Energy Recovery Pressure Exchanger PX Q400 User manual

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

1

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................................................. 3

ABOUT THIS MANUAL ......................................................................................... 3

DEVICE BASICS.................................................................................................... 3

PX DEVICE IN RO SYSTEMS................................................................................... 4

CIRCULATION PUMP WITH PX DEVICES ............................................................... 4

PX OPERATIONAL LIMITS..................................................................................... 4

2. SAFETY............................................................................................................................... 5

HIGH PRESSURE REMAINS AFTER SHUTDOWN .................................................... 6

LOW PRESSURE ISOLATION AND OVER-PRESSURIZATION .................................... 6

HYDROSTATIC TESTING ....................................................................................... 7

3. STORAGE AND HANDLING INFORMATION......................................................................... 7

STORAGE AND HANDLING INFORMATION........................................................... 7

LIFTING............................................................................................................... 7

LIFTING EQUIPMENT ..............................................................................................7

HORIZONTAL LIFTING PROCEDURE ........................................................................8

VERTICAL LIFTING PROCEDURE .............................................................................. 9

INSTALLATION .................................................................................................... 9

4. OPERATION........................................................................................................................ 10

FEEDWATER SUPPLY ........................................................................................... 10

START AND STOP PROCEDURES........................................................................... 10

STARTUP SEQUENCE ..............................................................................................10

SHORT TERM SHUTDOWN SEQUENCE ................................................................... 11

LONG TERM SHUTDOWN SEQUENCE..................................................................... 12

FEEDWATER FILTRATION .................................................................................... 12

FLOW CONTROL.................................................................................................. 12

LUBRICATION FLOW RATE ......................................................................................12

HIGH-AND LOW-PRESSURE FLOW RATES .............................................................. 13

FLOW BALANCE ...................................................................................................... 13

4.5. FLUSHING........................................................................................................... 14

4.6. PURGE AIR .......................................................................................................... 15

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

2

5. SERVICE ............................................................................................................................. 15

SPARE PARTS AND TOOL KITS .............................................................................. 15

DISASSEMBLY PROCEDURE ................................................................................. 16

DISASSEMBLY PROCEDURE FOR THE PX DEVICE ON THE RACK OR PIPING ............. 17

PX DISASSEMBLY.....................................................................................................18

ASSEMBLY PROCEDURE ...................................................................................... 24

CARTRIDGE ASSEMBLY ...........................................................................................24

6. TROUBLESHOOTING .......................................................................................................... 30

PRELIMINARY PROCEDURES................................................................................ 30

INSTRUMENTATION............................................................................................ 30

TROUBLESHOOTING GUIDE ................................................................................ 31

7. LEARNING MORE AND CONTACTING ENERGY RECOVERY.................................................. 33

8. REVISION LOG.................................................................................................................... 33

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

3

1. INTRODUCTION

About This Manual

This manual contains instructions for the installation and operation of Energy Recovery, Inc.

PX Q400 energy recovery devices for Reverse Osmosis (RO) systems. This information is

provided to ensure the long life and safe operation of your PX® Pressure Exchanger® (PX)

energy recovery device. This manual is intended for use by personnel with training and

experience in the installation and operation of fluid handling systems. For additional information

regarding using the PX device in RO systems, refer to Energy Recovery’s website:

www.energyrecovery.com or contact Energy Recovery customer service.

Device Basics

The PX energy recovery device transfers pressure energy from the RO high-pressure concentrate

reject stream to a low-pressure feedwater stream. It does this by putting the streams in direct,

momentary contact in the ducts of a rotor. The rotor is fit into a ceramic sleeve enclosed

between two ceramic end covers with precise clearances that, when filled with high-pressure

water, create an almost frictionless hydrodynamic bearing. The rotor spinning inside the

hydrodynamic bearing is the only moving part within the device.

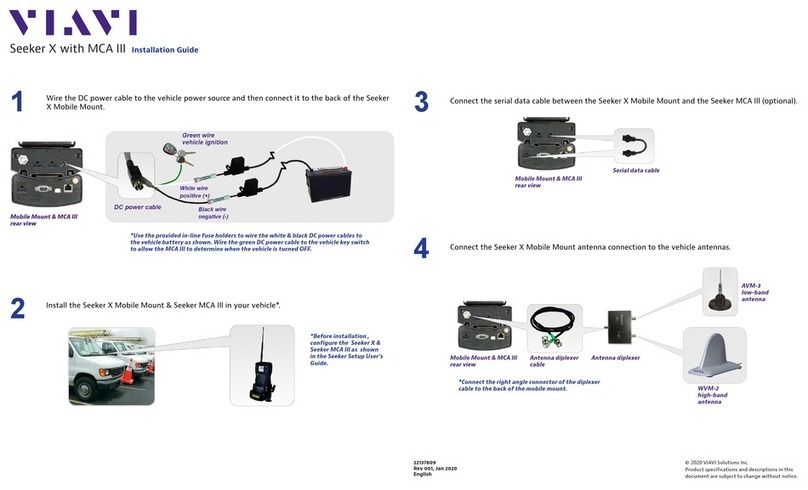

Figure 1-1: Typical flow path of RO system with PX technology

C

A

B

F

I

G

H

D

E

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

4

PX Device in RO Systems

Figure 1-1 illustrates a typical flow schematic for a RO system equipped with a PX device. There

are two independent flow paths in the PX device, the low-pressure (LP) side [B to H] and the

high-pressure (HP) side [G to D]. The reject concentrate from the RO membranes [G] passes

through the PX device or an array of devices operating in parallel. The pressure of the

concentrate reject is transferred directly to a portion of the incoming feedwater at up to 98%

efficiency. This pressurized feedwater stream [D], which is nearly equal in volume and pressure

to the concentrate reject stream [G], passes through a circulation pump. The circulation pump

propels flow in the high-pressure loop [E-F-G-D] at a rate controlled by either a variable

frequency driver on the motor or a control valve at the discharge of the circulation pump. Fully

pressurized feedwater from the circulation pump merges with flow from the high-pressure

pump discharge [C] to feed the membranes [F].

