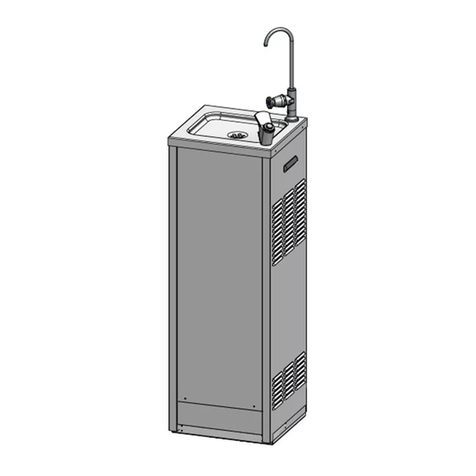

enware DFSA121-CBF User manual

I00442_Dec21

Installation and Maintenance Instructions

Freestanding Water Chiller with

Bubbler and Heavy Duty Bottle Filler

DFSA121-CBF

enware.com.au

2 Call 1300 369 273 www.enware.com.au

937

245

295

320

320

360

805 -810 MAX

160

75

160

½” WATER

INLET

40mm DRAIN

CONNECTION

BACK FACE OF WATER CHILLER

product description

Enware water chillers supply chilled water on demand. Supplied with heavy duty bottle ller

with capstan handle. Drinking bubbler can be removed, to optimise hygiene, with supplied

deletion kit. Suitable for public areas such as gyms and building sites and ofce buildings.

KEY FEATURES

• Flow rate of up to 18 litres/hour of chilled water

• 4 Litre storage tank

• Heavy Duty Bottle Filler with capstan handle

• Hygienic, polished stainless steel tops designed for rapid draining

• Adjustable levelling feet

• Stainless steel storage tank

• FDA approved internal pipework

• Environmentally friendly R134A refrigerant

• Side carry handles and removable front access panel for easy installation

• Includes internal waste trap

• Supplied with bottle ller ready to t and including delete kit for bubbler if it is not

required

BOTTLE FILLLER

BUBBLER

WA

TER CHILLER

All measurements are in millimetres.

937

245

295

320

320

360

805 -810 MAX

160

75

160

½” WATER

INLET

40mm DRAIN

CONNECTION

BACK FACE OF WATER CHILLER

www.enware.com.au Call 1300 369 27 3

IMPORTANT - This must be read before proceeding with installation

1. Enware products are to be installed in accordance with the Plumbing Code of Australia

(PCA) and AS/NZS3500. Installations not complying with PCA and AS/NZS 3500 may

void the product and performance warranty provisions. Reference should also be made

to the ABCB and Local Government regulations when considering the choice of, and the

installation of these products.

2. Electrical installation must be in accordance with AS/NZS3000-2018.

3. Water connection to the water cooler should be made through an approved Non-Return

Isolating Valve/ Stop Tap and installed in an accessible position.

* Note: Non-Return Isolating Valves/Stop Taps are not supplied with this product.

4. Water supply pressure must not exceed 500kPa. It is recommended that an approved

500kPa Pressure Reduction Valve be installed with all water chillers to safe-guard against

pressure surges that may occur in the supply lines, especially at night.

5. For use with potable water only.

NOTE: Enware Australia advises:

1. Due to ongoing Research and Development, specifications may change without notice.

2. Component specifications may change on some export models.

installation compliance

technical data

Chilled Water Production up to 18 Litres/hour

Recommended Water

Supply Pressure

50-500 kPa

(Use of pressure reduction valve is recommended if inlet pressure

may exceed 500 kPa)

Power Supply 240V / 50 Hz

Power Connection 3 pin 10 A plug with 2m lead

IP Rating IP23

Water Inlet Connection 1/2” BSP male

Water Drain Connection 40mm DWV PVC

Storage Tank 4 Litres

Compressor Size 362 W

Condensor Wire tube

Refrigerant R134A

Climate Condition SN.N *

Net Weight 30kg

Bottle Filler Flow Rate 2 L/min - 7 L/min

adjustable

* Suitable for use in ambient temperatures of 10°C to 32°C

4 Call 1300 369 273 www.enware.com.au

WARNING:

• Enware water chillers are not suitable for outdoor use. The appliance must not be exposed

to rain.

• Stainless steel panel (non-powder coated) chillers are not designed or recommended for

use in corrosive environments such as enclosed chlorinated pool areas.

