Energetiq LDLS EQ-9-HP User manual

Model EQ-9-HP

LDLS™

Laser-Driven Light Source

Operation Manual

Revision 3 June 2022

Part Number DOC-8240

Copyright © 2018 Energetiq Technology Inc. All rights reserved.

Energetiq products are covered by US and foreign patents. All technical information, including

drawings, schematics and specifications contained in this manual are the property of Energetiq

and shall not be reproduced in whole or in part without the written consent of Energetiq. The

content of this manual is subject to change without notice.

Energetiq Technology Inc.

205 Lowell Street, Wilmington, MA 01887 USA

Tel. +1 (781) 939-0763

E-mail: support@energetiq.com

http://www.energetiq.com

TABLE OF CONTENTS

Table of Contents.........................................................................................................4

Chapter 1...................................................................................................................................................... 1

General Information....................................................................................................1

Safety............................................................................................................................................... 1

Chapter 2...................................................................................................................................................... 7

Description ....................................................................................................................7

General ........................................................................................................................................... 7

Specifications................................................................................................................................. 8

System Description .................................................................................................................... 10

Power Supply Controller........................................................................................................... 11

Lamp House................................................................................................................................ 13

Chapter 3.................................................................................................................................................... 15

Installation................................................................................................................... 15

Unpacking.................................................................................................................................... 15

Connections................................................................................................................................. 15

RS-485 Serial Interface .............................................................................................................. 22

Installation Procedure................................................................................................................ 25

Chapter 4.................................................................................................................................................... 26

Operation.................................................................................................................... 26

Starting.......................................................................................................................................... 26

Stopping ....................................................................................................................................... 26

Chapter 5.................................................................................................................................................... 28

Troubleshooting ........................................................................................................ 28

Fault Indicator Block Diagram................................................................................................ 28

Appendix A................................................................................................................................................ 31

Revision Control........................................................................................................ 31

C h a p t e r 1

GENERAL INFORMATION

Safety

WARNING

CAUTION

This unit emits ultraviolet (UV) radiation that is

harmful to humans. Avoid exposure to the

direct or reflected output beam. Make certain

that the appropriate output beam shields and

optics are in place prior to energizing the unit.

All interlocks must be satisfied prior to

operation; failure to do so may lead to

hazardous conditions.

The EQ-9-HP emits dangerous levels of UV

radiation. Even short exposures to skin or eyes

may cause burns. Ensure that only authorized

personnel are in the vicinity of source during

operation. Personnel in vicinity of operating

source should wear protective eyewear, clothing,

and gloves. Lighted UV warning lights and signs

posted on doors to lab areas may help prevent

accidental exposure.

2 EQ-9-HP Operation Manual DOC-8240 Rev. 3

WARNING

WARNING

When working near the emitted light, always wear protective devices (conforming to ISO

4007/4849/4850/4854/4855 or equivalent regulations). The lamp installed in this housing

emits intense ultraviolet rays, which are harmful to the eyes and skin. Looking directly into

the emitted light or allowing the light to fall on the skin will damage eyesight or cause skin

burns.

This label indicates hazardous

UV radiation.

WARNING

If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

The power supply must be properly grounded by the outlet to prevent electrical shocks.

Securely plug in the power supply connector to avoid looseness or play. Loose connections

may result in faulty operation.

Indication of the symbols

The following symbols can found on this equipment.

Alternating current

The EQ-9-HP utilizes an internal Class 4 IR laser

capable of causing severe injury to eyes or skin.

Do not open or attempt to service this unit.

Contact Energetiq regarding any problems with

the unit.

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 3

General Precautions

The output beam from the EQ-9-HP should be blocked when not in use with an electronic

shutter or other appropriate beam blocking device. Due to the possibility of generating ozone

with some models of EQ-9-HP when ambient oxygen is exposed to short wavelength light,

the beam should always be enclosed in an appropriate beam pipe, tube, or enclosed space. We

suggest purging any beam transport space with dry nitrogen gas.

The EQ-9-HP source must also be cabled correctly and connected to a 12VDC power source

with a protective earth ground prior to operation.

Refer to the Installation section of this manual in Chapter 3 for details of the facilities

connections.

There are no user-serviceable parts inside the EQ-9-HP. For any problems encountered

during operation, please contact Energetiq Technology for assistance. If there is a

component failure, do not attempt to open the Power Supply Controller or Lamp

House enclosure of the EQ-9-HP.

