eove EOVE-70 User manual

1

102-035 Rev DG _ 13/09/2022 _ Apply from API39 Version

EOVE–70

SECRETION MANAGEMENT DEVICE

TECHNICAL MANUAL

EO-Display version

2

Current version: API39

PAGES

CHANGES AND MODIFICATIONS

71 / 79

Update of preventive maintenance schedule –Pump must be replaced when the counter

reaches 1000h

83-84

Preventive maintenance alarms

3

SUMMARY

1 Warnings........................................................................................................................................ 10

1.1 Warnings and safety rules..................................................................................................... 10

1.2 Responsibilities...................................................................................................................... 10

1.3 Maintenance and guarantee................................................................................................. 10

2 General information...................................................................................................................... 11

2.1 Technical description............................................................................................................. 11

2.2 The Technical data................................................................................................................. 15

2.3 Structure and operation........................................................................................................ 15

2.3.1 EOVE-70 SMD module structure ................................................................................... 15

2.3.2 EO-Display housing unit structure................................................................................. 16

2.3.3 Operation of EOVE-70 SMD module ............................................................................. 17

3 EOVE-70 Interface ......................................................................................................................... 22

3.1 Main menu ............................................................................................................................ 22

3.2 Preferences............................................................................................................................ 24

3.3 Maintenance menu ............................................................................................................... 25

3.3.1 Maintenance menu interface........................................................................................ 25

3.4 EOVE-70 interface servicing .................................................................................................. 28

3.4.1 Interface software update............................................................................................. 28

3.4.2 API version change ........................................................................................................ 32

3.4.3 Android system update ................................................................................................. 33

3.4.4 Help interface and user manual update........................................................................ 36

3.4.5 Language selection........................................................................................................ 40

3.4.6 Brightness of the screen................................................................................................ 42

3.4.7 Transition Beep.............................................................................................................. 42

3.5 Clear patient data.................................................................................................................. 43

4 SMD management......................................................................................................................... 44

4.1 Communication ..................................................................................................................... 44

5 Calibration ..................................................................................................................................... 47

6 EOVE-70 SMD Servicing................................................................................................................. 50

6.1 EO-Toolkit presentation & settings ....................................................................................... 50

6.2 Events Log menu / Data retrieval.......................................................................................... 51

6.2.1 Events log ...................................................................................................................... 51

6.2.2 Export Clinical data from EO-Display............................................................................. 52

4

6.2.3 Download Clinical data from EO-Toolkit ....................................................................... 55

6.3 Display the observance ......................................................................................................... 56

6.4 Software update.................................................................................................................... 58

6.5 Serial numbers management ................................................................................................ 62

6.6 Counters management.......................................................................................................... 65

7 Conditions and procedures of the EOVE-70 maintenance............................................................ 68

7.1 Preventive maintenance requirements................................................................................. 68

7.2 Repair requirements in case of EO-70 SMD failure............................................................... 68

8 Cleaning and disinfection .............................................................................................................. 68

8.1 Surface disinfection............................................................................................................... 68

8.2 Keredusy disinfection............................................................................................................ 69

8.3 Guarantee of the cleanliness of the appliance...................................................................... 69

9 Periodical controls......................................................................................................................... 70

10 Preventive maintenance operations......................................................................................... 71

10.1 Preventive maintenance schedule ........................................................................................ 71

10.2 List of required preventive maintenance.............................................................................. 71

10.2.1 1-year servicing operation............................................................................................. 71

10.2.2 2 years maintenance operation .................................................................................... 72

10.2.3 4 years maintenance operation .................................................................................... 72

10.2.4 Other maintenance operation....................................................................................... 72

10.3 Filter and valves..................................................................................................................... 72

10.3.1 Control the pneumatic sealing of the patient circuit port ............................................ 73

10.3.2 Inhalation & Exhalation valves ...................................................................................... 74

10.4 Battery................................................................................................................................... 74

10.4.1 Internal battery information ......................................................................................... 74

10.4.2 Configuration of the new battery.................................................................................. 76

10.5 Pump ..................................................................................................................................... 79

10.6 Turbine .................................................................................................................................. 79

10.7 Solenoid valve........................................................................................................................ 79

10.8 Inspiratory flow sensor.......................................................................................................... 80

11 Curative maintenance ............................................................................................................... 81

11.1 Alarms.................................................................................................................................... 81

11.1.1 Failure warning alarm.................................................................................................... 81

11.1.2 Alarms conditions.......................................................................................................... 82

11.2 EO-Toolkit Event log .............................................................................................................. 84

5

11.3 Troubleshooting .................................................................................................................... 84

11.3.1 Troubleshooting trees ................................................................................................... 84

