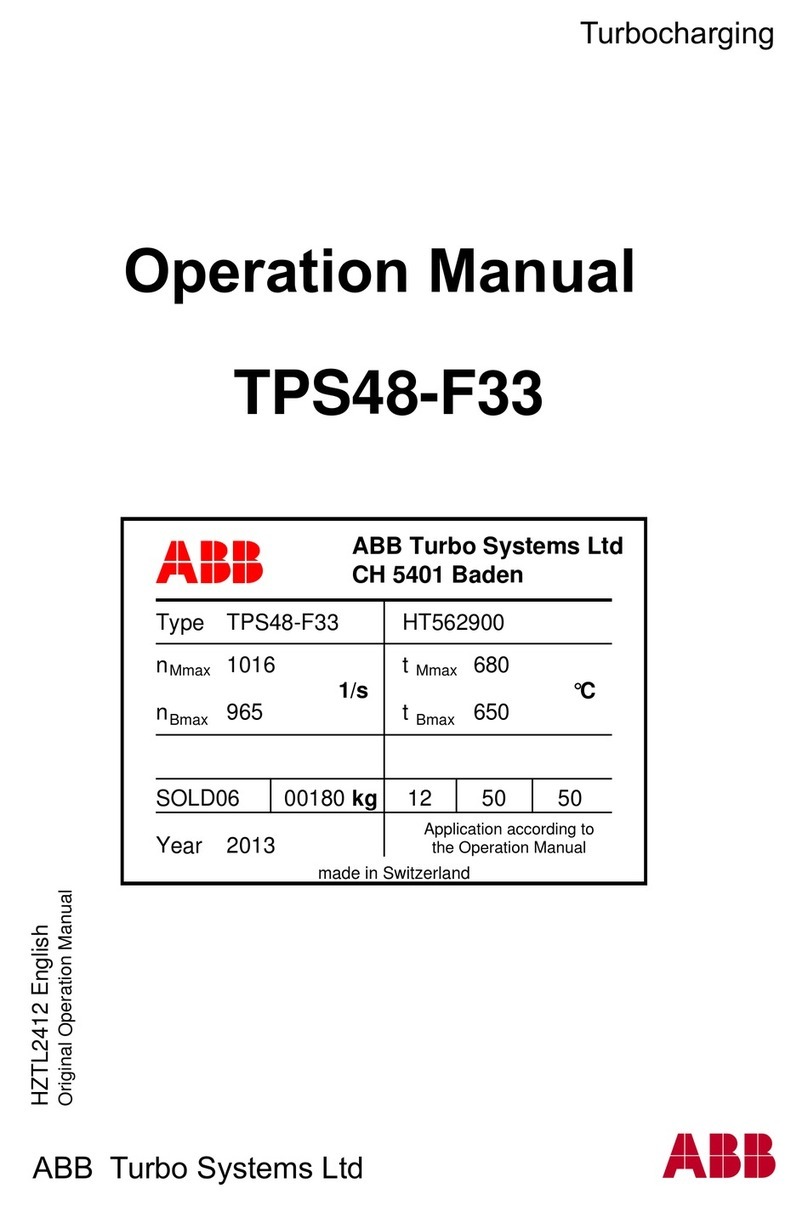

Operating the Chemical Mix Station

GETTING STARTED

1) Fill your engine with gasoline.