• Consideration must also be made at the time of installation to adverse environmental/

atmospheric conditions such as, but not limited to, dust, corrosion, or freezing. These

conditions may void the warranty.

• Do not operate this appliance at ambient temperatures below 0°C, as it may cause the

water inside the water chiller to freeze and damage internal components.

• The appliance is not suitable for installation in an area where a water jet could be used.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play

with the appliance.

CAUTION:

• Mains Power Electrical Components. For the purpose of safety and hygiene, access to

the internal components of this appliance is restricted to persons having knowledge and

practical experience of the appliance.

• Ensure the electrical supply is turned off, before taking the front panel off to access internal

components.

• If the power supply cord is damaged, it must be replaced by the manufacturer, its service

agent or a qualified electrician in order to avoid a hazard.

• In order to avoid a hazard due to inadvertent resetting of the thermal cutout, this appliance

must not be supplied through an external switching device, such as a timer, or connected

to a circuit that is regularly switched on and off by the utility.

• Do not damage the refrigerant circuit. Care should be taken not to puncture refrigeration

system lines. Some lines contain gas under high pressure.

• Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of

obstruction.

• Do not use mechanical devices or other means to accelerate the defrosting process, other

than those recommended by the manufacturer.

• If freezing occurs, do not operate the appliance, until ambient temperatures is again above

0°C and frozen unit has completely thawed.

www.enware.com.au Call 1300 369 27 5

FRONT

PANEL

FIXING

SCREWS

installation

DFSA121-CBF water chiller is ready for final assembly on

site.

Remove water chiller and bottle filler from the packaging.

Remove the front panel of the chiller unit by unscrewing

the two fixing screws. Pull panel forward and slide down to

remove the front panel. SEE IMAGE 1

IMPORTANT - Ensure chiller unit is disconnected from

power supply before accessing the inside of the chiller

unit.

INSTALLING BOTTLE FILLER

1. Fit bottle filler to the basin top of the water chiller,

ensuring the location pin fits into the pre-drilled hole.

Fit spacer washer and backnut from underneath, and

tighten the backnut with a spanner to secure the bottle

filler assembly. SEE IMAGE 2

2. Screw the tube adaptor to the 1/2” bottle filler thread,

ensuring that the rubber seal is in place in the adaptor -

tighten firmly, but do not overtighten. SEE IMAGE 2

3. Push the 1/4” tube firmly into the adaptor socket until

it bottoms out - pull back gently to check that the tube

has locked. SEE IMAGE 3

IMAGE 1

IMAGE 2

Push tube in to connect. Pull back gently on the tube

to check it is locked.

To disconnect, ensure the system

is depressurized, push the collet

square against the tting.

With the collet held in this position

the tube can be removed.

IMAGE 3

6 Call 1300 369 273 www.enware.com.au

REMOVING BUBBLER (OPTIONAL)

The Water chiller is supplied with parts to allow the drinking

bubbler to be deleted or temporarily removed if not required.

1. Loosen and remove the back nut from under the bubbler.

2. Disconnect the 1/4'” tube by removing the small

compression fitting.

3. The bubbler can be removed and the rubber blanking

plug pushed into place. SEE IMAGE 4

4. Trace the 1/4” tube back to the tee-piece, then

disconnect all the tubes from the tee piece by holding the

collet at the joint in place and pulling the tube free from

the fitting. SEE IMAGE 3

5. Replace the tee-piece with elbow provided, connecting

the supply tube to the bottle filler. SEE IMAGE 5

IMAGE 4

IMAGE 5

CONNECT

TO 40MM

WASTE

BOTTLE

TRAP

WATER

INLET

IMAGE 6

WATER CHILLER INSTALLATION

1. Place water chiller in desired position and adjust levelling

feet so that the water chiller is stable and sitting level.

Note: This appliance must be placed in a horizontal

position. Ensure there is at least 50mm of gap between

the back of the unit and any wall for fan ventilation.

2. From inside of the chiller unit, connect the 40mm bottle

trap (supplied) to the waste connection located on the

underside of the top tray. Connect DN40 DWV PVC

drain pipe to the bottle trap. SEE IMAGE 6

3. (Optional) Install a carbon filter (DFS002F- sold

separately) inside the chiller unit.

Cut or disconnect the 1/4” tube that feeds the bottle filler

(&/or bubbler) and install the carbon filter in the line.

