THT-EX THT-L1219 User manual

1

Operating Instructions

Universal Explosion Proof LED Lighting

Model THT-L1219

Top Hi-Tech Co., Ltd.

5F., No. 113, Zhongcheng Rd.,

Tucheng District,

New Taipei City, 236 Taiwan

Website: www.tht-ex.com

TEL: +886 2 22689570

FAX: +886 2 22689571

e-mail: sales@tht-ex.com

Revision: EX-L1219-01

Subject to alterations.

Contents

1. General Safety Instructions ………………………………………………………………..…………….……..1

2. Intended Field of Application ………………………………………………………………………………..…1

3. Technical Data ……………………………………………………………….……….……………..……….....2

4. Model Code …………………………………………………………………………………………...…….….2

5. Dimension ……………………………………………………………………………………….………….......2

6. Assembly and Installation ……………………………………………………………………….......................3

7. Maintenance …………………………………………………………………………………………………….4

8. Accessories and Spare Parts …………………………………………………………………………………....4

9. Transport, Storage and Disposal ……………………………………………………….……………………….4

1. General Safety Instructions

1.1 Before assembly/commissioning:

Read through the operating instructions.

Give adequate training to the assembly and

operating personnel.

Ensure that the contents of the operating

instructions are fully understood by the

personnel in charge.

The national installation and assembly

regulations (e.g. IEC/EN 60079-14) apply.

1.2 When operating the device:

Ensure the operating instructions are made

available for the person in charge on

location at all times.

Observe these instructions, other working

instructions and national safety regulations.

Verify the implementation of safety

instructions.

2. Intended Field of Application

The Universal Explosion Proof LED Lighting, Model THT-L1219 is intended for using in gas explosive

atmospheres (Zone 1 and Zone 2 according to IEC60079-10-1) and dust explosion hazards (Zone 21 and Zone

22 according to IEC60079-10-2). The use in other potentially explosive atmospheres does not correspond to the

designated use and is therefore not allowed.

The apparatus is designed for using in indoor and outdoor environments.

WARNING

This manual contains basic safety instructions to be observed during installation, operation and

maintenance of the apparatus, and for properly and safety run of the apparatus according to its

performance data. Any damage of the apparatus may result explosion protection null and void. This manual

represents the most relevant information about the product, applicable codes and regulations shall

supplement it. Non-observance will endanger persons, plant and the environment. The person in charge is

required to secure its employment in the industrial unit. Any improper usage, as well as non-compliance

with the rules under this manual, shall release the manufacturer’s all responsibilities.

