Enduraplas XSTREAM User manual

This manual suits for next models

14

Table of contents

Other Enduraplas Paint Sprayer manuals

Enduraplas

Enduraplas STEEL BOOM User manual

Enduraplas

Enduraplas FIELD BOSS ECOLITE SFB060FG712V User manual

Enduraplas

Enduraplas SPOT CHIEF SSC025212V User manual

Enduraplas

Enduraplas IceMaster Systems Liquid Master W Series User manual

Enduraplas

Enduraplas FIELD BOSS 365 SFB060FG225GH User manual

Enduraplas

Enduraplas ICEMASTER LIQUID MASTER T Series User manual

Enduraplas

Enduraplas CLEAN BOSS PRO User manual

Enduraplas

Enduraplas Gold Series User manual

Popular Paint Sprayer manuals by other brands

Workhorse

Workhorse ATV 2507 Assembly, operation and parts manual

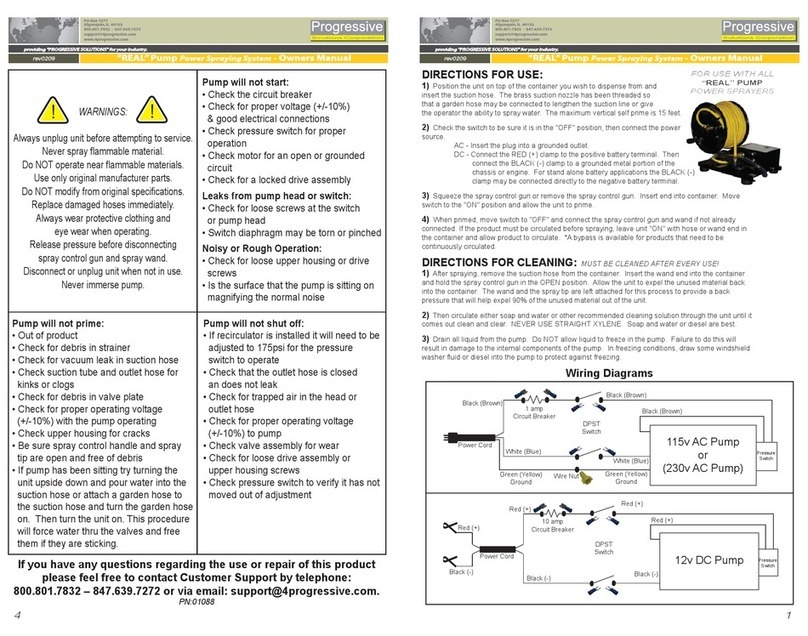

Progressive

Progressive Paint Sprayer owner's manual

Titan

Titan HELIX 0138010 operating manual

Anest Iwata

Anest Iwata TOF-50 Series instruction manual

horsch

horsch Leeb 4 AX operating instructions

SATA

SATA SATAjet 100 B F RP operating instructions

Titan

Titan 460e series operating manual

Titan

Titan IMPACT 740 operating manual

Mesto

Mesto 3555B operating instructions

SAMES KREMLIN

SAMES KREMLIN FPro S Series Translation from the original manual

BARGAM

BARGAM AT Biturbo Series Maintenance & Operation Manual

Parkside

Parkside PDFP 500 B2 Operation and safety notes