4. Install a non-return isolating valve or a stop tap (not

supplied) at the water supply as required. Flush all

foreign matter from the water supply line, then connect

water supply to the 1/2” BSP male inlet fitting located at

the rear of unit. SEE IMAGE 5

www.enware.com.au Call 1300 369 27 7

5. Turn the water supply on and purge the air from the

stainless steel chilling tank by pressing the push button

on the bubbler or turning on the bottle filler. Water may

spit from the outlets during this procedure and care

should be taken not to let water splash on walls and

furniture. Allow the water to flow for 5 minutes, starting

and stopping it frequently.

6. Check all plumbing for leaks. Check the bottle trap and

drain pipe connections for water-tightness.

7. Replace the front panel to the chiller unit.

8. Connect power cable to an electrical outlet.

(Electrical connection: a flexible 2m service lead, 3 pin

10 AMP plug supplied to connect the chiller to a 240V

50Hz AC supply.)

Turn power on. The refrigeration unit and the fans should

start to activate.

9. Once water is cooled and chiller function is checked,

turn off the power and disconnect the power cable.

Open the front panel and check all plumbing for leaks

once again.

IMPORTANT - Chiller unit must be disconnected

from power supply before accessing the inside of

the chiller unit.

10. Replace front panel of the water chiller and secure

the panel using screws provided.

Connect power cable and turn power back on.

Remove protective film from stainless steel panels.

8 Call 1300 369 273 www.enware.com.au

operation

ON

ON

OFF

BOTTLE FILLER

To turn on water flow, turn handle and hold.

To turn off water flow, let go of handle.

Water flow stops automatically.

(Handle can be turned either way until it

reaches a stop.)

PUSH

BUBBLER

To turn on water flow, push button down.

To turn off water flow, let go of button.

Water flow stops automatically.

www.enware.com.au Call 1300 369 27 9

flow adjustment

BOTTLE FILLER

Adjusting water flow rate (2 L/min - 7 L/min):

1. Unscrew and remove the regulator screw

cover cap using a slotted screw driver.

(Note this is only a cover - the regulator

screw is inside once the cover is removed.)

2. Locate the regulator screw inside. Turn the

spring action handle on full and adjust the

screw - tighten to reduce the flow or loosen

to increase the flow.

3. Once the desired water flow is achieved, put

the cover cap back on.

-

+

Regulator

screw

inside

Cover cap

Regulator Screw

Location

BUBBLER

Adjusting water stream height:

1. Unscrew hex cover nut from bubbler

body using a spanner (while water is

on). The nut and push button can be

removed to reveal the top of the spring

cartridge and the cartridge locking ring.

2. Locate the flow adjustment screw in

the top of the cartridge. While pressing

the cartridge to fully on position, using

a small slotted screwdriver, screw the

adjustment screw in to reduce stream

height, or out to increase stream height.

3. Replace the push button and hex cover

nut and tighten.

4. Re-test bubbler fountain for correct

operation.

HEX DRESS NUT

(892537)

PUSH BUTTON

CARTRIDGE

RETAINING NUT

CARTRIDGE

(BUB294)

SPOUT

BODY

T

YPE 61 SPANNER FOR CARTRIDGE RETAINING NUT (892530)

INLET SCREEN MESH (892531)

FLOW ADJUSTMEN

T

SCREW

10 Call 1300 369 273 www.enware.com.au

Grub

Screw

Spindle

Dome

Handle Insert

Circlip

SBA

HandleHandle

(BUB260C)

Colour Indicator Button

PART ENWARE

SALES CODE

Cam action top assembly BUB261

Cam action SBA BUB260C

Spring action SBA service kit

Includes 2x piston o-rings, 1x

spring, 1x light spring, 1x ball

bearing, 1x ball seating washer, 1x

seat o-ring, 1x red fibre washer

BUB289

Cam action dome

(with grub screw)

BUB221C

Grub screw 10-24 UNC x 3/16 SS 672455

Cam action handle (incl. circlip,

handle insert, blue colour indicator,

Anti-Vandal handle key)

VP378

Colour indicator button

(specify cold, warm or hot) MIS595

PART ENWARE

SALES CODE

Anti-vandal handle key MIS590

Spout O-ring 672357

Regulator O-ring BS008 672345

Backnut (brass) MIS517

Spacer 672473

Allen key 3/32” MIS592

Backnut

Spacer

Cam Action

Top Assembly

(BUB261)

