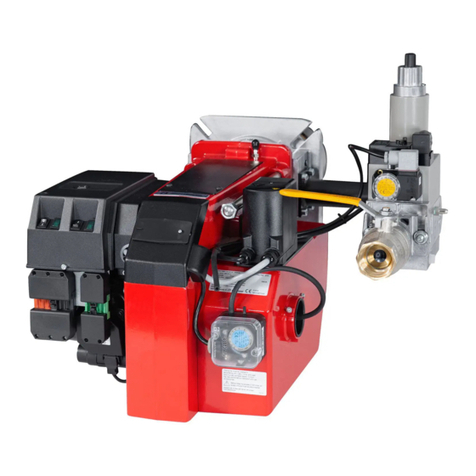

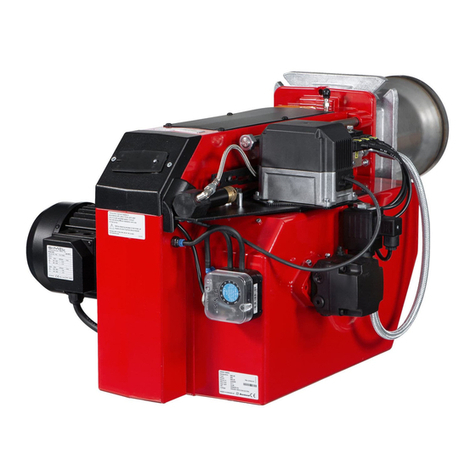

GENERAL INSTRUCTIONS

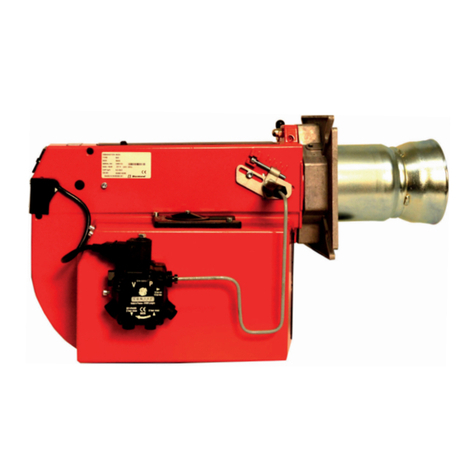

Adjustment of burner

The burner is from the factory pre-set

to an average value that must then be

inaccordancewithboilermanu-facturers

instructions. These must include the

average water temperature and CO2

or O2concentration.

General instructions

The installation of the gas burner

must be carried out in accordance

with current regulations and standards.

The installers of gas burners should

therefore be acquainted with all regu-

lations and ensure that the installation

complies with the requirements. The

should be made with the greatest

care and only the correct gas should

be used.

Operating instructions

The operating instructions accom-

panying the burner should be left

in a prominent position in the boiler

room.

Instructions

The user should be thoroughly

instructed in the function of the gas

burner and the whole installation.

The supplier must instruct the user.

Inspection and maintenance

Daily inspection is advisable.

Start up

the boiler and the electric connection,

the leakage control, the venting and

the electric function test have been

carried out, the burner will be ready

for start-up.

Howerer, study the sections dealing

-

bustion air and combustion head.

Open the ball valve and switch on the

main switch. If the burner starts the

Adjustment of burner head

-

ment device changing the position of

the brake plate in the burner head. This

drop over the combustion device in

order to obtain a good pulsation free

combustion.

Which position to use depends on

input and overpressure in the boiler.

172 305 28 07-01

A general rule is that the lower capacity

the smaller the opening between

brake plate and combustion device.

Commissioning of installation

Control of the combustion. The com-

bustion quality is checked by means

in accordance with the table. Check

gas volume on the gas meter so that

the correct input is achieved.

Service

Service should only be carried out

parts should be of the same make and

approved by the same authorities as

the original. If the burner is converted

re-commissioned. If town gas is to be

to suit (e.g.a larger gas armature or a

different spring in the governor may

be required).

Gas quality CO2

lambda 1,2

02max. CO2

Natural gas 10,0 3,5 11,9

LPG 11,5 3,5 13,9

ELECTRIC EQUIPMENT

Technical data

Reset after lock-out Immediately

Supervision of ionization current

Short circuit current max. 0,5 mA

Min. required ionization current 6 µ A

Recommended range of measuring device 0...50 µ A

a - b

Start-up sequence

b - b´

"idle steps" up to the self shut-down

of the sequence switch

b ( b´) - a

Post-purge sequence

172 405 27 07-01

a

b´

b

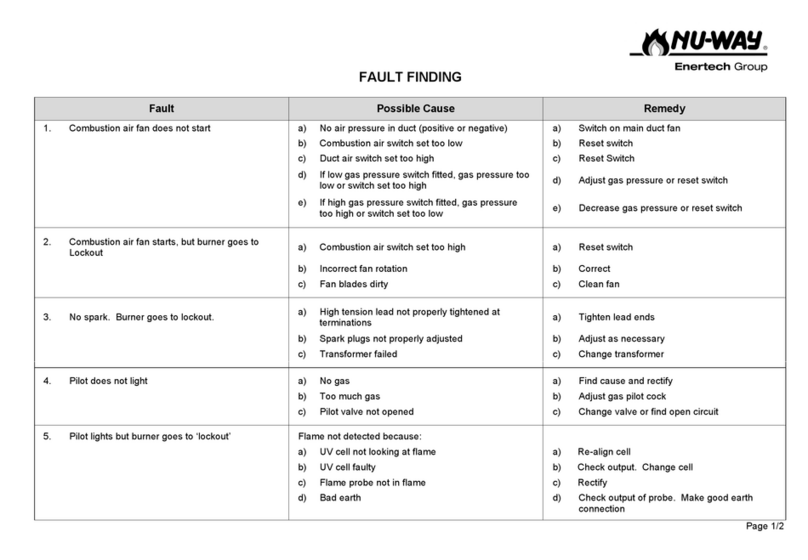

In the event of fault conditions the

fuel supply is always interrupted

immediately and, simultaneously,

the sequence switch stops and thus

the lockout indicator. The symbol

appearing above the reading mark

P Interruption of the start-up

sequence, because the OPEN

signal has not been supplied to

terminal 8 from damper motor

to switch «max.». Terminals 6,

7and 14 are under tension until

the fault has been remedied.

1 the fault has been remedied.

Lockout

signal has been received on

completion of the 1st safety

time.

time also causes the control

to go to lockout!

◄No start, because, e.g., the

CLOSE signal has not been

supplied to terminal 8 or a

contact has not been closed

between terminals 12 and 4

or 4 and 5.

▀ Lockout due to a fault in the

2 Lockout,

signal has been received on

completion of the 2nd safety

burners).

▲Interruption of the start-up

sequence, because the OPEN

signal has not been supplied to

terminal 8 from damper motor

to switch «max.». Terminals 6,

7and 14 are under tension until

the fault has been remedied.

▼ Interruption of the start-up

sequence, because the posi-

position has not been supplied

to terminal 8 by the damper

motor. Terminals 6, 7 and 14

are under tension until

▌ Lockout,

signal has been lost during

burner operation or air pressure

failure has occured.

◄ Lockout on completion

of control programme se-

quence due to extraneous light

leaking fuel valves) or due to

Control programme under fault conditions and lockout indication

gas burner control: LFL1....