TFP1241

Page 4 of 4

Copyright © 2005-2010 Tyco Fire Suppression & Building Products. All rights reserved.

5.

Verify that the Inlet Pressure Gauge

of the Pressure Regulator indicates

sufcient nitrogen cylinder pressure.

It is recommended that the nitrogen

cylinder be replaced whenever its

pressure falls to 200 psi or below.

NITROGEN CYLINDER REPLACE-

MENT PROCEDURE

Replace the nitrogen cylinder in accor-

dance with the following instructions.

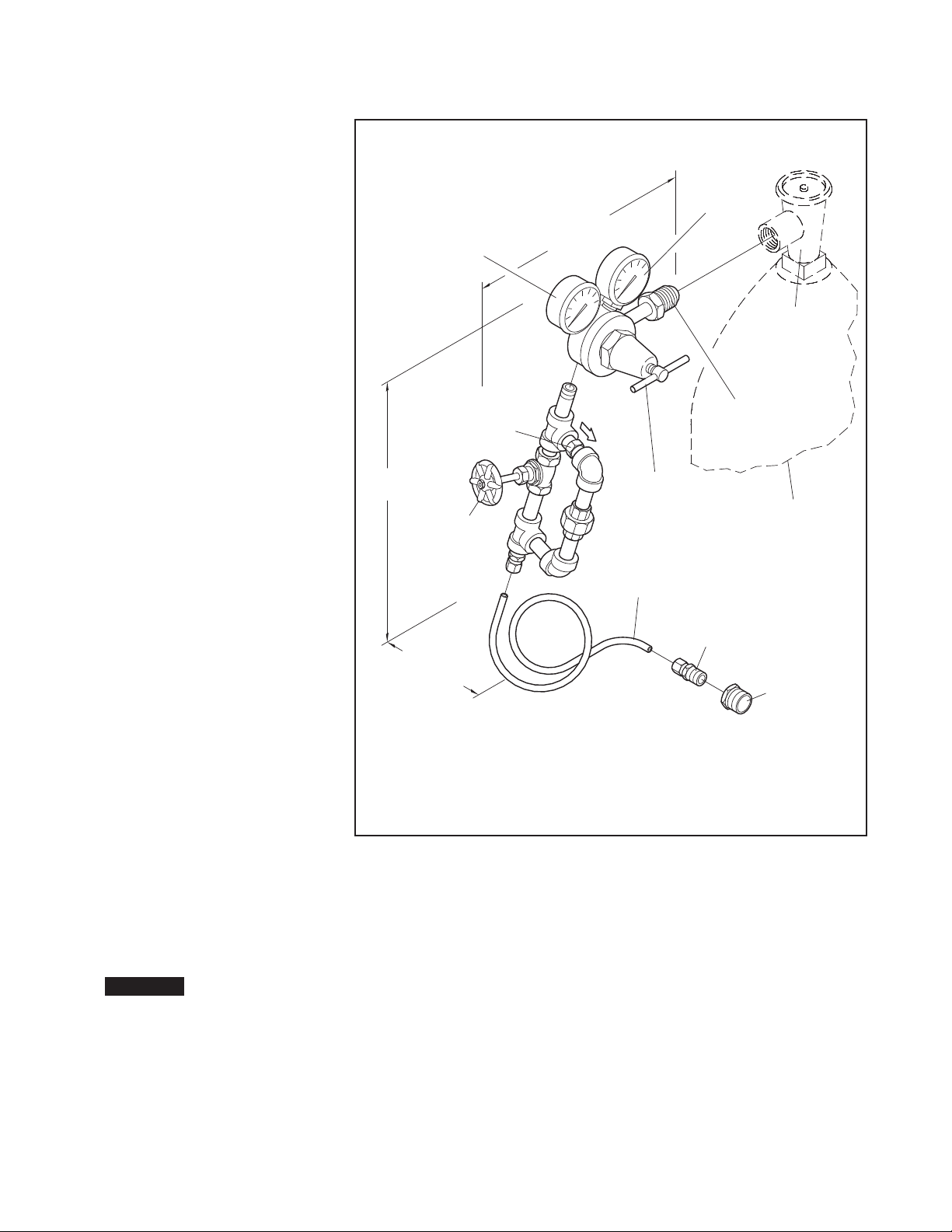

1.

Close the control valve in the air sup-

ply trim to the system.

2. Close the Cylinder Control Valve.

3.

Remove the Model AMD-3 Device

from the Cylinder Control Valve by

slowly unscrewing the inlet connec-

tion to the Pressure Regulator.

4.

Following the steps outlined in the

caution below, replace the nitrogen

cylinder.

CAUTION

The following instructions with re-

gard to the nitrogen cylinder must

be strictly followed. Failure to do

so may result in personal injury or

property damage.

a. Secure the cylinder to a wall or

post, ensuring that it will not tip

or fall if accidently bumped.

b.

Inspect the Cylinder Control

Valve outlet for dirt, dust, dam-

aged threads, oil, or grease. Re-

move dirt and dust with a clean

cloth. If damaged threads, oil,

or grease are present, replace

the cylinder.

c.

