SQD Series Torque Wrench

14. Once the Cap Screw is removed, use the pliers

to pull the Compression Member (item 2.9) from

the Piston Assembly. The Compression Member

(item 2.9) has a ball bearing in the threaded

hole, and is connected to the Piston Rod, (item

2.11) with a internal O-ring.

15. Push the Piston Rod (item 2.11) and Piston

Bottom, (item 2.12 ) out the back of the wrench

using a punch. A hammer is not necessary as

the Piston Assembly should come out freely.

16. Gently pull the Piston Bottom (item 2.12) from

the Piston Rod (item 2.11). It is also connected

together by an internal O-ring.

17. Remove the two bearings, Glyd-ring and O-ring

from the Piston Assembly.

18. To remove the two drive bearings (item 3.4), use

a socket and soft blow hammer to carefully drive

them out.

19. Use a brass pick to remove the Glyd-ring,

Bearing and O-rings in the Wrench Housing

(item 2.6).

INSPECTION

1. Examine the Wrench Housing’s interior, (item

2.6) for signs of wear or scratches.

2. Inspect the Compression Bolt (item 2.8) and

Ratchet Lever (item 3.8) for signs of excessive

wear.

3. Examine the Piston Assembly for signs of wear

and scratches that may cause leakage.

4. Inspect the Ratchet Wheel (item 3.5) and the

Ratchet Block (item 3.2) for broken teeth, cracks

and wear.

5. Examine all O-rings, Bearings, and Glyd-rings

for wear, scratches and possible deformation

from incorrect fluids.

6. Make sure all threads are in good condition.

ASSEMBLY

1. Replace two O-rings, bearing and Glyd-ring in the

Wrench Housing (item 2.6). To install the Glyd-

ring, form the ring as shown in Figure 1, and

then use round stock to reform the ring.

Note: When replacing seals, it is important to

use the grease provided in the repair kit when

reassembling.

2. Replace the two bearings, two O-rings, and the

Glyd-ring on the Piston Rod (item 2.11) and

Piston Bottom (item 2.12). Then push the two

pieces together.

3. Gently push the Piston Assembly into the

Wrench Housing (item 2.6), being careful not to

damage any seals or bearings.

4. Through the front of the wrench, push the

Compression Member (item 2.9), into the Piston

Rod (item 2.11). Position the larger end of the

Compression Member toward the top of the

wrench.

5. Reinstall the Cap Screw in the Piston Assembly,

while holding the Compression Member (item

2.9) in place with a pliers. Be careful not to

damage it.

6. If replacing drive bearings, use a socket to

push them back into place using a soft blow

hammer. Be careful not to damage bearings

during assembly.

7. The Compression Bolt (item 2.8) has a slight

offset hole to one side. The hole should face the

top of the Ratchet Lever (item 3.8) when rein-

stalling into the clearance hole.

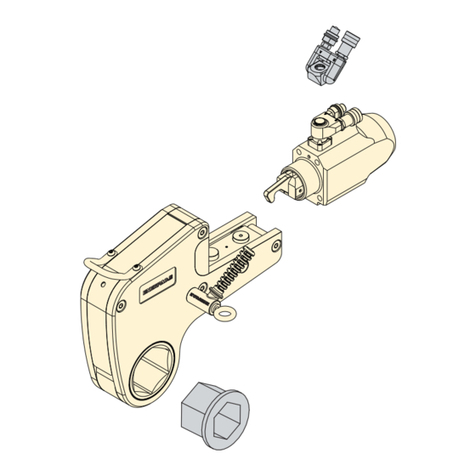

8. Place together the Ratchet Wheel (item 3.5) and

Ratchet Block (item 3.2). Slide these pieces into

the Ratchet Lever (item 3.8) with the springs.

Note: Make sure the Ratchet Wheel and

Block are both centered in the Ratchet Lever.

9. Push the Compression Member (item 2.9) into

the wrench so that the Ratchet Lever (item 3.8)

can be reinstalled.

10. Before installing the Ratchet Lever (item 3.8),

make sure the ball bearing is in the threaded

hole of the Compression Member (item 2.9).

11. Install the Ratchet Lever (item 3.8) into the

Wrench Housing (item 2.6).

2