Circulation Pump with PX Devices

In the typical RO system illustrated in Figure 1-1, a circulation pump is required to move water

through the membranes and PX device or array. The high-pressure flow through the PX unit(s)

is controlled by either a variable frequency drive operating the circulation pump or a flow control

valve at the circulation pump discharge. Recommended practice is to use a slightly oversized

circulation pump to accommodate for the projected range of concentrate flow and head

requirements. The head requirements are a sum of the pressure losses from the membrane,

piping, and PX device differential pressure (head). Seasonal variations, membrane fouling, and

other process variations should also be considered when sizing your circulation pump. Energy

Recovery carries a line of circulation pumps with capacities from 20 gpm (4.5 m3/hr) up to 2,200

gpm (500 m3/hr). Energy Recovery circulation pumps can be installed on the same manifold to

run in parallel to achieve higher capacities.

PX Operational Limits

Successful operation of the PX Q400 energy recovery device requires observation of some basic

operating conditions and precautions. The PX unit must be installed and operated in accordance

with this manual and good industrial practice to ensure safe operation and a long service life.

Failure to observe these conditions and precautions can result in reduced service life, damage

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

5

to the equipment, and/or harm to personnel. For operational conditions, refer to the Technical

Data Sheet of the product. Table 1-1 provides a summary of system performance limits.

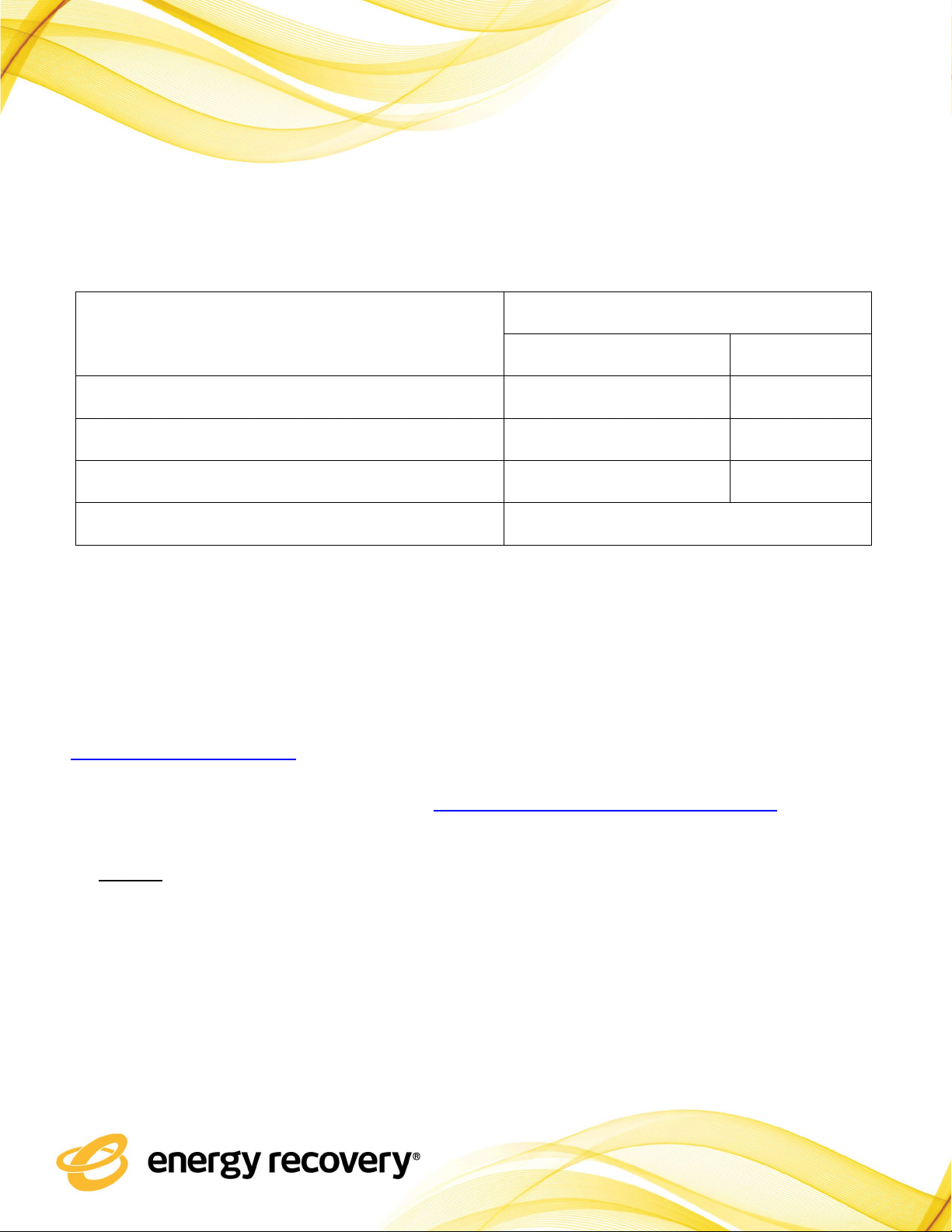

Table 1-1: System Performance Limits

Parameter

Operational values limits

English Units

Metric Units

Maximum high pressure (HP IN or HP OUT)

1,200 psig

82.7 bar

Maximum feedwater inlet pressure (LP IN)

145 psig

10 bar

Storage, operating, and feedwater temperature range

33-120 °F

1-49 °C

pH range

1-12 (short term at limits)

Further information about PX or other Energy Recovery products or service can be found by

contacting Energy Recovery at:

Energy Recovery Inc.

1717 Doolittle Drive, San Leandro, CA 94577

Tel: 1 510 483-7370

www.energyrecovery.com

For parts and/or inquiries, please e-mail: [email protected].Be sure to

include model and serial number along with company name and location in the e-mail.

2. SAFETY

The PX device is designed to provide safe and reliable service; however, it is used in a high-

pressure industrial process. Operations and maintenance personnel must follow the basic safety

rules associated with high-pressure equipment and seawater RO processes. Proper installation

and maintenance of shutdown devices and over-pressure and over-flow protection equipment

are an essential part of any RO system. Operation of the PX device outside of the designed

operating range can result in damage and may be unsafe.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

6

The flags shown and defined below are used throughout this manual. They should be given

special attention when they appear in the manual.

