Energy Recovery TurboCharger AT-95 User manual

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 2 of 54

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

ERI™ TurboCharger™ Energy Recovery Device

TABLE OF CONTENTS

1.0 Introduction...............................................................................................................................................3

2.0 Safety ........................................................................................................................................................3

2.1 Safety Precautions

2.2 CE Statement

2.3 Lifting

2.4 Noise

2.5 Available Support Resources

3.0 Unpacking..................................................................................................................................................6

3.1 Inspect Arrival

3.2 Unpacking Box

3.3 Content List

4.0 Design Considerations................................................................................................................................8

4.1 Material of Construction –Selecting the Correct Material for Your Application

4.2 How the ERI TurboCharger Energy Recovery Device Works

4.3 ERI TurboCharger Energy Recovery Devices in SWRO Systems

4.4 ERI TurboCharger Energy Recovery Devices in 2-Stage RO Systems

4.5 ERI TurboCharger Energy Recovery Device Features and Operation

4.6 ERI TurboCharger Bypass Valve Considerations

5.0 Installation...............................................................................................................................................12

5.1 Piping Considerations

5.2 Cavitation and Backpressure

5.3 Stray Currents and Grounding

5.4 Source Water Supply

5.5 Flushing

5.6 Debris and Initial Flushing

6.0 Startup and Operation.............................................................................................................................15

6.1 System Performance Specifications, Precautions, and Conditions

6.2 Start and Stop Procedures

6.2.1 System Start Up Sequence

6.2.2 Short Term (One to Three Days) System Shutdown Sequence

6.2.3 Medium Term (4-14 Days) System Shutdown Sequence

6.2.4 Long Term (More Than Two Weeks) System Shutdown Sequence

6.2.5 Membrane Cleaning

7.0 Spare Parts and Toolkits......................................................................................................................... 17

8.0 Service.................................................................................................................................................... 19

8.1 Disassembly Procedure

8.1.1 AT Disassembly Procedure

8.1.2 LPT Disassembly Procedure

9.0 Troubleshooting..................................................................................................................................... 40

10.0 ERI Customer/Field Support……................................................................................................................ 42

11.0 Revision Log............................................................................................................................................. 42

12.0 Appendix A - Halo Disassembly Procedure................................................................................................ 43

13.0 Appendix B - Glycerin SDS……………………………………………….……………………………………………………………………. 49

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 3 of 54

1.0 Introduction

This manual contains instructions for the installation, operation, and servicing of the Energy Recovery

TurboCharger™energy recovery devices in reverse osmosis systems. This information is provided to ensure

the longevity, safe operation, and proper performance of your Turbocharger energy recovery device. Please

read this manual thoroughly before installation and operation, and keep it for future reference. This manual

is intended for use by personnel with training and experience in the installation, operation and maintenance

of pressurized-fluid systems and machinery.

2.0 Safety

During installation, maintenance or repair of the ERI TurboCharger device, safety systems should be

installed prior to initial operation or before attempting any repairs. Failure to take responsibility for

safety may lead to damage of the device and/or injury of personnel.

2.1 Safety Precautions

The ERI TurboCharger device has been designed to provide safe and reliable service. However, it is installed in

high pressure/flow systems and is a piece of industrial rotating machinery. Therefore, operations and

maintenance personnel must exercise good judgment and proper safety practices to avoid damage to the

equipment, to avoid damage to surrounding areas, and to prevent injury. It must be understood that the

information contained in this manual does not relieve operation and maintenance personnel of the

responsibility of exercising normal good judgment in the operation and care of this product and its

components. The safety officer at the location where this equipment is installed must establish a safety

program based on a thorough analysis of local industrial hazards. Proper installation and care of shutdown

devices and over-pressure, over-flow, and under-flow protection equipment must be an essential part of any

such program. In general, all personnel must be guided by all basic rules of safety associated with high-

pressure equipment and processes. Operating the turbocharger outside of its intended use or application can

result in damage to the turbocharger and/or personnel.

2.2 CE Statement

Energy Recovery, Inc. declares that ERI Advanced Turbocharger (AT) and Low Pressure Turbocharger (LPT)

product lines comply with the essential requirements for CE certification. A CE label is located on the

turbocharger nameplate. A copy of the Declaration of conformity is available on request.

2.3 Lifting

Described below are the proper procedures to lift the turbocharger. Safe lifting precautions must be taken

when handling this product. Review the estimated listed weights and lifting method on Table 2.3.1.

Approximate center of gravity is contained on unit drawings.