2

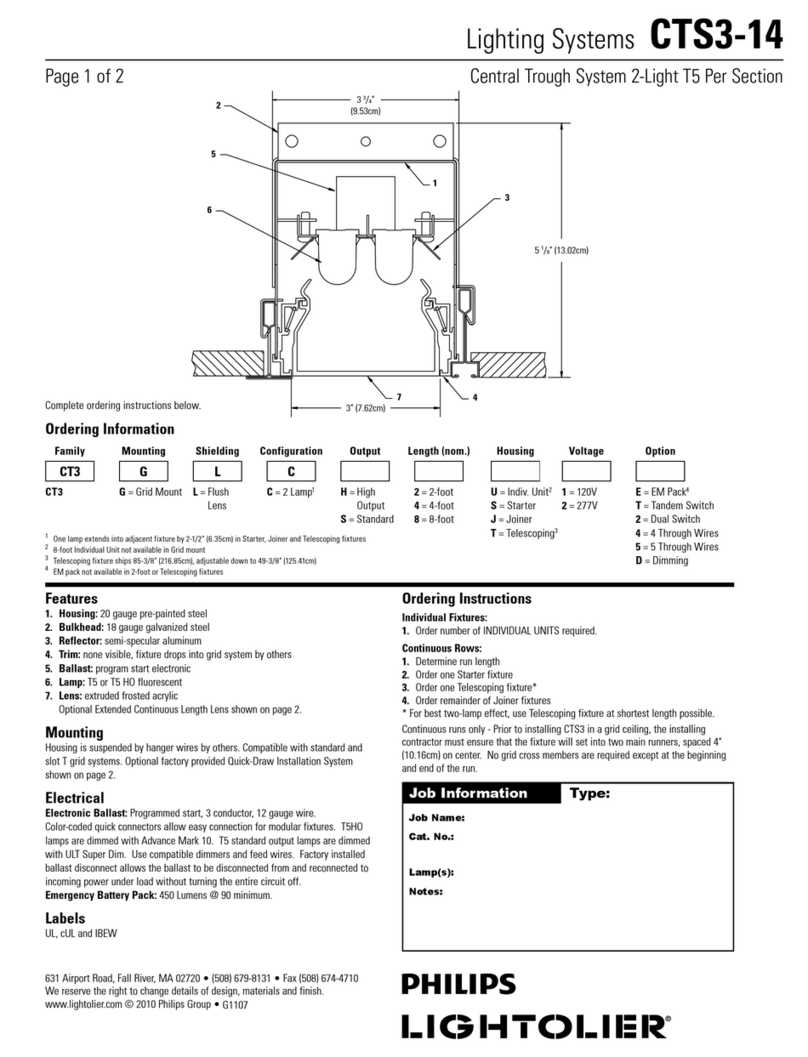

3. Technical Data

Item

L1219A

L1219B

L1219C

L1219D

Explosion Protection

IECEx

Gas Explosion

Protection

Dust Explosion

Protection

ATEX

Gas Explosion

Protection

Dust Explosion

Protection

Ex d IIB+H2 T6 Gb

Ex tb IIIC T...°C

II 2 G Ex d IIB+H2 T6 Gb

II 2 D Ex tb IIIC T...°C Db

Ex d IIB+H2 T5 Gb

Ex tb IIIC T...°C

II 2 G Ex d IIB+H2 T5 Gb

II 2 D Ex tb IIIC T...°C Db

Ex d IIB+H2 T5 Gb

Ex tb IIIC T...°C

II 2 G Ex d IIB+H2 T5 Gb

II 2 D Ex tb IIIC T...°C Db

Ex d IIB+H2 T6 Gb

Ex tb IIIC T...°C

II 2 G Ex d IIB+H2 T6 Gb

II 2 D Ex tb IIIC T...°C Db

Color of LED light

Cool White, Warm White,

Green & Red

Cool White & Warm White

Cool White & Warm White

Blue, Green, Red & Yellow

Number of LED module

1

5

4

warning light set

Color, Rated Voltage and

Wattage of LED

See section 4:Model Code

Power Factor

cos φ ≧0.9

Ambient Temperate Range

-20°C ~ +40°C

Degree of Protection

IP64

Material

Enclosure: Aluminum alloy; Glass: Tempered glass

LED Service Life

60,000 hrs

Entrance Hole

Tall Top Cover:

4×G3/4” threaded holes

Short Top Cover:

1×G3/4” threaded hole

Tall Top Cover:

4×G3/4” threaded holes

Short Top Cover:

1×G3/4” threaded hole

Tall Top Cover:

4×G3/4” threaded holes

Short Top Cover:

1×G3/4” threaded hole

Tall Top Cover:

1×G3/4” threaded hole

Cable Gland

G3/4 x 1.814; 7 ... 12mm

Fitting Cable

Size of Tube

Fitting Cable

ID:Ø8.0, L=25.6mm

OD: Ø7.0~ Ø8.0

ID:Ø8.5, L=25.6mm

OD: Ø7.5~ Ø8.5

ID:Ø10.0, L=25.6mm

OD: Ø9.0~ Ø10.0

ID:Ø12.0, L=25.6mm

OD: Ø11.0~ Ø12.0

Weight/Top Cover Type

Tall

Short

Tall

Short

Tall

Short

Tall

Without mounting bracket

7.9kg

7.5kg

9.5kg

8.9kg

9.1kg

8.5kg

7.7kg

Wall mounting

8.4kg

7.8kg

10kg

9.4kg

9.6kg

9.0kg

9.0kg

Hanging mounting

8.4kg

7.8kg

10kg

9.4kg

9.6kg

9.0kg

9.0kg

Ceiling mounting

8.7kg

8.1kg

10.3kg

9.7kg

9.9kg

9.3kg

9.3kg

Stanchion mounting 25°

9.3kg

8.7kg

10.9kg

10.3kg

10.5kg

9.9kg

9.9kg

Stanchion mounting 90°

9.1kg

8.5kg

10.7kg

10.1kg

10.3kg

9.7kg

9.7kg

Pendant mounting

8.4kg

7.8kg

10kg

9.4kg

9.6kg

9kg

9kg

4. Model Code

4.1 L1219A

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

THT-EX

1219

*

*

S

*

1

*

-*

(1) Brand name.

(2) Series designation, 1219=L1219 series.

(3) C.C.T., C=Cool white, W=Warm white, R=Red light, G=Green light.

(4) Voltage, A=24Vac, B=100Vac, C=110Vac, D=200Vac, E=220Vac, F=120Vac, G=208Vac.

(5) Type of LED carrier, S=Short Cylinder.

(6) Type of Top Cover, A=Tall type (L1105T), B=Short type (L1105S).

(7) LED quantity, 1=1 LED.