High-Pressure Remains After Shutdown

The high-pressure section of a RO system equipped with a PX energy

recovery device can remain pressurized after shutdown. Pressure

decreases as water slowly flows through the hydrodynamic bearing of the

PX unit. If more rapid system depressurization during shutdowns is required, the system should

be designed with accommodating valves and piping. Always make sure the RO system is fully

depressurized before disconnecting any piping or equipment.

Low-Pressure Isolation and Over-Pressurization

If the low-pressure side of the PX energy recovery device is isolated before

the high-pressure side is depressurized, the PX unit or the low-pressure

piping may be damaged by over-pressurization. High-pressure water will

seep through the PX device’s hydrodynamic bearing to low-pressure regions in the PX unit. To

prevent this over-pressurization scenario, use appropriate pressure relief valves, rupture disc

and/or depressurization procedures.

These flags denote highlighted items.

These flags denote items that, if not strictly observed, can result in

serious injury to personnel.

NOTE

CAUTION

DANGER

These flags denote items that, if not strictly observed, can result in

damage or destruction to equipment.

DANGER

DANGER

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

7

Hydrostatic testing

The PX shall not be subjected to hydrostatic testing outside of ERI’s test

facility. If hydrostatic testing of the plant piping and machinery is needed,

please remove the PX before doing so. Failure to do so may cause damage

to the device and/or injury.

3. STORAGE AND HANDLING INFORMATION

Storage and Handling Information

PX devices are packed with plugs installed on the connection ports. Keep the plugs in place until

the unit is to be fitted to the piping. This will keep the inside of the unit clean.

Follow these guidelines to reduce the potential for damage:

•The PX units must never be exposed to temperatures below 33F (1C) or above 120F (49C)

during storage or operation. If possible, store in a climate-controlled building or

warehouse.

•Avoid direct sunlight, rain or weather.

•Never lift or support the units with the end ports or side ports.

•Use a crane for lifting whenever one is available.

Lifting

Lifting Equipment

•Overhead Lift Machine (fork lift, overhead crane, floor crane)

oMinimum rating of 500 Lbs (227kg)

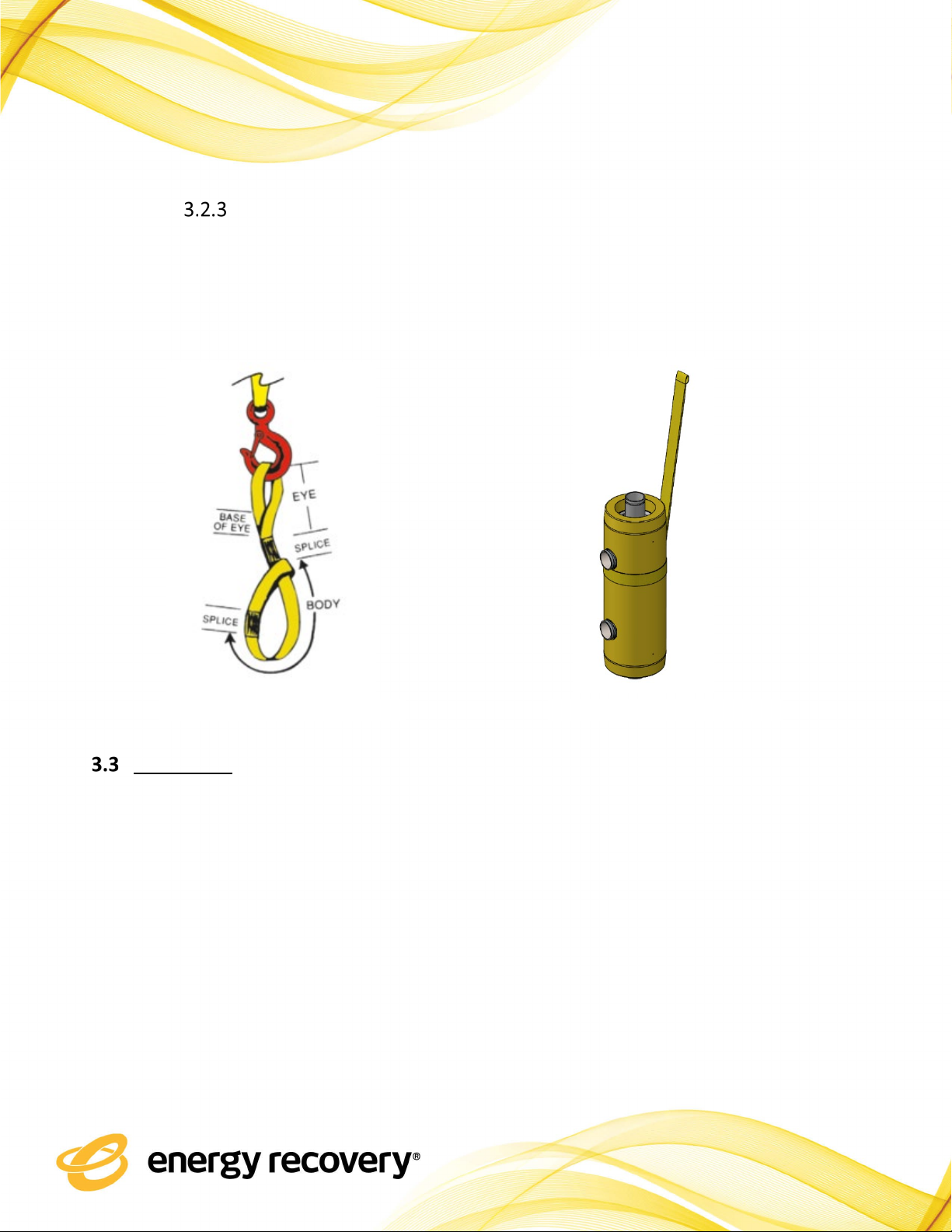

•Qty two (2) Flat-Eye Web sling

oMinimum rating – 1200 lbs (545kg)

oMinimum length – 9 ft (2.7m)

DANGER

DANGER

Always use caution when working with heavy objects – The ERI PX-Q400

weighs approximately 360 LBS (164 KG) – and can be difficult to move and

manipulate.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

8

Horizontal Lifting Procedure

1) Space two (2) Flat-Eye Web Sling along the outer diameter of the PX as shown in Figure

3-1. Ensure slings are equally spaced with respect to the center-plane of the PX.