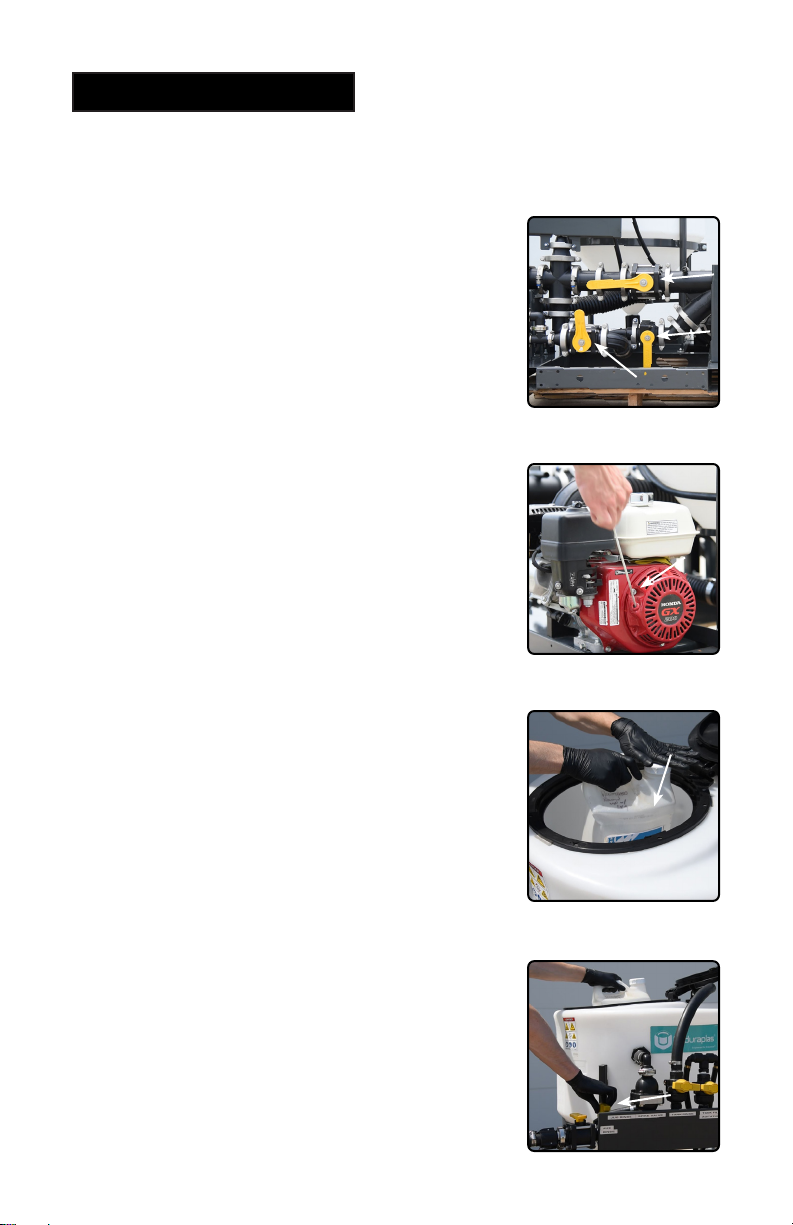

Jug rinse

Spike valve Tank rinse

Tank fill agitation

Auxiliary rinse

Bulk tote valve 1 & 2

Main valve

Venturi valve

3-way source valve

9Version 1.0

English

3) Remove safety items from the knife.

Operating the Chemical Mix Station

6) Hook up the supply hose and discharge

hose.

GETTING STARTED

4) Run water through the system to check for leaks caused

by shipping damage.

5) Strap the unit down to your truck.

