VH FAN COIL • I.O.M. MANUAL

8VH Fan Coil IOM • ©April, 2002 • Environmental Technologies, Inc.

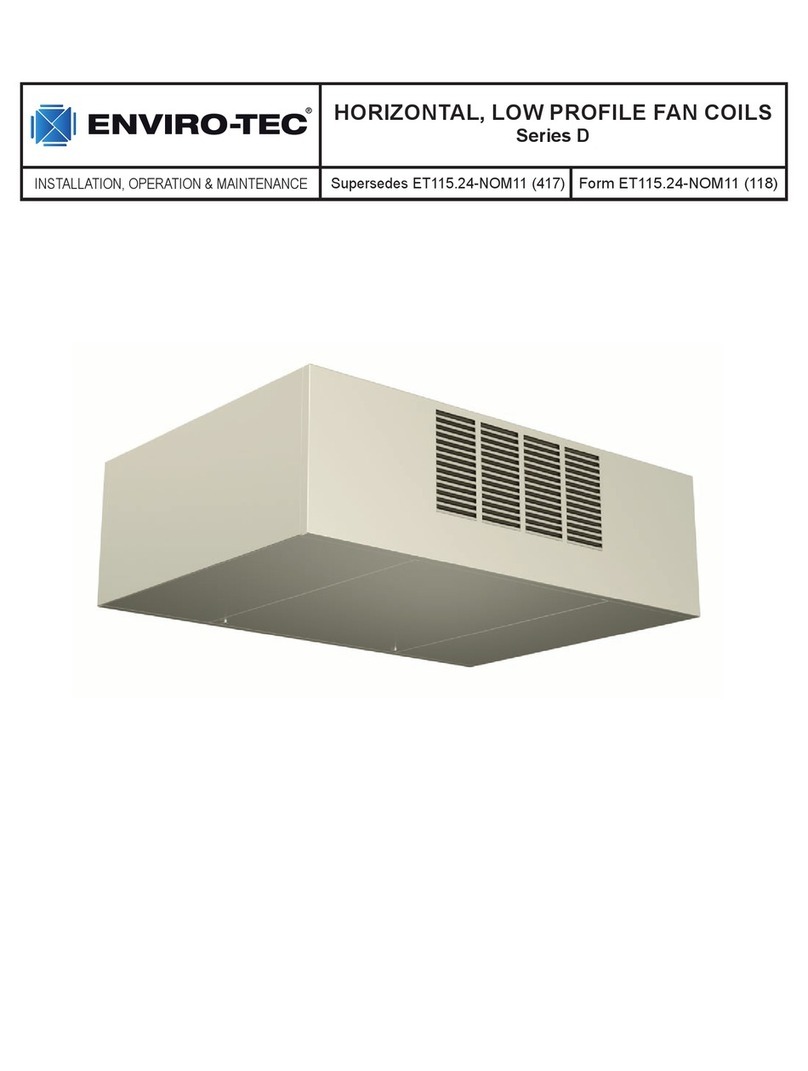

HANDLING & INSTALLATION

While all equipment is designed and fabricated of sturdy construction and may present a rugged appear-

ance, great care must be taken to assure that no force or pressure be applied to the coil, risers, piping or

drain stub-outs during handling. Do not use the risers for lifting the unit. Also, depending on the options

and accessories, some units could contain delicate components that may be damaged by improper han-

dling. Wherever possible, all units should be maintained in an upright position and handled by the exte-

rior casing, with no impact forces applied that may damage internal components or painted surfaces.

The equipment covered in this manual IS NOT suitable for outdoor installations. The equipment should

never be stored or installed where it may be subjected to a hostile environment such as rain, snow, extreme

temperatures, or hazardous chemicals.

During and after installation, special care must be taken to prevent foreign material such as paint, plas-

ter, and drywall dust from being deposited in the drain pan or the heater, motor and blower wheels. Failure

to do so may have serious adverse effects on unit operation and in the case of the heater, motor and blow-

er assembly, may result in immediate or premature failure. All manufacturers’ warranties are void if for-

eign material is allowed to be deposited on the heater, motor or blower wheels of any unit. Some units

and/or job conditions may require some form of temporary covering during construction.

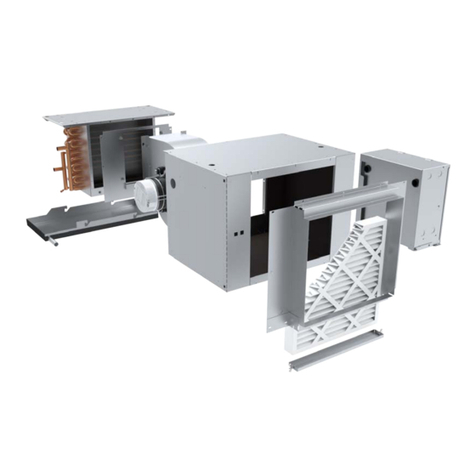

Condensate pan is internally sloped toward drain connection. Make assurance that unit is level and plumb.

Level the unit to insure proper coil operation and condensate drainage. After units are positioned and ris-

ers centered in pipe chase, make unit plumb in 2 directions, using unit frame as a reference. Avoid any

interference with wiring, coil, or coil connections, drain pain, and structural components inside the cabi-

net while using bolts or lag screws to anchor the unit to building. See page 12 for critical penetration

areas.

After mounting the unit, it is then ready for the various service connections such as water, drain and elec-

trical. At this time it should be verified that the proper types of service are actually provided to the unit.

On those units requiring chilled water and/or hot water, the proper line size and water temperature should

be available to the unit. The electrical service to the unit should be compared to the unit nameplate to

verify compatibility. The routing and sizing of all piping, and the type and sizing of all wiring and other

electrical components such as circuit breakers, disconnect switches, etc. should be determined by the indi-

vidual job requirements and should not be based on the size and/or type of connection provided on the

equipment. All installations should be made in compliance with all governing codes and ordinances.

Compliance with all codes is the responsibility of the installing contractor.

COOLING/HEATING MEDIUM CONNECTIONS

CAUTION: Toxic residues and loose particles resulting from manufacturing and field piping techniques

such as joint compounds, soldering flux, and metal shavings may be present in the unit and the

piping system. Special consideration must be given to system cleanliness when connecting to solar,

domestic or potable water systems.

Submittals and Product Catalogs detailing unit operation, controls, and connections should be thorough-

ly reviewed BEFORE beginning the connection of the various cooling and/or heating mediums to the unit.

All accessory valve packages should be installed as required, and all service valves should be checked for

proper operation.

If coil and valve package connections are to be made with “sweat” or solder joint, care should be taken

to assure that no components in the valve package are subjected to a high temperature which may dam-

age seals or other materials. Many two-position electric control valves, depending on valve operation, are