2.3.1 Lifting with Mechanical Lift

1. Inspect lifting equipment for cracks and wear.

2. Inspect Unit for slippery surfaces

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 4 of 54

3. Place the slings around the end caps. For TurboCharger models AT-2150 and larger, use the provided

lifting eye hooks attached to the top of unit casing.

4. Lift slightly above surface and then inspect if level

5. Adjust slings as necessary to level the unit.

6. Continue using mechanical lift as needed.

2.3.2 Lifting by Hand

1. Inspect Unit for slippery surfaces

2. Lift with the appropriate number of people using Table 2.3.1.

3. Crouch down with back straight.

4. Place hands supporting under the end-cap ports flanges.

5. Lift the turbocharger up using your legs, not back.

6. Lower unit onto new surface using legs.

Model

Approx. Weight

Lifting Method

AT-95

22lb [10kg]

One Person or mechanical lift

AT-250

57lb [25kg]

Two person or mechanical lift

AT-350

75lb [34kg]

Two person or mechanical lift

AT-425

100lb [45kg]

Mechanical lift only

AT-550

150lb [68kg]

Mechanical lift only

AT-875

230lb [104kg]

Mechanical lift only

AT-1100

325lb [147kg]

Mechanical lift only

AT-1500

575lb [261kg]

Mechanical lift only

AT-2150

980lb [445kg]

Mechanical lift only

AT-3250

1790lb [812kg]

Mechanical lift only

AT-4150

2600lb [1179kg]

Mechanical lift only

AT-6000

3350lb [1519kg]

Mechanical lift only

AT-7800

5500lb [2495kg]

Mechanical lift only

LPT-32

20lb [9kg]

One Person or mechanical lift

LPT-63

30lb [14kg]

One Person or mechanical lift

LPT-125

75lb [34kg]

Two person or mechanical lift

LPT-250

160lb [73kg]

Mechanical lift only

LPT-500

200lb [91kg]

Mechanical lift only

LPT-1000

425lb [193kg]

Mechanical lift only

LPT-2000

800lb [363kg]

Mechanical lift only

Table 2.3.1 Estimated Weights of TurboCharger

Avoid stepping on any external TurboCharger piping/tubing or

using external TurboCharger piping/tubing as handles

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 5 of 54

2.4 Noise

Ear protection must be worn during operation of TurboCharger units. Noise level can exceed 85dB(A) during

operation. Noise level emission varies per unit specific design and operating condition.

2.5 Available Support Resources

ERI technicians are based worldwide and are available to assist you. ERI provides many technical services with

the goal of making your project a success. ERI technicians are available for commissioning, Piping and

Instrumentation Drawing (P&ID) reviews, control logic reviews, and technical consultation. We are always

available by phone to answer any system design or operational questions at 1-510-483-7303, (Attn. Technical

Support). Please go to our website at www.energyrecovery.com to find local contact information in your area

model and serial number for your device available for future reference.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 6 of 54

3.0 Unpacking

3.1 Inspect Contents

Energy Recovery Inc.’s commitment to quality includes the procurement of top quality materials and fabrication

to extremely tight tolerances. Assembled ERI™TurboCharger™devices are subjected to extensive testing in our

wet test facility. Each turbocharger unit is tested for efficiency, boost pressure, and flow rates. Testing records

are maintained and each unit is tracked with a serial number. Each turbocharger unit should be inspected

immediately upon arrival at a customer’s site and any irregularities due to shipment should be reported to the

carrier. Turbochargers are packed with plugs on the fittings and foam piece on the turbo end cap to protect the

unit from damage during transport. The Turbocharger must never be exposed to temperatures below 33 degrees

Fahrenheit (F) [1 degree Centigrade (C)] or above 120 degrees F [49 degrees C] during storage or operation.

3.2 Unpacking Box

1. Cut the securing bands wrapped outside of box.

2. Remove box lid.

3. Remove fasteners securing TurboCharger legs to box.

4. Carefully lift the TurboCharger out of the crate using the mechanical lifting procedure found in the safety

section of this manual.

Figure 3.2 Unpacking Box

3.3 Content List

Reference the turbocharger outline drawings and bill of material to ensure that all auxiliary items are properly

included. The serial number should be recorded and referenced when making technical and commercial inquires.

Reference the Table 3.3 and Figure 3.3.1 for items to be contained in a standard arrival box.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 7 of 54

Figure 3.3.1 Box Contents

Item

Note

Turbocharger

AT-425 pictured above

Product Manual

This current document

Table 3.3 Box Contents

Unpacking: Prior to installation, make sure all shipping components are extracted from product.

