ENVIRONMENTAL SENSOR TECHNOLOGY CO.INC. EST-1000 User manual

EST-1000

EST-1000

EST-1000

EST-1000

Handheld

Handheld

Handheld

Handheld Intelligent

Intelligent

Intelligent

Intelligent Toxic

Toxic

Toxic

Toxic Gas

Gas

Gas

Gas Detector

Detector

Detector

Detector

User

User

User

User Manual

Manual

Manual

Manual

(

Please read this manual carefully before using

)

ENVIRONMENTAL

ENVIRONMENTAL

ENVIRONMENTAL

ENVIRONMENTAL SENSOR

SENSOR

SENSOR

SENSOR TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

TECHNOLOGY CO

CO

CO

CO .

.

.

. INC.

INC.

INC.

INC.

Contents

Contents

Contents

Contents

I. Product Overview ................................................................................... 1

II. Product Description ................................................................................ 1

III. Performance Parameters ....................................................................... 3

IV.

Notes ................................................................................................... 4

V.

Operational Processes ............................................................................. 4

VI. Menu Description ................................................................................ 6

VII. Calibration Method .............................................................................. 9

VIII. Troubleshooting ................................................................................. 10

IX. Instrument Supporting ........................................................................ 11

Appendix Type & Specification of the Sensor ............................................. 11

1 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

I.

I.

I.

I. Product

Product

Product

Product Overview

Overview

Overview

Overview

EST -1 000 series handheld intelligent toxic gas detector is an intelligent hand-held alarm that

detects the concentration of toxic gas in the target gas with high precision and low power

consumption by an advanced electrochemical technology.

EST- 1 000 series adopt a natural gas diffusion testing method (external handheld pump for

option ). The sensor is the advanced electrochemical toxic gas ones, which are of high

sensitivity and excellent repeatability. It is equipped with a LCD liquid crystal display, which

can observe the concentration of the target gas online, check the time, date and week, It has

two levels of alarm output. When it exceeds the pre-set alarm point, the sound and light alarm

signal will be started immediately. It has two kinds of calibration methods, i.e. the software

and hardware. The calibration can be finished without opening the cover.

This instrument has the following features:

1. Advanced electrochemical sensor makes the performance stable and reliable.

2. External power supply of DC5V, a rechargeable 3.7V lithium battery built inside and

chargeableness upon connected to the external power supply are all provided.

3. Large-screen LCD can display various parameters, with two methods of viewing, i.e. with

data and curves.

4. The time, date and week can be set and displayed. All the time information can be checked

by a.

5. It is of the intelligent design, full functions, zero setting, alarm settings and convenient

calibration.

6. The shell is compact and lightweight, which can be put in the pocket or bag and also can be

hung on the body and is easy to carry.

7. Two levels of the sound and light alarm are available. The four bright LEDs alert the user

when alarming.

II.

II.

II.

