MSG Equipment MS015 User manual

Other MSG Equipment Test Equipment manuals

MSG Equipment

MSG Equipment MS008 User manual

MSG Equipment

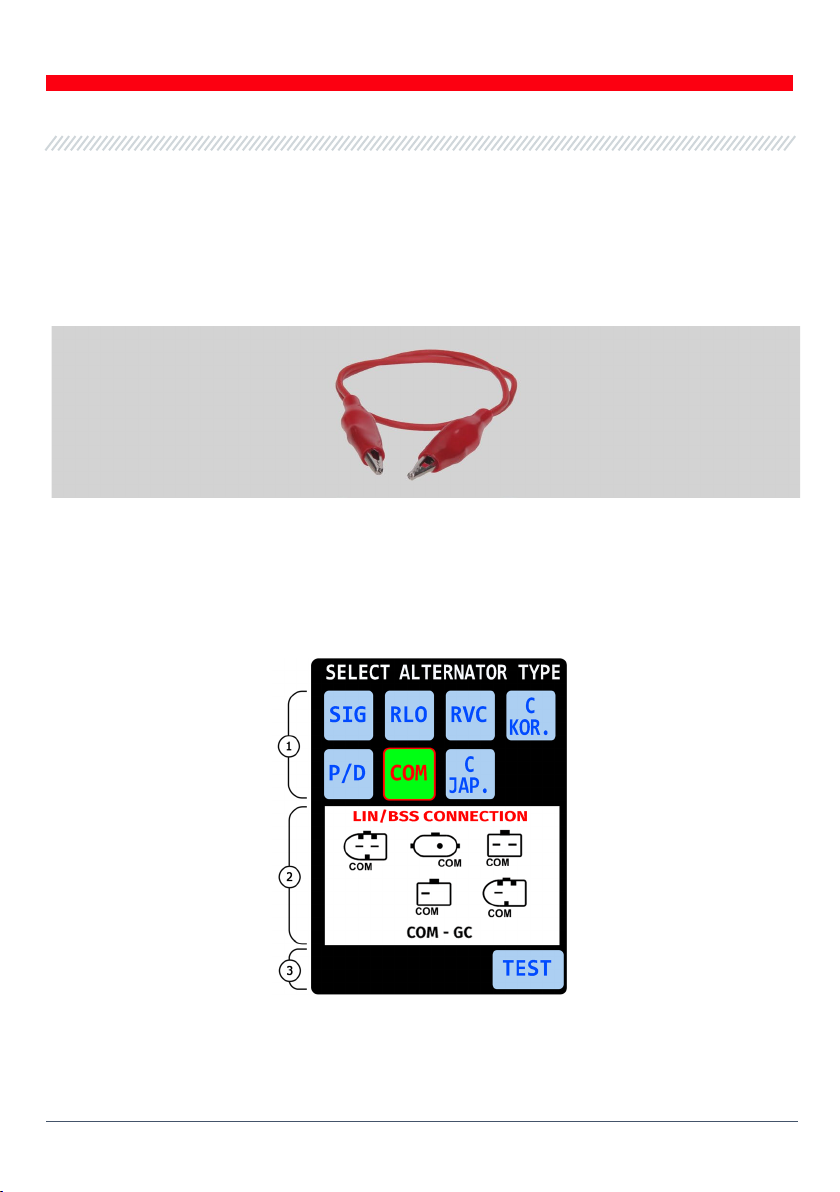

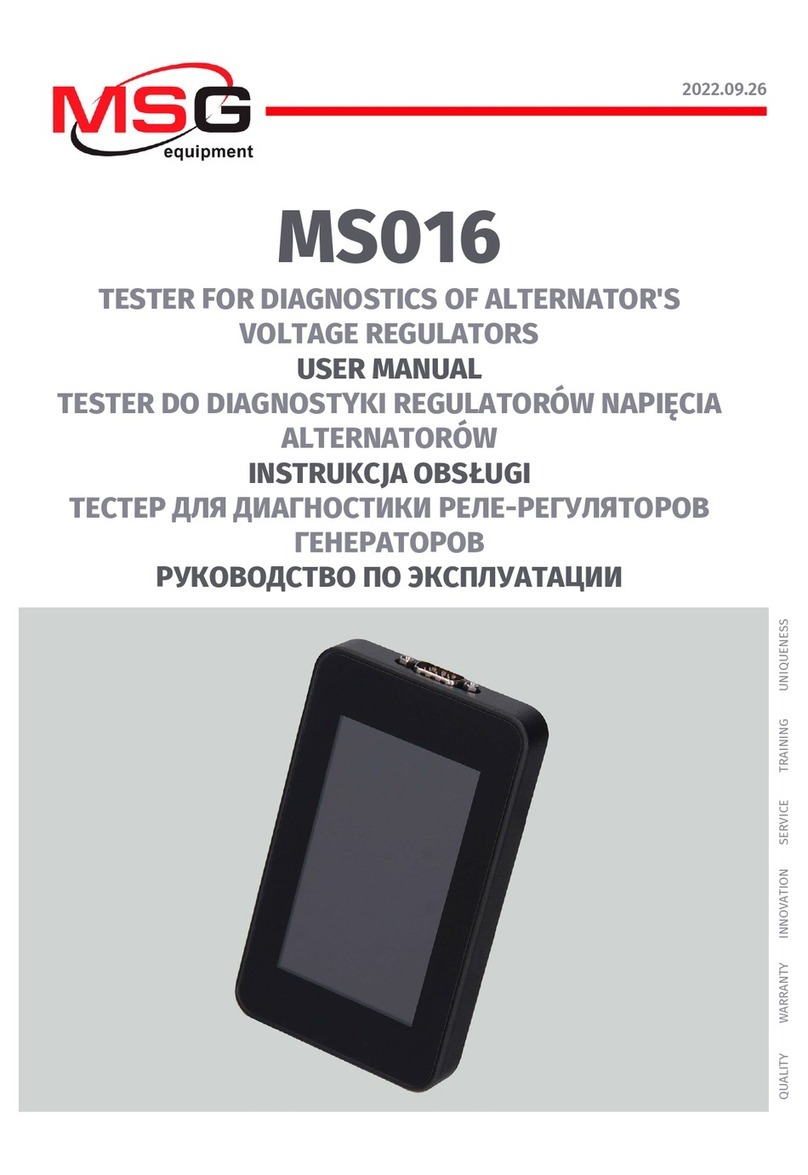

MSG Equipment MS016 User manual

MSG Equipment

MSG Equipment MS002 COM User manual

MSG Equipment

MSG Equipment MS800 User manual

MSG Equipment