(8) LED watts choose, 1=10W, 2=20W, 3=33W.

(9) Mounting type. W25=Wall mounting 25°; W90= Wall mounting 90°; H25=Hanging mounting 25°; H90= Hanging

mounting 90°; C90=Ceiling mounting 90°; S25=Stanchion mounting 25°; S90=Stanchion mounting 90°; P30=Pendant

mounting.

Remarks:

1.33W for Green and Red LED light source is not available.

2.24V Cool white and Warm white LED light source can be used with 20watt model only.

3.Green Light and Red Light LED source can be used with 10W and 20W under work voltage 220V only.

3

4.2 L1219B

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

THT-EX

1219

*

*

C

*

5

*

-*

(1) Brand name

(2) Series designation, 1219=L1219 series.

(3) C.C.T., C=Cool white, W=Warm white.

(4) Voltage, A=24Vac, B=100Vac, C=110Vac, D=200Vac, E=220Vac, F=120Vac, G=208Vac.

(5) Type of LED carrier, C=Cylinder.

(6) Type of Top Cover, A=Tall type (L1105T), B=Short type (L1105S).

(7) LED quantity, 5=5 LEDs.

(8) LED watts choose, 1=10W, A=10W+20W, B=10W+33W, D=10W+20W+33W.

(9) Mounting type. W25=Wall mounting 25°; W90= Wall mounting 90°; H25=Hanging mounting 25°; H90= Hanging

mounting 90°; C90=Ceiling mounting 90°; S25=Stanchion mounting 25°; S90=Stanchion mounting 90°; P30=Pendant

mounting.

Remarks:

1.When LED watts choose is “1,” it consists of 10W LED, the highest wattage is 50W.

2.When LED watts choose is “A,” it consists of 10W and 20W LED, the highest wattage is 90W.

3.When LED watts choose is “B,” it consists of 10W and 33W LED, the highest wattage is 73W.

4.When LED watts choose is “D,” it consists of 10W, 20W and 33W LED, the highest wattage is 83W.

4.3 L1219C

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

THT-EX

1219

*

*

T

*

4

*

-*

(1) Brand name

(2) Series designation, 1219=L1219 series.

(3) C.C.T., C=Cool white, W=Warm white.

(4) Voltage, A=24Vac, B=100Vac, C=110Vac, D=200Vac, E=220Vac, F=120Vac, G=208Vac.

(5) Type of LED carrier, T=Triangular.

(6) Type of Top Cover, A=Tall type (L1105T), B=Short type (L1105S).

(7) LED quantity, 4=4 LEDs.

(8) LED watts choose, 1=10W, 2=20W, A=10W+20W, B=10W+33W, D=10W+20W+33W.

(9) Mounting type. W25=Wall mounting 25°; W90= Wall mounting 90°; H25=Hanging mounting 25°; H90= Hanging

mounting 90°; C90=Ceiling mounting 90°; S25=Stanchion mounting 25°; S90=Stanchion mounting 90°; P30=Pendant

mounting.

Remarks:

1. When LED watts choose is “1,” it consists of 10W LED, the highest wattage is 40W.

2. When LED watts choose is “2,” it consists of 20W LED, the highest wattage is 80W.

3. When LED watts choose is “A,” it consists of 10W and 20W LED, the highest wattage is 70W.

4. When LED watts choose is “B,” it consists of 10W and 33W LED, the highest wattage is 63W.

5. When LED watts choose is “D,” it consists of 10W, 20W and 33W LED, the highest wattage is 73W.

6. When voltage is 24V, only 80W is available.

4.4 L1219D

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

THT-EX

1219

*

*

W

A

0

1

-*

(1) Brand name

(2) Series designation, 1219=L1219 series.

(3) C.C.T., B=Blue light, Y=Yellow light, R=Red light, G=Green light.

(4) Voltage, A=24Vac, B=100Vac, C=110Vac, D=200Vac, E=220Vac, F=120Vac, G=208Vac.

(5) Type of LED carrier, W=Warning Light.

(6) Type of Top Cover, A=Tall type (L1105T).

(7) LED quantity, 0=Warning light set.

(8) LED watts choose, 1=10W.

(9) Mounting type. W25=Wall mounting 25°; W90= Wall mounting 90°; H25=Hanging mounting 25°; H90= Hanging

mounting 90°; C90=Ceiling mounting 90°; S25=Stanchion mounting 25°; S90=Stanchion mounting 90°; P30=Pendant

mounting.

