Entron iPAK2v2 User manual

User Manual

iPAK2v2 Weld Control

Firmware Version

V2.10

May 22

Document No. 700253-2

2 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

DISCLAIMER

Information contained in this document is believed to be accurate and reliable. The manufacturer does not provide any

representations or warranties, expressed or implied, as to the accuracy or completeness of such information and shall

have no liability for the consequences of use of such information. The manufacturer reserves the right to make changes

to information published in this document, including without limitation specifications and product descriptions, at any

time and without notice.

BF ENTRON accepts no liability for any injury, loss or damage caused by improper installation, use or application of its

products. The user shall only use the product for purposes that are proper and in accordance with all applicable laws,

rules, and regulations.

Copyright © 2022 by BF ENTRON

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any

means, including photocopying, recording, or other electronic or mechanical methods, without the prior written

permission of the publisher.

TRADEMARKS

BF ENTRON and/or its affiliates’ trademarks may not be used in connection with any product or service that is not BF

ENTRON’s, in any manner this is likely to cause confusion among customers or in any manner that disparages or

discredits BF ENTRON. All other trademarks not owned by BF ENTRON are the property of their respective owners, who

may or may not be affiliated with, connected to, or sponsored by BF ENTRON.

3 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

Document Revisions

Languages

This document is only published in the English language.

Date

Document

Number

Approved

By

Document Changes

14-01-2022

700253-0

Kelby

Henn

Initial release of iPAK2v2 Manual on new template

22-03-2022

700253-1

Sean

Simmons

Added New Images.

05-05-2022

700253-2

Sean

Simmons

Added Programming Parameters section. Added Valve Delays

feature.

4 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

Table of Contents

1BACKGROUND .................................................................................................................................................. 9

1.1 Description of the User .............................................................................................................................. 9

1.2 Conventions Used in This Manual.............................................................................................................. 9

1.3 Explanation of Symbols............................................................................................................................ 10

1.4 Important Safety Instructions .................................................................................................................. 11

1.5 Technical Support .................................................................................................................................... 13

1.5.1 Internet...............................................................................................................................................................13

1.5.2 Documentation Request.....................................................................................................................................13

1.5.3 Service and Technical Support............................................................................................................................13

2INTRODUCTION .............................................................................................................................................. 14

2.1 Weld Control ............................................................................................................................................ 14

2.2 Features ................................................................................................................................................... 14

2.3 Product Specifications.............................................................................................................................. 15

2.3.1 Power Specifications...........................................................................................................................................16

2.3.2 Function and Monitoring Specifications.............................................................................................................17

2.3.3 iPAK2v2 Weld Timer Specifications ....................................................................................................................17

2.3.4 Environmental Specifications .............................................................................................................................18

2.4 Main Component Overview ..................................................................................................................... 19

2.5 Wiring Diagrams...................................................................................................................................... 20

2.5.1 Customer Connections Diagram (3U3661).........................................................................................................21

2.5.2 Wiring Diagram (3U3719)...................................................................................................................................22

2.6 Standard Machine ................................................................................................................................... 23

2.7 Multi-Welding Machine........................................................................................................................... 24

2.8 Modes of Current Control ........................................................................................................................ 26

2.8.1 Pulse Width Mode “P/W”...................................................................................................................................27

2.8.2 Constant Current Uncalibrated Mode “CCu”......................................................................................................27

2.8.3 Constant Current Calibrated Mode “CCC”..........................................................................................................27

2.9 Installation............................................................................................................................................... 28

2.9.1 Installation Instructions......................................................................................................................................28

2.9.2 Configure the Control .........................................................................................................................................33

2.9.3 Current Calibration .............................................................................................................................................41

2.10 Force Calibration...................................................................................................................................... 56

5 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2.10.1 Force Calibration Procedure...............................................................................................................................58

2.11 Preventative Maintenance....................................................................................................................... 60

3COMMUNICATIONS SETUP ............................................................................................................................ 61

3.1 Overview .................................................................................................................................................. 61

3.2 Set the IP Address of the Control ............................................................................................................. 62

3.3 Ethernet Communications ....................................................................................................................... 65

3.3.1 Connect via NetFlash™ Programming Software.................................................................................................65

3.3.2 Configure for EtherNet/IP (EIP) ..........................................................................................................................67

3.3.3 Configure for MODBUS-TCP/IP...........................................................................................................................68

3.4 MODBUS-RTU .......................................................................................................................................... 69

