7

GB

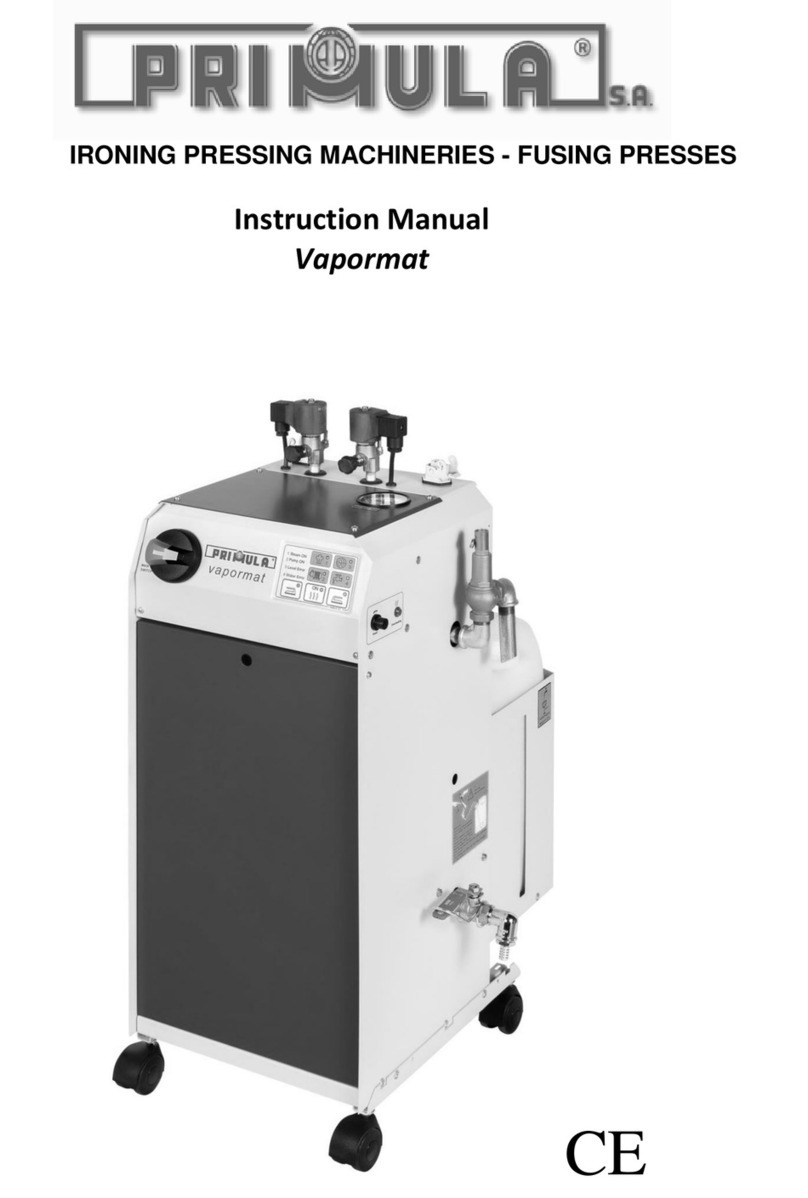

1.2 Installation locations and con-

nections

• Theassemblylocationofthesteamgen-

eratormayliemax.oneooraboveorbe-

low the steam cabin and the length of the

line between the steam generator and the

steam jet should not exceed 6 m.

If the distance is larger, the steam line

must be selected one dimension larger

than stated in these instructions.

Two steam jets should be provided for

steam generators >9 kW.

Please follow the instructions below for

assembly of the system components.

• The electrical installation must be de-

signed acc. DIN VDE 0100.

The system must be supplied via a separate

power circuit with a residual current circuit

breaker (I Δ= 30 mA) which disconnects

the device at all poles from the mains with

a contact opening width of at least 3mm.

The electrical installation may only be un-

dertaken by a licensed electrician.

• The steam generator water connec-

tion is a 50 cm-long reinforced hose (R

3/8") on a connection bracket provided

on-site (R 1/2") with 1-6 bar water pres-

sure, directly from the water mains.

At more than 6 bar water pressure, a pres-

sure reducing valve (setting 4-6 bar) is to

be provided.

• Forthewaterdrainforcontrolandclean-

ing purposes, the drain must be con-

nected with the outlet via a funnel si-

phon made of heat-resistant material.

The funnel and the drain must be di-

mensioned large enough so that they

arebrieyabletohold5-7lofuid.

Place the collecting funnel at least 30 cm

below the drainage outlet.

• Provide the following connection lines /

empty pipes

Designation Empty pipe Line

Temperature sensor Yes 2 x 0.5 mm²

Wall lamp Yes 2 x 1.5 mm²

Fragrance dosage pump

Yes 4 x 0.75 mm²

Supply air fan Yes 3 x 1.5 mm²

• For the steam line, the minimum

pipe diameter must be 35 mm.

The steam line(s) from the steam gen-

erator to the steam jets should be

made of copper or stainless steel pipe

withsufcientheatinsulation(20mm).

You can nd the position of the

steam jet in the cabin drawing.

The steam line must not be lockable

and it must not be possible to shut it

off. It must be protected against outside

inuences(kinkingordeformation).

Only45°bendsmaybeusedduetoow

reasons.

• Connecttheoptionalsupplyairfanwiththe

steam jet using a pipeline (HT pipe DN 40).

For assembly, please observe the Assem-

bly instructions enclosed with the fan.

Always mount the applica-

ble check valve horizontally.

If possible, do not mount the supply air fan

on the outer wall of the cabin.