2) One sling can be used if configured as “Double Choker Hitch” shown in Figure 3-2.

3) Once unit is properly strapped it can be lifted and transported, to final destination,

carefully using either of these methods:

a. Overhead lift and/or Jib Crane

b. Fork Lift

c. Floor Crane

Figure 3-2: Single sling Double Choker Hitch method

Figure 3-1: Space slings evenly along the PX housing.

Center-Plane

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

9

Vertical Lifting Procedure

1) Wrap the PX using the single Sling “Choker” method shown in Figure 3-3.

2) Place Sling below top side-port shown in Figure 3-4. Carefully lift and place unit as

required.

Installation

PX devices can be installed and operated in any orientation. Each unit has four connections

labeled HP IN, HP OUT, LP IN, and LP OUT.

•HP IN is the high-pressure concentrate inlet.

•HP OUT is the high-pressure feedwater outlet to the circulation pump.

•LP IN is the low-pressure feedwater inlet.

•LP OUT is the low-pressure concentrate outlet.

The PX unit must be supported by its housing and not by the pipe fittings. Prevent the PX unit

from supporting piping or manifolds. The PX device should be kept in its original packing until

Figure 3-3: Single Choker method

Figure 3-4: Single sling use on PX

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

10

the initial startup of the RO train. Proper piping, piping support, and housing support must be

employed to minimize external stresses on all pipe fittings. Use shims to support and align the

housing. Suitable flexible couplings should be used for joining fittings and piping. Use only water-

soluble lubricants such as glycerin on coupling gaskets; do not use grease. Please request

dimensional drawings of a PX device and a piping detail for use for piping, manifold, and support

rack design.

Prior to installation of the PX device, all associated piping should be thoroughly flushed to assure

that no debris enters and/or damages the PX unit. Temporary installation of basket strainers at

both inlets to the PX device or PX device array can be used.

4. OPERATION

Feedwater Supply

Standard RO process chemicals are not harmful to the PX.

Start and Stop Procedures

The following procedures are general guidelines for the startup and shutdown of PX unit

systems. Procedure details will vary by plant design. Contact Energy Recovery if your process

design significantly differs from that shown in Figure 1-1. Always ensure that the operating limits

listed in Section 1.5 are followed.

Startup Sequence

1. All valves should be in their normal operating positions.

CAUTION

Thoroughly flush associated piping with clean water before installing the

PX unit. Foreign material entering the unit may cause damage.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

11

2. Start the feedwater supply pump. The feed flow through the PX unit(s) may or may not

cause the rotor to begin to rotate. Rotation will produce a humming sound that is audible

at close proximity to the PX unit(s).

3. Adjust the feedwater flow to the desired flow rate using the low-pressure outlet flow

control valve (FCV).

4. Open air vent valves to vent the high-pressure piping. This is necessary to allow air to

escape the system and to allow the high-pressure piping to fill with water pushed through

the high-pressure pump by the feedwater supply pump.

5. After the high-pressure piping is full of water, start the circulation pump. Rotor speed will

increase. Bleed any remaining air from the system.

6. Adjust the high and low-pressure flows to the PX unit to make them equal.

7. After the feedwater supply and circulation pump have run for sufficient time to purge all

air from the system, start the high-pressure pump. The RO system pressure will increase

to the point where the permeate flow will approximately equal the flow from the high-

pressure pump. The sound level from the PX unit will increase. Small variations in sound

level and rotor speed are normal.

8. Close the air vent valves.

9. Verify that pressure at the device low-pressure outlet exceeds minimum requirements.

10.Verify the high and low-pressure flow rates. Adjust flows as necessary to achieve balanced

flow to the PX units.

Short Term Shutdown Sequence

1. Throttle the LPOUT FCV to avoid overflow in the LP side of the unit when the high-

pressure pump is turned off.

2. Shut off the main high-pressure pump.

3. Wait until the system pressure drops to the osmotic pressure of the seawater, e.g. 400

psig (28 bar).

4. Shut off the circulation pump.

5. Shut off the feedwater supply pump.

6. If necessary, open a purge valve to expedite depressurization.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

12

Long Term Shutdown Sequence

If the process is to be shut down for long term (the time frame depends on the characteristics

of the RO system and feedwater), the RO system including the PX units must be thoroughly

flushed with fresh water to remove any salt, and precautions should be taken to inhibit

biological growth. The high-pressure and low-pressure sides of the PX unit must be flushed

separately. The low-pressure side should be flushed with fresh water through the feedwater

feed line to the PX unit and to the concentrate drain. The high-pressure flush is typically

performed by circulating water through the PX unit and the membranes using the circulation

pump. Lubrication flow for the PX device rotors must be provided through the high-pressure

pump or some other injection point in the high-pressure loop during fresh water flushing. The

PX units should receive a final flush with the same solution used to preserve the RO membranes.

Feedwater Filtration

Like the RO membranes, the PX device requires filtered water. Particulates entering the PX

device are passed through to the membranes. Particles entering the PX device may also prevent

the rotor from spinning and can effect performance, resulting in the need to service the device.

The PX device filtration requirement applies during commissioning, normal operation, as well as

the membrane Clean in Place (CIP) process; refer to the technical data sheet for filtration

requirements.

Flow Control

Flow rates and pressures in a typical RO plant will vary slightly over the life of a plant due to

temperature variations, membrane fouling, and feed salinity variations. The PX unit’s rotor is

turned by the flow of fluid through the device. The speed of the rotor is self-adjusting over the

PX unit’s operating range. The ratio of the high and low-pressure flow rates affects the degree

of mixing between the feedwater and concentrate streams that occurs within the unit.