10 Swift Blender™

English

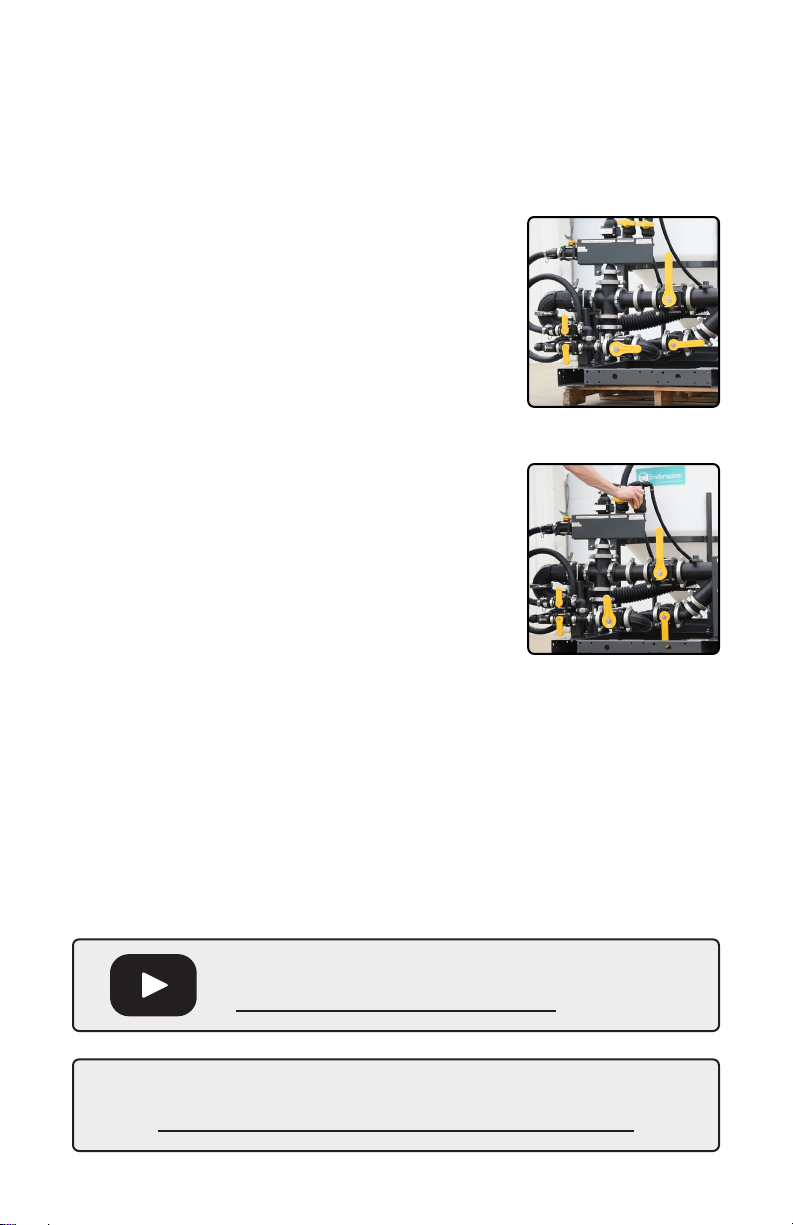

8) and start the pump.

10) To rinse the jug, open the jug rinse

valve while firmly holding the jug on the

knife to avoid chemical spillage. Let the jug

rinse for 10 seconds before turning the jug

rinse valve back off.

Operating the Chemical Mix Station

GETTING STARTED

9) Open the lid, spear the jug onto the jug

knife emptying all contents..

7) Close the 3-way source valve and the

Venturi valve, open the main valve.

11Version 1.0

English

Discover More Helpful Tips:

blog.enduraplas.com/liquid-storage-transport

Watch Instruction Videos:

www.youtube.com/enduraplas

11) To empty the mixing tank, close the

main valve, open the venturi valve, switch

the 3-way source valve to draw from the

mixing tank. Then start your pump.

12) To properly dissolve dry chemical and

increase mixing quality, turn off all valves,

and turn on the agitation valve after adding

your chemical to the tank.

12 Swift Blender™

English

STORING/WINTERIZING

1) Drain Tank

Fill your tank with clean water and start your pump and open the

main valve (after, you can also open the 3-way source valve and

the venturi valve to blow out those lines). Let the pump run until

the tank is completely drained.

2) Blow out Plumbing Lines

Using compressed air, blow out the hose lines to remove all water

from the system.

3) Flush with Anti-freeze

Pour a small amount of anti-freeze into your tank and run the

pump for a minute or so to let the anti-freeze through the sys-

tem.

4) Store Unit Inside

Close the output valve so the remaining anti-freeze does not leak

out. Store the mixing station inside to keep it out of the elements.

13Version 1.0

English

TROUBLESHOOTING

CONDITION CAUSE REMEDY

Pump will not

prime

1) Insufficient motor

RPM

2) Air leak on suction

plumbing

3) Issues with the

fittings

1) Increase motor RPM

until pump primes

2) Tighten/replace

fittings

3) Ensure the suction

and discharge valves

are open and camlocks

are tightened

Pressure drops/

fluctuates during

standard

operation

1) Restriction on suction

line

2) Pump sucking air

1) Inspect tank and

suction lines and

remove restriction

2) Tighten fittings

14 Swift Blender™

English

WARRANTY

LIMITED WARRANTY

1. Poly Tank Limited Warranty -Subject to other terms in this Limited

Warranty, Manufacturer warrants to the original end user that this

Tank will be free from material defects caused during the

manufacturing process for a period of 5 years from the Purchase

Date provided such warranty to the original end user shall be

extended to 10 years from the Purchase Date if the original end

user registers the Tank with Manufacturer within 30 days of the

Purchase Date. To register the Limited Warranty, registration must

be completed in accordance with the requirements set forth at

enduraplaswarranty.com

Other Products and Parts Limited Warranty -Subject to other

terms in this Limited Warranty, Manufacturer warrants to the

original end user that products and parts manufactured by

Manufacturer (other than tanks) will be free from material defects

caused during the manufacturing process for a period of 1 year

from the Purchase Date unless otherwise expressly stated in

writing by Manufacturer that an extended warranty applies.