4

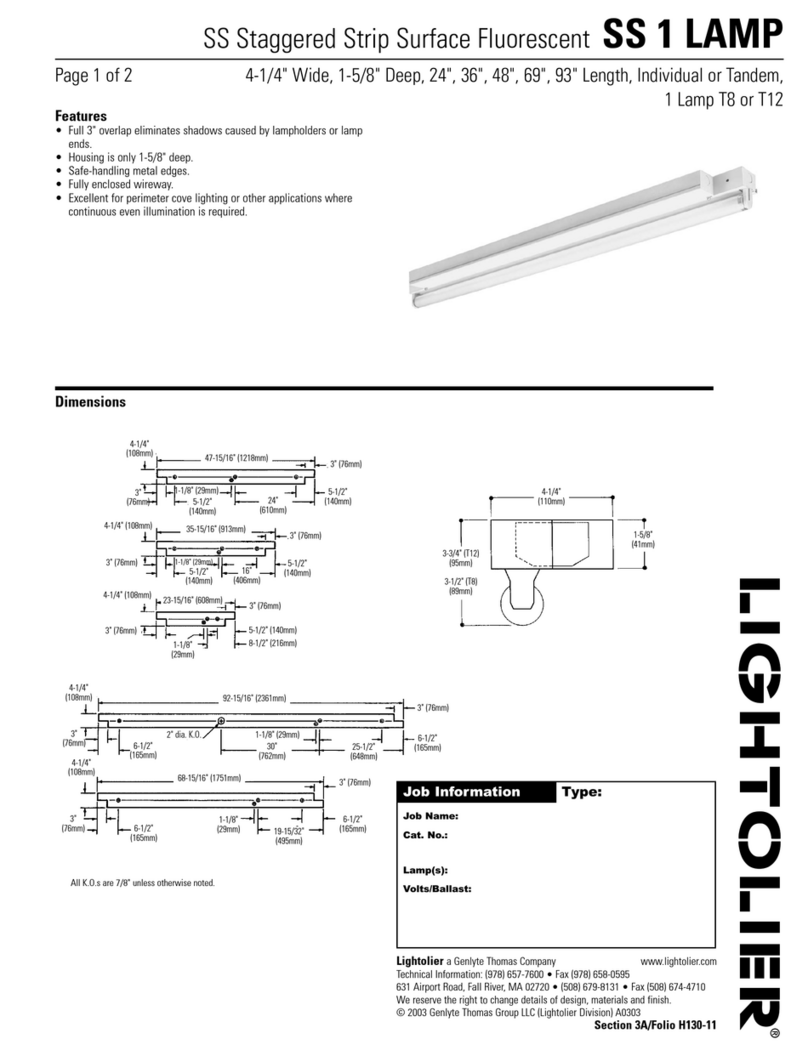

5. Dimensions (All Dimensions in mm) – Subject to Alterations

Tall Top Cover Type

Short Top Cover Type

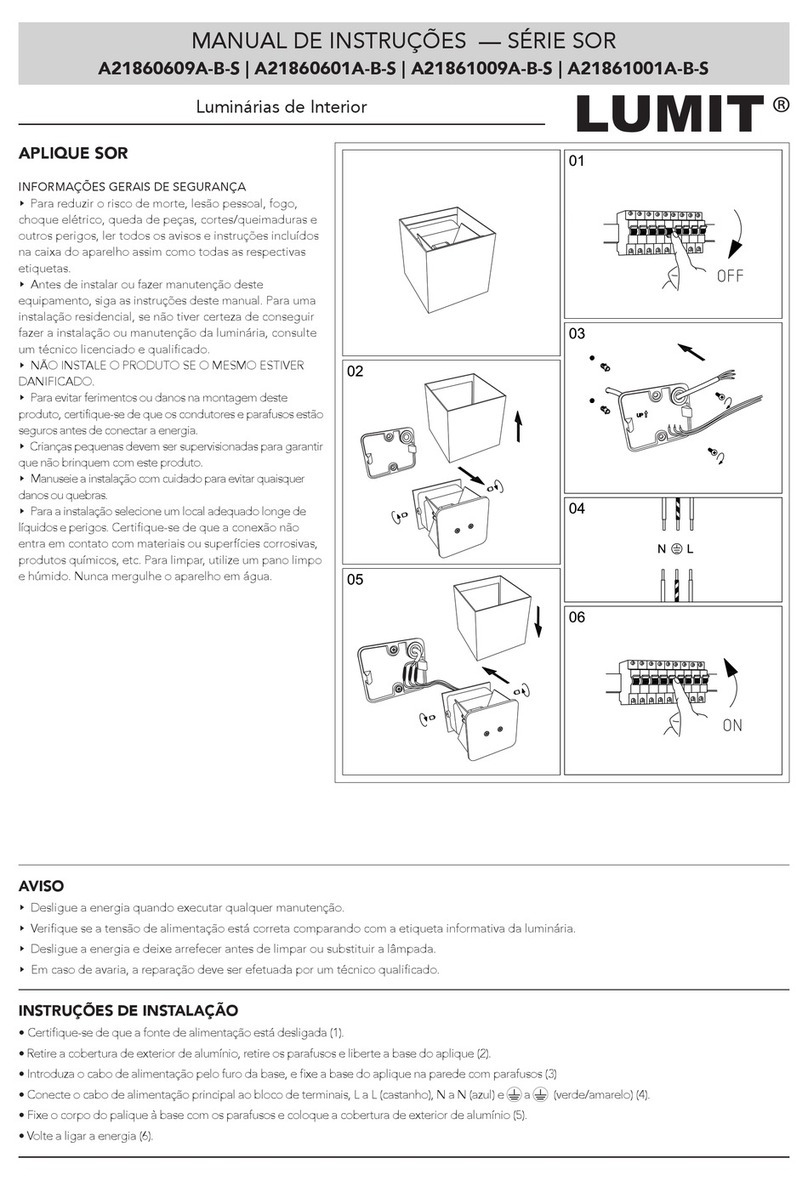

6. Assembly and Installation

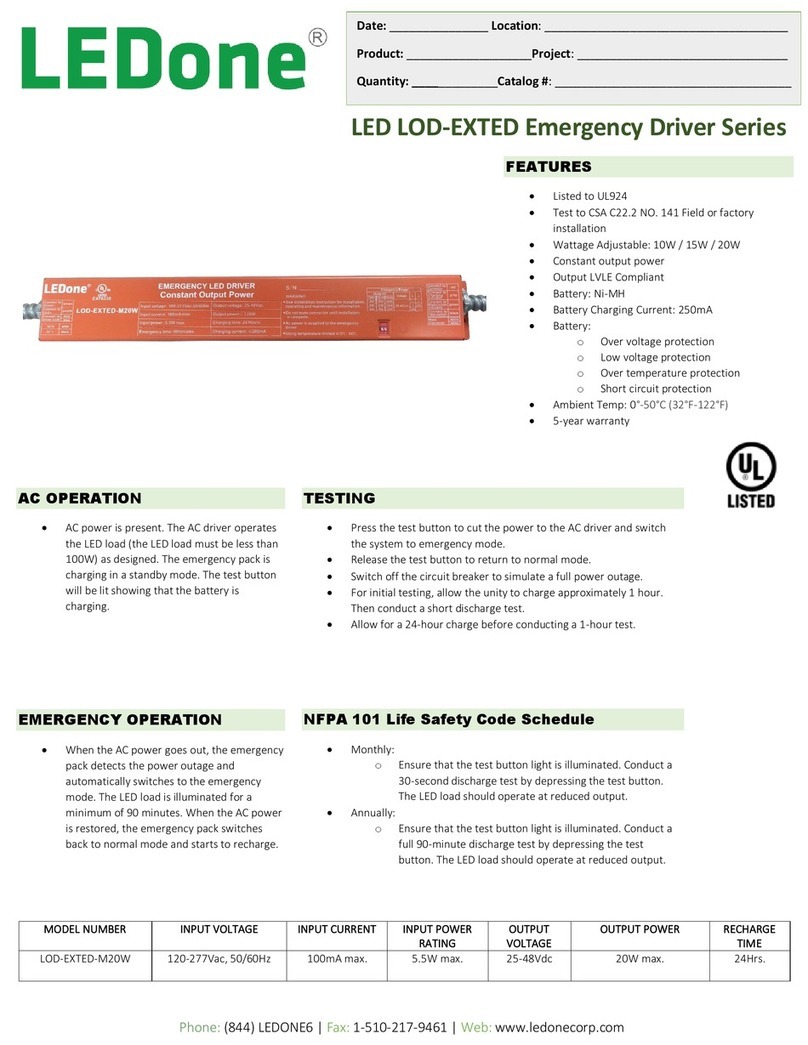

6.1 Electrical Connection

Overview

A: Top Cover

B: M6 Screw×4

1: Sleeve

2: O-Ring

3: Connector (G 3/4”)

4: Pressure nut

5: Washer

6: Tube

7: Washer

8: O-Ring

9: Body

10: O-Ring

11: M4 Screw×2

12: Nut Plate

13: M4 Socket Set Screw×1

Cable Entries

6.1.1.1 Short Type of Top Cover

This Short Type of Top Cover is equipped with one cable entry hole by mounting a Cable Gland. To mount the Cable

Gland proceed as follows:

Electrical Connection

Loosen the 4×M6-screw (B) of Top Cover (A) of

the luminaire.