Lubrication Flow Rate

In a PX device, some of the high-pressure water flows through the hydrodynamic bearing to low-

pressure regions in the assembly. The lubrication flow rate varies with system pressure

according to the PX’s performance curves. If the PX device has a damaged o-ring or is damaged

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

13

by debris, overflow, or insufficient discharge pressure, excess lubrication flow may occur.

Monitoring lubrication flow is a good way to check the integrity of an operating PX unit.

Lubrication flow can be monitored using any of the following three methods:

•Measure the flow rate of the low-pressure feedwater to the high-pressure pump and the

flow rate of the permeate. The difference is approximately the lubrication flow rate.

•Measure the flow rate of the high-pressure concentrate to the PX unit and the high-

pressure feedwater from the PX unit. The difference is approximately the lubrication flow

rate.

•Measure the flow rate of the low-pressure concentrate from the PX unit and the low-

pressure feedwater to the PX unit. The difference is approximately the lubrication flow

rate.

Please note that this method of monitoring is to help establish trends. The value obtain may not

be exact.

High- and Low-Pressure Flow Rates

The high-pressure flow through the PX unit is set by adjusting the circulation pump with a

variable frequency drive or with a flow control valve and verified with a high-pressure flow

meter. The flow rate of the high-pressure feedwater out of the PX unit equals the flow rate of

the high-pressure concentrate to the PX unit minus the bearing lubrication flow.

The low-pressure flow through the PX unit is controlled by the feedwater supply pump and a

control valve in the concentrate discharge from the PX unit(s). This valve also adds backpressure

on the PX device required to prevent cavitation. The low-pressure flow rate must be verified

with a flow meter. The flow rate of the low-pressure concentrate from the PX unit equals the

flow rate of the low-pressure feedwater to the PX unit plus the bearing lubrication flow rate.

Flow Balance

The high and low-pressure flows to and from the PX device should be equal or “balanced” for

optimum RO operation. Operating the PX unit with unbalanced flows can result in higher

contamination of the feedwater feed by the concentrate reject. Balanced flows help limit the

mixing of concentrate with the feed. A feedwater inlet flow that is much less than the feedwater

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

14

outlet flow will result in lower quality permeate, increased feed pressure, and higher energy

consumption. For more information refer to Energy Recovery document 80088-01 Mixing

Technical Bulletin or contact Energy Recovery customer service.

4.5. Flushing

There are two types of flush: Feedwater Flush and Fresh Water or Permeate Flush. Regardless

of the flush water used, all parts of the PX device must be flushed, i.e. low-pressure flow

channels, high-pressure flow channels, and lubrication channels.

Feedwater Flushing is part of a normal shutdown sequence as described in Section 4. After both

permeate and concentrate production have ceased, flow on both the high-pressure and low-

pressure sides of the PX devices continues. The flow path of the Feedwater Flush, with reference

to Figure 1-1, is B-C-D-E-F-G-H driven by the feedwater pump and the circulation pump. A

Feedwater Flush is typically continued until conductivity measurements at process locations G

and H are satisfactory (TDS close to feedwater TDS).

A Permeate Flush or Fresh Water Flush is performed on a partially or fully depressurized system.

This is accomplished by introducing permeate simultaneously to the PX device low-pressure

inlet [B] and either to the high-pressure pump inlet [A] or through some other injection point

such as a CIP connection. Permeate may be produced during this flushing process. If so, it may

be necessary to block permeate flow to divert lubrication flow through the PX devices. The

circulation pump must be run to flush HP side of the PX device (s).

For more detail information refer to relevent Energy Recovery technical bulletins.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

15

4.6. Purge Air

Entrained or trapped air or other gases must always be purged from the RO system before

pressurizing the system. Entrained air in a pressurized system can result in damage to the PX

unit. Prior to pressurizing the RO system, vent or flush for sufficient time to allow for the removal

of all air from the RO system.

5. SERVICE

Spare Parts and Tool Kits

The PX Q400 energy recovery device needs no scheduled periodic maintenance. However, in the

event that disassembly is desired or required, the PX Q400 unit is designed so that it can be

assembled and disassembled in the field with only basic tools and equipment. These tools are

listed in Table 5-1. These tools, with the exception of the hoist and torque wrench, are included

in the PX Q400 tool kit (Energy Recovery Part Number 20469-01). In addition, the PX Q400 unit

can be mounted on a stand or on blocks to facilitate service, or the LP connection port can be

unthreaded in order to support the unit on the housing.

Entrained or trapped air must be purged from the RO system before every

pressurization.