Figure 3.3.2 Red Cap Removal

Remove red cap and foam roll from the turbocharger end cap

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 8 of 54

4.0 DESIGN CONSIDERATIONS

4.1 Material of Construction –Selecting the Correct Material for Your Application

Selecting the correct material for your application is critical in preventing both pitting and crevice corrosion.

Figure 4.1 below illustrates the risk of pitting and crevice corrosion for various grades of stainless steels

relative to the chloride ion (Cl-) amount in the associated fluid stream1. It is important to evaluate both sides

of the TurboCharger as the chloride ion concentration in the brine stream is much higher than the feed

stream.

Figure 4.1 –Pitting/Crevice Corrosion

4.2 How the ERI TurboCharger Energy Recovery Device Works

The ERI TurboCharger device recovers hydraulic energy from the high pressure concentrate (brine) stream in

the reverse osmosis (RO) process and transfers that energy to a feed stream. That feed stream may be

seawater going into a single stage RO membrane block, or it may be first stage brine stream being boosted in

pressure for a second stage membrane block for further recovery of permeate or flux balancing.

The ERI TurboCharger device consists of a pump section and a turbine section (Figure 4.2). Both pump and

turbine sections each contain a single stage impeller. The turbine impeller extracts hydraulic energy from the

brine stream and converts it to mechanical energy. The pump impeller converts the mechanical energy

produced by the turbine impeller back to pressure energy in the feed stream. Thus the turbocharger is

entirely energized by the brine stream. It has no electrical requirements, external lubrication, or pneumatic

requirements.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 9 of 54

Figure 4.2 –AT Turbocharger Cross-Section

4.3 TurboCharger Energy Recovery Devices in SWRO Systems

Figure 4.3 illustrates how the turbocharger works as a feed pressure booster in an RO system. The Hydraulic

Turbocharger device or “TURBO” is designed to produce a pressure boost in the RO feed stream (A, C, & E)

using the hydraulic energy available in the brine stream (G). Low pressure feed flow (A) passes through the

main feed pump which provides a pressure boost (C-A). The feed water passes through the turbocharger

which provides an additional pressure boost (E-C). The feed water then enters the membrane pressure

vessels (E). A percentage of the feed water exits the membrane as permeate (F). The rest exits as high

pressure brine (G). The brine passes through the turbocharger which extracts the pressure energy (G-H). The

brine leaves the turbocharger at low pressure for disposal (H).

Figure 4.3 –Typical Turbocharger Installation for SWRO

4.4 TurboCharger Energy Recovery Devices in 2-stage RO Systems

A

I

H

G

E

F

C

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 10 of 54

Figure 4.4 illustrates how the turbocharger works as an interstage pressure booster in a 2-stage RO system.

The Hydraulic Turbocharger device or “TURBO” is designed to produce a pressure boost in the RO feed

stream (C & E) using the hydraulic energy available in the brine stream (G). The brine water from the 1st

stage passes through the turbocharger which provides the required interstage pressure boost (E-C). The

water then enters the 2nd stage membrane pressure vessels (E). A percentage of the 2nd stage feed water

exits the membrane as permeate (F). The rest exits as high pressure brine (G). The 2nd stage brine passes

through the turbocharger which extracts the pressure energy (G-H). The 2nd stage brine leaves the

turbocharger at low pressure for disposal (H).

Figure 4.4 –Typical Turbocharger Installation for 2-stage BWRO

4.5 ERI™TurboCharger™Energy Recovery Device Features and Operation

The turbocharger incorporates a number of features designed to insure simple operation, long operating life,

proper performance and high availability. The flow of water on the turbine side energizes the turbine

impeller. The turbine impeller extracts hydraulic energy from the brine stream and converts it to mechanical

energy. The pump impeller converts the mechanical energy produced by the turbine impeller back to

pressure energy in the feed stream.

The process fluid provides all required bearing lubrication eliminating any external oil or grease

requirements.

Brine Pressure Control (H) - The turbocharger can discharge brine against a back pressure. The unit does not

require a brine disposal pump.

All ERI Turbocharger devices are equipped with a Primary Nozzle, a secondary Auxiliary Nozzle (AN), and an

Auxiliary Nozzle Control Valve (ANCV) as shown in Figure 4.5. The Main Nozzle is sized to provide a

concentrate system resistance (concentrate pressure) equal to the maximum design pressure at the design

concentrate brine flow rate. The ANCV controls flow to AN in the turbine casing. The ANCV can accommodate

a 10-20% brine pressure variation at a constant brine flow, should the system conditions require it.