The EQ-9-HP utilizes a quartz lamp containing a high-pressure gas fill. Explosion of

the lamp and possible injury from flying fragments can occur if the lamp is

mishandled.

Do not open the enclosure of either the Lamp House or the Power Supply Controller.

Dangerous invisible infrared laser beams and hazardous voltages exist inside the

Lamphouse. Opening the chassis both voids the warranty and exposes the user to dangerous

radiation and hazardous voltages.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

4 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Laser Information

The EQ-9-HP uses a patented (U.S. Patent #7,435,982, others pending) laser drive system to

excite a plasma that radiates in the UV as well as the visible bands. A class 4 laser is located in

the Lamphouse enclosure. The optical configuration of the Lamp House ensures that the

direct laser beam cannot exit the unit. The EQ-9-HP laser product is designated as Class 1

during all normal operation.

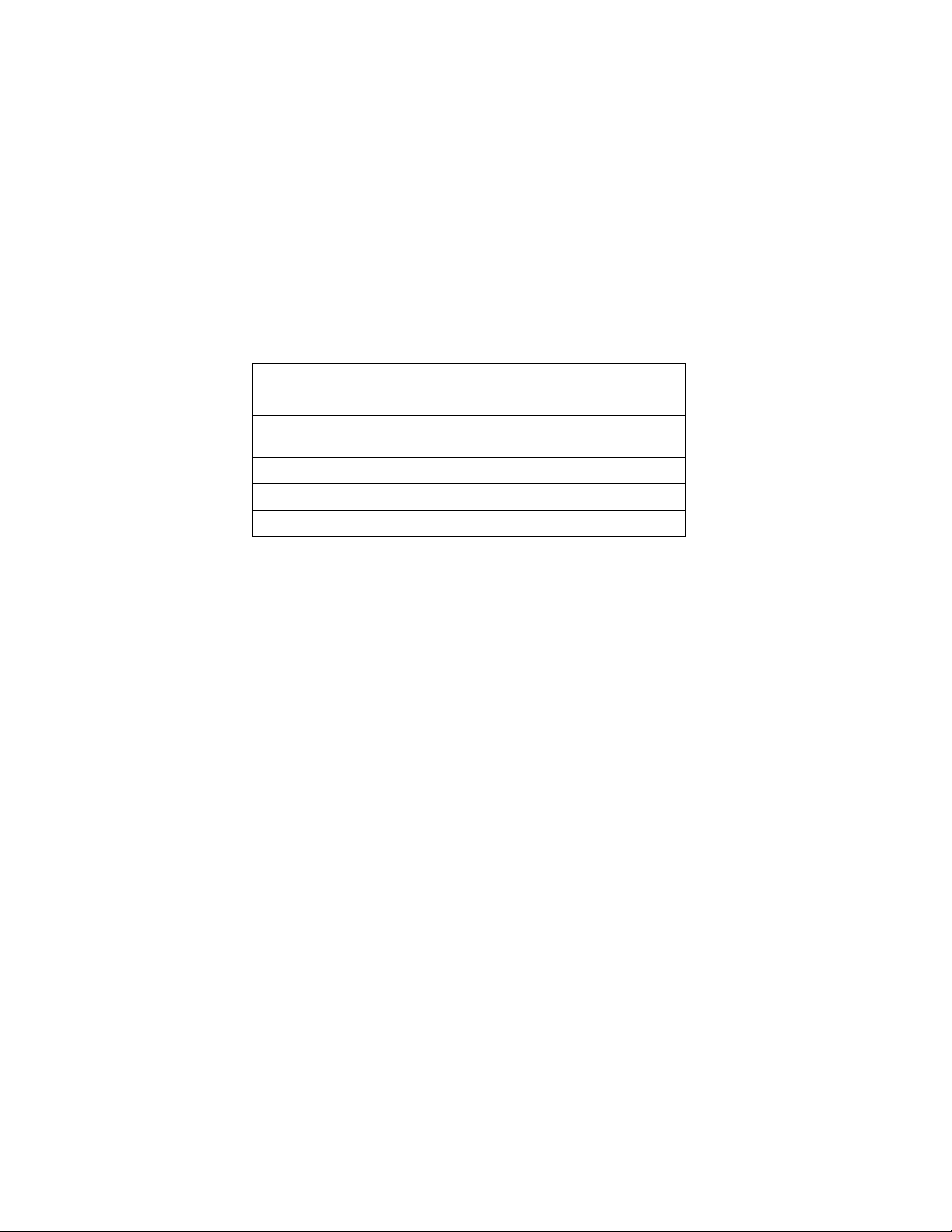

The parameters of the non-accessible internal laser are given below in Table 1.