3.5 WSP3 Pendant ......................................................................................................................................... 71

4ENTRON PROGRAMMING TOOLS................................................................................................................... 72

4.1 NetFlash™ ................................................................................................................................................ 72

4.1.1 System requirements..........................................................................................................................................72

4.1.2 Installing NetFlash™............................................................................................................................................73

4.1.3 Removing NetFlash™..........................................................................................................................................73

4.1.4 Running NetFlash™.............................................................................................................................................73

4.1.5 Main window components.................................................................................................................................73

4.1.6 The target IP address..........................................................................................................................................75

4.1.7 Restart control....................................................................................................................................................76

4.1.8 Control type........................................................................................................................................................76

4.1.9 Networks window...............................................................................................................................................77

4.1.10 Edit Control Parameters .....................................................................................................................................79

4.1.11 Editing Parameters .............................................................................................................................................81

4.1.12 Log Tab................................................................................................................................................................82

4.1.13 Flash Programming Tool.....................................................................................................................................83

4.1.14 Setup NetFlash™ Users/Security ........................................................................................................................85

4.2 WSP3........................................................................................................................................................ 87

4.2.1 Keypad ................................................................................................................................................................87

4.2.2 Diagnostic Screen ...............................................................................................................................................88

4.2.3 Menus.................................................................................................................................................................89

5PROGRAMMING WELD PROGRAMS .............................................................................................................. 90

5.1 Overview .................................................................................................................................................. 90

5.2 What is a weld program? ........................................................................................................................ 90

6 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

5.3 Parameters .............................................................................................................................................. 91

5.4 Weld Program Types................................................................................................................................ 97

5.5 Programming a Spot Weld with the WSP3 ............................................................................................ 104

5.6 Programming a Spot Weld with NetFlash ............................................................................................. 110

5.7 Program Selection.................................................................................................................................. 115

5.7.1 Internal Program Selection...............................................................................................................................115

5.7.2 External Program Selection ..............................................................................................................................115

5.7.3 Program Selection for Spot Welding ................................................................................................................115

5.7.4 Program Selection for Seam Welding...............................................................................................................115

6FAULTS & TROUBLESHOOTING .................................................................................................................... 116

6.1 Fault and Status Messages .................................................................................................................... 116

6.2 LED Indicators on Timer ......................................................................................................................... 118

6.2.1 Heartbeat LED...................................................................................................................................................118

6.2.2 Ready LED .........................................................................................................................................................119

6.2.3 Sequence LED ...................................................................................................................................................119

6.2.4 Weld LED...........................................................................................................................................................119

6.2.5 Data Send/Receive LEDs...................................................................................................................................119

6.2.6 Network Status / Module Status LEDs..............................................................................................................119

6.3 How to Reset Faults ............................................................................................................................... 120

6.3.1 WSP3 Pendant ..................................................................................................................................................120

6.3.2 NetFlash™ Software..........................................................................................................................................120

6.3.3 Discrete Input ...................................................................................................................................................121

6.3.4 Fieldbus Input ...................................................................................................................................................121

7INPUTS & OUTPUTS...................................................................................................................................... 122

7.1 Inputs ..................................................................................................................................................... 122

7.2 Outputs .................................................................................................................................................. 124

7.3 Discrete Connections ............................................................................................................................. 125

7.3.1 Inputs................................................................................................................................................................125

7.3.2 Outputs.............................................................................................................................................................125

7.3.3 Analog Signals (0 to 10V) ..................................................................................................................................125

7.3.4 Discrete Connections Schematic ......................................................................................................................126

7.3.5 Softstart............................................................................................................................................................127

8READ & WRITE DATA WITH EXTERNAL DEVICES.......................................................................................... 128

8.1 Overview ................................................................................................................................................ 128

7 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

8.2 MODBUS ................................................................................................................................................ 128

8.2.1 Function Codes .................................................................................................................................................128

8.2.2 Inputs................................................................................................................................................................128

8.2.3 Outputs.............................................................................................................................................................130

8.2.4 Programming Parameters.................................................................................................................................137

8.3 Ethernet/IP (EIP) .................................................................................................................................... 149

8.3.1 Implicit Messaging............................................................................................................................................149

8.3.2 Explicit Messaging.............................................................................................................................................150

9ADVANCED FEATURES.................................................................................................................................. 152

9.1 History Log ............................................................................................................................................. 152