I

H

G

E

F

C

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 11 of 54

NOTE:the ANCV does not bypass flow around the turbocharger. It is a unique way to achieve variable area

nozzle flow without the energy wasting throttling and bypassing valve arrangements needed by constant

speed reverse running pump turbines. The auxiliary nozzle control valve operation is described in further

detail in the ERI Document 80230-01 Technical Bulletin, Turbocharger Auxiliary Nozzle and Valve.

Figure 4.5 –Auxiliary Nozzle Line and Control Valve Arrangement

4.6 ERI™TurboCharger™Bypass Valve Considerations

The Turbocharger device bypass valve shown in Figure 4.3 (I) is typically installed when a wide operating

range of system pressures are expected, such as in brackish water applications. As the system operating

pressure varies, the available brine pressure may not be enough to drive the required amount of brine flow

through the primary turbine inlet nozzle, see Figure 4.5. The auxiliary nozzle valve acts as a variable orifice

but in some cases may not be sufficient in obtaining the desired flow. The bypass valve is then used to obtain

the desired flow by diverting a small amount of the main flow from the Turbocharger device turbine inlet (G)

to the brine exhaust (H). The bypass valve (I) can also be used to facilitate the fresh water flush sequence,

which is typically conducted at lower pressures.

It is important to note that when a bypass is in use, it is highly recommended that the auxiliary

valve be FULLY OPEN. This allows the maximum amount of brine to enter the turbine side

therefore maximizing the amount of energy recovery.

A system installed with the Turbocharger device bypass allows the operator to achieve the

desired brine flow. At lower system operating pressures, the restrictions through the turbine side

of the device will not allow adequate flow through the turbine side of the Turbocharger device

(G & H) resulting in an increase in membrane recovery rates. In this scenario, the bypass valve

should be opened. Conversely, if membrane recovery is lower than designed the bypass should

be fully closed and the auxiliary nozzle control valve should be used.

BRINE

PRIMARY NOZZLE

TURBINE

IMPELLER

VOLUTE

AUXILIARY NOZZLE

VALVE

AUXILIARY NOZZLE

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 12 of 54

5.0 INSTALLATION

5.1 Piping Considerations

The turbocharger should be installed such that it is not supported by the associated process piping nor shall it

support the associated process piping. All piping must be independently and externally supported to ensure

there are no pipe stresses on the turbocharger. All standard Turbocharger connections are grooved-end

flexible pipe coupling type.

To minimize flow turbulence, ERI recommends three (3) pipe diameters of straight pipe at each of the three

(3) high pressure connections and five (5) pipe diameters of straight pipe at the turbine exhaust connection.

To facilitate removal of the turbocharger, ERI recommends the use of removable pipe spools at each

connection as well as anchor bolts through the base. Provisions must be taken to ensure that the

turbocharger can be lifted out of the installation, if necessary. For instance, there must be enough vertical

clearance in order to lift the unit up and off of the anchor bolts.

NOTE: Avoid stepping on any external TurboCharger piping/tubing or using external TurboCharger

piping/tubing as handles.

Systems Using Positive Displacement Feed Pumps

The use of a pulsation dampener is required. The pulsation dampener must be installed between the high-

pressure pump discharge and pump suction of the turbocharger.

A pressure relief valve should be used in the high pressure feed piping. The pressure relief valve should be

placed between the turbocharger pump section discharge and the membrane pressure vessel. When

applicable, high-pressure alarms and shutdowns should be utilized.

The discharge pulsation dampener must be installed per the manufacturer’s recommendations. Damage to

the turbocharger may occur if the pulsation dampener is not operating properly.

5.2 Cavitation and Backpressure

Cavitation is the formation of vapor cavities in a liquid –i.e. small liquid-cavitation-free zones ("bubbles" or

"voids") –that are the consequence of cavitational forces acting upon the cavitational liquid. Often, when a

fluid is cavitating, it will sound like large stones or gravel is flowing in the piping. Cavitation in the turbine

exhaust connection of the turbocharger can cause severe damage to the thrust bearing. This damage can

cause the bearing to fail which may result in extensive internal damage to the rotor. To help mitigate

cavitation, the operator must maintain a minimum backpressure at the turbine exhaust connection of the

turbocharger.

NOTE: The amount of backpressure required to eliminate cavitation is SITE SPECIFIC. The amount of

required backpressure is a function of operating conditions, piping layout, temperature, etc. ERI strives to

provide as much guidance as possible before the turbocharger is shipped. However, the final backpressure

requirement cannot be determined until the turbocharger is running at site. Provisions should be taken to

ensure backpressure can be controlled and measured at site.

