Ennis-Flint StreetHeat SR-60Hybrid User manual

StreetHeat SR-60Hybrid

Operations Manual

Operations Manual Contents

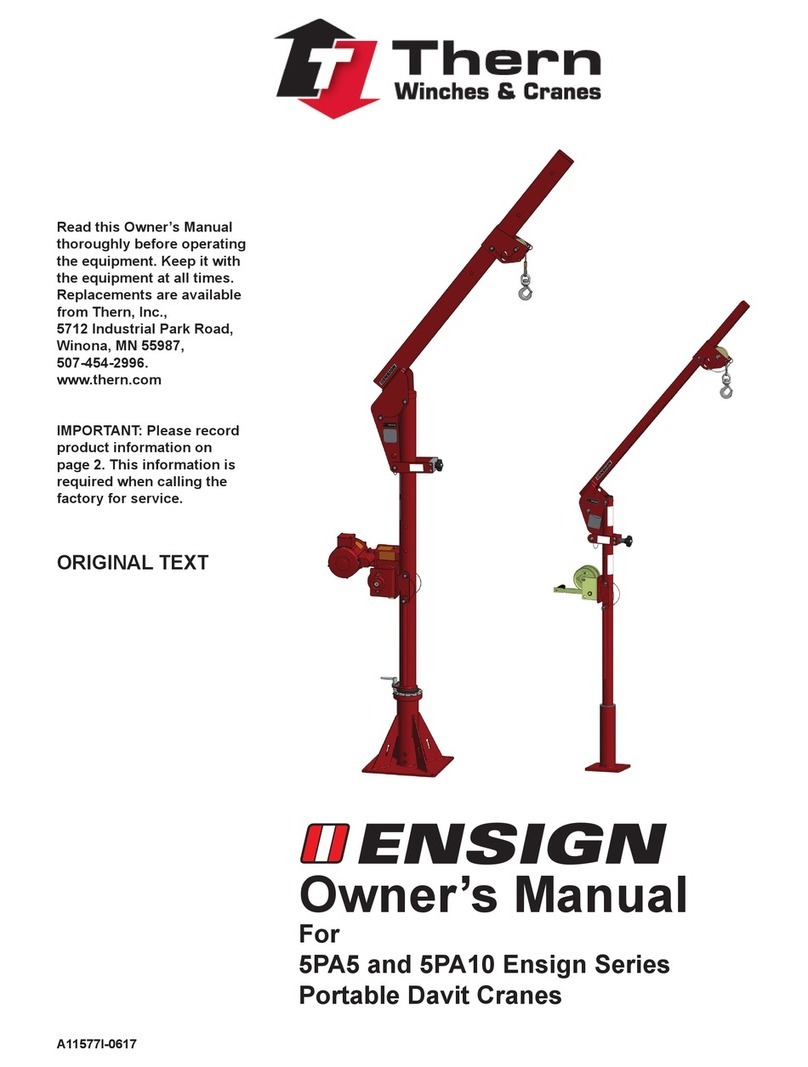

Machine in picture is an

model SR-60

Hyb

rid

2

3

1. Introduction

The SR-60Hybrid is a pavement heater designed specifically for imprinting of

asphalt pavements.

When asphalt pavement is heated, it

becomes soft, enabling it to be

imprinted using StreetHeat

templates.

Once printed and coated, the final

result is a beautiful, long lasting

StreetHeat textured asphalt

surface.

3. Safety

Key Safety Points

NOTE:

5

6

3. Safety – Cont’d

Safety - The SR60Hybrid is a propane-fired heating apparatus. Operating it

carelessly or without reading the operating instructions could lead to serious

injury. Keep everyone clear of the heaters while they ignite on the first

cycle.

Smoking - Never smoke when operating this equipment or while handling the

propane bottles and hoses.

Qualified Personnel

a) Operators must have read and fully understood this manual.

b) No one under the influence of drugs or alcohol should operate this

equipment.

Safety Equipment Required

a) Safety glasses

b) Gloves

c) Steel toe boots

d) Long pants

e) Ear protection

f) Fire extinguisher

g) High visibility vest

Propane Bottles

a) Always ensure that the propane bottles are safely secured to the

transport trailer when mobilizing.

b) Frequently check for leaky fittings using a small spray bottle containing a

soapy water solution.

c) Always transport propane bottles in the upright position and with the

regulator and hoses removed.

Front Leg-

Rails

CAUTION: Make sure the drive

belt is aligned.

Rail Clamps

4. Preparing for Work

7

8

4. Preparing for Work – Cont’d

4. Heater Wings - Fold down the

heater wings by releasing the

latch, ensuring that it hangs

into place at the desired height

setting.

5. Heater Wing Camber - The

heater wings have adjustable

settings to allow for variances

on the surface grade. Use the

lever and adjustable pins a the

top of the heater wing cable to

set the desired camber.

Machine in picture is an

older model SR-60

4. Preparing for Work - Cont'd

Propane Supply-

Electrical Supply

CAUTION:

9

10

4. Preparing for Work – Cont’d

9. Bottle Valves - Open the

propane bottle valves slowly and

check the bottle pressure

(gauge closest to tank). If

pressure is low the bottles

require refilling. Make sure that

regulator pressure (right hand

gauge) is set to a maximum of 50

psi

10. Power On Sequence

1. Start the generator.

2. Push the reset button on the

yellow ground fault protector on

the right hand side of the

handlebar.