Disassemble the Cable Gland; assemble the Body

(9) and O-ring (10) of Cable Gland and tighten the

Body (9) with the entry hole of the Top Cover, 650

kgf-cm.

Insert the cable from outside trough each parts of

Cable Gland and the Top Cover (A) which has

been tightened with Body (9) of Cable Gland.

Introduce the wires of the luminary with wires of

the cable by attached closed-end-terminals as

following (see right picture):

White-wire connects to Neutral;

Red-wire connects to Live;

Green-wire connects to Ground.

Re-attach the Top Cover and tighten it by using

the respective M6 screws (B), 24.5 kgf-cm.

Green:

Ground wire

Red: Live wire

White:

Neutral wire

4

5

Orderly assemble the O-ring (8), Washers (7) & (5) and Tube (6), and Screw tighten Pressure nut (4) with the

Body of Cable Gland by appropriate tool, 600 kgf-cm.

Screw and tighten the M4 Socket Set Screw (13), 24.5 kgf-cm.

Position the Nut Plate, then screw and tighten the 2 M4 screws provided, 24.5 kgf-cm.

Assemble the O-ring (2) with the Connector (3), and attach the Sleeve (1) with the Main Body (9).

Check the tightness of the Cable Gland and Top Cover, ensure the IP protection guaranteed. The Cable Gland

is assembled completely.

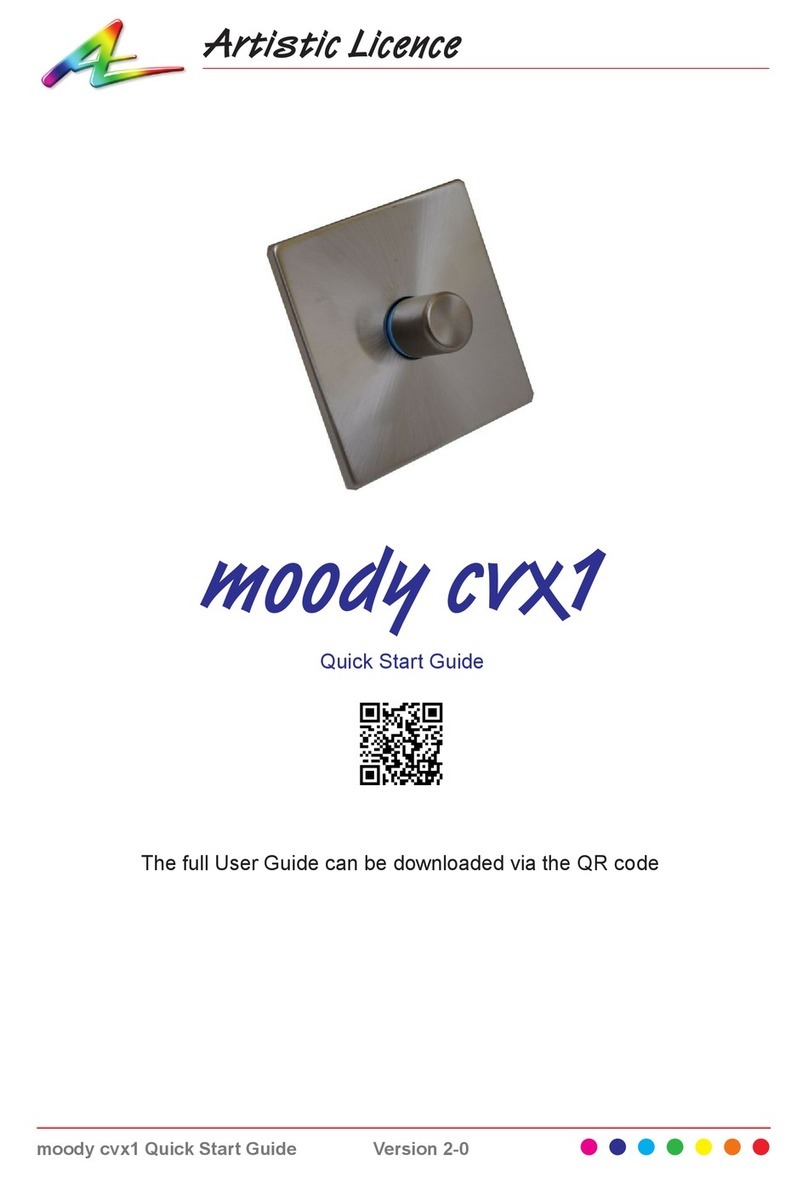

Assemble the Cable Gland by following procedure:

Step 1

Step 2

Make sure above red-line areas have been set with

matching O-Rings. Check below 7 parts are contained:

①Body②Nut Plate③Washer④Tube ⑤Pressure Nut

⑥Connector⑦Sleeve

Note:

The cable must be certified with EN/IEC.

