envea HYCONTROL SHIELD Lite User manual

Shieldlite20 Quick Start guide EN V1_2.docx 1 of 4 June 2023

Quick Start Guide

For first time users, we recommend the use of the SPS-Shieldlite system manual

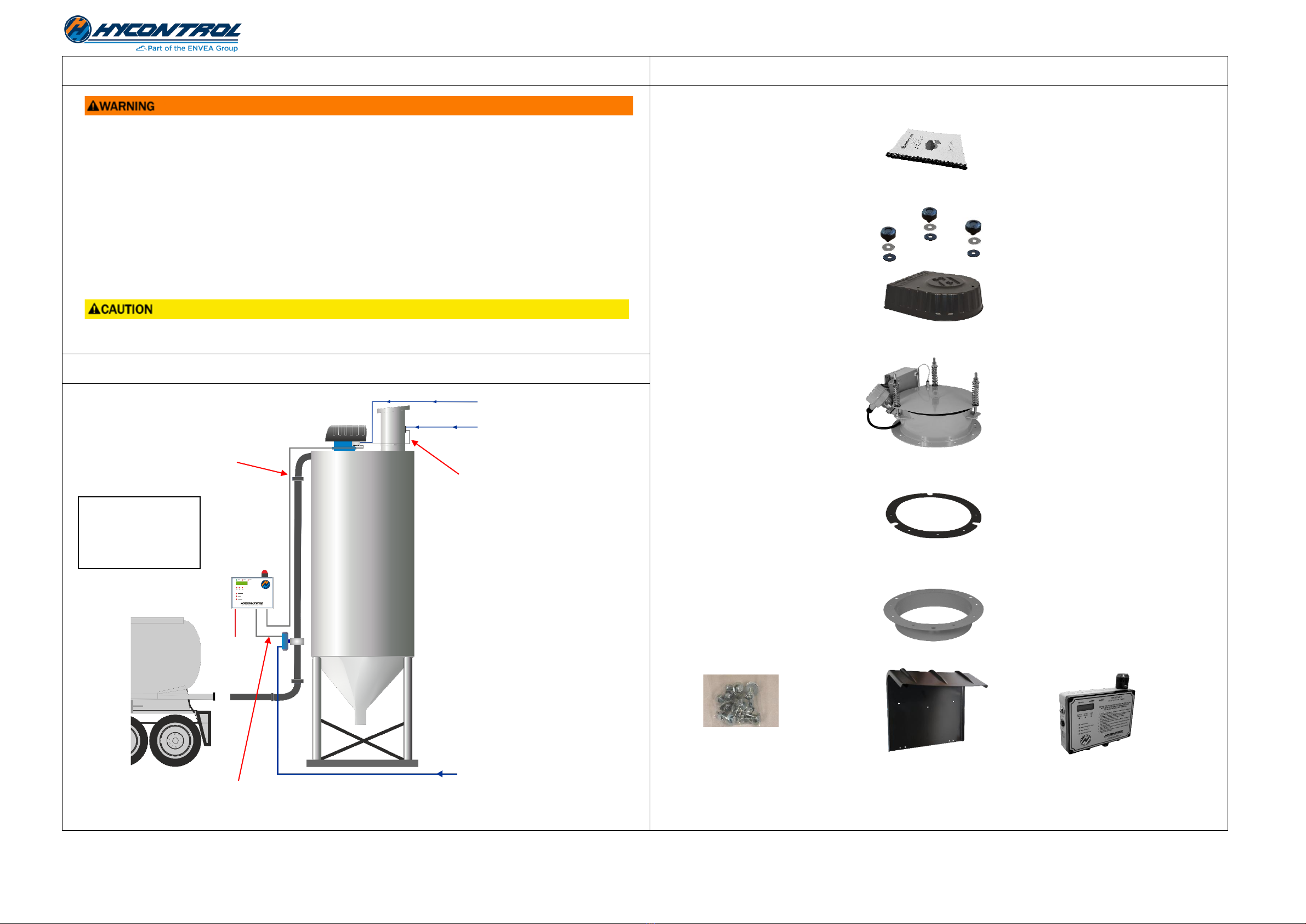

SPS-SHIELDLITE SYSTEM

2. PARTS LIST

Failure to follow safe operating / installation and maintenance guidelines could result in serious injury or death

➢Use suitable PPE for tasks to be performed and for the environment you are working in.