CAUTION

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

16

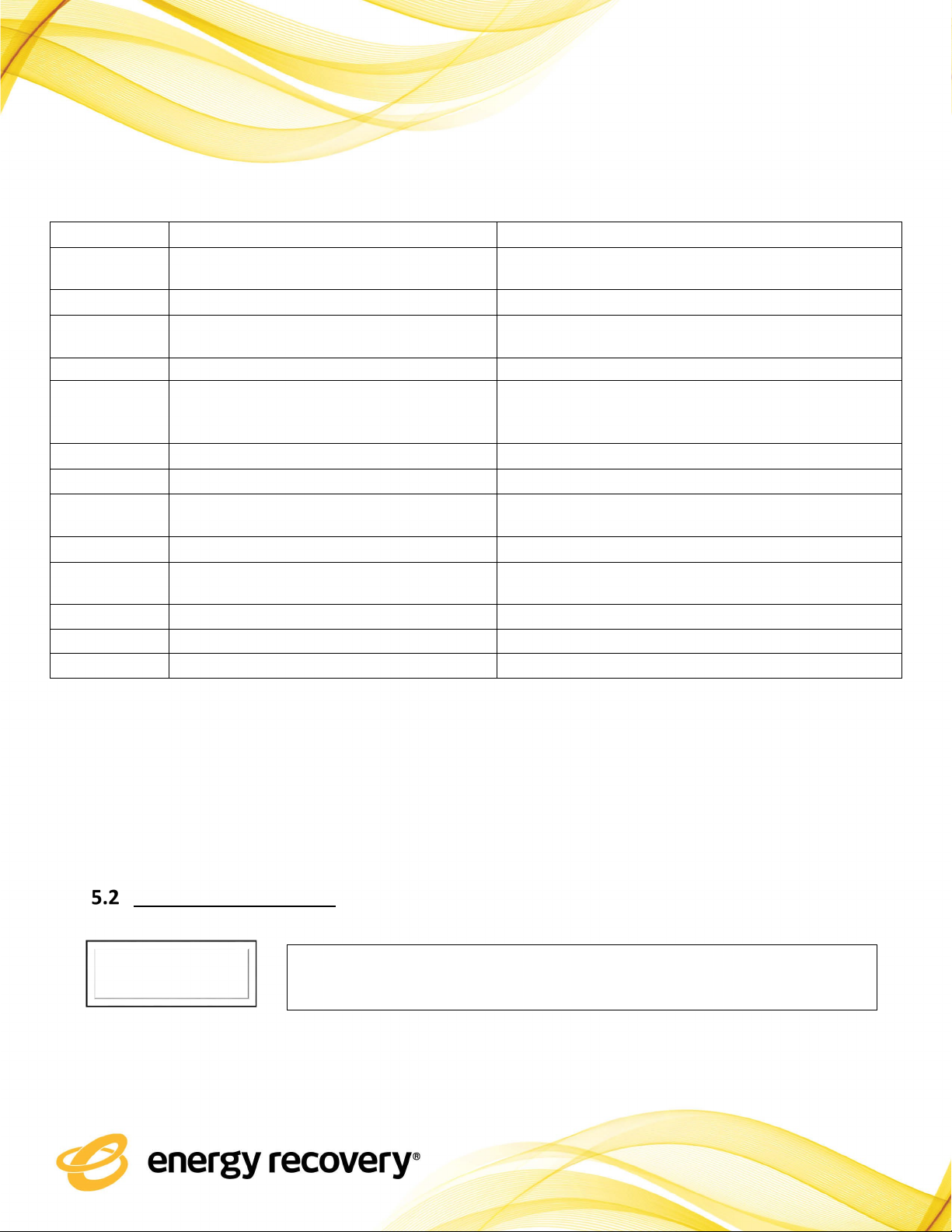

Table 5-1: Tool Kit 20469-01 bill of materials

Part Number

Description

Purpose

20471-01 KIT, TOOL, HEAD PULLER, 9"

Tool designed to facilitate removal of Head Assembly.

Glycerin included to lubricate O-rings.

10608-01 TOOL, REMOVAL, INTERCONNECT, 3"

Tool to remove Interconnects.

43684-01 TOOL, INSTALLATION, O-RING, 9" SIDE PORT

Tool to reduce O-ring damage during install or removal

of Cartridge.

30207-01

TOOL, LIFTING STRAP, FABRIC

Attached to the housing to support lifting purposes.

10506-01 NUT, LIFTING EYE, 5/8"-11, 316

Lifting Eye for cartridge. To be used in conjunction with

All Thread found in 20471-01 and Coupling Nut 30092-

01.

30092-01 NUT, COUPLING, 1/2"-13, TO, 5/8"-11, RED

Couples All Thread found in 20471-01 with Cartridge.

30100-01

ROD, SPINNING, ROTOR

Rod to help spin the rotor during assembly.

10130-01 WRENCH, ALLEN, TEE, 1/4"

Tool to remove socket head cap screws from head

assembly.

10137-01

WRENCH, COMBO, 3/4", CARBON STEEL

Tool for Hex Bolts.

10225-01

ANTI-SEIZE, .25 OZ, TUBE, NICKEL, MSDS

REQUIRED

Anti-Seize for threaded connections.

10327-01

WRENCH, STRAP, 3/4" MIN, 6-5/16" MAX

Tool designed to install and remove LP connection ports.

10329-01

WRENCH, CRESCENT, 6"

Tool for Hex bolts.

10085-01

NUT, LIFTING EYE, 1/2"-13, 316

Lifting Eye for cartridge

Replacement seals and alignment pins are included in Energy Recovery’s standard spare parts

kits (Energy Recovery Part Number 20467-01). One spare parts kit should be used each time a

PX unit is opened for service.

Replacements for other components in the PX assembly are available. Refer to assembly

drawing for PX component descriptions, part numbers, and the bill of materials.

Disassembly Procedure

CAUTION

Metal objects can chip or crack ceramic. Use caution when handling ceramic

components to avoid damage.