Insert the cable into and through each part of Cable

Gland successively, as set forth in above picture. Use

watertight tape to twist round the screw part as red

circle of above picture.

Note:

It's recommended to twist round the screw part with 3-

circle.

Step 3

Step 4

Connect the Green-wire with the Ground-wire, connect

the White-wire with the Neutral-wire and connect the

Red-wire with the Live-wire by using the Closed-end-

terminal, then put the said wires in the connection

chamber of lighting fixture.

Note:

1. Pull the wires to ensure the Closed-end-terminal

are fixed.

2. Ensure the description of voltage on the cables fit

with the requirement of use.

Tighten the Cable Gland with the entry hole of cable of

lighting fixture by using a wrench.

Note:

1. Torque Range: 65N.m.

2. O-Ring used in the connection area of Cable Gland

and the lighting fixture, as red circle area on above

picture, should not be pressed and extended over

the outside diameter of Cable Gland.

1

2

3

4

5

6

7

6

Step 5

Step 6

Put the parts that are worn by the cable as described in

the Step 2 into the Cable Gland, then clockwise screw

the "Pressure Nut" with 60N.m torque range, as set

forth on above picture.

Note:

Please see the left picture to learn how to screw the

Pressure Nut.

Press the Nut Plate against the cable and use M4

screws to fix the Pressure Nut with cable. Use a M4

screw to fix the cable from the side face of the Pressure

Nut, as set forth on above left picture.

Note:

Make sure the M4 screws are completely tightened to

make the cable be fully fixed.

Step 7

Step 8

Put the "Connector" in the volume of "Sleeve" and

tighten the "Sleeve" with the body of Cable Gland, as

above picture.

Completion of the Cable Gland setting.

6.1.1.2 Tall Type of Top Cover

This Tall Type of Top Cover is designed with four

cable entry holes that users can choose either of

them connecting the power as necessary. (See

right picture).

Choose a cable entry hole as necessary and mount

the Cable Gland with the top cover and introduce

wires of the luminary with wires of outside cable

by following the steps as described in the section

of Electrical Connection of 6.1.1.1 –Short Type of

Top Cover.

Rest of cable entry holes that are not used for

electrical connection should be tightened by the

plug nut, 650 kgf-cm,as provided, to ensure the

protection of flame-proof does work effectively.