➢All installation, operation and maintenance work must be undertaken by qualified authorised personnel.

➢All applicable industry and statutory regulations must be followed.

➢Any site-specific equipment should be used.

➢Ensure all tools are in good working order.

➢DO NOT undertake any operation or work on the PRV on the silo top unless qualified and authorised to do

so.

➢For full manual, refer to https://www.hycontrol.com/downloads/manuals.

The product described in this document is NOT suitable for use in an ATEX classified area.

1. SYSTEM OVERVIEW

WEATHER COVER

PRESSURE RELIEF VALVE

UPSTAND /

SPIGOT FLANGE

SPS-SHIELDLITEDB

INSTRUCTION MANUAL

3x METAL PENNY WASHERS

3x RUBBER WASHERS

3x HAND KNOBS

GASKET

9 x M10 30mm

BOLTS &

WASHERS

WEATHER COVER FOR

SPS-SHIELDLITEDB

PRESSURE SENSOR

LEVEL PROBE

Filter control

3 core screened cable

Inlet fill valve

6 core screened cable

(control and feedback)

24V DC and comms

4 core screened cable

(Maximum 100m length)

AIR SUPPLY TO

FILL VALVE

6 –8 bar (87 - 116psi)

100 –240V

AC Supply

CONTINUOUS AIR SUPPLY TO PRV

7 –10 bar (101 –145psi)