Anti-Vandal

Handle Key

Cover Cap

Regulator

O-ring

Regulator Screw

Anti-Rotation

Pin

Spout

Spout O-ring

1/2” BSP x

1/4” tube

adaptor

components & spare parts

Cam Action Top Assembly (BUB261)

BOTTLE FILLER

www.enware.com.au Call 1300 369 27 11

BUBBLER

WATER CHILLER

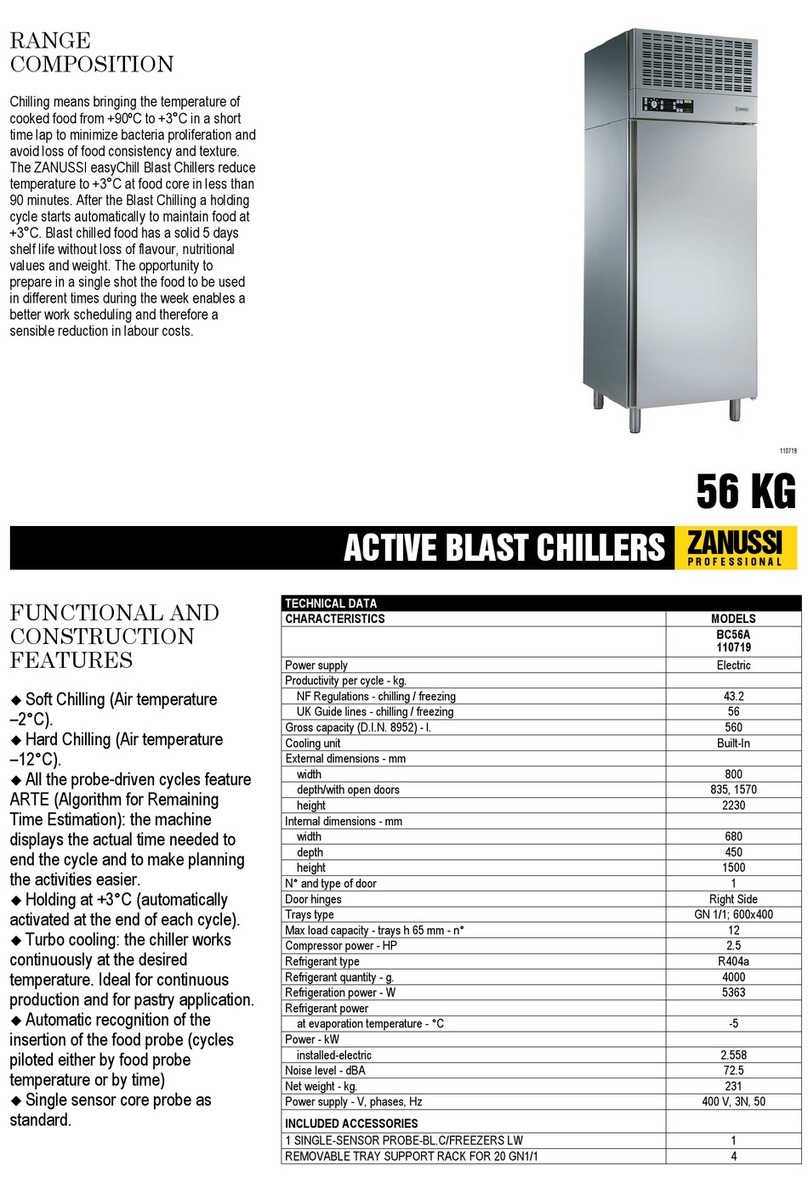

REFRIGERATION SYSTEM - The entire refrigeration system is hermetically sealed. Should

the system fail to operate, contact the manufacturer immediately.

Note: tampering with the refrigeration system in any way may void warranty.

WATER TEMPERATURE CONTROL SCREW - Located internally on the shelf, has been

factory set to provide chilled water at approx. 5°C to 10°C .

PART ENWARE SALES CODE

Bottle trap 40mm white adjustable height DFSAS202

Carbon inline water filter DFS002F

Thermostat DFSAS200

PRV 1/4" DFSAS201

PART ENWARE SALES CODE

Cartridge BUB294

Bubbler complete BUB290

HEX DRESS NUT

(892537)

PUSH BUTTON

CARTRIDGE

RETAINING NUT

CARTRIDGE

(BUB294)

SPOUT

BODY

T

YPE 61 SPANNER FOR CARTRIDGE RETAINING NUT (892530)

INLET SCREEN MESH (892531)

FLOW ADJUSTMEN

T

SCREW

12 Call 1300 369 273 www.enware.com.au

Every 6 months or periodically as required, the appliance and its surrounding area should be

inspected for water leaks, the bottle filler and bubbler should be tested for correct operation

and external panels should be given a light wipedown.