Inspect the Pressure Regula-

tor inlet for dirt, dust, damaged

threads, oil, or grease. Re-

move dirt and dust with a clean

cloth. If damaged threads, oil,

or grease are present, have the

pressure regulator serviced by

an authorized agent of the Vic-

tor Equipment Company.

d.

With the cylinder securely in

place and while standing to

the side or rear of the Cylin-

der Control Valve, momentarily

crack open the Cylinder Control

Valve. This procedure is intend-

ed to blow out any foreign mat-

ter that may be inside the valve

outlet.

e.

Attach the Model AMD-3 Device

to the Cylinder Control Valve

and securely wrench-tighten.

5.

Open the Cylinder Control Valve in

accordance with Step 4 in the Op-

erating Procedure section.

6.

Open the control valve in the air sup-

ply trim to the system.

7.

Check the Pressure Regulator con-

nection for leaks.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are warranted solely to the

original Buyer for ten (10) years against

defects in material and workmanship

when paid for and properly installed

and maintained under normal use and

service. This warranty will expire ten

(10) years from date of shipment by

TFSBP. No warranty is given for prod-

ucts or components manufactured by

companies not afliated by owner-

ship with TFSBP or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modied or repaired in

accordance with applicable Standards

of the National Fire Protection Asso-

ciation, and/or the standards of any

authorities having jurisdiction. Mate-

rials found by TFSBP to be defective

shall be either repaired or replaced, at

TFSBP’s sole option. TFSBP neither

assumes, nor authorizes any person

to assume for it, any other obligation

in connection with the sale of products

or parts of products. TFSBP shall not

be responsible for sprinkler system de-

sign errors or inaccurate or incomplete

information supplied by Buyer or Buy-

er’s representatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential

damages, including but not limited to

labor charges, regardless of whether

TFSBP was informed about the pos-

sibility of such damages, and in no

event shall TFSBP’s liability exceed an

amount equal to the sales price.

The foregoing warranty is made in lieu

of any and all other warranties, express

or implied, including warranties of mer-

chantability and tness for a particular

purpose.

This limited warranty sets forth the

exclusive remedy for claims based on

failure of or defect in products, materi-

als or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full

extent permitted by law. The invalidity,

in whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name, including de-

scription and Part Number (P/N).