AIR SUPPLY TO FILTER

DISPLAY PANEL

MUST BE MOUNTED

AT FILL POINT

VISIBLE TO DRIVER

Shieldlite20 Quick Start guide EN V1_2.docx 2 of 4 June 2023

Quick Start Guide

3. INSTALLATION

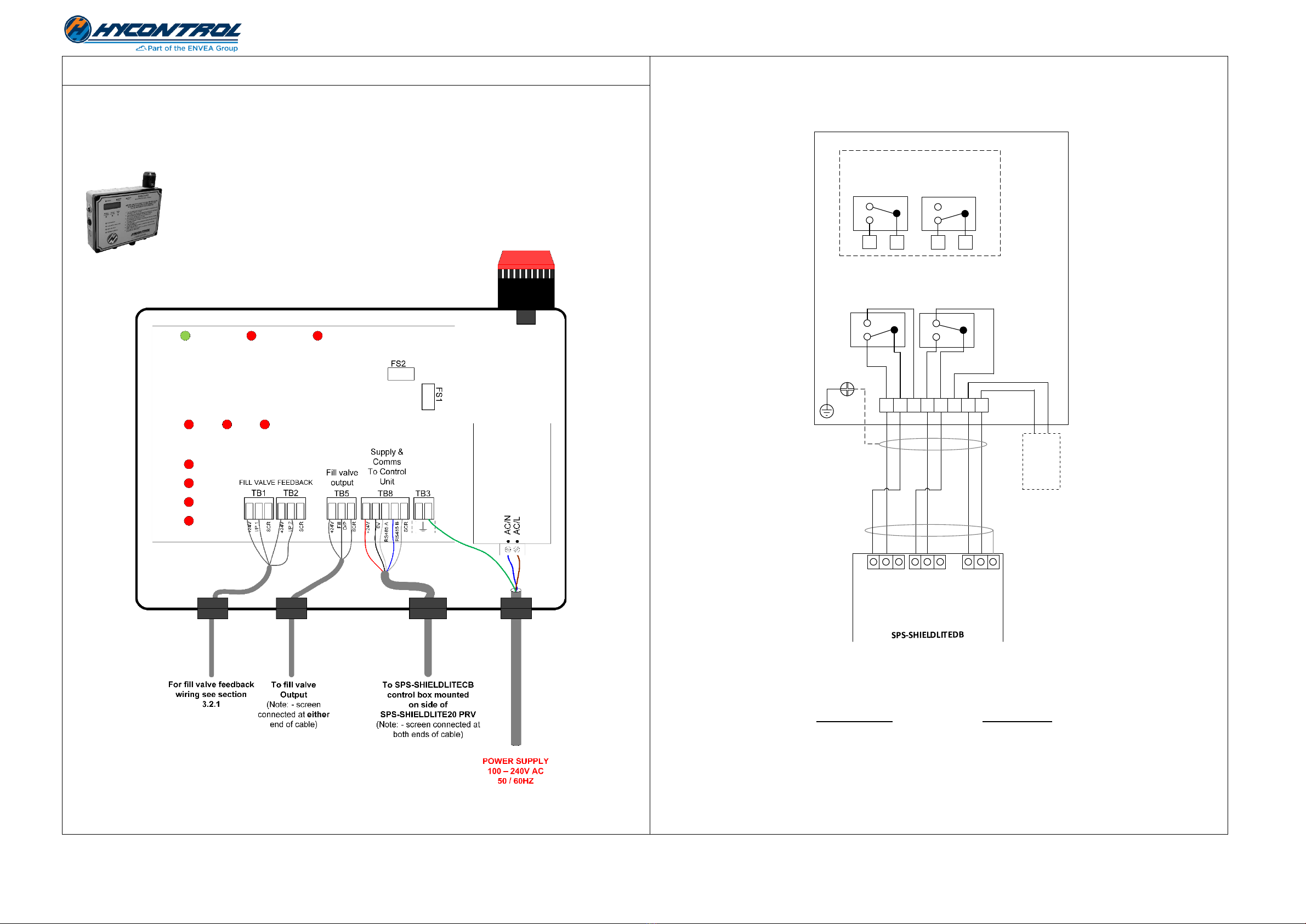

3.2 WIRING THE FILL VALVE

3.2.1 Wiring to a fill valve with open / close position switch feedback

Fill O/P

+24V

I/P 2

+24V

+24V

I/P 1

Scr

TB1 TB2 TB5

FILL VALVE FEEDBACK Fill valve

output

GROUND

Optional

connection

to cable

screen at

switch box

Scr

Scr

8

7

6

5

4

3

2

1

TOP

SWITCH

(SW1)

BOTTOM

SWITCH

(SW2)

Fill valve switch position feedback

Fill valve switch box

Connection

to cable

screen at

instrument

NO COM

NC

NO COM

NC

FILL VALVE

SOLENOID

NC

COM

NO

NO COM

NC

TOP

SWITCH

(SW1)

BOTTOM

SWITCH

(SW2)

2

15

4

Switch positions - valve CLOSED

Switch positions - valve OPEN

Expected voltages

Fill valve closed Fill valve open

24V DC on I/P 1 0V DC on I/P 1

0V DC on I/P 2 24V DC on I/P 2

Note: - All voltages measured with respect to Terminal TB5 Scr on SPS-SHIELDLITEDB PCB.

TB1, TB2 and TB5 connections can share the same cable requiring only one screen connection at the display panel

end. If separate cables are used, each cable must have its own screen connection e.g. TB1 Scr, TB2 Scr and TB5 Scr.

3.1. MOUNTING THE DISPLAY UNIT

3.1.1 Wiring the SPS-SHIELDLITEDB display panel

Display panel mounting considerations

•DISPLAY PANEL MUST BE MOUNTED AT FILL POINT VISIBLE TO DRIVER.

•Power from an isolatable power supply.

•Mount at head height so easily viewable and within comfortable reach.

•Protect from the elements –use weather cover supplied.

Figure 1: - Wiring SPS-SHIELDLITEDB display panel

Figure 2: - Fill valve switch box wiring

Shieldlite20 Quick Start guide EN V1_2.docx 3 of 4 June 2023

Quick Start Guide

3.3 PRV MOUNTING CONSIDERATIONS

When positioning the spigot allow for a 40” (1.0m) diameter footprint free of any obstructions for correct

positioning, wiring and removal of covers. Be aware of the following points:-

•

•DO NOT mount probe in fill path of the material as this

will cause premature wear and failure.

•Ensure there is sufficient space to remove and install

probes for maintenance.

•DO NOT install in front of ladder access.

•We recommend removal of old PRVs to prevent false

venting.

•Mount as close to filter as possible but not in way of fill.

•Beware of internal fill pipes, ladders, split silos etc.

We recommend cutting the main access hole after welding

on the spigot.