5.3 Stray Currents and Grounding

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 13 of 54

Since the TurboCharger is a metallic device, Energy Recovery recommends that it be grounded once it is

installed in its final location. Failure to ground the device can result in corrosion, typically at the four piping

connections. A threaded bolt is located on the turbine-side support leg which is available for connecting a

ground lug.

5.4 Source Water Supply

All fluid entering the device should be filtered to 10 micron nominal. The chemicals used for membrane

elements are typically acceptable to the turbochargers. All air must be purged from both the low- and high-

pressure circuits before the RO system is pressurized. If the RO system will be started automatically, sufficient

time must be allowed in the startup sequence so that air may be purged before the HP pump is started.

5.5 Flushing

RO membranes typically require occasional flushing. There are two types of flush: Feed Water Flush and

Fresh Water or Permeate Flush. Regardless of the flush water used, all parts of the turbocharger device must

be flushed.

Feed Water Flushing is part of a normal shutdown sequence as described below. After permeate production

has ceased, flow on both sides of the Turbochargers continue. Due to the main nozzle size in the turbine side

of the turbocharger, flushing flow through the turbine side will be limited. Typically, a bypass line is installed

around the turbine side of to facilitate system flushing, Figure 4.2 (I). The flow path of the Feed Water Flush,

with reference to Figure 4.2, is A-C-E-I-H driven by the feed water pump. It is important to note that even

though the majority of the flush water will flow through 4.2 (I), a portion of the flow will pass through 4.2 (G)

and the turbine side. This is an important point since flushing both sides of the turbo is recommended. A

Feed Water Flush is typically continued until conductivity measurements at process locations F and H are

satisfactory.

A Permeate Flush is performed on a partially- or fully-depressurized system. This is accomplished by

introducing permeate to the high-pressure pump inlet [A] or through some other injection point such as a CIP

connection. Permeate may be produced during this flushing process. Again, a bypass will be required in order

to facilitate permeate flushing.

5.6 Debris and Initial Flushing

Prior to initial startup, all piping associated with the turbocharger energy recovery device should be

thoroughly flushed to assure that no debris enters and/or damages the turbocharger. Energy Recovery, Inc.

recommends the installation of basket strainers at both inlets to the turbocharger. Basket strainers protect

the turbocharger from damage caused by debris coming from upstream failures that sometimes occur as a

result of corrosion, worn parts, or filter failures. If permanent strainers are not an option for the system,

ERI™recommends installation of temporary strainers during startup and commissioning activities.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 14 of 54