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

17

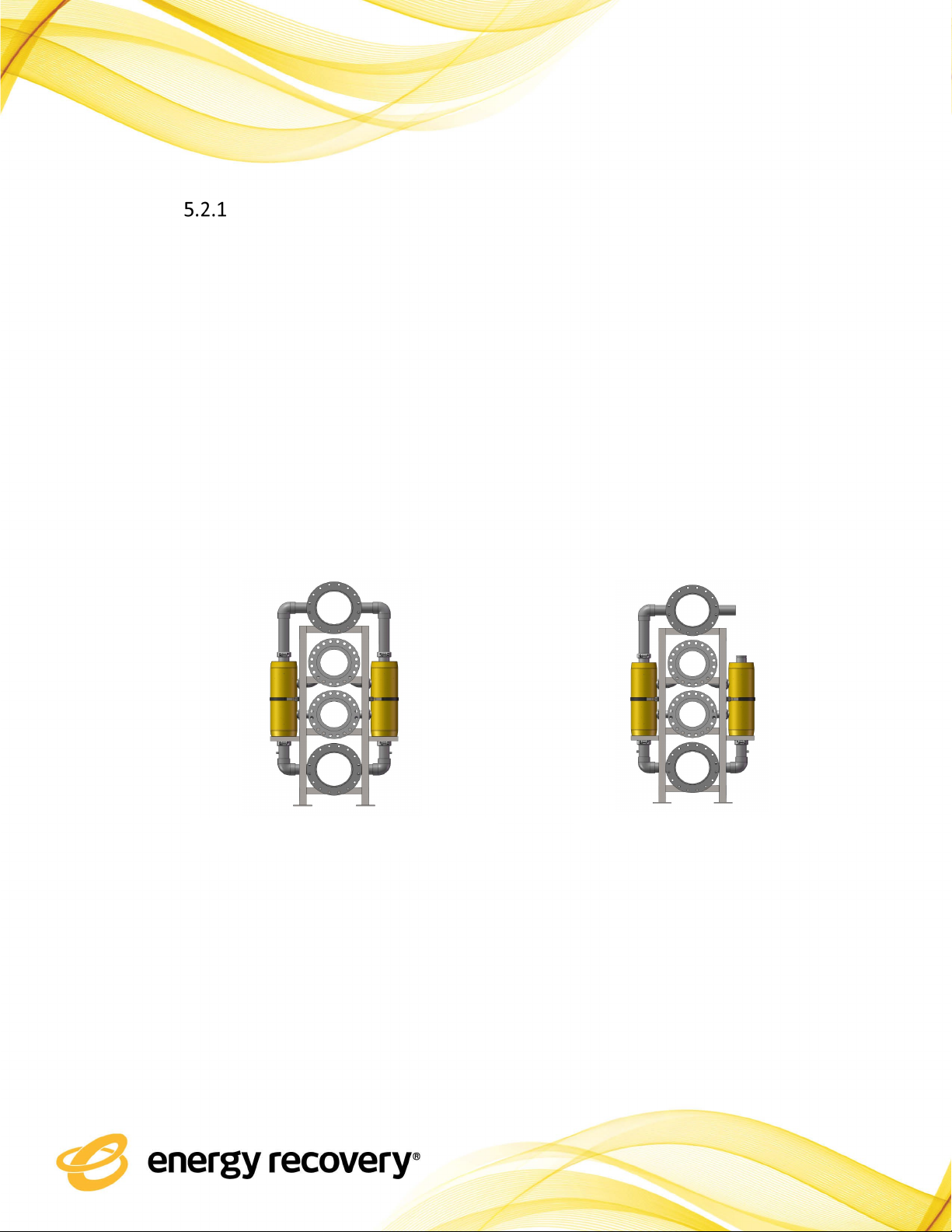

Disassembly Procedure for the PX Device on the Rack or Piping

1. Depressurize all high-pressure and low-pressure piping to and from the PX unit.

2. Close all valves to and from the PX unit/rack or drain system.

3. Disconnect and remove the low-pressure piping from the upward facing end of the unit.

See Figure 5-2 as reference.

4. If more access is required, the PX can be removed from the rack.

a. Remove the all HP and LP couplings from the PX.

b. Remove the all HP and LP pipes connected to the PX.

c. Install sling around the PX as described in Section 3.2.

d. Remove the Saddle and Strap from the PX.

e. Remove the PX from the rack following the procedure listed in Section 3.2.

i. Bottom LP port may need to be removed if access is needed. Refer to

Section 5.2.2 Step 1.

5. Proceed with disassembly as directed in Section 5.2.2.

Figure 5-1: PX device on array rack

Figure 5-2: LP port removed on array rack

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

18

PX Disassembly

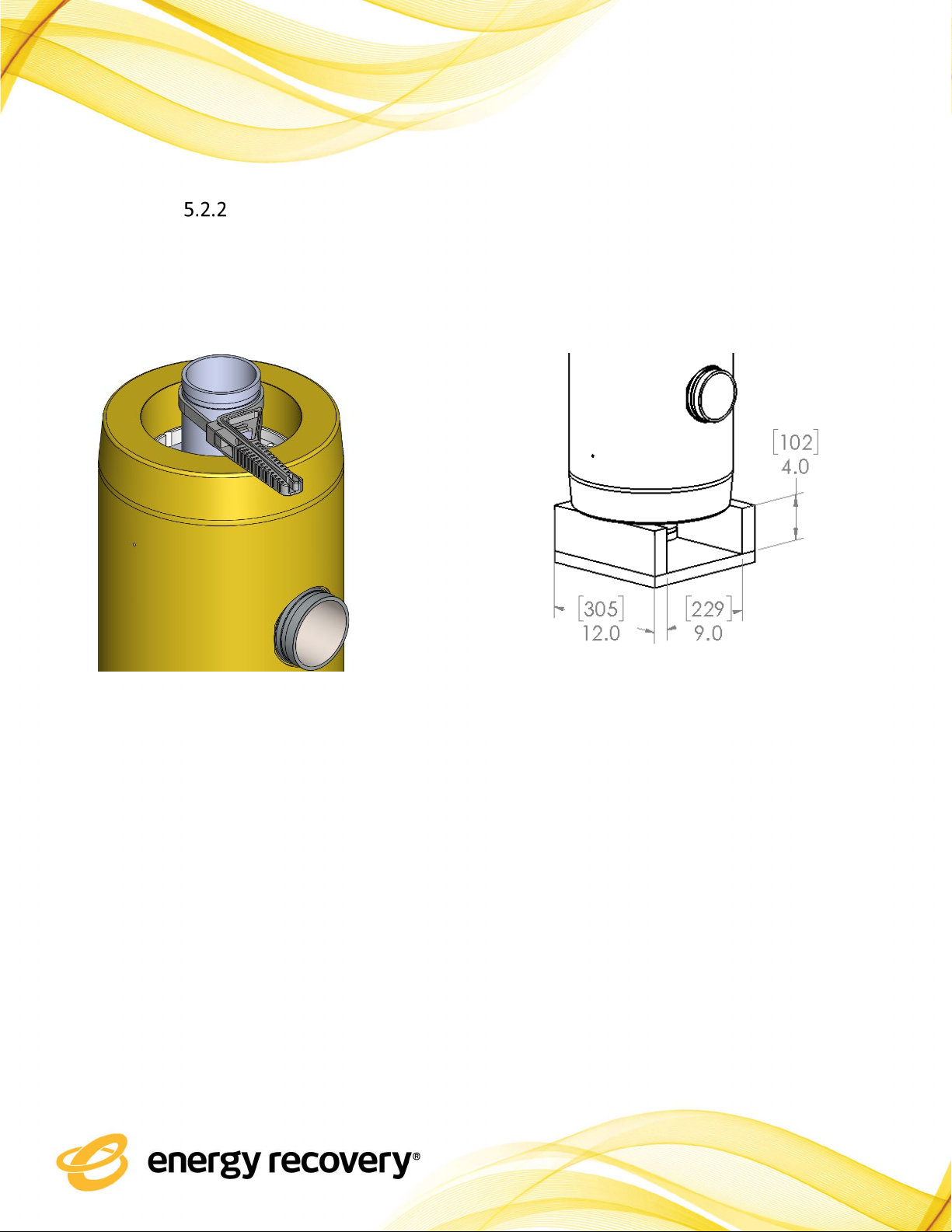

1. Unscrew and remove the bottom LP port Figure 5-3. Otherwise, use blocks or a stand to

support the unit by the bottom end of the fiberglass housing shown in Figure 5-4. Do not

support the unit or apply stress to the low-pressure port.