II. Product

Product

Product

Product Description

Description

Description

Description

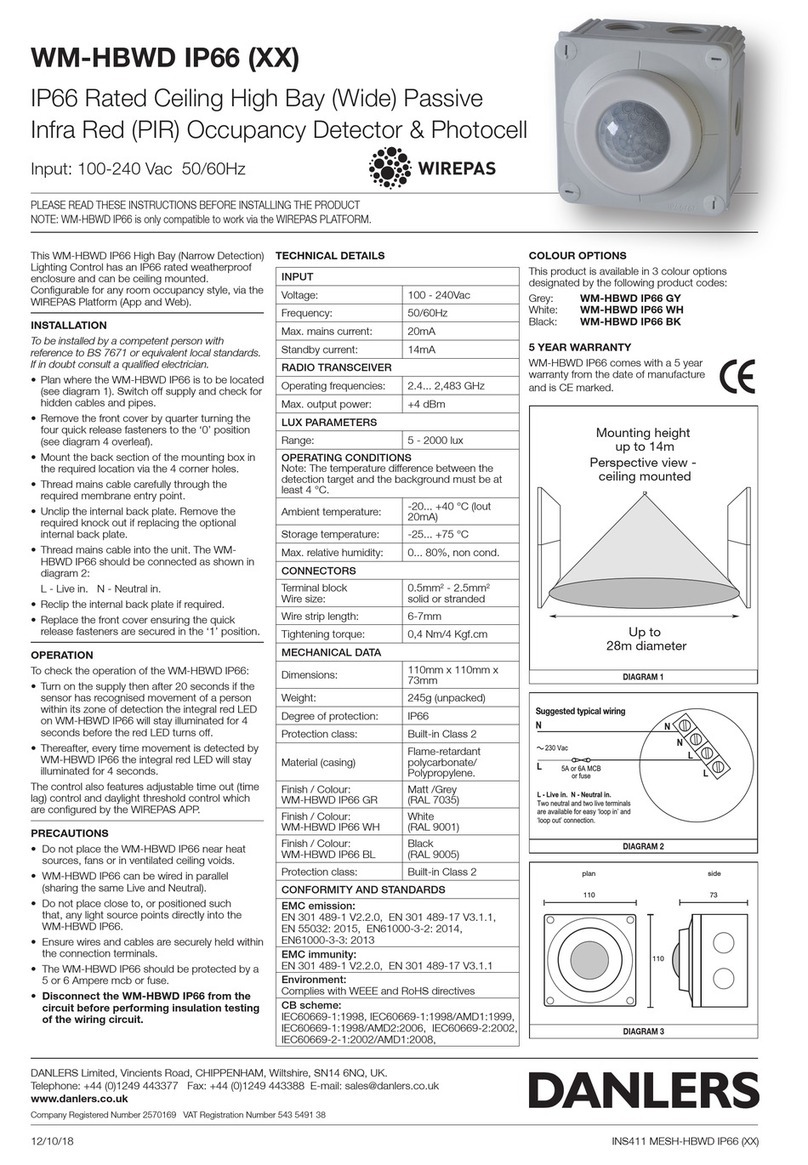

There are five functions, an LCD display and 4 LED lights in the front of the product, which is

shown as follows:

2 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

Among them, the LCD screen is used to display the gas concentration, time and various

information parameters. The two LED lights on the top are alarm lamps, which flash

alternately when the gas alarms. The LED at the left side of the bottom of the LCD is the

power light, which is green and lights when the battery voltage is not enough. While the LED

at the right side is the communication light that becomes red and flashes once when

communicating one set of the data ( applicable for EST-2000 series only) .

The five buttons on the panel respectively are Power/Confirm, Menu/Shift, Back, Plus/Up and

Minus/Up.

1. Power/Confirm: long press (for about 3 seconds) facilitates the power and the instrument

switches the on-and-off machine. Short press facilitates the Confirm.

2. Menu/Shift: after booting, long press (for about 3 seconds) facilitates the menu to enter the

menu mode. Short press facilitates the shift.

3. Back: long/short press will both facilitate the Back and it will return to the last menu or exit

the menu mode.

4. Plus/Up: add a displayed unit to the value or turn upward for an option. Long press

facilitates the continuous operation.