Filters if used should be replaced, depending on usage. Water storage tank should be purged

by running the tap for 5 minutes, before installing a new filter.

Every 12 months or as required, the bubbler stream height should be re-adjusted. If the

bubbler or bottle filler is leaking, the cartridge or bottle filler SBA should be replaced or

serviced.

The internal condenser and fans should be kept free of dust/ lint. It should be checked

periodically and cleaned with a brush or vacuum cleaner. Water cooler must be disconnected

from the power supply before following this procedure.

service & maintenance

www.enware.com.au Call 1300 369 27 13

BOTTLE FILLER - DOME ADJUSTMENT

Adjust the position of the dome if:

- there is play on the handle that needs to be adjusted;

- if the tap is not shutting off completely / water constantly running; or

- if there is no water flow

Adjust the dome by carrying out the

following steps:

1. Using a 3/32” or 2.5mm Allen key, undo

the grub screw located on the side of the

dome cover near the hex.

2. Unscrew the dome from the SBA slowly.

The water flow should stop.

3. Now this time, screw the dome into the

SBA. Water should begin to flow from the

outlet.

4. At this point, unscrew the dome just

slightly by approx. 1/4 to 1/2 a turn - the

water should stop flowing from the outlet.

This is the ideal position of the dome.

If the dome is screwed in too far, the handle will push the SBA piston down and let water

through constantly. If the dome is wound too far out, the handle will have too much play

and will feel loose.

5. Once the correct dome position is achieved, install the grub screw ensuring it is tightened

square against one of the SBA flats underneath to maximize vandal resistance.

6. Re-test the tap for correct operation.

7. If problems persist, refer to TROUBLESHOOTING.

14 Call 1300 369 273 www.enware.com.au

BOTTLER FILLER - SERVICING SPRING ACTION SBA

It is recommended that the spring action be periodically serviced. As a guide, every 6 months

the spindle should be cleaned and re-greased, and the handle insert and other components

checked for tightness. The servicing interval will vary depending on the frequency of use of

the product, water quality and the general environment.

On Cam Action product it is recommended to periodically check that the handle insert is

secure, by tightening with the Anti vandal handle spanner.

If the components inside the SBA are worn or damaged, replace the SBA or use the service

kit to replace components.

REMOVING THE TOP ASSEMBLY TO ACCESS SBA, CLEANING & REFITTING

1. Using a 3/32” or 2.5mm Allen key undo the grub screw located near the hex of the dome.

2. Unscrew the dome from the SBA.

3. Remove any grease or scale build up in the dome and the top assembly components. Use

a diluted solution of CLR for cleaning if necessary.

CLEANING AND LUBRICATING THE SPINDLE

The spring action can be maintained by simply cleaning and lubricating the spindle (piston)

using a silicon-based lubricant approved for potable water. This can be done without turning

off the water supply.

1. Pull out the piston (the top part) of the SBA and wipe off any excess grease. SEE IMAGE

NEXT PAGE

2. Clean the two small o-rings. Replace them if necessary, and re-grease them.

3. Push the piston back into the SBA.

REPLACING THE SBA

1. Shut off water supply and remove the top assembly.

2. Use a suitable spanner (26mm) and unscrew the SBA from the tap body. Make sure the

seal o-ring is not left on the seat of the body and the old red fibre washer is also removed.

3. Replace with a new SBA.

4. Turn on water supply.

5. Depress the piston to start water flow. Release the piston to stop the flow and check for

leakage. If a leak is present refer to Troubleshooting to identify cause of leakage and rectify

before proceeding.

www.enware.com.au Call 1300 369 27 15

SERVICING THE SBA WITH SERVICE KIT

1. Pull the piston assembly out from the SBA and

remove the 2 piston o-rings.

2. Use a spanner to unscrew bottom inlet port,

remove spring and stainless steel ball in the port.

3. Insert a small screw driver in centre hole of the

ball seating washer and remove the ball seating

washer by levering it out.