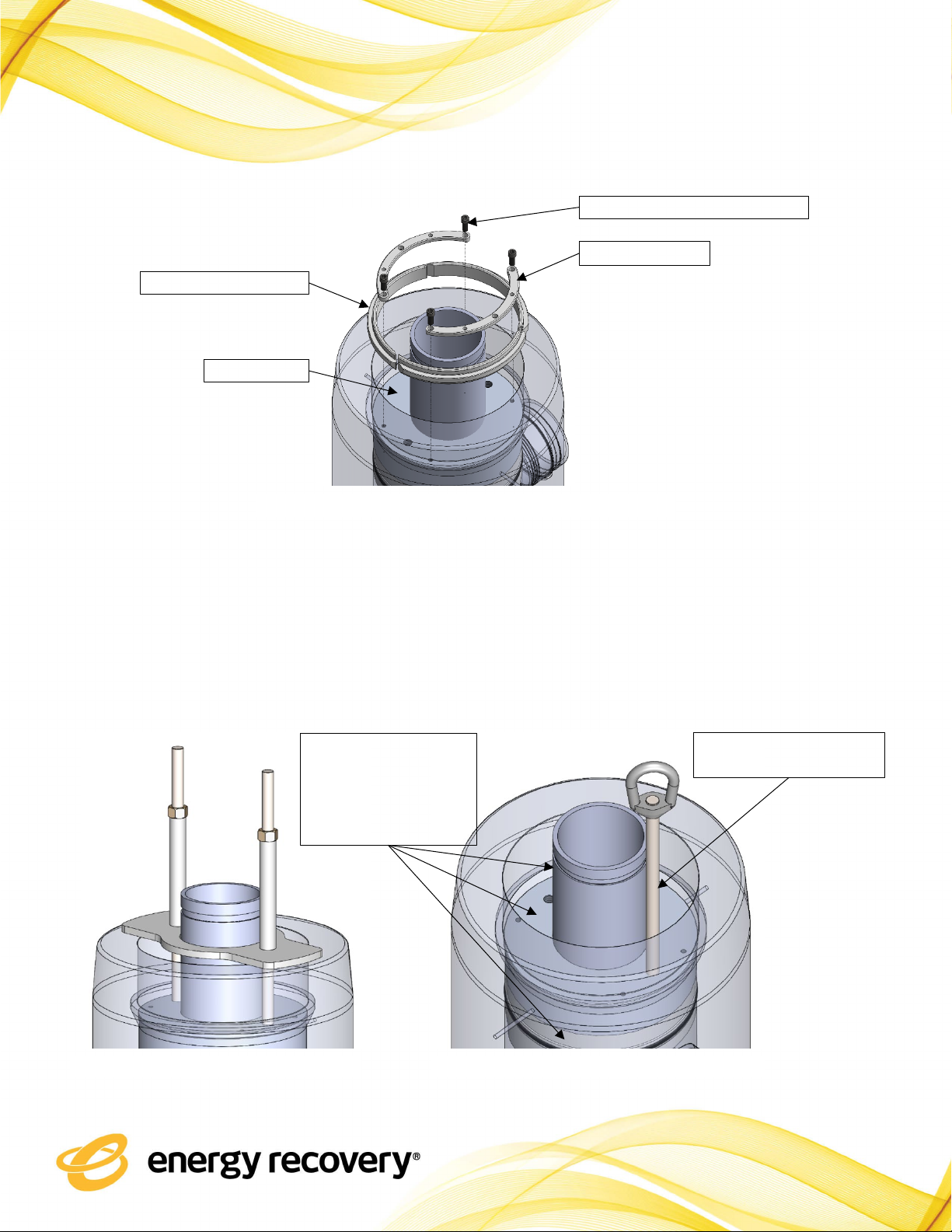

2. Remove four (4) 5/16-inch socket-head cap screws, two (2) Securing Ring, and three (3)

Segmented Lock Ring from the top of the PX unit using a 1/4-inch Allen wrench as shown

in Figure 5-5.

a. Tip: Segmented Lock Ring maybe compressed due to pressurization of the PX. In

this instance, gently tap on the Bearing Plate with a plastic or wooden rod to loosen

the Head Assembly.

Figure 5-3: PX Q400 with Pipe Strap tool Figure 5-4: PX Support block shown as reference

Typical Dimensions shown in Inches [mm]

PX Q400 Energy Recovery Device

Energy Recovery Document Number 80882-01-00

19

3. Extract Head Assembly from the housing using an Energy Recovery Head Puller tool

20471-01 shown in Figure 5-6. Assisted lifting can be achieved using the All-thread and

Lifting Eye 5/8-11” as shown in Figure 5-7. Take care not to apply stress to the LP port if

it is still in place. Always use a wood block to protect the edge of the housing if force is

necessary to remove the head assembly.

a. Estimated weight of the Head Assembly is 25 lbs (11.3 kgs).

(2) Securing Ring

(4) 5/16-inch socket-head screw

Figure 5-5: Disassembly of PX Segmented and Securing Rings

(3) Segmented Lock Ring

Bearing Plate

Figure 5-6: Head puller tool, PN 20471-01

Figure 5-7: Assisted lifting of the Head Assembly

Head Assembly - 25lbs

(11.3kg)

•LP Port

•Bearing Plate

•Seal Plate

All-thread located in Head

Puller Tool 20471-01.

Table of contents

Other Energy Recovery Test Equipment manuals