9.1.1 Currents............................................................................................................................................................152

9.1.2 Force.................................................................................................................................................................152

9.1.3 Viewing the Log ................................................................................................................................................153

9.1.4 Exporting History Log........................................................................................................................................154

9.1.5 Resetting History Log........................................................................................................................................154

9.2 Security Settings..................................................................................................................................... 155

9.2.1 PIN Codes..........................................................................................................................................................156

9.2.2 Edit Switch ........................................................................................................................................................156

9.2.3 NetFlash™ User Security...................................................................................................................................157

9.3 Updating the Firmware.......................................................................................................................... 158

9.4 Backup & Restoring ............................................................................................................................... 160

9.4.1 WSP3 Pendant ..................................................................................................................................................160

9.4.2 NetFlash............................................................................................................................................................165

9.5 Electrode Management ......................................................................................................................... 166

9.5.1 Steppers............................................................................................................................................................166

9.5.2 Counters ...........................................................................................................................................................169

9.5.3 Calibration ........................................................................................................................................................171

9.6 Seam Welding........................................................................................................................................ 172

9.6.1 Programming a Seam Weld with NetFlash.......................................................................................................172

9.7 Multi-weld Operations........................................................................................................................... 177

9.7.1 Electrode & Transformer Assignment ..............................................................................................................177

9.7.2 Linking Programs ..............................................................................................................................................179

9.7.3 Multi-Electrode Operation................................................................................................................................180

9.7.4 Cascade Operation............................................................................................................................................184

8 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

9.8 Analog Control Mode............................................................................................................................. 186

9.9 Valve Control.......................................................................................................................................... 187

9.10 Valve Delays........................................................................................................................................... 188

9.10.1 Programming Valve Delay Parameters using NetFlash.....................................................................................189

9.10.2 Programming Valve Delay Parameters using WSP3 .........................................................................................192

9.11 Current Limits......................................................................................................................................... 194

9.12 Duty Cycle Limiter .................................................................................................................................. 196

10 TUTORIALS.................................................................................................................................................... 197

10.1 Controlling an Air over Oil System ......................................................................................................... 197

10.2 Using Valves to Control a Multi-Head Machine..................................................................................... 199

10.2.1 Configure Control for Extended Mode .............................................................................................................199

10.2.2 Configure the Control for Multi-Electrodes......................................................................................................200

10.2.3 Program the WAV Output for Each Weld Program in the Cascade Sequence .................................................201

10.2.4 Link Programs Together (Cascade) ...................................................................................................................203

10.3 Controlling a Multi-Welder/Cascade ..................................................................................................... 205

10.3.1 Configure Control for Extended Mode .............................................................................................................205

10.3.2 Assign Electrode to a Transformer ...................................................................................................................207

10.3.3 Programming a Multi-Welder/Cascade Sequence ...........................................................................................207

10.4 Configuring & Calibrating iPAK2v2 with the WSP3 Pendant ................................................................. 209

10.4.1 Configure the Weld Control..............................................................................................................................210

10.4.2 Reset & Turn Off Electrode Stepper .................................................................................................................212

10.4.3 Calibrate Current (Toroid / Rogowski coil) .......................................................................................................213

10.4.4 Calibrate CCC –Constant Current Calibrated ...................................................................................................216

10.4.5 Set the Regulation configuration setting to Secondary....................................................................................219

11 TERMINOLOGY ............................................................................................................................................. 220

12 ADDITIONAL WIRING DIAGRAMS................................................................................................................. 222

12.1 Customer Connections Diagram (3U3661) ............................................................................................ 222

12.2 3U3721................................................................................................................................................... 223

12.3 3U3722................................................................................................................................................... 224

12.4 3U3723................................................................................................................................................... 226

BACKGROUND

Description of the User

9 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

1BACKGROUND

1.1 Description of the User

This manual has been written to inform qualified custom equipment manufacturers, integrators, control engineers, weld

engineers, and/or maintenance technicians how to safely install, setup, operate, and maintain the weld control.

Qualified Personnel Only

The information contained in this manual is intended for Qualified Personnel, as defined

by the National Electrical Code (NEC). Always follow Electrical Safety in the Workplace

per NFPA 70E or equivalent standard in your location.

This manual has been written for the iPAK2 MFDC weld control product line with an iPAK2v2 weld timer. The manual

applies to the V2.09 version of firmware on the iPAK2v2 timer.