2. Other Warranties Disclaimed and Excluded

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED,

WHICH EXTEND BEYOND THE LIMITED WARRANTY HEREIN

STATED, AND MANUFACTURER EXPLICITLY DISCLAIMS AND

EXCLUDES ANY AND ALL OTHER WARRANTIES INCLUDING

BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY,

FITNESS FOR PARTICULAR PURPOSE, CUSTOM OR USAGE

OF TRADE, AND COURSE OF DEALING. NO AGENT,

EMPLOYEE OR REPRESENTATIVE OF MANUFACTURER HAS

AUTHORITY TO BIND MANUFACTURER TO ANY

REPRESENTATION OR WARRANTY EXCEPT AS STATED IN

THIS LIMITED WARRANTY.

15Version 1.0

English

3. Limitation of Liability under the Limited Warranty -In addition to

those warranties disclaimed and excluded in clause 2 above,

Manufacturer expressly further limits its warranty and liability

under the Limited Warranty as set forth below in this clause 3.

3.1. The liability of Manufacturer under this Limited Warranty is

excluded to the extent that any defect has been caused or

contributed to by:

a) any accident, contamination, tampering, willful damage,

abuse, modification, improper storage, improper use

(including but without limitation the storage of material) or

negligent act of, or omission by, any person other than

Manufacturer;

b) the improper installation of the Goods, or deterioration of

the base on which any of the Goods rest or are mounted

to;

c) any damage to the Goods caused by storm, wash away,

landslide, mudslide, lightning, or any other natural

phenomenon, vermin or other pests, and any

undermining of the base of the Tank through any cause

whatsoever;

d) the repositioning of the Goods from their original

installation;

e) weathering or degradation of the Goods due to extreme

climatic conditions;

f) improper installation of extra fittings;

g) any staining or discoloration, including from trees or ash

fall-out from fires or other causes;

h) a Tank not being placed on a base that is free of any

protruding objects of any kind;

i) a Tank being used for any purpose other than the storage

of suitable liquids at the ambient temperatures.

16 Swift Blender™

English

3.2. Without limiting the generality of clause 3.1:

a) Manufacturer will not be liable for any personal injury,

indirect or incidental damages, consequential losses, loss

of liquids, loss of profit or any like claims whatsoever

arising from any use of, or incidental to, or repairs to any

of the Goods by a party other than Manufacturer;

b) to the extent that any component or material (including,

but without limitation the polyethylene) used in the

manufacture of any of the Goods is supplied and/or

manufactured by a third party, the liability of Manufacturer

is limited to Manufacturer’s right of redress (if any)

against the third-party supplier/manufacturer;

c) Tanks feature a vented lid at the time of manufacture.

Any subsequent pressurization of the Tank by removing

the vent, sealing the vent, or otherwise will cause this

Limited Warranty as to such Tank to be null and void.

d) The liability of Manufacturer under this Limited Warranty

is limited to, at Manufacturer's discretion:

e) providing a replacement Good (including shipping but

excluding other replacement costs);

f) refunding an amount equal to a sum equal to the current

Retail price divided by the months in the warranty,

multiplied by the months remaining in the warranty

period;

g) repairing the Good at no cost.

4. Proof of Purchase -The original invoice or other similar proof of

purchase of the applicable must be provided by Purchaser to

Manufacturer when making a claim under this Limited Warranty.

Warranty claims must be received in writing by Manufacturer

within the Limited Warranty period.

17Version 1.0

English

5. Claims and Questions -If you have questions about this Limited

Warranty or to make a warranty claim, contact Manufacturer at:

6. Definitions -For this Limited Warranty the following definitions

apply:

a) Manufacturer means Enduraplas LLC.

b) Purchase Date means the date upon which the

applicable goods were purchased by the original end

user.

c) Purchase Price means the actual price paid for the Tank

by the original Purchaser.

d) Tank means the storage Tank manufactured by

Manufacturer and purchased by the original end user

Purchaser being the subject matter of the Limited

Warranty.

e) Good(s) mean Tanks and/or other products or parts

manufactured by Enduraplas LLC.

f) Limited Warranty means this written Limited Warranty.