5. Minus/Up: reduce a displayed unit to turn downward for an option. Long press facilitates

the continuous operation

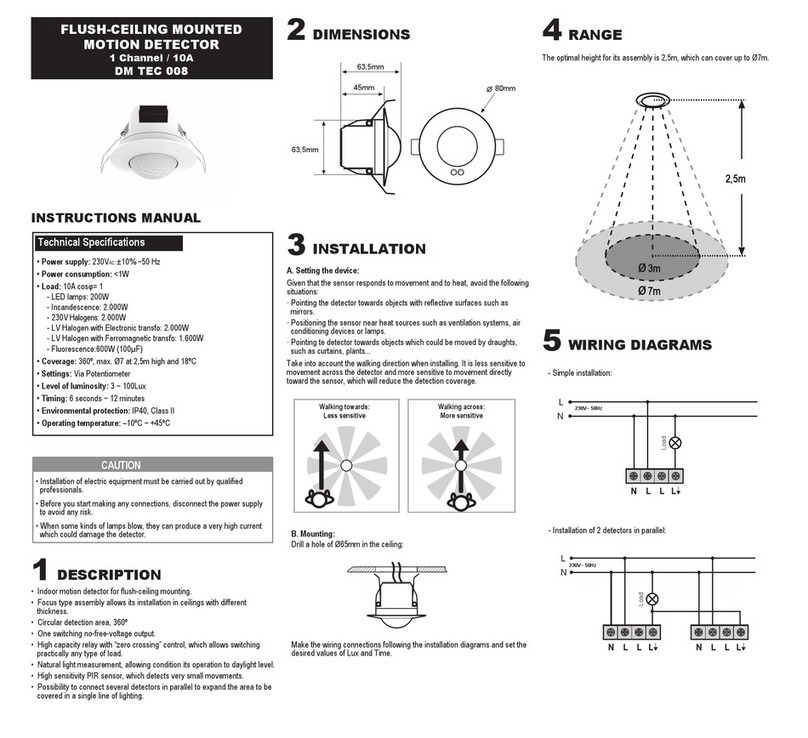

In addition, there is a power connector on the left side of the product and the battery is

installed in the back cover of the product. The parts and names of the products are shown in

the following figure.

3 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

III.

III.

III.

III. Performance

Performance

Performance

Performance Parameters

Parameters

Parameters

Parameters

Product name Gas detection alarm Sensor name

Optional (electrochemical

sensor)

Type of product EST-2000 Type of sensor Optional

External power

supply

5VDC/500mA Detecting target Toxic gas (optional)

Type of battery Lithium ion battery Detection principle Electrochemical

Battery voltage 3.7V (charge limitation 4.2V) Detection method Diffusion

Battery capacity 800mAh Detection range Optional

Shutdown current < 0.1mA Accuracy ± 5%FS

Startup current < 10mA Resolution Optional

Alarm current < 50mA

Operating

temperature

-10 ℃-40 ℃

Protection class IP65 dustproof and waterproof Humidity 0-95%RH

Way of display LCD liquid crystal display Pressure range 860-1060hpa

Way of alarm Two levels of the sound and light alarm Preheat time 60 seconds

Alarm error ≤± 10% alarm set value Response time T90 ≤ 30S (most)

Data storage N/A Service life 2 years (in the air)

Signal output N/A Zero drift ≤± 2%FS/6h

Dimensions of

appearance

120*60*35mm Span drift ≤± 5%FS/6h

Weight of

machine

≤ 250g (including batteries) Repeatability ≤± 2%FS

Note:

Note:

Note:

Note: Please

Please

Please

Please refer

refer

refer

refer to

to

to

to the

the

the

the corresponding

corresponding

corresponding

corresponding sensor

sensor

sensor

sensor technical

technical

technical

technical manual

manual

manual

manual for

for

for

for the

the

the

the sensor

sensor

sensor

sensor parameters.

parameters.

parameters.

parameters.

4 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

IV.

IV.

IV.

IV. Notes

Notes

Notes

Notes

The use, maintenance and calibration of the instrument shall be taken by special people.

1. Both of the zero point and full scale shall be calibrated once every three months;

2. The detection probe shall be cleaned on a regular basis. Otherwise, the dust and impurities

will plug into the gas hole, which will make the sensitivity of the sensor decreased.

3. Since the date of the delivery to the user, if the instrument fails to operate normally within a

year due to the quality problems, our company will repair or replace it for the user for free. If it

is over a year, the labor cost will be charged.

4. Since there is the acid solution in the electrochemical sensor, the users shall not disassemble

it by themselves. Be careful not to damage the film. If the acid solution contacts the skin, the

users shall wash immediately with water in 10 minutes and then go to a doctor.

V.

V.

V.