This document should be carefully read before installing and operating the weld control. Failure to follow the

instructions defined in this manual could create a safety hazard or impact the warranty on the product.

1.2 Conventions Used in This Manual

The following style conventions are used in this document:

Bold Italics type font is used for emphasis

•Bulleted lists generic lists and do not define a sequence or procedures

1) Numerical lists define a sequence or procedures

Courier text is used for system output, such as an error message or script

URLs, complete paths, filenames, prompts, and syntax

BACKGROUND

Explanation of Symbols

10 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

1.3 Explanation of Symbols

This section defines the symbols used throughout this document.

DANGER!

Danger indicates a hazard with a high level of risk which, if not avoided, will result in

immediate, serious personal injury or loss of life. Examples are: exposed high voltage;

exposed fan blades.

WARNING!

The Warning symbol indicates a hazard with a potential hazard which could result in

personal injury or loss of life. Examples are: not using proper personal protect; removal

of guards.

CAUTION!

The Caution symbol indicates a hazard which could result in non-life threating personal

injury or damage to equipment. CAUTION may also be used to alert against unsafe

practices.

PACEMAKER

Individuals with cardiac devices should maintain a safe distance due to strong magnetic

fields arising from resistance welding. The function of cardiac pacemakers and

defibrillators may be disturbed, which may cause death or considerable health

damages! These persons should avoid the welding system unless authorized by a

licensed physician.

NOTICE

The Notice symbol is used for making recommendations on use or supplementary

information. Non-compliance with these recommendations may result in damage to the

control, welding machine or workpiece and voiding of the warranty.

HELPFUL TIP

The Helpful Hint symbol is used to provide additional information on a topic that may be

helpful to the user.

BACKGROUND

Important Safety Instructions

11 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

1.4 Important Safety Instructions

Before installing, starting up, or operating the iPAK2v2, carefully read all safety instructions to ensure safe use of

the product.

SAVE THESE INSTRUCTIONS

The safety instructions are part of the product. Keep the instructions in a safe and easily accessible place near

the product.

Never open the enclosure door when the breaker is in the ON position.

Never operate control with the door open.

Always disconnect power to the weld control before servicing or establishing electrical

connections with the product.

Use product only as described in this manual.

Stop Operation if any problems occur. If the equipment is not working as it should, has

been dropped, damaged, left outdoors, or has been in contact with water, contact

ENTRON.

Only apply the specified power. Application of a voltage or current beyond the specified

range can cause electric shock or fire.

Upon receipt of unit, inspect unit for damage from shipping. Before applying power to

product, inspect electrical connections to verify the connections are secure.

BACKGROUND

Important Safety Instructions

12 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

Except for the internal water-cooling system, keep water and water containers away

from product. Water ingress can cause a short circuit, electric shock, or fire.

Keep free of dust and debris.

Do not install the product in any of the following environments:

damp environments where humidity is 90% or higher;

dusty environments; environments where chemicals are handled;

environments near a high-frequency noise source;

hot environments where temperatures are above 40° C / 104° F;

cold environments where temperatures are below 0° C / 32° F;

environments where water will condense.

It is not recommended that holes be drilled into the cabinet. Metal debris inside the

cabinet can cause a short circuit, electric shock, or fire. If holes must be drilled is

imperative that all components are protected from debris. Drilling holes in the cabinet

may allow dust and other materials to enter the cabinet.

Individuals with cardiac devices should maintain a safe distance due to strong magnetic

fields arising from resistance welding. The function of cardiac pacemakers and

defibrillators may be disturbed, which may cause death or considerable health

damages! These persons should avoid the welding system unless authorized by a

licensed physician.

Always ensure cooling water is adequately flowing at the proper rate, temperature, and

is of sufficient quality. For water quality requirements, refer to AWS J1.2M/J1.2.2016

Guide Installation and Maintenance of Resistance Welding Machines.

BACKGROUND

Technical Support

13 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

1.5 Technical Support

1.5.1 Internet

The latest version of the documentation and other helpful resources in the ENTRON Document Library page found in the

Resource section of the ENTRON website: https://www.entroncontrols.com

1.5.2 Documentation Request

Documentation, user instructions and technical information can be requested by emailing ENTRON Controls at

Please include your name and email

1.5.3 Service and Technical Support

For service and technical support, we request that customers fill out the Technical Support Form found on our website

at link below:

TECHNICAL SUPPORT FORM LINK

https://www.entroncontrols.com/resources/technical-support.html

After the web form has been completed, your case will be assigned to one of our technical specialists who will contact

you directly.