11.3.2 EO-Toolkit troubleshooting assistance.......................................................................... 84

11.3.3 Common SMD failure .................................................................................................... 86

12 EO-70 SMD module: Replacement procedures......................................................................... 87

12.1 List of components................................................................................................................ 87

12.1.1 EOVE-70 SMD module structure ................................................................................... 87

12.2 Air Filter................................................................................................................................. 88

12.3 Battery................................................................................................................................... 89

12.4 Module disassembly.............................................................................................................. 90

12.4.1 Opening the module...................................................................................................... 90

12.4.2 Closing the module........................................................................................................ 90

12.5 Pneumatic subassembly........................................................................................................ 91

12.5.1 Turbine .......................................................................................................................... 91

12.5.2 Pneumatic block ............................................................................................................ 91

12.5.3 Patient circuit port......................................................................................................... 92

12.5.4 Pump.............................................................................................................................. 92

12.5.5 Inhalation/exhalation valves block................................................................................ 93

12.5.6 Motherboard................................................................................................................. 93

12.6 Pneumatic connections......................................................................................................... 94

12.6.1 Left view of pneumatic block assembled ...................................................................... 95

12.6.2 Right view of pneumatic block assembled.................................................................... 95

12.7 Electrical wiring ..................................................................................................................... 96

12.7.1 Motherboard electrical connections............................................................................. 96

12.8 Internal pneumatic circuit..................................................................................................... 97

12.9 Pneumatic block .................................................................................................................... 99

12.10 Turbine ............................................................................................................................ 101

12.11 Turbine board.................................................................................................................. 101

12.12 Inhalation / exhalation valves ......................................................................................... 102

12.12.1 Inhalation / exhalation valves installed in pneumatic block ................................... 102

12.12.2 Inhalation / exhalation valves installed in valves block........................................... 103

12.13 Solenoid valves................................................................................................................ 104

12.14 Pump................................................................................................................................ 105

12.15 Inspiratory flow sensor.................................................................................................... 107

12.16 Motherboard................................................................................................................... 108

6

12.17 Keyboard.......................................................................................................................... 110

13 Performances controls via EO-Toolkit..................................................................................... 110

13.1 Materials requirement ........................................................................................................ 110

13.2 Performance controls.......................................................................................................... 111

13.2.1 EO-Toolkit Configuration............................................................................................. 112

13.2.2 Generate a snapshot ................................................................................................... 114

13.2.3 Update software versions ........................................................................................... 115

13.2.4 Test of the LEDs and the keyboard.............................................................................. 116

13.2.5 Electrical interfaces and communication.................................................................... 118

13.2.6 Performance and turbine tests ................................................................................... 120

13.2.7 Battery charge control................................................................................................. 124

14 Manual performance controls................................................................................................. 125

14.1 Inspection sheet .................................................................................................................. 125

14.2 OP1: Software controls........................................................................................................ 125

14.3 OP2: Control of keyboard LEDs and buttons....................................................................... 128

14.3.1 OP2-1: Turn on and configurate external DC power on 28V - 4A. .............................. 128

14.3.2 OP2-2: Press the ventilation button on the keyboard ................................................ 129

14.4 OP3: Control of electrical interfaces and communication with docking station ................ 129

14.4.1 OP3-1: Operation on 12VDC power ............................................................................ 129

14.4.2 OP3-2 : Operation on AC power.................................................................................. 129

14.4.3 OP3-3 : Operation on internal battery ........................................................................ 130

14.4.4 OP4-1: Set point ± 60 mbar in automatic mode.......................................................... 130

14.4.5 OP4-2: Inspiratory trigger control ............................................................................... 132

14.4.6 OP4-3: Set point ± 60 mbar in manual mode.............................................................. 133

14.5 OP4-4: Turbine performance controls ................................................................................ 135

14.6 OP5: Battery charge control................................................................................................ 135

15 Test of the pneumatic block.................................................................................................... 136

15.1 Pneumatic sealing control................................................................................................... 136

15.2 Solenoid valves electrical operation.................................................................................... 138

16 Test of rear valves block.......................................................................................................... 139

16.1 Pneumatic sealing of the rear valves block subassembly ................................................... 139

17 EO-Display housing unit: replacement procedures................................................................. 140

17.1 Opening and closing the EO-Display housing unit............................................................... 140

17.1.1 Docking station structure............................................................................................ 140

17.1.2 EO-Display Opening..................................................................................................... 141

7

17.1.3 EO-Display CPU Board electrical connections ............................................................. 142

17.1.4 Electronic boards removal........................................................................................... 143

17.1.1 EO-Display CPU board assembly ................................................................................. 146