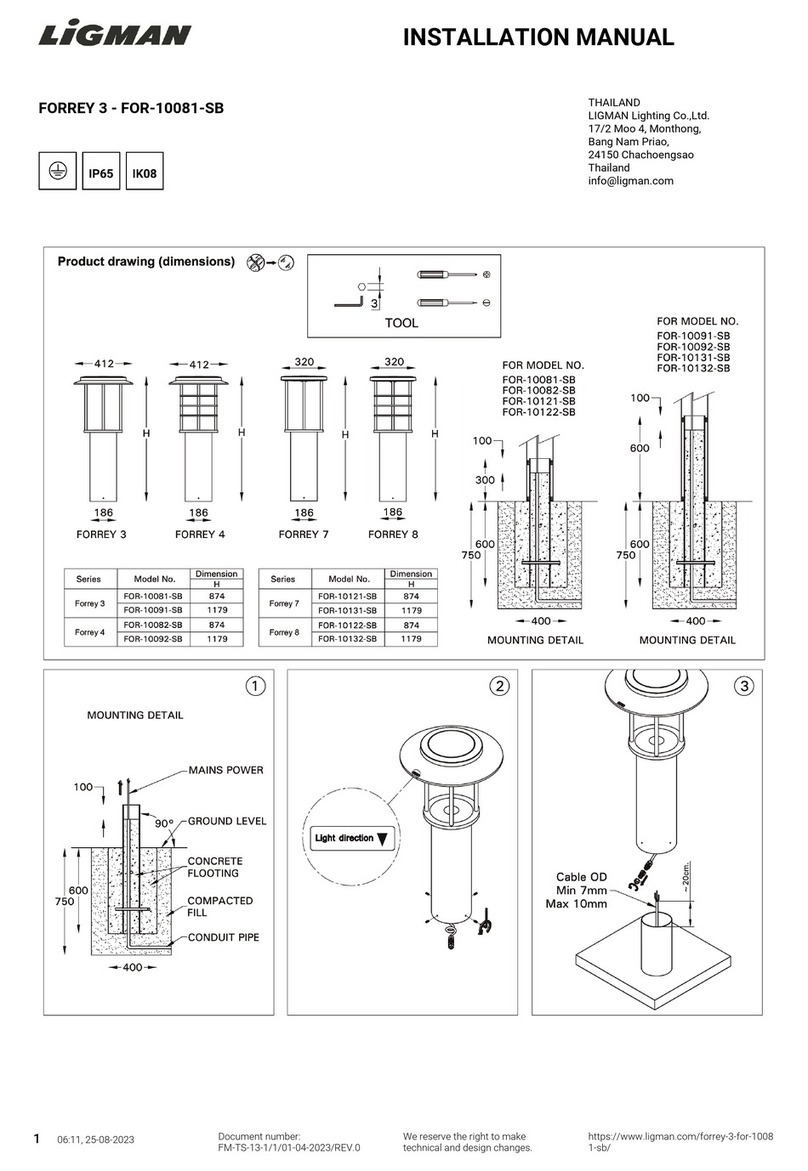

6.2 Mounting Bracket Installation

6.2.1 Wall/Hanging Mount Bracket

The mount bracket is for the use of both wall

mount (Figure 1) and hanging mount (Figure 2).

Position the bracket holders and fix it by means of

the provided M6 screws, 24.5 kgf-cm.

Secure the wall mounting bracket to the structure

by using four fasteners (M8/SUS316, not

provided).

The lighting can be adjusted to 25°and 90°.

Figure 1

Figure 2

7

6.2.2 Ceiling Mount Bracket

The mount bracket is for the use of ceiling mount

(Figure 3).

Position the bracket holders and fix it by means

of the provided M6 screws, 24.5 kgf-cm.

Secure the wall mounting bracket to the structure

by using four fasteners (M8/SUS316, not

provided).

6.2.3 Pendant mount

The mounting type is for the use of bending tube

mounting (Figure 4).

Tube mounting thread is M35.

Thread the tube mounting on conduit and torque

until wrench-tight as requirement, 6600 kgf-cm.

6.2.4 Stanchion 25° & 90°

The mounting types are for the use of bending

tube mounting, 25° & 90° (Figure 5, 6).Tube

mounting thread is M35.

Thread the tube mounting on conduit and torque

until wrench-tight as requirement, 6600 kgf-cm.

6.3 Ground wire

External earth screw location as showing in the Red Circle of below pictures.

The external earth ground wire installation and terminal type as show the following picture.

Ground wire cross-sectional area=4mm²,max LED current=1A; @V=110Vac-10%.

Both ground screw and washer material is M4*5 stainless steel.

Torque Requirement: 7 kgf.cm.

Screw material is SUS316.

Ensure wire is tied assured.

Figure 5

Figure 6

Figure 3

Figure 4

O Type

U Type

5

8

6.4 Putting into Service

Before putting into operating, it’s necessary to ensure that:

the lighting is correctly installed.

the connection has been correctly made.

the cable has been inserted correctly.

7. Maintenance

7.1 Regular Maintenance

Consult the relevant national regulations (e.g. IEC/EN 60079-17) to determine the type and extent of

inspections.

Arrange the plan of regular inspection with the equipment, one time per 3-month at least, so that any defects

in the equipment which may be anticipated are promptly detected.

To check as part of the maintenance schedule as following:

Cracks or damages on the glass cover and/or on the enclosure.

Condition of the connecting cables.

Screws of the mounting bracket are tightened.

8. Accessories and Spare Parts

9. Transport, Storage and Disposal

Transport and storage is only allowed in the original packaging, on the way pointed out on the carton

box.

Transport –Shock-free in its original carton, do not drop, and handle carefully.

Store –Store in a dry place in its original packaging.

Disposal –Ensure environmentally friendly disposal of all components according to the legal

regulations.

WARNING

To avoid dangers due to energized parts, all connections and wiring must be disconnected from the

power supply. Secure the connections against unauthorized activation.

To avoid risk of burn to hands, let the housing, the cable gland and the protective glass cool down for

approximate 30 minutes before touching them.

Maintenance work is not permitted on flameproof enclosures. Repairs are only to be carried out by

the manufacturer. Unauthorized repair shall cause the manufacturer’s liability and warranty

expires.

WARNING

Use only original THT-EX accessories and spare parts. For accessories and spare parts, see data sheet at

www.tht-ex.com.

Table of contents

Other THT-EX Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

LIGMAN

LIGMAN FORREY 3 installation manual

ML Accessories

ML Accessories UNDKIT3WWW Installation & maintenance manual

Kogan

Kogan KAMODLGT10A user guide

ADB Safegate

ADB Safegate RELIANCE Intelligent Lighting Platform III user manual

Jandy

Jandy APURE35 Installation and operation manual

Laserworld

Laserworld CS-300G DMX user manual