7. State Law -Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation and

exclusion may not apply to certain parties. Some states do not

allow limitation on how long an implied warranty lasts, so the

above limitation may not apply to certain parties. This limited

warranty gives specific legal rights and other rights, which vary

from state to state, may also apply.

8. Governing Law -This Limited Warranty will be governed by the

laws of the State of Minnesota, without giving effect to any choice

of law rule that would cause the application of the laws of any

other jurisdiction

18 Swift Blender™

English

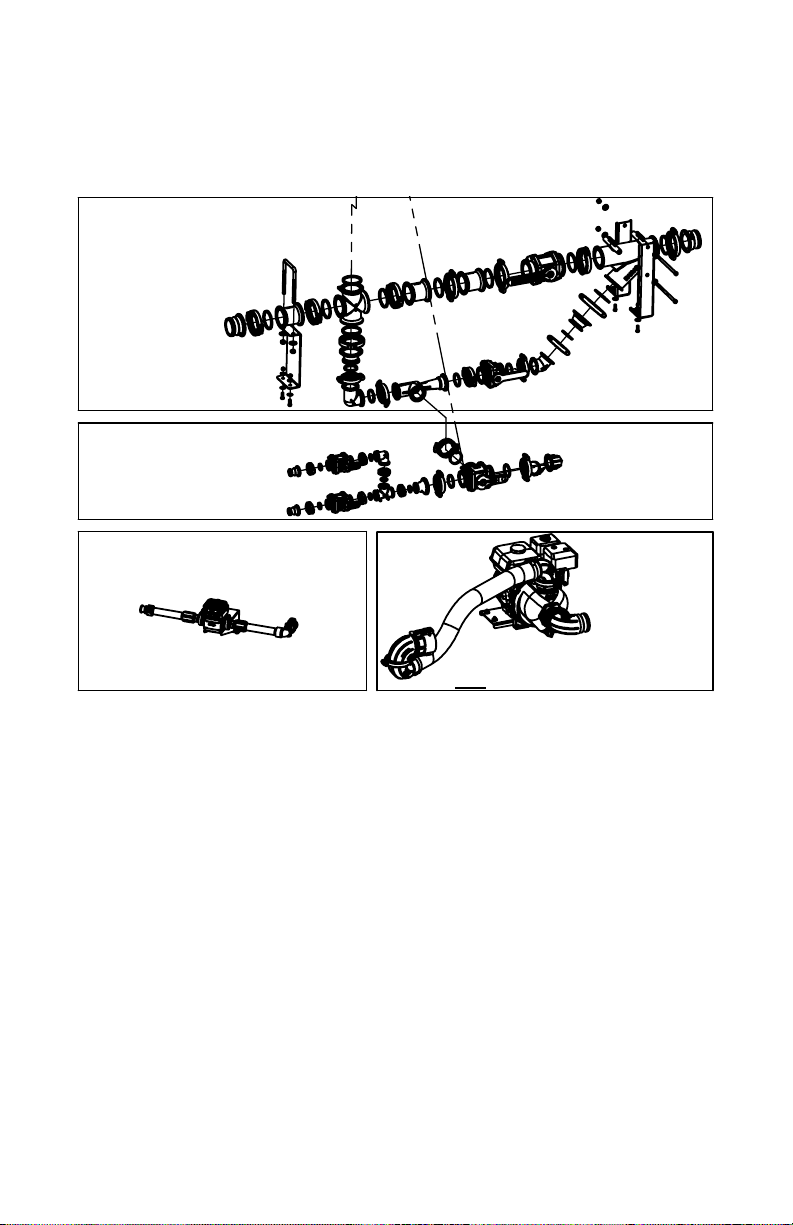

OVERVIEW

A

C

D

E

F

G

Flow Meter Kit

CHSSBFM01

Pump & Engine Kit

add

-3P

to part# (CHSSB001-3P)

View B

View C

DETAIL

C

SCALE

2 : 35

DETAIL

D

SCALE

2 : 35

View A

View D

19Version 1.0

English

OVERVIEW

A

C

D

E

F

G

Flow Meter Kit

CHSSBFM01

Pump & Engine Kit

add

-3P

to part# (CHSSB001-3P)