Wavelength

974 nm

Emission Type

CW

Laser Power for classification

<8 mW via 7mm measurement

aperture

Beam Diameter

~25 mm at aperture

Divergence

>100 mRad

Transverse Beam Mode

Diffuse

Table 1: Embedded Laser Parameters

No regular maintenance is required for the EQ-9-HP. Any service to the system must be

performed only by factory authorized and trained technicians. To avoid injury, under no

circumstances should the user open or modify the Lamp House or Power Supply Controller

enclosure.

The unit must not be operated if the covers are removed or it is defective in any way. Contact

Energetiq if any problems with the equipment are suspected.

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 5

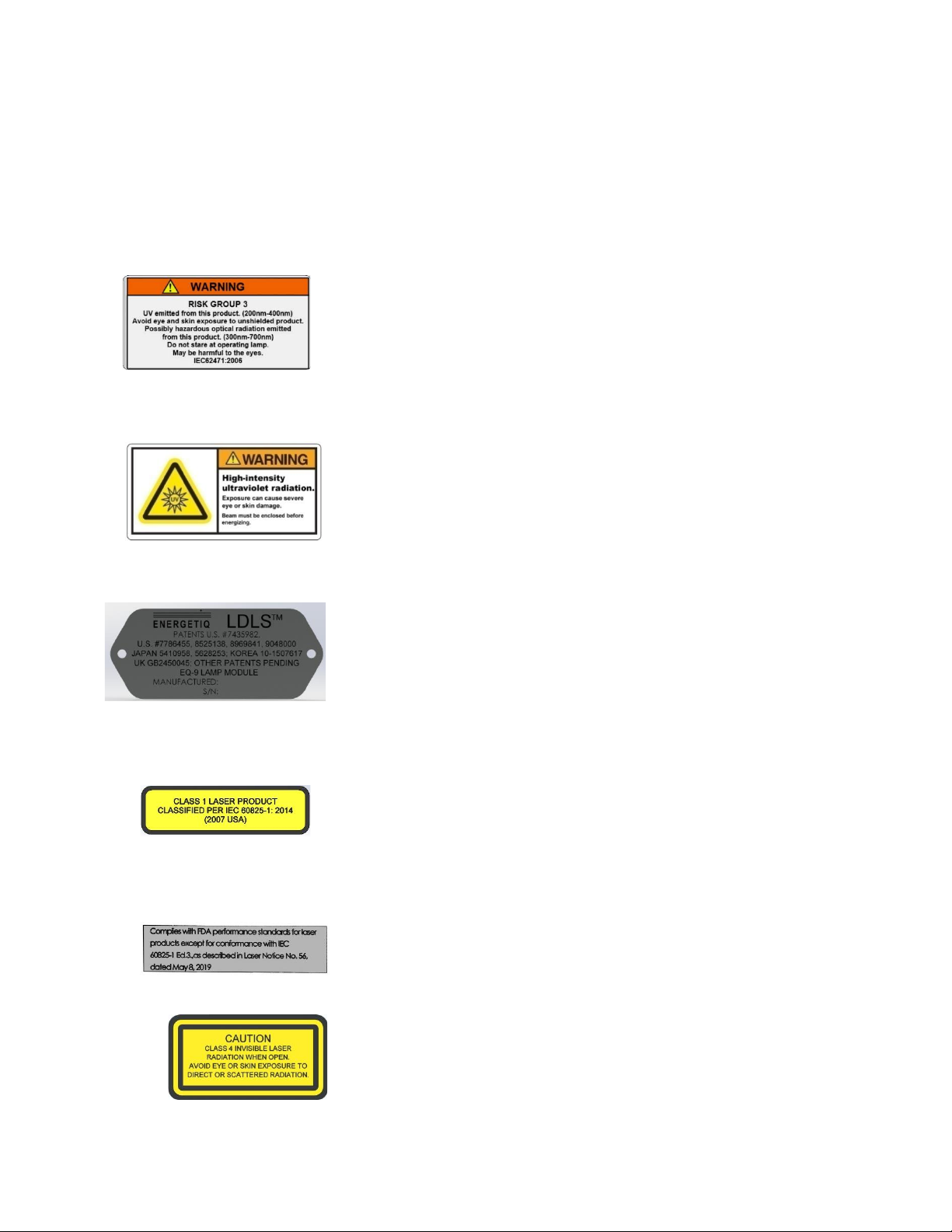

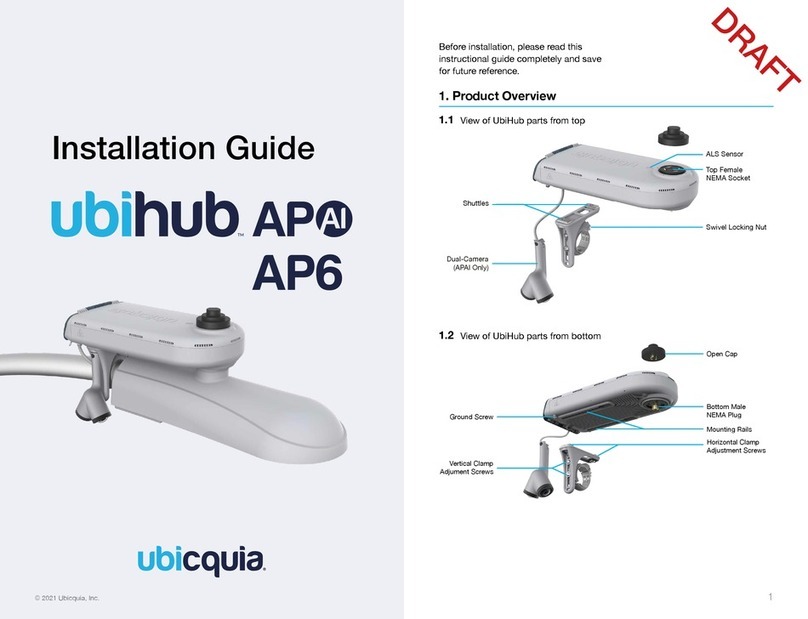

Labels and Safety Notification

The following safety labels appear on the product. Figure 1 shows the location of each label

on the EQ-9-HP system.

UV Hazard warning label –indicates hazardous levels of UV

light are present.

UV Hazard warning label –indicates hazardous levels of UV

light are present.

Manufacturer’s identification label – gives the manufacturer’s

name, the model number, serial number, and date of manufacture

of the equipment.

Explanatory label –states the classification of the laser product.

Class 1 is the lowest hazard level classification.

Certification label –states that the equipment has been tested

and verified to meet the standards indicated.

Non-interlocked housing label –notifies of a potential hazard

when covers are removed.

6 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Figure 1: Safety Label Locations

Safety Interlocks

The EQ-9-HP is equipped with interlocks to prevent operation of the device when any of the