4. Clean all brass and chrome components.

Remove any debris or scale, especially on the

piston, spindle and in the dome. Use a diluted

solution of CLR for cleaning if necessary. Check

all brass components for wear or damage.

5. Lightly grease the two small piston o-rings

with a silicon based, potable water approved grease (e.g. Hydroseal Tap Lubricant or

Molykote111) and fit the two o-rings to the piston.

6. Now reassemble the SBA with new components from Service Kit. Place the ball seating

washer, ball and spring back in the bottom inlet port, and tighten up the bottom inlet port

to the SBA. Refit the seat o-ring and seating washer. Push the piston into the SBA.

RE-FITTING THE TOP ASSEMBLY

1. Grease the inside of the dome around spindle mechanism

2. Fit the dome and handle assembly.

3. Adjust the position of dome. SEE DOME ADJUSTMENT

SBA SPRING

STAINLESS STEEL BALL

BALL SEATING WASHER

PISTON O-RINGS

PISTON

HANDLE

If the handle feels loose, check that the handle

insert is fitted, and tighten with the Anti Vandal

Handle Key.

To take off handle, use the Anti-Vandal Handle Key

to loosen the insert. Handle pulls off the spindle.

16 Call 1300 369 273 www.enware.com.au

Enware product should be cleaned with a soft damp cloth using only mild liquid detergent

or soap and water. Do not use cleaning agents containing a corrosive acid, scouring

agent or solvent chemicals.

Do not use cream cleaners, as they are abrasive. Epoxy coated surfaces should only

be cleaned with a cloth and clear water or mild detergent. Use of unsuitable cleaning

agents may damage the surface. Any damage caused in this way will not be covered by

warranty.

If re-greasing spring action SBA spindles, always use a silicon-based potable water

approved lubricant such as Hydroseal ‘O’ Ring Lubricant or Molykote 111 silicone based

grease.

cleaning

www.enware.com.au Call 1300 369 27 17

troubleshooting

WATER CHILLER

PROBLEM CAUSE RECTIFICATION

No water at outlets Water not connected or turned

off

Connect and turn on water supply

Water frozen Adjust water temperature control on

thermostat to higher setting. Do not

operate the appliance, until ambient

temperature is again above 0°C and

frozen unit has completely thawed.

Water not cooled Power is not connected Turn power supply on

Fan ventilation not adequate Ensure there is gap behind back of

chiller to allow air flow from vents

Temperature setting too high Adjust water temperature control on

thermostat to lower setting

Poor water flow at outlets Bubbler stream is not adjusted Adjust bubbler stream

Carafe filler handle is too loose Adjust carafe filler adjusting nut and

handle

Carbon filter is blocked Replace carbon filter

Water leaks at outlets Bubbler cartridge is damaged Replace bubbler cartridge. Ensure

water pressure is below 500kPa

Carafe filler handle is too tight Adjust carafe filler nut and handle

Water tastes foul Carbon filter has been

contaminated

Replace carbon filter

Water in tank is stale Purge water in tank by running the

bubbler for 5 minutes

BUBBLER

PROBLEM CAUSE RECTIFICATION

Water runs constantly

from

bubbler outlet

Debris in cartridge Replace cartridge BUB294

Cartridge has been damaged Replace cartridge BUB294

Seating washer damaged or

spring broken

Install a pressure reduction valve.

Replace cartridge BUB294

No flow from bubbler

outlet

Water supply turned off Turn water on

Debris fouling inlet or outlet

ports of cartridge

Remove blockage

Rubbish/debris fouling outlet Remove blockage

Water discharge from top

of bubbler

Cartridge is damaged Replace cartridge BUB294

18 Call 1300 369 273 www.enware.com.au

troubleshooting

PROBLEM CAUSE RECTIFICATION

Water runs constantly from

outlet

Dome screwed in too far Adjust dome. See DOME

ADJUSTMENT

Dome incorrectly adjusted Adjust dome. See DOME

ADJUSTMENT

Debris fouling ball seating

washer or stainless steel ball

Dismantle SBA and clean

SBA ball seating washer is

damaged or spring is broken

Replace SBA components using SBA

service kit BUB289,or replace SBA

No flow from outlet Water supply turned off Turn water on

Debris fouling inlet or outlet

ports of SBA

Remove SBA and remove blockage

Rubbish/debris fouling outlet Remove blockage from outlet

Dome incorrectly adjusted Adjust dome. See DOME

ADJUSTMENT

Handle feels too loose Dome screwed out too far

Dome incorrectly adjusted

Adjust dome. See DOME

ADJUSTMENT

Handle insert is loose Tighten handle insert with Anti-Vandal

Handle Key

Spring action does not

move

Piston in SBA is seized Clean piston and piston o-rings,

and re-grease. Use SBA service

kit BUB289. (See service and

maintenance)