For all other questions, our customer service team is available to assist. The contact information for each our

manufacturing and service sites is shown in the table below. Please contact the site for your specific region.

Manufacturing Site

Country

Phone

Email

Regions Supported

ENTRON UK

England

+44-1384-455401

Europe, Asia, Africa, Rest of

World

ENTRON US

USA

+1-864-416-0190

USA, Canada

ENTRON MX

Mexico

+52-844-415-9081

Mexico, Central America

INTRODUCTION

Weld Control

14 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2INTRODUCTION

2.1 Weld Control

The iPAK2v2 Weld Control is a Medium Frequency Direct Current (“MFDC”) electronic inverter that controls the

energizing power for a medium frequency welding transformer. The inverter control is powered from a standard 3 Phase

50/60 Hz supply and provides a 1 kHz output.

MFDC weld controls are commonly used in many resistance welding applications. They are more energy efficient and

can produce a higher quality weld process than AC weld controls.

Advantages of MFDC relative to AC welding:

•Reduced cost per weld

•True 3 phase load distribution with reduced primary currents

•Better power factor

•Capacitive mains loading

•High rate of heat input, resulting in reduced weld times

•Lower peak currents making expulsion (ie weld splash) less likely

•High secondary current capability

•High speed constant current response

•Longer electrode life due to shorter weld times

•Requires smaller welding transformer size

2.2 Features

The iPAK2v2 weld control is designed for a number of resistance welding processes. These include spot, spot repeat,

projection, multi-welding, roll-spot, and seam welding. The iPAK2v2 weld controller is available in a range of current

outputs, ranging from 360 Amps up to 6,000 Amps primary current. The iPAK2v2 product portfolio covers a number of

industrial resistance welding applications ranging from precision micro-welding of thin sheets all the way to heavy

industrial applications such as coil joining in steel mills.

The primary features are:

•Store up to 256 weld schedules (Programs)

•Data log for up to 6,000 welds

•Real time clock

•3 weld intervals: Pre-Heat + Main Heat + Post Heat

•Secondary or Primary constant current regulation

•Built in Ethernet/IP

•2 Analog Inputs (0 –10 V)

•1 Analog Output

•16 Discrete Inputs & Outputs (24 V dc short circuit protected, monitored guided contact relay)

•Aux Valves (7)

INTRODUCTION

Product Specifications

15 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

•Four modes of programming control (WSP3 Hand Held Pendant, NetFlash™ Software, MODBUS,

Ethernet/IP)

•Analog control mode

•Force profiling

•Electrode management (stepper functions)

•Current and Force monitoring

•C-Monitor checks secondary circuit for shunting or wear conditions

•Communication via Ethernet/IP, RS232 for WSP3 Pendant, RS485, MODBUS TCP/IP, or MODBUS RTU

An iPAK2v2 weld control is also available in Multi-Welder (Cascade) configurations. This configuration type allows a user

to control multiple weld transformers and multiple weld actuators with a single control. The features of the multi-weld

configuration are:

•Control up to 8 weld transformers

•Control up to 8 weld valves (WAV)

•7 auxiliary valves under program control

•Electrode manager (stepper function) for up to 8 electrodes

For more information on multi-welding refer the section Multi-Welding Machine of this manual.

2.3 Product Specifications

The iPAK2v2 Weld Control is available in various current outputs and the product specifications for the standard iPAK2v2

product line is defined in this section.

INTRODUCTION

Product Specifications

16 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2.3.1 Power Specifications

Description

Value

Standard Voltage

3 Phase AC 380V –480V (+10% / - 20%)

Alternate Voltage –LV

3 Phase AC 230 (+/- 10%)

Line Frequency

50 / 60 Hz

Output Current Options 20% Duty Cycle

360 A Water Cooled

600 A Water Cooled

1000 A Water Cooled

1500 A Water Cooled

3000 A Water Cooled

4500 A Water Cooled

6000 A Water Cooled

DC BUS Levels at Line Voltage

305V 1000Hz at 220 VAC Line

525V 1000Hz at 380 VAC Line

650V 1000 Hz at 480 VAC Line

Maximum Power at 480VAC 20% Duty

234kVA (360 A)

390kVA (600 A)

650kVA (1000 A)

975kVA (1500 A)

1,950kVA (3000 A)