17.1.2 EO-Display handle removal ......................................................................................... 147

17.1.3 EO-Display screen connections ................................................................................... 148

17.1.4 Cooling fan removal..................................................................................................... 150

17.1.5 EO-Display keyboard replacement.............................................................................. 151

17.2 EO-Display assembly............................................................................................................ 152

17.2.1 EO-Display peripheral connections ............................................................................. 152

17.2.2 EO-Display handle assembly........................................................................................ 154

17.2.3 EO-Display screen assembly........................................................................................ 155

17.2.4 EO-Display fan assembly ............................................................................................. 157

17.2.5 EO-Display closing ....................................................................................................... 159

18 EO-Display housing unit: Performance controls ..................................................................... 160

18.1 OP6-1: Operation on power source and charge control..................................................... 160

18.2 OP6-2: Software versions.................................................................................................... 161

18.3 OP6-3: Test of the communication with the module.......................................................... 162

18.4 OP6-4: Operation on internal battery of EO-70 SMD module ............................................ 163

18.5 OP6-5: Check USB ports ...................................................................................................... 163

18.6 OP6-6: Wi-Fi feature test (optional).................................................................................... 164

18.7 OP6-7: Interface setting ...................................................................................................... 164

18.8 OP6-8: EO-Display switch off from EO-70 SMD module ..................................................... 164

18.9 OP6-9: Visual inspection...................................................................................................... 164

19 EO-70SMD disposal ................................................................................................................. 165

19.1 Use of dangerous substance ............................................................................................... 166

19.2 Emissions in the air.............................................................................................................. 166

19.3 Rejects in surface water and groundwater table................................................................ 166

19.4 Waste, especially dangerous substance.............................................................................. 166

19.5 Use of raw material, energy................................................................................................ 167

19.6 Noise, vibrations, smell, dust, electromagnetic field.......................................................... 167

19.7 Transportation..................................................................................................................... 167

19.8 Risks caused by environmental accidents........................................................................... 167

19.9 Biosphere contamination.................................................................................................... 167

20 APPENDIX 1: Troubleshooting trees........................................................................................ 169

20.1 Supply Fail............................................................................................................................ 169

8

20.2 Battery Fail........................................................................................................................... 170

20.3 Turbine Fail.......................................................................................................................... 171

20.4 Speed Fault.......................................................................................................................... 172

20.5 Sensors failure / CPU Fail / Memory Fail / Device information lost.................................... 173

20.6 Insp. Flow Fail...................................................................................................................... 174

20.7 Keyboard Fail....................................................................................................................... 175

20.8 No communication between the unit and the ventilator ................................................... 176

21 APPENDIX 2: Software installation.......................................................................................... 177

21.1 EO TOOLKIT.......................................................................................................................... 177

22 APPENDIX 3: Inspection sheet................................................................................................. 181

23 APPENDIX 4: Spare parts list.................................................................................................... 182

24 Appendix 5: Components serial numbers ............................................................................... 186

9

INTRODUCTION

Technical Manual –EOVE-70 MANAGEMENT

10

1Warnings

1.1 Warnings and safety rules

This manual is specific to the EOVE-70 (ref EO70) Secretion Management Device (SMD). It provides

information for maintenance technicians and operators.

Anyone who installs or conducts maintenance operations on the device must be qualified and trained

and must have read and understood the entire manual before beginning any operations. Any

temporary personnel or those in training must be supervised by a qualified technician.

For other warnings or safety rules, refer to the user manual.

1.2 Responsibilities

EOVE will not be responsible for damages or injuries caused by non-compliance with safety instructions

and other instructions in this manual or by negligence during servicing, maintenance or repair of the

ventilator.

1.3 Maintenance and guarantee

The guarantee of the appliance will only apply if maintenance is performed in strict compliance with

the instructions in this manual. Maintenance of the appliance is compulsory.

Maintenance and replacement components are guaranteed and delivered by EOVE. In case of use of

incorrect replacement components, EOVE cannot certify and ensure the proper functioning of the

ventilator and the safety of the user and their entourage.

Replacement components are available from the EOVE catalogue and the EOVE Spare Parts List.

Technical Manual –EOVE-70 MANAGEMENT

11

2General information

The EOVE 70 (ref EO70) Secretion Management Device (SMD) provides treatment for patients not able

to manage their secretions on their own. It provides Insufflation –Exsufflation mode for adults and

pediatric patients as prescribed by an attending doctor.