V. Operational

Operational

Operational

Operational Processes

Processes

Processes

Processes

1. Instrument Booting

Connect to the battery (if it is connected, long press the Power/Confirm for about 3 seconds)

and the alarm light is on, as well as the buzzer sounds, which means the instrument boots

successfully. The LCD shows “ POWER ON ” for about 0.5 seconds, which is shown as follows.

(The display is for reference only. Please be subject to the actual object. The same below)

Then the LCD shows the company LOGO “ ” for about 0.5 seconds, which is

shown as follows. And then it shows the type of the instrument and the program version for

about 0.5 seconds, which is shown as follows:

5 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

Next, enter the sensor and wait for the warm-up for about 60 seconds. Accompanied by the

sound of the buzzer, the LCD shows the countdown time, which is shown as the following left

picture. After the completion (it shows 00 seconds), the LCD shows “ Turn on ” for about 1

second, the alarm light is on, the buzzer sounds and it waits for the completion, which is

shown as the following right picture.

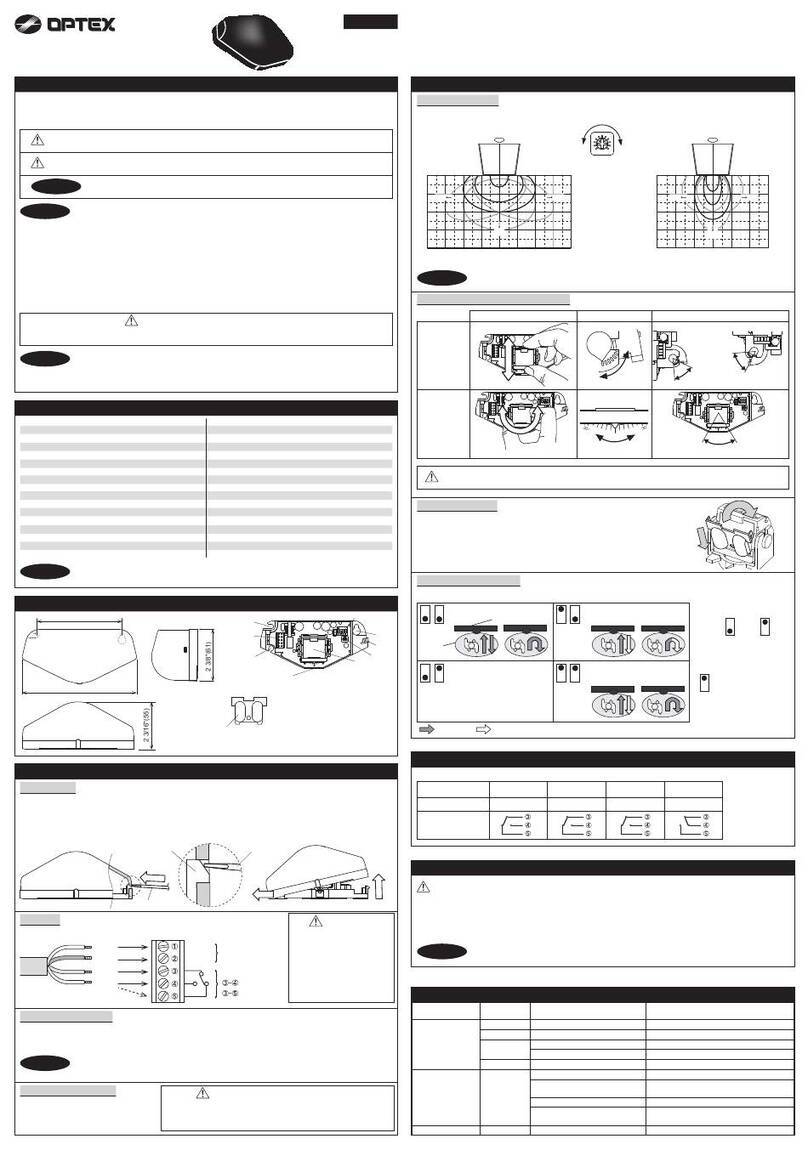

2. Detection Status

After the successful booting, the instrument enters the detection status automatically and the

LCD shows all kinds of information at real time, which is shown as follows:

The top of the LCD shows the time, battery

capacity and other signs at real time, such as the

alarm status, buzzer status and link status of the

communication.