View B

View C

DETAIL

C

SCALE

2 : 35

DETAIL

D

SCALE

2 : 35

View A

View D

20 Swift Blender™

English

DETAIL

A

SCALE

2 : 35

7

37

869

39

42

9

6

38

55

70

40

43

68

54

72

23

53

22

66

1

63

65

64

5

71

56

67

41

54

39

39

37

49

64

63

65

View A

DETAIL VIEW A

This manual suits for next models

1

Table of contents

Other Enduraplas Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT562900 Operation manual

ABB

ABB A100-H Series Original assembly instructions

ABB

ABB HT570190 Operation manual

Siemens

Siemens SIRIUS 3RA243-8X.32-1 Series Original operating instructions

Plymovent

Plymovent DRAFTMAX BASIC ULTR A Installation and user manual

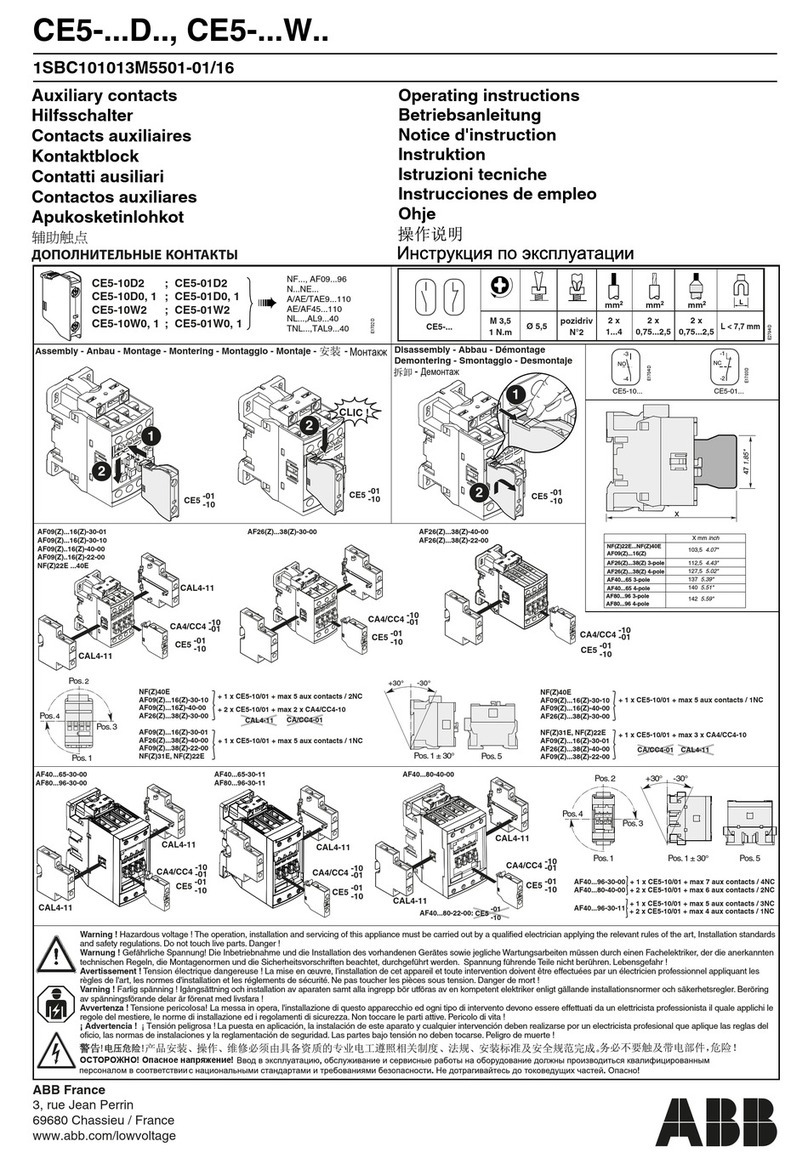

ABB

ABB CE5 D Series operating instructions

Holmatro

Holmatro CORE hose C U Series manual

Terex

Terex Genie Super Hoist Operator's manual

riverhawk

riverhawk IM-186 instruction manual

Carlisle

Carlisle IntelliSpray IS30 Installation and quick start guide

SMC Networks

SMC Networks EX260-MPN1 instruction manual

Rockwell Automation

Rockwell Automation 194R-SC1 Operating