envea M-Sens WR3 User manual

OPERATING INSTRUCTIONS

M-Sens WR3

ONLINE EXTENDED MOISTURE MEASUREMENT FOR SOLIDS

ENVEA Process GmbH - Gutedelstraße 31 – 79418 Schliengen - GERMANY

Tel.: +49 (0) 7635 827248-0 / info.process@envea.global / www.envea.global

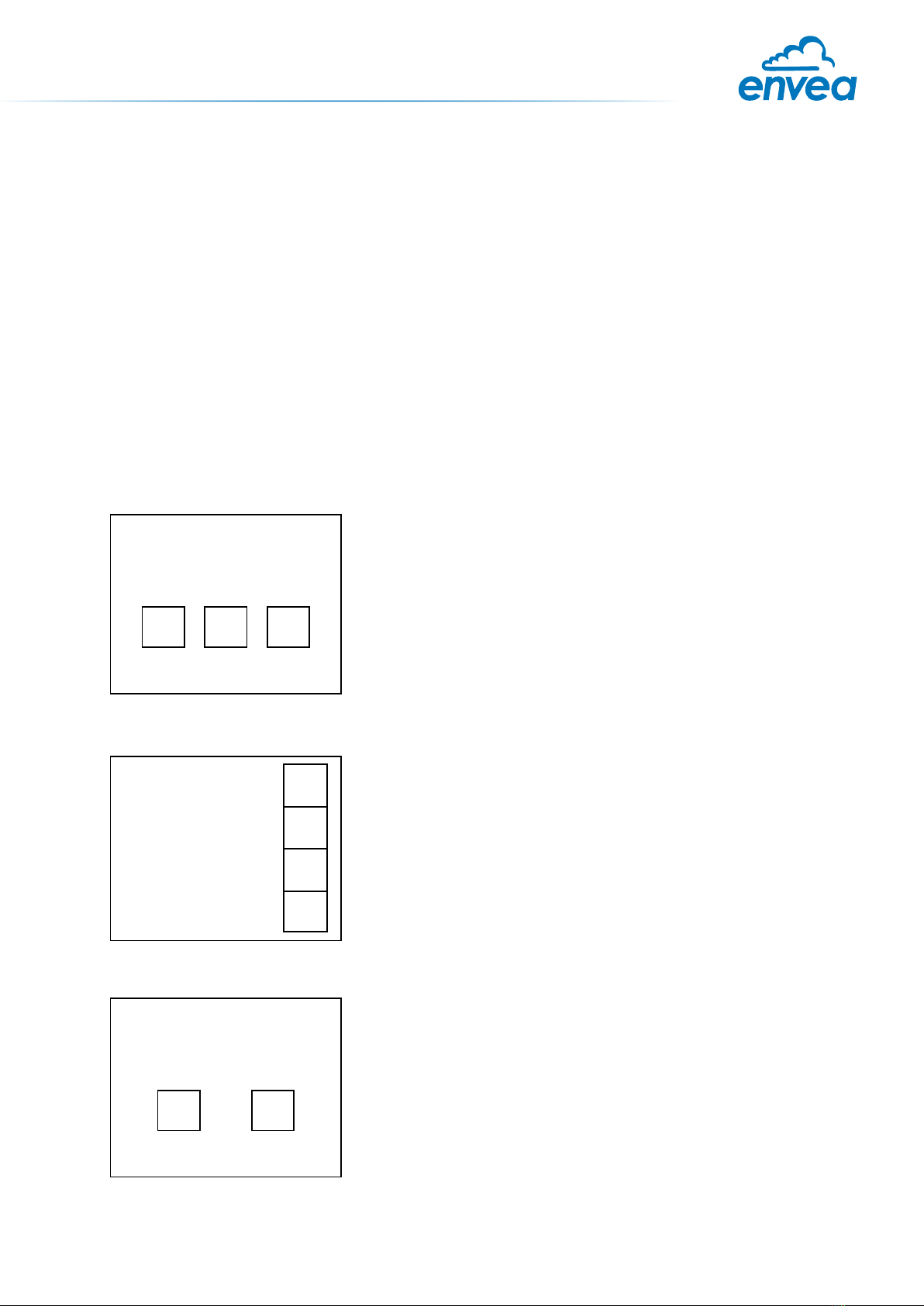

The display is touch-sensitive. Available keys are displayed directly in context. When the measuring

system is rst started, a query is initiated to select the language and sensor.