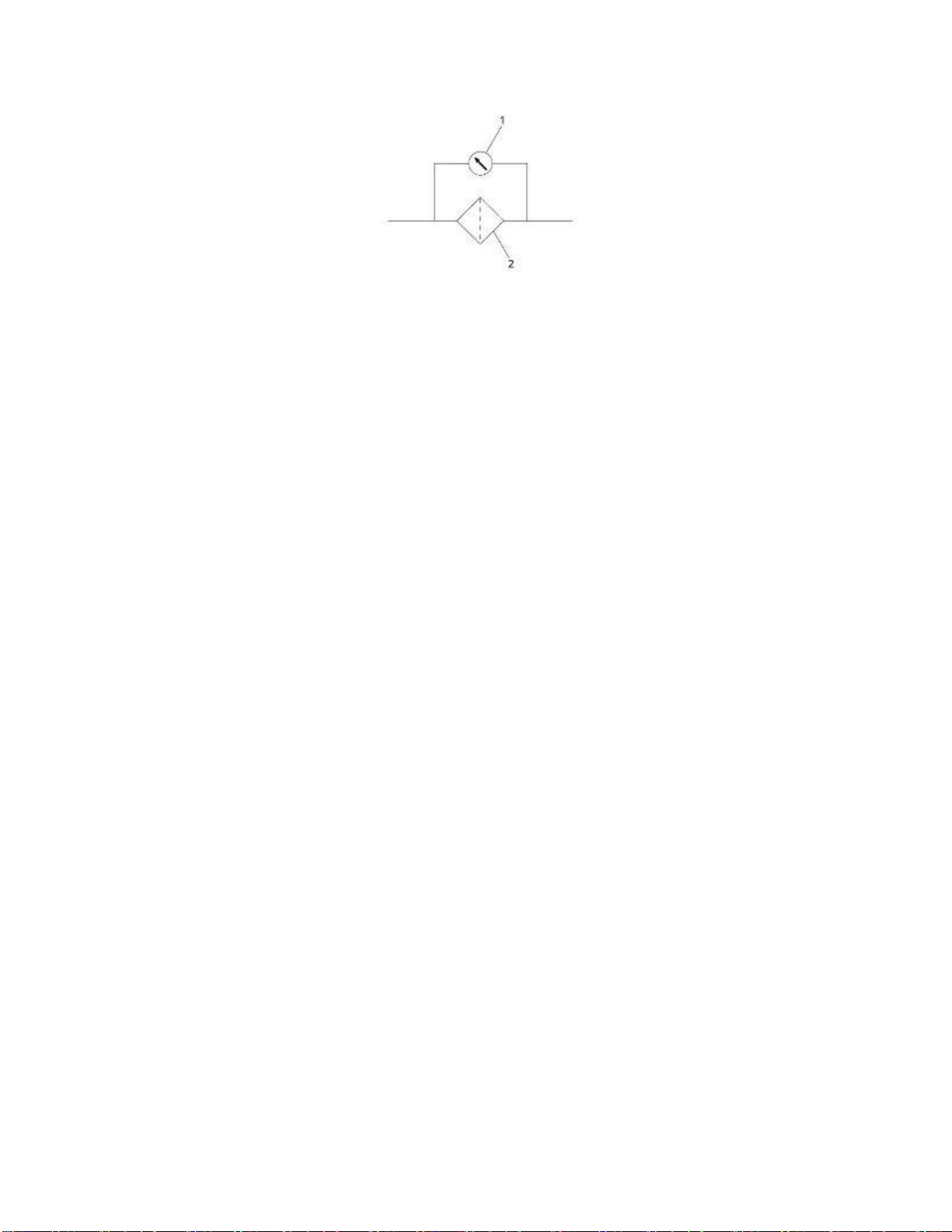

Figure 5: Temporary Filter Setup During the Flushing Process

1. Differential pressure gauge 2. Filter

Use a filter with a length 3 times the diameter of the piping.

Conical filters have proven suitable.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 15 of 54

6.0 STARTUP AND OPERATION

6.1 System Performance Specifications, Precautions, and Conditions

Successful operation of the turbocharger requires observation of some basic operating conditions and by

taking basic precautions. The turbocharger must be installed, operated, and maintained in accordance with

this manual and good industrial practice to ensure safe operation and a long service life. Failure to observe

these conditions and precautions can result in damage to the equipment and/or harm to personnel. Table 6.1

provides a summary of system performance limits.

Table 6.1 System Performance Limits

Parameter

AT TurboCharger

LPT TurboCharger

English Units

SI Units

English Units

SI Units

Maximum working pressure

1,200 psig

82.7 bar

600 psig

41.3 bar

Minimum turbine back pressure 1

site specific

Minimum filtration requirement (nominal)

10 micron

10 micron

Fluid temperature range

33-120 ◦F

1-49 ◦C

33-120 ◦F

1-49 ◦C

pH range

1-12

1-12

1–Minimum turbine back pressure is site specific. Please refer to the original turbocharger proposal for the required back pressure

for your installation. Back pressure may need to be increased at site depending on actual operating conditions.

6.2 Start and Stop Procedures

The following procedures are general guidelines for the startup and shutdown of turbocharger systems.

Procedure details will vary by plant design. Contact ERI if your plant significantly differs from that shown in

Figure 4.2 or 4.3. Always ensure that the operating limits listed in Section 6.1 are not violated.

6.2.1 System Start Up Sequence

1. All valves should be in their normal operating positions.

2. Turbocharger Auxiliary Valve should be fully open.

3. Open all air vents. Air vents should be installed at the highest points of the header piping. This is

necessary to allow air to escape the system and to allow the high-pressure piping to flood with water

pushed through the high-pressure pump by the supply pump. NOTE: Some high-pressure pumps do not

allow water to flow through while the pump is not operating. A bypass around the HPP may be required.

Please consult with your HPP manufacturer.

4. Start the feed water supply pump. The feed flow through the turbocharger unit may or may not cause

the rotor to begin to rotate. This is normal.

5. Adjust the feed water flow to the desired flow rate.

6. Repeat venting procedure as necessary to ensure ALL ENTRAINED AIR IS PURGED.

7. Close all air vents.

8. Start the high-pressure pump (HPP) with pressurization rate as per membrane manufacturer

recommendation.

9. Observe permeate and concentrate flow rates. Adjust the auxiliary valve, and bypass valve if applicable,

until desired system recovery is achieved.

10. If the HPP is fully ramped to design speed and the required system pressure has not been achieved to

produce the required permeate flow, close the auxiliary valve until the correct flow is achieved.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 16 of 54

11. If the auxiliary valve is fully closed and the system pressure is not achieved, please check inlet water

quality and temperature then compare these values to design.