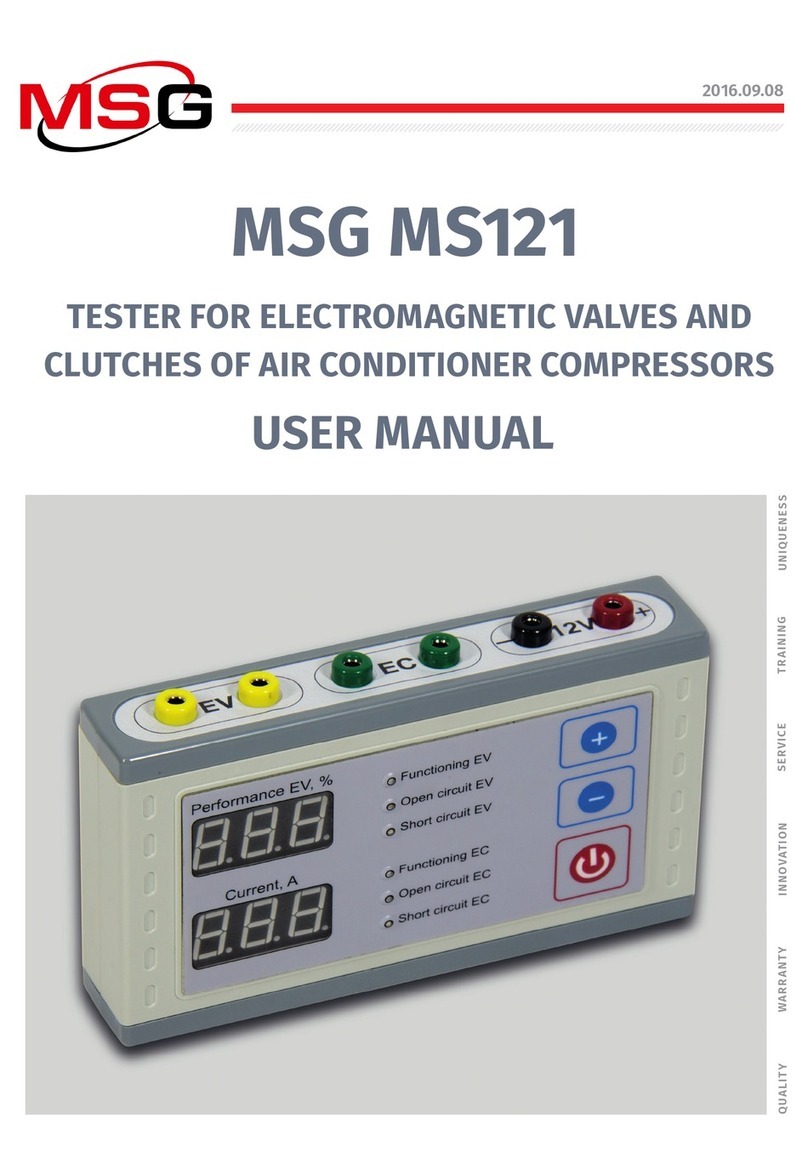

MSG Equipment MS121 User manual

MSG Equipment

MSG Equipment MS031 User manual

MSG Equipment

MSG Equipment MS1000+ User manual

MSG Equipment

MSG Equipment MS005 User manual

MSG Equipment

MSG Equipment MS300 User manual

MSG Equipment

MSG Equipment MS016 User manual

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started