10

IP1938EN - 2017-12-07

Display Application Description

TO - Setting the secondary automation opening time with interlocked bar-

riers. [s]

00 - Minimum

30 - Maximum

TS - Setting renewal of automatic closing time after safety release. [%]

00 - Minimum

99 - Maximum

WO - Setting opening preflashing time. [s]

Adjustment of the lead time for the switch-on of the flashing light, in relation to

the start of the manoeuvre from a voluntary command.

00 - Minimum

05 - Maximum

WC - Setting closing preflashing time. [s]

Adjustment of the lead time for the switch-on of the flashing light, in relation to

the start of the manoeuvre from a voluntary command.

00 - Minimum

05 - Maximum

US - Selecting contact C-NO use.

OF - Contact C-NO always open

01 - Courtesy light or independent light

02 - Flashing light

(see QIK80EH installation manual)

03 - Barrier closed signalling

04 - Barrier open signalling

05 - Barrier operating signalling

06 - Barrier opening signalling

07 - Barrier closing signalling

ON - Contact C-NO always closed

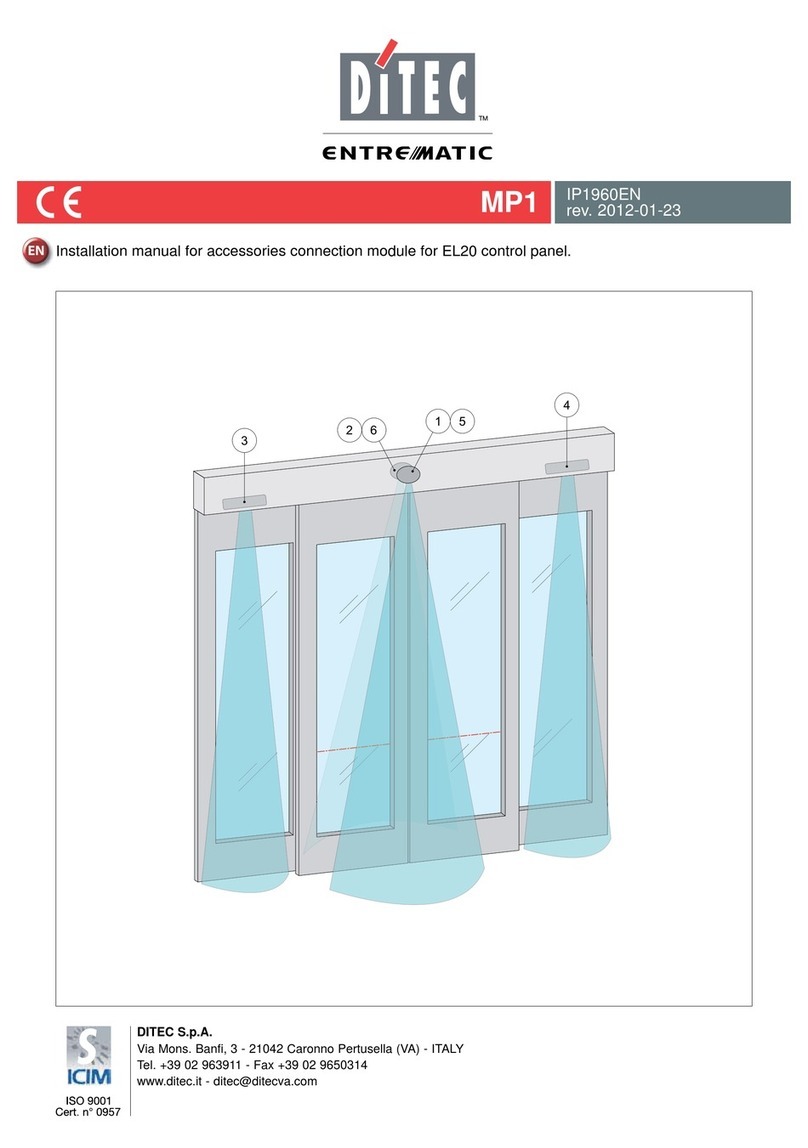

MP1

LU - Setting switch-on time for courtesy light. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 1” to 59” with 1 second intervals;

- from 1’ to 2’ with 10 seconds intervals;

- from 2’ to 3’ with 1 minute interval;

NO - Disabled

ON - Permanent switch-on, switch-off using radio command (only QIK80EH).

LG - Setting switch-on time for independent light. [s]

Adjustment occurs with intervals of varying sensitivity.

- from 1” to 59” with 1 second intervals;

- from 1’ to 2’ with 10 seconds intervals;

- from 2’ to 3’ with 1 minute interval;

NO - Disabled

ON - Switch-on and switch-off using radio command.

BA

i

NOTE: the courtesy light switches on at the start of each operation.

i

NOTE: the switching on of the light does not depend on the start of an

operation, but it is possible to control it separately using the relevant

transmitter key.