The left side of the LCD shows the types of

gases.

The right side of the LCD shows the

measurement unit.

The large figure in the middle of the LCD is the

real-time gas concentration.

The lowest line of the LCD shows the average

and maximum value measured since this booting.

3. Time Check and Graphics Status:

In the detection state, press the Confirm (shortly press “ Power/Confirm ” ) to enter the state of

checking the time and date. The LCD shows as the following left picture shows. Then press

the Back and exit and return to the detection state;

In the detection state, press the shift (shortly press “ Menu/Shift ” ) to enter the state of checking

the graphics. The LCD shows the gas concentration at real time in the curve. The types of the

gases and concentration value are shown beneath the curve. Then press the Back to exit and

return to the detection state, which is shown as the following right picture.

6 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

4. Instrument Shutdown

There are three ways of shutting down the instrument, which are the automatic shutdown when

the battery capacity is too low, the automatic shutdown when the set time is up and the manual

shutdown when pressing the power (long press the “ Power/Confirm ” for about 3 seconds). The

buzzer sounds when shutting down, the LCD shows the “ POWER OFF ” for about 0.5 seconds

(shown as the following left picture) and then all are off. The instrument is shut successfully

and enters the low power consumption standby mode. If it automatically shuts down because

the power capacity is too low, it will show “ Battery Low ” first before showing “ POWER OFF ” ,

which is shown as the following right picture.

VI.

VI.

VI.

VI. Menu

Menu

Menu

Menu Description

Description

Description

Description

1. Main Menu

In the detection state, press the Menu (long press “ Menu/Shift ” for about 3 seconds) to enter

the Main Menu. LCD shows the “ Main Menu ” and six options divided by two screens. Use the

Up/Down to scroll through the options and the two screens will be switched automatically. The

highlighted option is the current selected option as bellow:

7 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

2. Timepiece Setting

Select the first option “ 1. Timepiece ” in the Main Menu and then press the Confirm to enter

the setting of timepiece. There are three options in the sub-menu of Timepiece: “ 1. Time: ” , “ 2.

Date: ” and “ 3. Y (W): ” the first option is to set the hour and the minute, the second option to

set the month and the date and the third option to set the year and the week. Press the

Up/Down to scroll through the options and press the Back to return to the Main Menu and

pressing the Confirm again could enter the parameter altering status. Press the Shift to select

the parameter to be altered and press the Plus and Minus to make the alteration and then press

the Confirm to save it and return to the Main Menu. Pressing the Back will not save the

alteration but return directly. The highlighted option is the current selected option as bellow:

3. Alarm Setting:

Select the second option “ 2. Alarm ” in the Main Menu and then press the Confirm to enter the

setting of alarm. There are three options in the sub-menu of Alarm: “ 1. Low: ” , “ 2. High: ” and

“ 3. Mode: ” ; the first option is to set the low value, the second option to set the high value and

the third option to set the mode of the alarm. Press the Up/Down to scroll through the options

and press the Back to return to the Main Menu and pressing the Confirm again could enter the

parameter altering status. Press the Shift to select the value to be altered and press the Plus and

Minus to make the alteration and then press the Confirm to save it and return to the Main

Menu. Pressing the Back will not save the alteration but return directly. The highlighted option

is the current selected option as bellow:

8 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

4. Software Calibration:

Select the third option “ 3. Calibration ” in the Main Menu and then press the Confirm to enter

software calibration. There are three options in the sub-menu of Calibration: “ 1. Zero: ” , “ 2.