2,925kVA (4500 A)

3,900kVA (6000 A)

Current Rise Time

Less than 4 ms into Resistive Load

Table 1: iPAK2v2 Power Specifications Table

INTRODUCTION

Product Specifications

17 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2.3.2 Function and Monitoring Specifications

Description

Value

Fixed Pulse Firing

Pulse Width Modulation

Current Control Primary

Primary Constant Current Percent Primary Limit

Current Control Secondary

Secondary Toroid (Rogowski Coil) Feedback

Primary Current Range

36A to 360A

60A to 600A

100A to 1000A

150A to 1500A

300A to 3000A

450A to 4500A

600A to 6000A

Timing Control

Milliseconds

Duty Cycle Limit

20% at rated capacity over 2000 ms time period

Table 2: iPAK2v2 Functions and Monitoring

2.3.3 iPAK2v2 Weld Timer Specifications

Description

Value

Communications

Ethernet IP 100 BaseT

Modbus TCP/IP 100 BaseT

R485

RS232 for WSP3 Pendant

Local Inputs

16 Inputs 24VDC

Local Outputs

16 Outputs 24VDC

Number of Weld Programs

256

Number of Steppers

8 Steppers with 10

Programmable Steps

Language

English

Table 3: iPAK2v2 Weld Timer Specifications Table

INTRODUCTION

Product Specifications

18 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2.3.4 Environmental Specifications

Description

Value

Operating Temperature

The cabinet internal ambient temperature must not

rise above 104 degrees Fahrenheit or 40 degrees

Centigrade under normal operation conditions

Humidity

The cooling water temperature must NOT be low

enough to cause the formation of condensation

inside the inverter.

Table 4: iPAK2v2 Environmental Specifications

2.3.4.1 Cooling Water Specifications

Description

Inverter

Size

Value

Maximum Water

Temperature

All

must not exceed 77 degrees Fahrenheit or 25 degrees

Centigrade

Water Quality

All

pH-7-8.5

Hardness max 12.5(UK) 10.5(US)

Chlorides 20mg/l max

Nitrates 10mg/l max

Sulphates 100mg/l max

Insoluble substances 250mg/l max

Deposits in cooling water may cause corrosion/abrasive wear

Tap water may meet requirements.

An algaecide is recommended.

Water Flow Rate

360A

1 gal/min or 5 liters/min

600A

1.5 gal/min or 7.5 liters/min

1000A

2 gal/min or 10 liters/min

1500A

2 gal/min or 10 liters/min

3000A

4 gal/min or 20 liters/min

4500A

6 gal/min or 30 liters/min

6000A

8 gal/min or 40 liters/min

Table 5: iPAK2v2 Cooling Water Specifications

INTRODUCTION

Main Component Overview

19 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

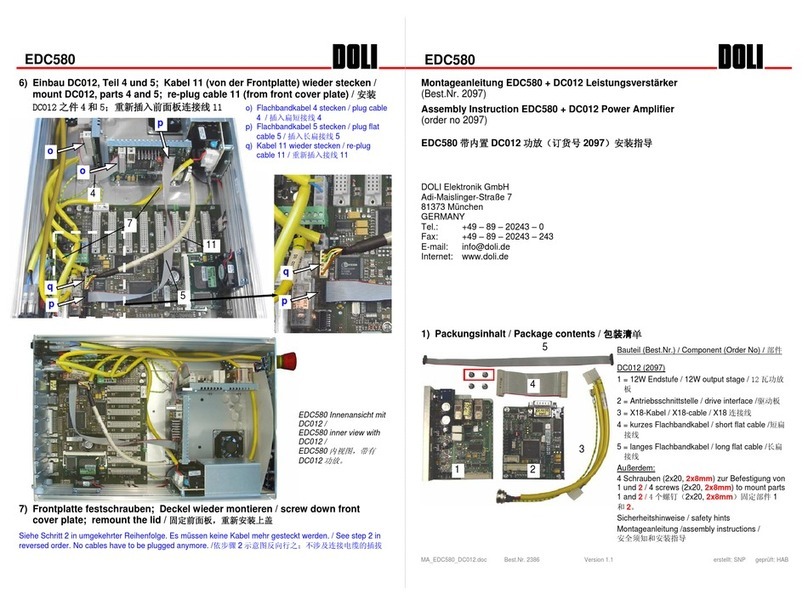

2.4 Main Component Overview

The iPAK2v2 weld control is an assembled unit. The major components of the standard 600 Amp iPAK2v2 configuration

are identified below and in Figure 1: iPAK2v2 600 Amp Control Layout.