following conditions are present:

1. An external interlock is open

External Interlock

External interlock pins are provided for the customer’s use (see Chapter 3 for connection

details). Any suitable normally-open contact or solid-state switch can operate the interlock

circuit.

The interlock circuit must be connected to enable the operation of the unit. Should the

interlock connection open during operation or standby, the source is immediately disabled, and

all light output from the aperture ceases.

Certification

Label

Explanatory

Label

Manufacturer’s

Identification label

UV Hazard

Warning Label

Non-interlocked

Housing Label

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 7

C h a p t e r 2

DESCRIPTION

General

The EQ-9-HP is a broad-band lamp system for use in a wide variety of applications. The lamp

produces high brightness, broad-band light from DUV wavelengths through visible and

beyond. The output is very stable, and has a long lifetime before any service is required. A

simple control interface ensures ease of use.

Some of the advantages of the EQ-9-HP include:

•Very high brightness across complete spectrum

–170nm through visible and beyond

•Eliminates need for multiple lamps (replaces D2/Tungsten/Xenon Arc)

–Simplified optical system

•Excellent spatial stability

–Repeatable measurements

•Superior short and long term power stability

–Repeatable measurements

•Electrodeless operation for long life

–Reduced consumable costs

–Minimal recalibration of instrument

The EQ-9-HP system consists of a Power Supply Controller unit, Lamp House unit, and

interconnecting cable. Connection to DC power is required for operation. Connection to

nitrogen purge gas is optional, but recommended in some cases. See Chapter 3 for connection

details.