Water discharge from top of

dome/ SBA

Piston O-rings are worn Replace O-rings using SBA service

kit BUB289. Re-grease piston (See

service and maintenance)

BOTTLE FILLER

www.enware.com.au Call 1300 369 27 19

product warranty for Australia Eecve 27 September 2021

Enware Australia Pty Limited (ACN 003 988 314)

(“we” or “us”) warrants that this product (also referred

to as “our goods”) will be free from all defects in

materials and workmanship for 12 months* from the

date of purchase. Our liability under this warranty is

limited at our opon to the repair or replacement of

the defecve product or part, the cost of repair of the

defecve product or part or the supply of an equivalent

product or part, in each case if we are sased the

loss or damage was due to a defect in the materials or

workmanship of the product or part. All products must

be installed in accordance with the manufacturer’s

instrucons, the PCA, and AS/NZS3500 including any

other applicable regulatory requirements.

exceptions

This warranty does not apply in respect of any damage or

loss due to or arising from:

a) Failure by you or any other person to follow any

instrucons for use (including instrucons and direcons

relang to the handling, storage, installaon, ng,

connecon, adjustment or repair of the product)

published or provided by us;

b) Failure by you or any other person responsible for the

ng, installaon or other work on the product to follow

or conform to applicable laws, standards and codes

(including the AS/NZ 3500 set of Standards, all applicable

State and Territory Plumbing Codes, the Plumbing Code

of Australia and direcons and requirements of local and

other statutory authories); or

c) Any act or circumstance beyond our control including

faulty installaon or connecon, accident, abnormal use,

acts of God, damage to buildings, other structures or

infrastructure and loss or damage during product transit

or transportaon.

making a claim

To make a claim under this warranty you must

nofy us in wring within 7 days of any alleged defect

in the product coming to your aenon and provide

us with proof of your purchase of the product and

completed the Online Product Service and Warranty

Form available on website www.enware.com.au/

warranty-service-form.

All nocaons and accompanying forms must be sent to

us marked for the aenon of the Enware Australia Pty

Limited, 9 Endeavour Road, Caringbah NSW 2229. We

can also be contacted by telephone (1300 369 273) or by

email (info@enware.com.au).

Your costs in making a claim under this warranty,

including all freight, collecon and delivery costs, are

to be borne and paid by you. We also reserve the right

at our cost to inspect any alleged defect in the product

wherever it is located or installed or on our premises.

* Condional Warranty:

Water chiller: 12 months parts and labour

Boler ller: 10 years (2 years parts and labour, then 8

years parts only warranty)

other conditions

Except as provided or referred to in this document, we

accept no other or further liability for any damages

or loss (including indirect, consequenal or economic

loss) and whether arising in contract, tort or otherwise.

Any benets available to you under this warranty are in

addion to any non-excludable rights or remedies you

may have under applicable legislaon, including as a

“consumer” under the Australian Consumer Law. To that

extent you need to be aware that: Our goods come with

guarantees that cannot be excluded under the Australian

Consumer Law. You are entled to a replacement or

refund for a major failure and for compensaon for any

other reasonably foreseeable loss or damage. You are

also entled to have the goods repaired or replaced if

the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

ADDRESS: 9 Endeavour Rd Caringbah NSW 2229 Australia

POSTAL ADDRESS: P.O. Box 2545, Taren Point NSW 2229 Australia

1300 369 273 (AUS) WWW.ENWARE.COM.AU INFO@ENWARE.COM.AU

ABN 23 003 988 314

Table of contents

Other enware Chiller manuals

Popular Chiller manuals by other brands

Carrier

Carrier AquaForce 30XAV 500 Installation, operation and maintenance instructions

CIAT

CIAT LX User brochure

AIREDALE

AIREDALE TurboChill TCC11R04G-01 Technical manual

Parker Hiross

Parker Hiross Hyperchill ICE007 user manual

Nordcap

Nordcap SF 12/7-CW CRIO CHILL manual

Mueller

Mueller CP2-10 Installation and operation manual