Span: ” and “ 3. Clear: ” ; the first option is to set zero calibration, the second option to set gain

calibration and the third option to clear the parameter of the calibration. Press the Up/Down to

scroll through the options and press the Back to return to the Main Menu and pressing the

Confirm again could enter the altering status. Press the Shift to select the value to be altered

and press the Plus and Minus to make the alteration and then press the Confirm to confirm the

calibration or the clearing and return to the Main Menu. Pressing the Back will not calibrate or

clear the value but return directly. The highlighted option is the current selected option as

bellow (the 4-digit data with the unit is the value after calibration and the 4-digit data without

the unit is current concentration value):

5. Parameter Setting:

Select the fourth option “ 4. Parameter ” in the Main Menu and there are only two options in the

sub-menu of Parameter: “ 1. Type: ” and “ 2. Rage: ” ; the first option is to set the type of the gas

and the second option to set the sensor; the last line indicates the ADC value of the gas and the

amount of the battery level and is for reference only. Press the Up/Down to scroll through the

list of the options (the last line could not be selected) and press the Back to return to the Main

Menu and pressing the Confirm again could enter the altering status. Press the Shift to select

the value to be altered and press the Plus and Minus to make the alteration and then press the

Confirm to confirm the alteration or the clearing and return to the Main Menu. Pressing the

Back will not alter or clear the value but return directly. The highlighted option is the current

selected option as bellow:

9 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

6. Instrument Setting:

Select the fifth option “ 5. Setting ” in the Main Menu and there are six options in the sub-menu

of Setting: “ 1.BLT: ” , “ 2. AOT: ” , “ 3. AOV: ” , “ 4. MAD: ” , “ 5.

LRV:

” and “ 6. Reset: ” ; the first

option is backlight time, the second option auto power off time, the third option the voltage of

auto power off, the fourth option the communication address of the module, the fifth option the

reference voltage of LCD (LCD grey scale) and the sixth option resetting (restoring to the

default values). Press the Up/Down to scroll through the list of the options and press the Back

to return to the Main Menu and pressing the Confirm again could enter the parameter altering

status. Press the Shift to select the value to be altered and press the Plus and Minus to make the

alteration and then press the Confirm to confirm the alteration or the clearing and return to the

Main Menu. Pressing the Back will not save the alteration or the clearing but return directly.

The highlighted option is the current selected option as bellow:

(Note: if the BLT is 0, it indicates the backlight is not turned off; if the AOT is 0, it indicates

non-auto power off)

VII.

VII.

VII.

VII. Calibration

Calibration

Calibration

Calibration Method

Method

Method

Method

To ensure the measurement accuracy of the instrument, calibration should be conducted on a

regular basis (it is recommended to calibrate once every three months) and recorded strictly.

During

During

During

During calibration,

calibration,

calibration,

calibration, calibration

calibration

calibration

calibration cap

cap

cap

cap should

should

should

should be

be

be

be added

added

added

added to

to

to

to the

the

the

the sensor

sensor

sensor

sensor (except

(except

(except

(except for

for

for

for zero

zero

zero

zero

calibration).

calibration).

calibration).

calibration). After

After

After

After installing

installing

installing

installing the

the

the

the calibration

calibration

calibration

calibration cap,

cap,

cap,

cap, import

import

import

import the

the

the

the standard

standard

standard

standard gas

gas

gas

gas through

through

through

through the

the

the

the end

end

end

end

of

of

of

of standard

standard

standard

standard gas

gas

gas

gas cap

cap

cap

cap of

of

of

of the

the

the

the gas

gas

gas

gas pipe

pipe

pipe

pipe and

and

and

and the

the

the

the other

other

other

other end

end

end

end of

of

of

of the

the

the

the gas

gas

gas

gas pipe

pipe

pipe

pipe is

is

is

is connected

connected

connected

connected with

with

with

with a

a

a

a

safe

safe

safe

safe place.

place.

place.

place. The instrument could be calibrated in 2 methods: the soft and hard. If hardware

calibration required the opening of battery cap of the instrument, use a small slotted

screwdriver to rotate the knob of calibration potentiometer (to avoid shock resulting in the

knob loosening which will bring errors to the measurement, the knob should be fixed by soft

10 /11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

silicone gel; when using it, you should only take the soft silicone and please apply silicone gel

on it after the calibration). If you don ’ t want hardware calibration, you could press the relevant

button to enter the menu-calibration mode in the detection state to realize the calibration of the

concentration of the gas with software.