Figure 1: iPAK2v2 600 Amp Control Layout

The flexible design of the iPAKV2 product line allows users to configure the product to meet their specific application.

Therefore, the major components and their location identified in this document may not be accurate for all controls.

Description

Function

iPAK2v2 Weld Timer

The weld timer is the programmable device that controls the welding sequence and can communicate with

external devices.

iPAK Inverter Module

The inverter module converts the 3 phase 380-480V 50/60 Hz AC line input into a 1kHz output high voltage

AC square wave output to the welding transformer. The unit is water cooled.

Circuit Breaker

A 3 Phase thermal magnetic breaker. This switches on the electrical voltage to the MFDC inverter and

internal PSUs. This will trip and interrupt the current flow when a short circuit fault is detected. This helps

to minimize damage caused by excessive current or a short circuit.

Isolation Contactor (Optional)

Optional device recommended for manual weld guns and robotic applications. The isolation contactor is an

interrupt device between the inverter module and welding transformer and can be controlled by the weld

timer.

Contactor Relay (optional)

The contactor relay energizes the Isolation Contactor.

24V Power Supply

The 24V Power Supply for the I/O

Fuses

The fuses protect the Control TX Module

Control TX

The Control TX is a universal voltage control module.

Water Manifold

The water manifold contains the connection points for the cooling water circuit. This comes standard.

Thread size is ¼ BSSP.

INTRODUCTION

Wiring Diagrams

20 | P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model: iPAK2v2

Firmware Version: V2.10

May 22 | Doc No 700253-2

2.5 Wiring Diagrams

The iPAK2v2 Timer is designed to be drive various size iPAK inverter modules and up to 8 transformers. This section

provides the schematic for customer connections on the iPAK2v2 Weld Timer and a generic Weld Control wiring

diagram. The drawing is applicable for the following product specifications:

Part Number

Part Description

Wiring

Drawing

Number

Issue

No.

No.

of

Pages

See

Page

10-58-B0-10-01-03-00-05

10-58-C0-10-01-03-00-05

10-58-C1-00-01-03-00-05

iPAK2v2-360AWBv2-125ET-1SW-BCM

iPAK2v2-600AWBv2-160ET-1SW-BCM

iPAK2v2-600AWBv2-175A-1SW-UL-BCM

3U3719

1

2

22

10-58-B0-10-01-03-10-00

10-58-30-10-01-03-10-00

10-58-C0-10-01-03-10-00

10-58-C0-10-01-13-10-01

10-58-40-10-01-03-10-00

10-58-41-00-01-03-10-00

iPAK2v2-360AWBv2-125ET-1SW

iPAK2v2-600AWB-160ET-1SW

iPAK2v2-600AWBv2-160ET-1SW

iPAK2v2-600AWBv2-160ES (SCHN/ETS/INT EIP)

iPAK2v2-1000AWB-250ET-1SW

iPAK2v2-1000AW-250A-1SW-UL

3U3721

1

2

223

10-58-C0-10-21-03-00-00

10-58-C0-10-31-03-00-00

10-58-C0-10-41-03-00-00

10-58-C0-10-21-13-00-01

10-58-30-10-41-13-00-01

10-58-40-10-41-13-00-00

10-58-D0-10-41-13-00-00

iPAK2v2-600AWBv2-160ET-2MUX-1SW

iPAK2v2-600AWBv2-160ET-3MUX-1SW

iPAK2v2-600AWBv2-160ET-4MUX-1SW

iPAK2v2-600AWBv2-160ES-2MUX (SCHN/ETS/INT EIP)

iPAK2v2-600AWB-160ES-4MUX (SCHN/ETS/INT EIP)

iPAK2v2-1KAWB-250ET-4MUX-1SW

iPAK2v2-1KAWBv2-250ET-4MUX-1SW

3U3722

2

4

224

10-58-50-20-01-13-00-00

10-58-60-20-01-13-00-00

10-58-60-20-01-13-00-00

iPAK2v2-LMI-1500A-400E-1SW

iPAK2v2 LMI 1500A-400E-ISO

iPAK2v2-LMI-3000A-800E-1SW

3U3723

1

5

226

Table 6: Standard Product Wiring Diagram List by Part Number

Table of contents

Other Entron Controllers manuals