12. Check the reject (concentrate) flow. If flow is as per design, startup is complete. Otherwise, open the

auxiliary valve slowly to achieve the required reject flow. If the aux valve is fully open and the correct

reject flow has not been achieved, an external bypass will be required.

13. Once startup is complete, please make sure that enough back pressure is available to prevent cavitation.

Refer to Section 5.2. Cavitation manifests itself as a very loud noise in the exhaust piping that sounds like

large stones are flowing through the piping.

14. Record pump speed, turbo boost, flows, pressures and product serial number for future reference.

NOTE: Frequent starting and stopping of the turbocharger can accelerate wear of the thrust bearing. If your

system starts and stops multiple times per day, please contact support@energyrecovery.com for further

technical guidance.

6.2.2 Short Term (1 to 3 Days) System Shutdown Sequence

1. Shut off the high-pressure pump.

2. As the high-pressure pump slows down, the turbo will also slow to a stop. Wait until the system pressure

drops to the feed water supply pump discharge pressure.

3. Shut off the feed water supply pump.

4. Flush the turbo with low TDS water or preferably permeate water to minimize crevice and pitting

corrosion.

6.2.3 Medium Term (4-14 Days) System Shutdown Sequence

1. Feed the turbocharger and the SWRO system with fresh water. With the flush pump operating, run the

system for 5 to 10 minutes until all the feed water is replaced.

2. Shut off the flush pump.

3. Isolate the fresh water supply source.

6.2.4 Long Term (More Than 2 Weeks) System Shutdown Sequence

If a plant is to be shut down for an extended period of time, the SWRO system including the turbocharger

must be thoroughly flushed with fresh water to remove any salt, and precautions should be taken to inhibit

biological growth. The turbocharger should receive a final flush with the same solution used to preserve the

SWRO membranes.

6.2.5 Membrane Cleaning

From time to time, the system will require cleaning to remove foulants, scale, etc. from the membranes.

Typically, a high pH chemical and low pH chemical are used. The cleaning process is typically carried out at a

significantly lower pressure than the normal operating pressure of the system. In general, these chemicals

will not harm the materials of construction of the TurboCharger. However, foulants, precipitates, other

debris, etc. that are dislodged or removed from the membranes could enter the turbine side of the

TurboCharger and damage the bearing. Additionally, due to the main turbine nozzle size, achieving full

cleaning flow through the turbine side will be difficult. For these reasons, ERI recommends that both the

pump and turbine side of the turbocharger be bypassed during the cleaning process. This can be achieved via

removable spool pieces, properly located CLEAN IN and CLEAN OUT connections, or valves. The same bypass

used for flushing can also be used for cleaning.

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 17 of 54

Once cleaning is completed, a fresh water flush is required after cleaning to ensure that all chemicals have

been removed and any particulates or precipitates have been flushed out.

7.0 SPARE PARTS AND TOOL KITS

In the event that disassembly is desired or required, the turbocharger is designed so that it can be assembled

and disassembled in the field with only basic tools and equipment. These tools are listed in Table 7.1.

Table 7.1 - Tools and Fixtures Required for Assembly and Disassembly

EQUIPMENT

PURPOSE

Water-soluble lubricant such as glycerin or

abrasive-free liquid soap

To install O-rings.

Please wear gloves when handling. An MSDS for

glycerin is found in Appendix B.

Hoist, capacity: 500-pound (227 kg)

To lift and remove ERI AT TurboCharger device

end caps from casing.

Hex Key

1. To hold turbine side rotor set screw while

removing rotating assembly from casing.

Please see table 8.1.1.4. (Does not apply

to LPT models).

2. To remove rotor retaining nut on LPT

models 32-63. See table 8.1.2.3 for model

specific sizing.

Slide Hammer

1. To remove turbine and pump side volute

dowel pins on AT-2150 and larger

models. Please see table 8.1.1.6 and

8.1.1.7 for model specific sizes.

10” Screwdriver

1. To be used on AT -7800 models in

keeping rotor stationery while pump side

retaining nut is removed. Strap wrench

can be used as an alternative.

2. To remove center bearing snap ring on AT

and LPT models.

3. To remove turbine side end cap on LPT

models

4. To remove thrust bearing retaining ring

on LPT models.

5. To remove pump side end cap on LPT

models.

Socket Wrench/Box Wrench

1. To remove retaining nut on pump side

rotor (AT models only). Please see table

8.1.1.5 for model specific sizing.

2. To remove rotor retaining nut on LPT

models 125-2000. See table 8.1.2.3 for

model specific sizing.