1. Hardware Zero Calibration

Power on the instrument for 30 minutes in clean air or pure nitrogen (the power on time of

polarization during the first use of the instrument should be over 2 hours). After the display is

stable, open the battery cap and adjust the zero calibration potentiometer in the instrument with

the screwdriver to make the value displayed on the LCD to be 0, which means that the

calibration is succeeded.

2. Hardware Gain Calibration

Import the standard gas of known concentration through the flow-meter, reducing the voltage

to 1.1 times of the normal atmospheric pressure and controlling the flow rate within the range

of 300ml/min to 500ml/min, and then direct the gas to the sensor through gas pipe and

standard gas covering. After the display of the instrument is stable (in about 3-5 minutes),

check whether the displayed value is in conformity with the concentration of the standard gas

passed. If not, open the upper covering and adjust the span potentiometer of the outer covering

of the instrument to make the displayed value in the panel to be in conformity with the

concentration of the standard gas. After the adjustment, the gas could be stopped. Then see

whether the value of the instrument could be returned to zero quickly in clean air. Repeat the

above action and contrast the result with the last one. If the results are pretty much the same

(within the basic error range), the adjustment could be stopped and the standard gas could be

turned off and the calibration is ended. If not, the above calibration should be repeated again

till the result is satisfied.

3. Software Zero Calibration

The calibration condition is same with that of hardware zero calibration. Press the relevant

button to adjust the instrument to zero calibration condition (please refer to the 4

th

point of the

6

th

section for detailed method). After the display is stable, if the value displayed on the LCD

is not 0, adjust the instrument till it is 0. Press the Confirm to save the data and then complete

software zero calibration.

4. Software Gain Calibration

The calibration condition is same with that of hardware gain calibration. Press the relevant

button to adjust the instrument to gain calibration condition (please refer to the 4

th

point of the

6

th

section for the detailed method). After the display is stable (in about 3-5 minutes after

importing the gas), if the value displayed on the LCD is not in conformity with the standard

gas, adjust the value till it is in conformity with the concentration of the standard gas. Press the

OK to save the data. After the data is saved, the gas could be stopped. And then see whether

the value of the instrument could be returned to zero quickly in clean air. Repeat the above

action once and contrast the result with the last one. If the results are pretty much the same

(within the basic error range), the adjustment could be stopped and the standard gas could be

turned off and the calibration is ended. If not, the above calibration should be repeated again

till the result is satisfied and then software zero calibration is completed.

Remark:

Remark:

Remark:

Remark: the

the

the

the calibration

calibration

calibration

calibration is

is

is

is of

of

of

of great

great

great

great importance

importance

importance

importance and

and

and

and non-professional

non-professional

non-professional

non-professional technicians

technicians

technicians

technicians should

should

should

should

not

not

not

not operate

operate

operate

operate at

at

at

at random.

random.

random.

random.

11

/11

ENVIRONMENTAL SENSOR TECHNOLOGY CO. INC.

VIII.

VIII.

VIII.