8 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Specifications

Physical Specifications

Dimensions (H x W x D)

•Lamp House: 109x 120 x 43 mm

•Power Supply Controller: 38 x 197 x 93mm

Weight

•Lamp House: 0.91 kg (2 lb)

•Power Supply Controller: 0.68 kg (1.5 lb)

Utility Requirements

•Electrical: 12VDC, 140W

•Cooling: Fan (30 CFM forced air cooling)

•Purge gas (optional): clean dry nitrogen, filtered (5um 20 psig (0.14 MPa) supply

pressure)

Remote Interface

Digital Inputs

•Type: Optocoupler LED

•Logic: Active High

•Input voltage: 5VDC

•Input current: 8mA

Digital Outputs

•Type: Open collector to ground (digital common)

•Logic: Active Low

•Voltage: 30VDC max.

•Sink current: 30mA max.

User Power

•Voltage: 5VDC, referenced to digital common

•Current: 50mA maximum

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 9

Figure 2: Recommended Cooling Configuration

Environmental Requirements

Operating

•Ambient temperature: 15–30°C (with 30 CFM forced air cooling)

•Relative Humidity: non-condensing, 80% max. for temperatures up to 31°C,

decreasing linearly to 50% max. at 40°C.

•Pollution Degree 2 (normally only non-conductive pollution; occasional,

temporary condensation possible)

•Installation Category II

•Indoor use only

Transport

•Temperature: -5–95°C

•Relative Humidity: non-condensing, 95% max.

Recommended

Cooling Direction

[30 CFM]