Initialization screen when the Evaluation unit in the eld housing

started rst time.

Selection of the menu language: Deutsch, English, Français.

If a language has been selected, the sensor to be used must be

selected. To be available:

SolidFlow 2.0, Paddy, PicoFlow, MaxxFlow HTC, DensFlow,

SpeedFlow 2.0, SlideControl 2.0, ProSens, M-Sens 2, M-Sens 3,

M-Sens WR3, AirFlow P.

If any data has been changed, the change will only be taken

into account when you exit the complete menu structure and

answer [Yes] when asked if you wish to save the changes.

Afterwards the start page appears.

If you want to communicate with our sensor using our dedicated software, you need to download the

latest version on our website and install it.

https://www.envea.global/solutions/process-optimization/dahs-software/

It might also be necessary to install drivers, also available on our website.

1st start note

For the 1st use of the sensor, correct sensor type should be selected via the screen or the software.

Software must be installed if needed.

1. SOFTWARE INSTALLATION

2. MSE 300-FH (WITH SCREEN)

Select Language

D E F

E

#

$

8

Sensor

SolidFlow

Save changings?

J N

1st start note

Our dedicated software must be used to connect to the sensor evaluation unit.

Select software language

Right click on „Sprache/Language/

Langue“ and select desired language.

Connect to sensor

Select the correct COM port and

connect to the device using the „read

device“ button.

Select correct sensor

In the menu „System“, under „Sensor“

(8.2.5 or 7.2.5), the correct sensor must

be selected.

After selecting the sensor, check the

box „Overwrite measurement calib.“

and conrm with the button „Device

program“.

For more informations and details, ple-

ase refer to the user manual of the sen-

sor.

3. MSE 300-DR / -DR2 (NO SCREEN)

2

CONTENTS Page

1. System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Regular use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Identication of dangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Technical progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Montage and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Delivery parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Auxiliary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Mounting of the sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.4 Mounting of the Evaluation unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 DIN Rail housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Field housing terminal layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Terminal layout C-Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7. Menu structure of M-Sens WR3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. Operator interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.1 Differences between the DIN Rail and eld housing Evaluation unit . . . . . . . . 27

8.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.3 PC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9. Wiring example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13. Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3

max. 300 m

C1-box

MSE 300-DRSensor

1

2

3

4

1

2

3

4

16 (+ 24 V)

15 (GND)

14 (A)

13 (B)

2 m cable converted

fixed at the sensor

up to 300 m with

correct cablediameter

1. System overview

A complete M-Sens WR3 unit consists of the following components:

•Flange (mounting in screw, hopper)

•1 to 3 sensors with 2 m connecting cable

•Evaluation unit MSE 300

•Optional: C1-box for connecting of sensor and Evaluation unit

The sensor is connected by a shielded, 4-wired cable to the Evaluation unit; the maximal

distance between these devices can be at most 300 m.

Fig. 1: Overview with C1-box and MSE 300-DR

Fig. 2: Overview with C1-box and MSE 300-FH

up to 300 m with

correct cablediameter

max. 300 m

MSE 300-FH

1

2

3

4

S

1

2

3

4

S

1 (+ 24 V)

2 (GND)

3 (A)

4 (B)

Shield

2 m cable converted

fixed at the sensor

Sensor

C1-box

Table of contents

Other envea Industrial Equipment manuals