VIII. Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

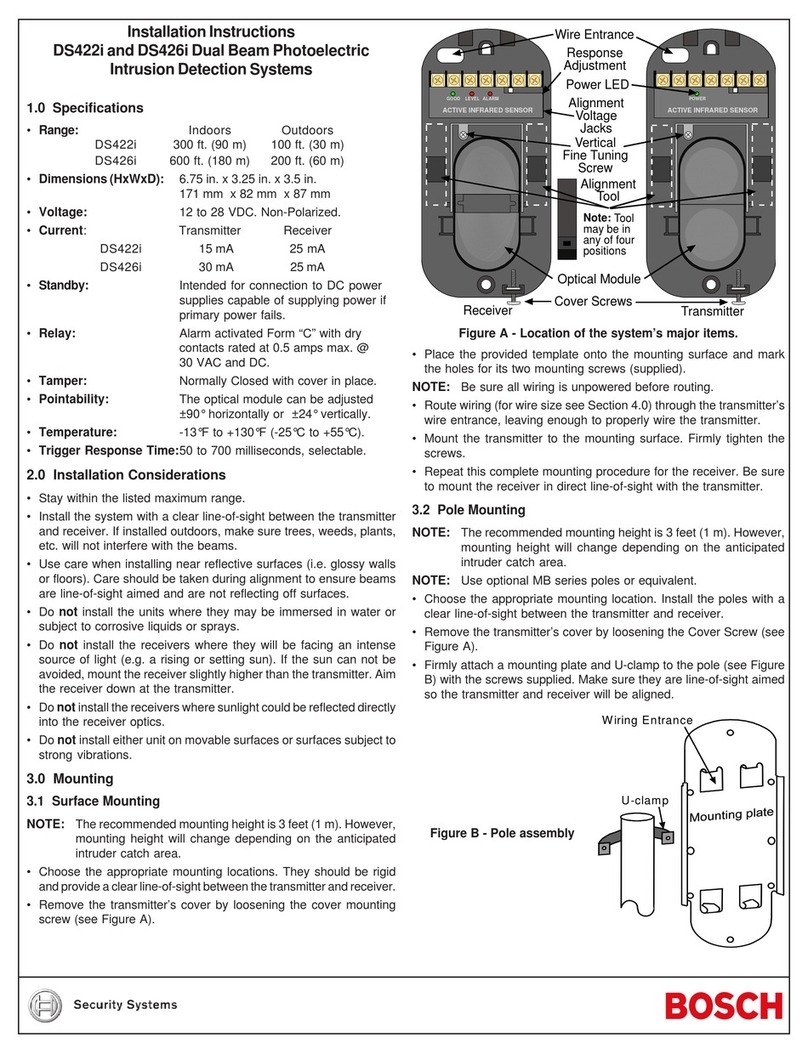

Troubles Reasons Treatment

Can not Start

Insufficient battery level

Circuit faults

Recharge or change the battery

Send

it

back to the factory to repair

High/Low

Readings

Zero point or high/low gain

calibration

Disabled sensor

Re-calibrate

Change the sensor

Unstable Readings

Not enough polarization time

Disabled sensor

Circuit faults

Self-excitation generated in the circuit

AC interference

Keep polarizing

Change the sensor

Send

it

back to the factory to repair

Adjust Span potentiometer to reduce the gain

Turn off high-frequency devices around (such as frequency

converter and interphone)

Slow Response

Time

Probe clogged with dust

Disabled sensor

Circuit faults

Clean up the dust on the protective covering

Change the sensor

Send

it

back to the factory to repair

IX.

IX.

IX.

IX. Instrument

Instrument

Instrument

Instrument Supporting

Supporting

Supporting

Supporting

1. One set of EST- 1 000 Hand-held Intelligent Toxic Gas Detector

2. One General 5V Power Adaptor

3. One Standard 3.7V Rechargeable Lithium Battery

4. One copy of EST- 1 000 Instructions for Use

5. One copy of Verification Certificate

6. One package of the product

Statement:

Statement:

Statement:

Statement:

The

The

The

The parameters

parameters

parameters

parameters described

described

described

described in

in

in

in the

the

the

the Instruction

Instruction

Instruction

Instruction may

may

may

may change

change

change

change in

in

in

in subsequent

subsequent

subsequent

subsequent

versions.

versions.

versions.

versions. Please

Please

Please

Please take

take

take

take the

the

the

the actual

actual

actual

actual object

object

object

object as

as

as

as the

the

the

the standard.

standard.

standard.

standard.

Appendix

Appendix

Appendix

Appendix Type

Type

Type

Type &

&

&

& Specification

Specification

Specification

Specification of

of

of

of the

the

the

the Sensor

Sensor

Sensor

Sensor

This manual suits for next models

1