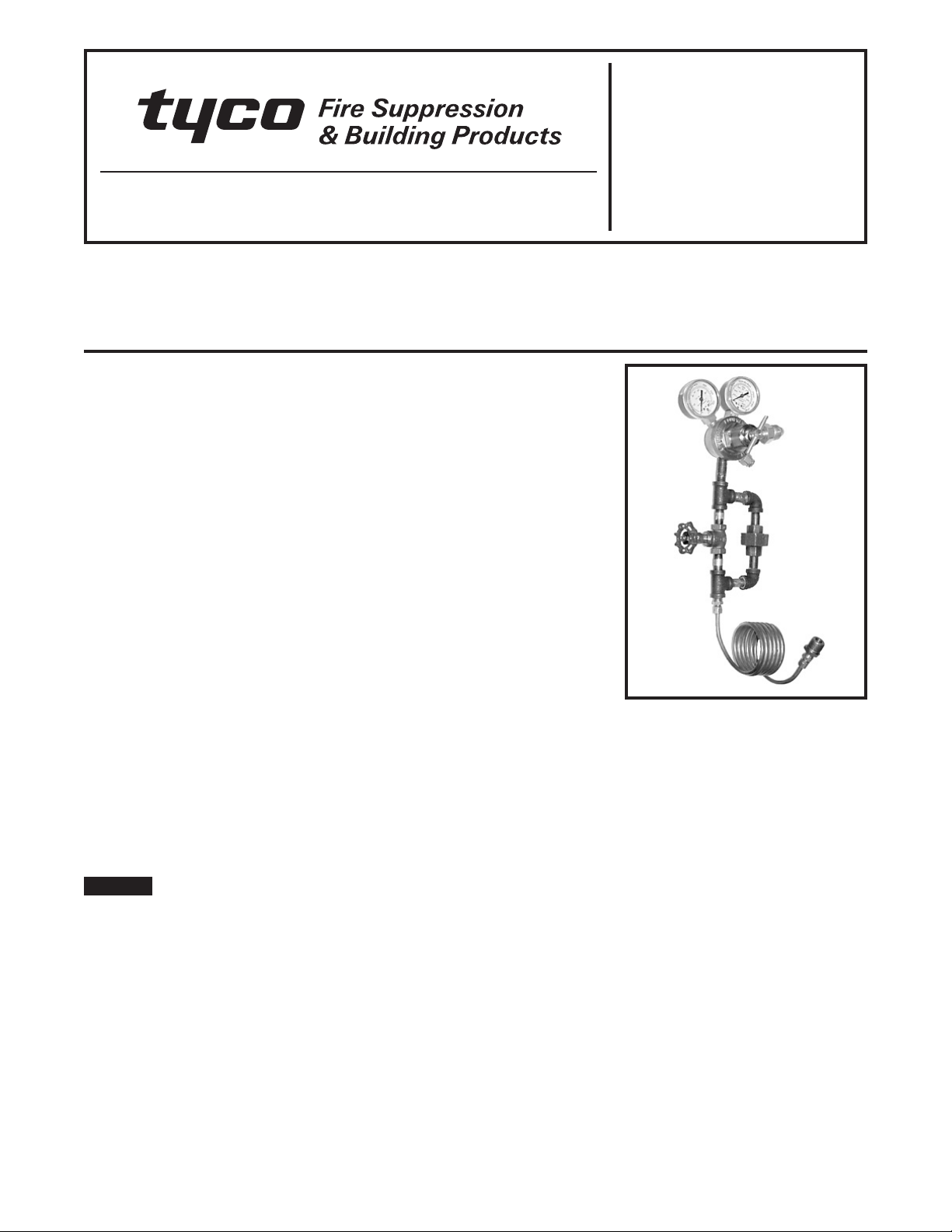

Model AMD-3 Device

Specify: Model AMD-3 Automatic

Nitrogen Maintenance Device,

P/N 52-328-2-001.

Replacement Parts

Specify: (description) for use

with the Model AMD-3 Automatic

Nitrogen Maintenance Device,

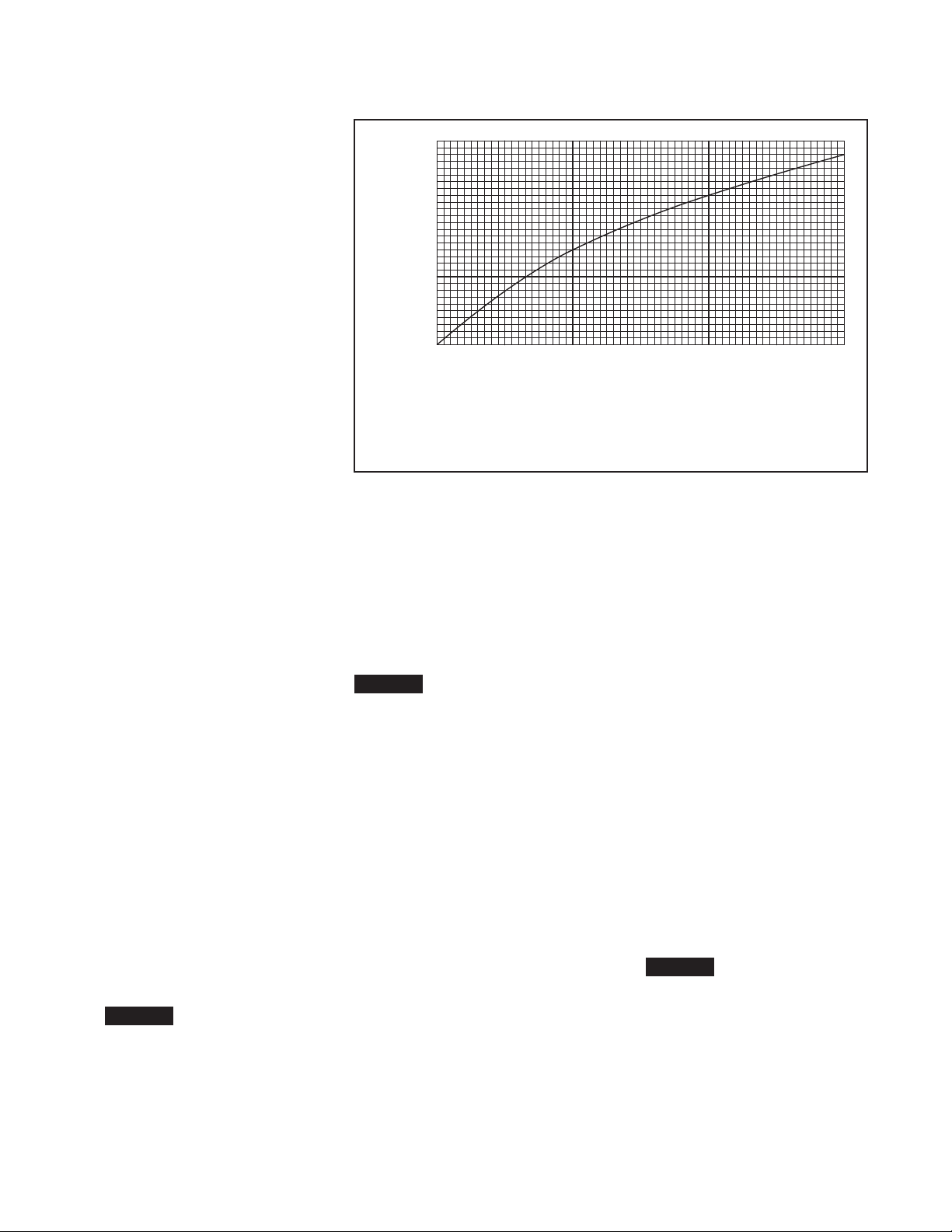

P/N (from Figure 1).