3. To remove end cap nuts (pump side and

turbine side) See tables 8.1.1.2, 8.1.1.3,

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 18 of 54

and 8.1.2.2, for model specific sizing.

4. To remove thrust line. See tables 8.1.1.1,

and 8.1.2.1 for model specific sizes.

Rubber Mallet with soft wood/plastic block

1. To remove center bearing from casing.

2. To remove AT- 7800 thrust bearing

3. To remove LPT thrust bearing

Thrust Bearing Extraction Tool (with 2 1-1/4”

box wrenches)

1. To remove thrust bearing on AT- 7800.

The following replacement parts are available for ERI turbo charger devices:

1. Bearing Kit

a. Includes all bearings (center, thrust and pump bearings)

b. Includes retaining rings

c. Includes bearing o-rings and casing o-rings

2. Rebuild kit

a. Dynamically balanced turbine and pump rotating assembly

b. Bearing kit

3. Auxiliary Line Assembly

a. Includes Auxiliary Valve

b. Includes fittings

4. Thrust Line Assembly

a. Includes fittings

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 19 of 54

8.0 SERVICE

If the feed water is filtered and the turbocharger unit is properly flushed before extended shut downs, the

turbocharger should operate maintenance- and trouble-free for many years. There are no shafts, couplings,

seals, or lubrication systems to maintain or monitor.

If a turbocharger must be assembled or disassembled, the procedures provided in this section should be

followed carefully. The tools and fixtures listed in Table 7.1 are required. The procedures provided in this

subsection are for complete assembly or disassembly of a turbocharger. Depending upon the reason for the

maintenance work, complete assembly or disassembly may not be required.

8.1 DISASSEMBLY PROCEDURE

8.1.1 AT Disassembly Procedure

Step 1 - Remove the thrust line from the Turbocharger

Unscrew the compression fittings on the thrust line at both ends. See Table 8.1.1.1 for fitting sizes.

Table 8.1.1.1 –AT Thrust Line Fitting Sizes

MODEL

TYPE

SIZE

QUANTITY

AT-95

Compression Hex Head

1/4” X 7/16"-20 UNF SAE STRAIGHT

2

AT-250

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-350

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-425

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-550

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-875

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-1100

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-1500

Compression Hex Head

3/8 X 9/16"-18 UNF SAE STRAIGHT

2

AT-2150

Compression Hex Head

3/8" X 1/4"-18 NPT

2

Energy Recovery Inc ERI™Document Number 80311-01 r6

Page 20 of 54

AT-3250

Compression Hex Head

1/2" X 3/8"-18 NPT

2

AT-4150

Compression Hex Head

1/2" X 1/2"-14 NPT

2

AT-6000

Compression Hex Head

1/2" X 1/2"-14 NPT

2

AT-7800

Compression Hex Head

5/8" X 3/4"-14 NPT

2

Step 2 - Remove nuts from pump side end cap

It may be easier to leave two nuts tightened until the rest are removed to prevent the end cap from shifting.

See Table 8.1.1.2 for nut sizes.

Table 8.1.1.2 –AT Pump Side End Cap Nut Sizes

MODEL

SIZE

QUANTITY

TORQUE REQUIREMENT

(IN-LB)

AT-95

3/8"-16 UNC

6

221

AT-250

1/2"-13 UNC

6

539

AT-350

1/2"-13 UNC

8

539

AT-425

1/2"-13 UNC

9

539

AT-550

5/8"-11 UNC

8

1074

AT-875

3/4"-10 UNC

8

1906

AT-1100

3/4"-10 UNC

10

1906

AT-1500

1"-8 UNC

9

3877

AT-2150

1-1/8"-8 UNC

16

3201

AT-3250

1-1/4"-8 UNC

16

4499

AT-4150

1-3/8"-8 UNC

16

6106

AT-6000

1-1/2"-8 UNC

16

8593

AT-7800

1-5/8"-8 UNC

24

10382

AT-95 through AT-1500:Pump side end cap can be removed by hand but the use of a hoist may expedite the

process.

This manual suits for next models

19

Table of contents

Other Energy Recovery Test Equipment manuals

Popular Test Equipment manuals by other brands

Harvest TEC

Harvest TEC 453 Installation and operation instruction manual

Humboldt

Humboldt HM-5470.3F ConMatic IPC product manual

Test Equipment Depot

Test Equipment Depot Druck DPI 811 user manual

Uson

Uson SPRINT LC owner's guide

Monarch

Monarch Nova-Strobe dax instruction manual

ASD

ASD AlcoMate Pro owner's manual