3. Pull the red power button on the

main control panel. If the

counter numbers do not light up,

push the reset button on the

yellow plastic control housing

on the right-hand side of the

handle bar.

11. Cycle Counter - Set the cycle

counter, using the button below

each digit, to the desired number

of cycles. One cycle means that

the heater goes forward and back

one time. Each cycle takes 20

seconds, three cycles take 1

minute. Push reset only if you

have stopped mid-cycle.

11

4. Preparing for Work – Cont’d

12. Pilot Light Location - The two

pilot lights (left and right) are

located between the center heater

and each of the heater wings.

13. Lighting the Pilots – open fully

the brass pilot valve and ignite the

pilot flame using a common

barbecue lighter. If the main line

from the propane tanks is full of air,

it may take a few seconds to bleed

the air off before the pilots will light.

14. Pilots Verification - Once you can

see or hear that the pilot flames are

lit, the SR60Hybrid is ready to begin

heating the asphalt. If the pilots do

not ignite, the machine will sense

this and the propane gas to the

heaters will not turn on.

Machine in pictures

above are an older

model SR-60

5. Operating Procedure

12

13

5. Operating Procedure – Cont’d

3. Starting the Heater – Once the

pilot flames have been ignited,

the timer has been set to the

desired number of cycles and the

machine is positioned correctly,

simply push the green button to

start the heating process. This

will light the heaters and cause

them to move back and forth

automatically.

4. Cycles – One heating cycle is

defined as the heater moving all

the way forward and back again

once. Each cycle takes 20

seconds and three cycles takes

one minute. The counter shows

the preset number of cycles

(lower numbers) and the

remaining cycles (upper

numbers). Once all the cycles

have been completed, the

heaters will automatically stop

cycling and the propane will be

cut off. The pilot flames will

continue to burn.

5. Flame Safety System – The

heaters will only move if the pilot

lights are burning. Safety

regulations require that the pilot

light sensors are set at 200ºC.

Note: If the red light is on, it

indicates that the Pilot light is not

lit.

Cycles Remaining

Preset Cycles

Adjust Presets

14

5. Operating Procedure – Cont’d

6. Automated Heating – The heating,

cycling of the heaters and shut-off is

completely automated, once the

green start button is pressed. If the

red stop button is pressed, the

cycling immediately stops and the

propane gas to the heaters is shut

off. To restart the machine pull the

red power button out and press the

green start button. The cycles will

have been reset to the preset

number.

7. Surface Temperature – The asphalt

surface temperature should be

constantly monitored using an

infrared thermometer to ensure

correct heating is taking place. Avoid

over heating the asphalt surface.

Blue smoke indicates that

overheating is taking place, which

could affect coating bond. Do not

heat the surface above 300ºF

(150ºC).

8. Depth Probing – Check depth of

softening of the asphalt by pushing a

small screwdriver into into the

asphalt surface. Once the asphalt is

soft to a depth of ½” to ¾” imprinting

can take place.

Machine in picture is

older model SR-60

Machine in picture is

older model SR-60

15

5. Operating Procedure – Cont’d

9. One side is too hot - If the surface

becomes significantly hotter on one side

than the other (for example 300ºF

(150ºC) left side & 220ºF (105ºC) right

side) correct this by raising one of the

heater wings to even out the

temperature across the heated area.

10. If one side is done before the other –

you can individually control each heater

bank at the control panel, so you can

turn off one panel while continuing to

heat with the other banks. Remember to

turn the valve on again later.

Machine in picture is

older model SR-60

16

6' 6 "

3'

3'

3'

11. Short Cycle - manually override the automatic heating process in

order to control the length the heaters move on the carriage.

Front Short Cycle (the front is the end farthest from the operator),

push the Front Short Cycle button on the control panel to force the

heaters to return to the front.

Rear Short Cycle has the same effect, but from the end of the heater

stroke.

CAUTION: DO NOT USE THE SHORT CYCLE BUTTON TO HOLD

THE HEATER AT THE REAR FOR MORE THAN A FEW SECONDS,

OR TIRE OVERHEATING MAY OCCUR.

5. Operating Procedure – Cont’d

Short Cycle

Controls

Front short

cycle

Rear short

cycle

17

12. Heating Zones - There are three separate heating zones which

can each be controlled independently of one another using the

switches on the control panel. Each heater bank also has it own

individual 3rd stage regulator and solenoid, which should be set

between 6-8psi.

5. Operating Procedure – Cont’d

6' 6"

3'

3'

3'

3 ft x 6.5 ft

(0.9m x 2m)

3 ft x 6.5 ft

(0.9m x 2m)

3 ft x 6.5 ft

(0.9m x 2m)

Independent Regulators

and Solenoid Valves

5. Operating Procedure -Cont'd

Hills

H

Umbilical Cord

18

19

6. Main Controls

On/Off and

emergency stop

Cycle Counter

automatically

stops cycling at

the end of

countdown

Manual override

to shorten

heating area

Heater start

button

Master Propane

valve

simultaneously

controls all 3

heater banks

Individual

propane valves

control all 3

heater banks

individually

20

6. Main Controls

Electrical Wiring Diagram

Table of contents