10 EQ-9-HP Operation Manual DOC-8240 Rev. 3

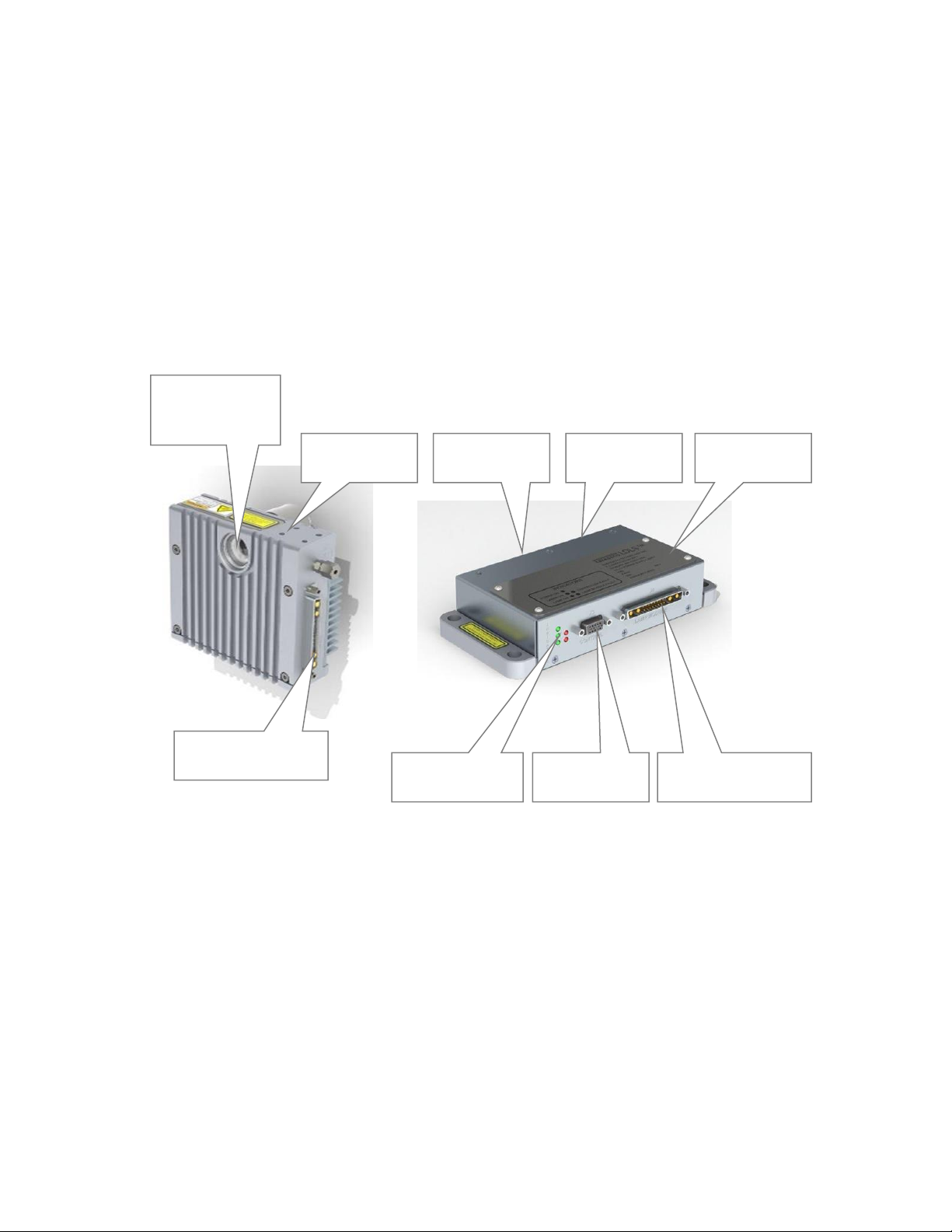

System Description

As shown in Figure the EQ-9-HP system consists of a Power Supply Controller unit, Lamp

House, Controller to Lamp house interconnect cable (not shown). Power and I/O interface

connections (also not shown) are either provided by the user or by Energetiq upon request.

The following sections provide descriptions of the system components and controls, and give

an overview of their functions. Refer to the “Installation” section of this manual (Chapter 3)

for more detailed information.

Figure 3: EQ-9-HP Lamp System

Lamp House Control

Connector

Lamp House Control

Connector

I/O Interface

Connector

Status Indicators

Optical Output

(Also opposite

side)

Lamp

House

Power Input

Connector

Power Supply

Controller

RS-485

Connector

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 11

Power Supply Controller

The Power Supply Controller contains:

•Laser power supply

•Thermo-electric cooler control system for laser

•Control electronics

•Status indicator LEDs

•Interface connectors

External features (refer to Figure 3):

Status Indicator LEDs

These five LEDs indicate the system status. The function of these indicators is shown below

in Table 2.

LED Label

Meaning (when lit)

POWER ON

DC power is connected to the EQ-9-HP Power Supply Controller

LAMP ON

UV Light is on

LASER ON

Laser power is ON and laser light is being produced within the Lamp

House

CONTROLLER FAULT

One of the following has occurred in the Power Supply Controller:

1. External interlock open

2. Controller internal temperature too high

3. Laser power not reaching setpoint

4. Laser Temperature Fault

LAMP MODULE FAULT

One of the following has occurred in the Lamp House module:

1. Control Cable not connected properly

2. Lamphouse internal termperature too high

3. Ignition Failure

Table 2: Status Indicator LED Functions

12 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Input/Output (I/O) Connector

Provides access to control and status signals. See Chapter 3 for pin assignments and functions.

This is the only operator interface to the EQ-9-HP –there are no local controls. Energetiq

offers the EQ-99-RC Remote Control Module which connects to the Input/Output

connector of the EQ-9-HP or EQ-99 and provides a means of local control. Contact

Energetiq for additional information.

Power Input Connector

This is a jack screw secured input connector for 12 VDC power. The EQ-9-HP can be

powered directly from a customer provided 12VDC power supply. See Chapter 3 for detailed

information.

Lamp House Control Connector (21-pin mixed D-sub)

Provides various power and control signals to/from the Lamp House module. No other

connector or cable may be used with the EQ-9-HP other than the one supplied.

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 13

Lamp House

The Lamp House assembly contains:

•Lamp

•Igniter

•Laser

•Thermoelectric cooler

•IR pumping optics

•Output windows

•Laser ON indicator

•Interface connectors

Figure 4: Lamp House Assembly

External features (refer to Figure 4):

Lamp

Window (front)

Control

Connector (to

Controller)

Purge Gas

Port

Laser ON

Indicator

14 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Lamp Windows

The lamp windows at the optical output provide protection from the high pressure bulb inside

the Lamp House. An internally-threaded SM1 adapter is provided for easy connection of

optical hardware.

Nitrogen Purge Inlet

This is the inlet fitting for nitrogen purge gas. Purge gas is optional but is recommended for

best performance when a deep UV bulb is provided. With no purge, ozone will form from

atmospheric oxygen and attenuate the light output in the 220 –280nm band. In addition,

atmospheric oxygen and water vapor will attenuate the output below 200nm. Bulbs chosen

for some OEM applications do not produce ozone and the purge fitting can be omitted.

