8L4442

6.4 Nut and Bolt Loosening Information

•Be aware that more torque is usually required to

loosen a fastener than to tighten it.

•Rusted fasteners (humidity corrosion) may require

up to twice the torque required for tightening.

•Fasteners that are corroded due to contact with

sea water or chemicals will require up to two and a

half times the torque required for tightening.

•Heat corrosion requires up to three times the

torque required for tightening.

Do not apply more than 75 percent of the

wrench’s maximum torque when loosening nuts or

bolts. Avoid making sudden start-stop movements

(“shock loading”). Failure to observe these precautions

may cause a catastrophic failure of the wrench to occur,

and wrench components under high tension could

become dangerous projectiles. Serious personal injury

could result.

6.5 Loosening Procedure

•Apply penetrating oil to the threads. Allow the oil

to soak.

•Set the pump to 10,000 psi (Loosening torque

equals about 100% of tightening torque).

•Change the drive and the reaction arm to the

loosening mode, ensuring the reaction arm abuts

squarely o a solid reaction point.

• Start the pump.

•Operate the pump until the nut has been loosened.

If the bolt / nut does not loosen with the

above procedure, it is an indication that you require the

next larger size DSX to loosen the bolt

7.0 MAINTENANCE

Lubrication frequency depends on factors known only

to the user. The amount of contaminants in the working

area is one factor. Wrenches used in a clean room

environment will obviously require less maintenance

than wrenches used outdoors and dropped in loose dirt

or sand.

1. When lubrication is required, lubricate all moving

parts.

2. Springs are used for the drive pawl assembly.

These springs can be replaced if necessary.

3. If the cylinder requires disassembly, it is

recommended that the cylinder seals be replaced

at the same time. Seal kits are readily available.

4. Hoses should be checked for cracks and leaks

before, and after each job. Hydraulic fittings can

become plugged with dirt and should be flushed

periodically.

5. Fittings should be kept clean and not allowed to

be dragged along the ground or floor as even small

particles of dirt can cause the internal valves to

malfunction.

All structural parts on the tools should be inspected at

least once a year to determine if there are any cracks,

chips, or deformities.

Preventative maintenance can be performed by the

user.

Full maintenance must be performed only by an Enerpac

authorized service center or a qualified and experienced

technician.

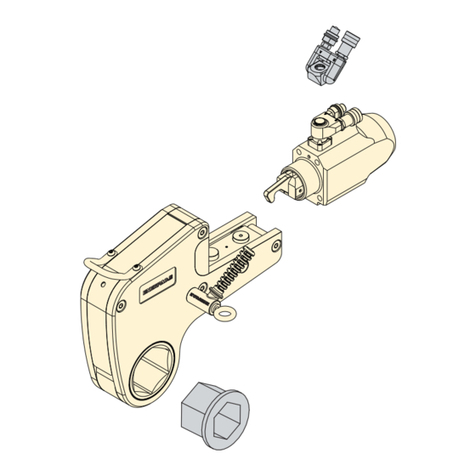

7.1 Preventative Maintenance (Fig.9/ Fig.10)

1. Check tightness of swivel assembly retaining

screws (40) and piston sleeve (7) (see Section 7.2).

2. Pressurize the wrench to 10,000 psi [690 bar]

pressure (in both advance and retract), and check

for any signs of leakage.

3. Relieve pressure and disconnect hydraulic hoses.

4. Clean all exposed components with a mild solvent.

5. Remove the shroud screws (11) and remove the

shroud (27). The tether (37) will continue to link the

shroud to the drive release assembly. To remove

the tether unscrew the round screw, slide o the

washer, and remove the tether line.

6. Remove the square drive (8) and drive retaining

release assembly (12, 13, 14) along with the two

bushes and drive retainer (9, 26)

7. Disengage the two access plugs (21), and slide out

the rod end pin (18). The drive plate (3) can now

separated from the wrench body (1).

8. Remove the ratchet (4), pawl (5) and pawl wave

springs (6).

9. Clean all components with a mild solvent.

10. Inspect all parts for damage. Any damaged

components must be replaced.

11. Dry all components. Apply a thin coat of

molybdenum disulphide grease in the areas shown

in Figure 10.

Be sure that the ratchet, drive plate, pawl,

pawl wave spring, square drive, and access plugs are

correctly installed in the following step. Ensure that the

square drive is inserted through the drive plate and rod

end of the piston assembly before installing the access

plugs. Failure to install these parts correctly will result in

component damage. Refer to figures 9 and 10.

12. Connect the wrench to the pump.

13. With wrench not on nut or bolt, check operation

at a nominal pressure to make sure the piston

advances and retracts freely.

14. Release the pressure and make sure that the piston

fully retracts.