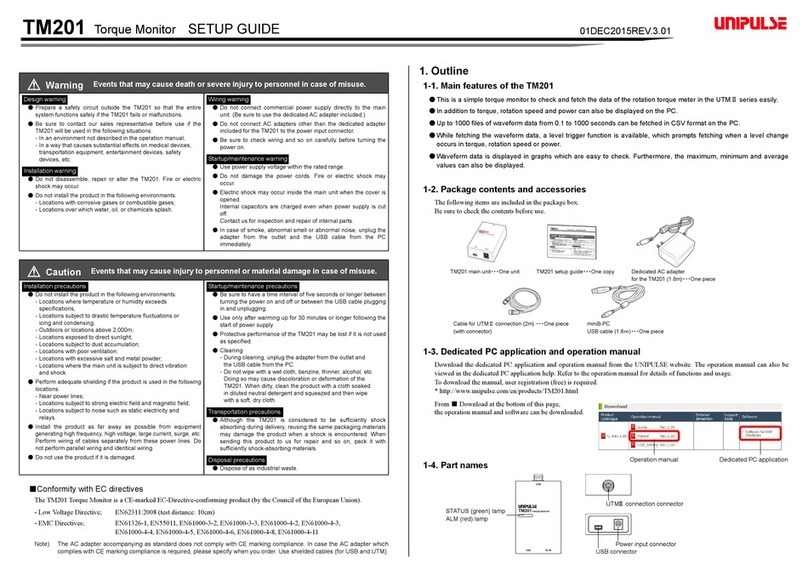

CONFORMITY TO EC DIRECTIVES

CONFORMITY TO EC DIRECTIVES

The F320 digital indicator conforms to EC directives (based on the EC Council of Ministers),

carrying a CE mark.

・Low-voltage directive:IEC/EN61010-1:2001(overvoltage category II)

・EMC directives: EN61326-1:1997, A1:1998, A2:2001

EN55011:1998, A1:1999 ClassA

EN61000-3-2:2000

EN61000-3-3:1995, A1:2001

EN61000-4-2:1995, A1:1998, A2:2001

EN61000-4-3:1996, A1:1998, A2:2001

EN61000-4-4:1995, A1:2001

EN61000-4-5:1995, A1:2001

EN61000-4-6:1996, A1:2001

EN61000-4-8:1993, A1:2001

EN61000-4-11:1994, A1:2001

RoHS-compliant product

The parts and attachments (including the instruction manual, packaging box, etc.) used for

this unit are compliant with the RoHS Directive restricting the use of hazardous substances

with regard to adverse effects on the environment and human body.

What is RoHS?

It is an abbreviation for Restriction on Hazardous Substances, which is implemented by the

European Union (EU). The Directive restricts the use of six specific substances in electric and

electronic equipment handled within EU borders. The six substances are lead, mercury,

cadmium, hexavalent chromium, PBB (polybrominated biphenyls), and PBDE

(polybrominated diphenyl ethers).

EN61000-4-5 (lightning surge immunity)in the EMC directives applies to

the F320 body and lightning surge protector in combination.

For the connection of the lightning surge protector, see page 14.

Please inquire of our sales person about the RoHS-compliance of the option.