There is no return fitting for the purge nitrogen. The purge flow normally escapes within the

Lamp House enclosure, and then to atmosphere.

Laser On Indicator

This LED is illuminated when the laser is ON.

Control Connector (21-pin mixed D-sub)

Provides various power and control signals to/from the Power Supply Controller. No other

connector or cable may be used with the EQ-9-HP other than the one supplied.

DOC-8240 Rev. 3 EQ-9-HP Operation Manual 15

C h a p t e r 3

INSTALLATION

Unpacking

Upon arrival, start by inspecting all parts of the system for completeness and any damage

incurred in shipping. The EQ-9-HP shipping box should contain:

1) EQ-9-HP Power Supply Controller unit

1) EQ-9-HP Lamp House unit

1) Black interconnecting cable from Lamp House to Power Supply Controller (21-

pin mixed D-sub).

OPTIONAL

1) EQ-99-RC Remote Control Module with interlock connector

1) I/O cable with 15 pin D- connector at each end

1) DC power supply with custom connector

If any part is missing or appears damaged, contact Energetiq immediately. Do not attempt to

substitute any parts. There are no user-serviceable parts inside the EQ-9-HP Lamp House or

Power Supply Controller unit.

Connections

Installation of the EQ-9-HP consists of connecting electrical and optional gas supplies, and

connecting the Lamp House module to the user’s equipment.

Electrical Power

The EQ-9-HP requires 12VDC at 11.7A minimum (140W rating). Power consumption is

approximately 100W during normal operation. Some OEM versions have higher current

requirements.

16 EQ-9-HP Operation Manual DOC-8240 Rev. 3

Power can be provided via a customer provided 12VDC power supply. The connector on the

EQ-9-HP is a jack screw secured connector. This protects from accidental removal of power

if the power cable is pulled. Connect to a 12VDC source as follows:

Connector

FCI DA3W3SA00LF

Pin A1

+12VDC

Pin A2

-12VDC return

Pin A3

Safety Ground

Purge Gas

Purge gas is optional but is recommended for best performance. With no purge, ozone will

form from atmospheric oxygen and attenuate the light output in the 220 –280nm band. In

addition, atmospheric oxygen and water vapor will attenuate the output below 200nm. Some

OEM units for near-UV and visible applications are equipped with bulbs which do not

produce ozone and the purge fitting may not be present.

If required, connect a source of nitrogen purge gas to the port on the Lamp House. The

fitting is a push-to-connect type, sized for 1/8" tubing.

Clean and dry nitrogen from either a Dewar or research-grade N2bottle is recommended. Do

not use any other purge gas. Grade 6 or better gas purity is recommended to maintain

cleanliness of the optics, and gas should be filtered to <5um. Supply pressure should be 20

psig (0.14 MPa). With a 20 psig inlet pressure, the EQ-9-HP will consume approximately 1 slm

of flow.

There is no return fitting for the purge nitrogen. The purge flow normally escapes within the

Lamp House enclosure, and then to atmosphere.

Optical Interface

The lamp windows accommodate light output of 0.56 NA. A pair of pins and four M4

threaded holes are available on the bottom of the EQ-9-HP for mounting. Four M4 threaded

holes are also available on the top surface of the Lamp House. An internally-threaded SM1

adapter is provided for connection of optical hardware. See Figure 5 below for mechanical

layout of the Lamp House.

Table of contents

Other Energetiq Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Vision & Control

Vision & Control LDLF60x120-R633/UDC Instructions for use

AAA-LUX

AAA-LUX WS Series installation guide

Philips

Philips hue 17466 V7 Series user manual

BADU

BADU JET Perla translation of original operation manual

ubicquia

ubicquia ubihub AP6 installation guide

Ledj

Ledj Pixel Bar LEDJ73A user manual

Uplus Lighting

Uplus Lighting 37X15ZWASH user manual

MJ LED LIGHTNING

MJ LED LIGHTNING MJ-1350 user manual

THT-EX

THT-EX THT-L1219 operating instructions

Lena Lighting

Lena Lighting MAGNUM MULTI BATTERY L Installation instruction

Chauvet

Chauvet CF-NEONB30 user manual

Larson Electronics

Larson Electronics EPL-HB-100LED-RT-UVA-20C-EPP instruction manual