3.4 REMOVING THE HIGH LEVEL PROBE FROM UNDERSIDE OF PRV

The high level probe of the SPS-SHIELDLITE20 system comes pre-fitted on the side of the PRV and already wired to

the PRV control box. Ensure to remove the level probe sensor from the underside of the PRV prior to installation by

cutting the 3 cable ties and removing the plastic tip protector.

3.5 WIRING THE SPS-SHIELDLITECB PRV CONTROL BOX

WARNING! NEVER APPLY AC MAINS VOLTAGE TO CONTROL BOX.

Remove cover of control box and wire the following cables to the control box’s PCB using the glands as shown in

Figure 8: -

1) Wire 4-core screened supply and communications cable from the

SPS-SHIELDLITEDB display panel TB8 to control box TB11.

2) Wire 3-core screened cable between control box TB3 and Hycontrol

HYVENT silo filter - see section 3.6.1.

The control box wiring is now complete.

Figure 6: - DP probe

mounting

1.1

Figure 7: - Control box located

on the side of the PRV

Figure 8: - SPS-SHIELDLITECB terminal wiring

Figure 5: - Shows level probe sensor

underside of PRV secured by 3 cable

ties and with tip protector

Figure 4: - Shows level probe mounted

on side of PRV

Figure 3: - Ideal location of PRV on silo top

Shieldlite20 Quick Start guide EN V1_2.docx 4 of 4 June 2023

Quick Start Guide

Output type

Filter output

24V

On/

Off

0V

HYVENT 24V

DC FILTER

CONTROLLER

SPS-SHIELDLITECB

TB3

LINK

13 14 15

1234512

L N PE

Output type

Filter output

1

24V

On/

Off

0V

2

WAM SILOTOP

Zero / R03 filter

SPS-SHIELDLITECB

TB3

3

4

LINK

S1

S2

3.6 WIRING THE ANCILLARIES

3.7 CONNECTING THE AIR-LINE

Connect the air-line into the pressure regulator as shown in Figure 11 and

check pressure on gauge is at 6 bar.

Note: - The air supply MUST be clean and dry and filtered to 25 microns.

4. COMMISSIONING

After completing the mechanical, electrical and pneumatic installation perform the following checks: -

Pre commissioning checks

1. Air pressure regulator on the SPS-SHIELDLITE PRV should be set at 6.0 bar (87psi).

2. Air pressure at the fill valve should be at least a constant 6 bar (87psi). Consider other demands on the

air supply which might affect this.

3. Confirm the specified AC voltage to the display panel (100V –240V AC 50Hz/60Hz).

4. Confirm the 24VDC output from the display panel at TB8 between pins 0V and +24V.

See section 3.1.1 for connector location.

Commissioning checks

5. At start-up, ensure the display shows the “SPS SHIELD LITE GLT key to start” screen.

6. Switch the GLT key-switch clockwise and release. If the initial check passes then the beacon and siren will flash

for five seconds during the test.

7. If the test is successful, the display will show “Safe to fill 90 min remaining”, the fill valve will open and a

delivery can commence.

8. If the test fails, a message will be displayed and the fill valve will remain closed. At this point further

investigation is required as to the cause of the test failure. See Trouble shooting section of full manual for

further details.

5. FURTHER INFORMATION

Hycontrol provides complete documentation and instructional videos for installing, commissioning, and operating

the SHIELD Lite system. Rather than multiple manuals for different components, SHIELD Lite requires only one.

All these resources are available through Hycontrol’s specialist website, www.siloprotection.com.

3.6.1 Wiring the 24V DC HYVENT silo filter

Table 1: - Hyvent program

3.6.1.1 24V DC Hycontrol Hyvent filter connection using external ON/OFF control

Connect TB3 as in diagram below. Link pins 12 to 13 on Hyvent 24V DC Filter controller.

Figure 9: - Wiring to a 24V DC powered Hycontrol Hyvent silo filter

3.6.2 WAM SiloTop zero / R03 filter connection

Connect TB3 as in diagram below. Link pins 3 to 4 on WAM silo. The filter should be set to sequence automatically

on power up.

Figure 10: - Wiring to a WAM SILOTOP zero / R03 filter

Controller program

Parameter

Setting

F01

0

F02

0.5

F03

30

F04

3

F05

0

F06

1

F07

1

F08

24

Figure 11: - Connecting the air-line

Other envea Industrial Equipment manuals