2.1 Technical description

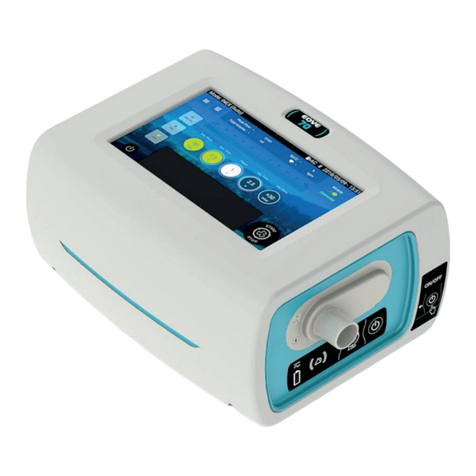

The EOVE-70 SDM consists of a ventilation module and a housing unit.

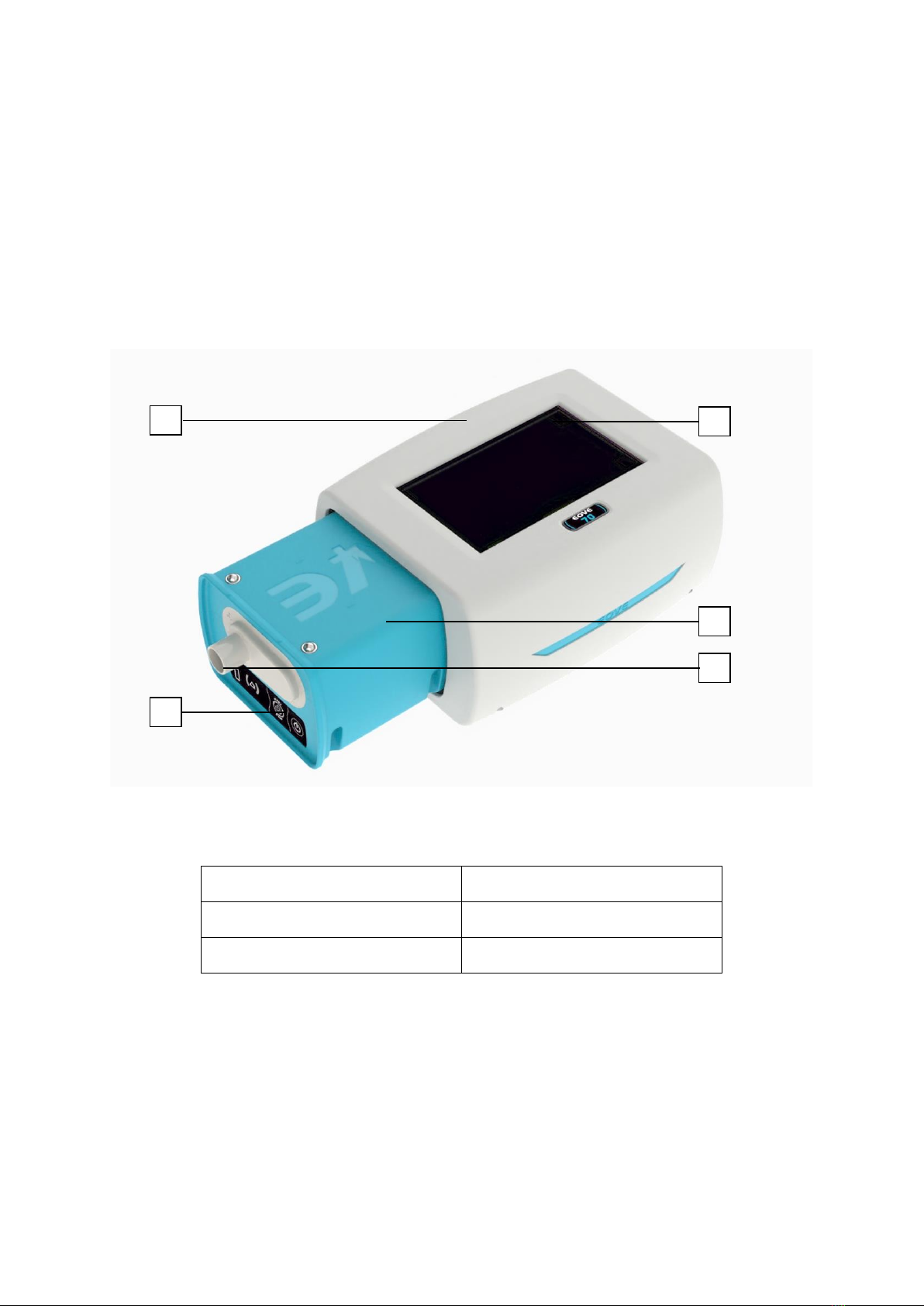

FRONT PANEL

EOVE-70 –Removable module

1. EO-Display housing unit

2. Display screen

3. Keyboard

4. SDM module

5. Circuit port

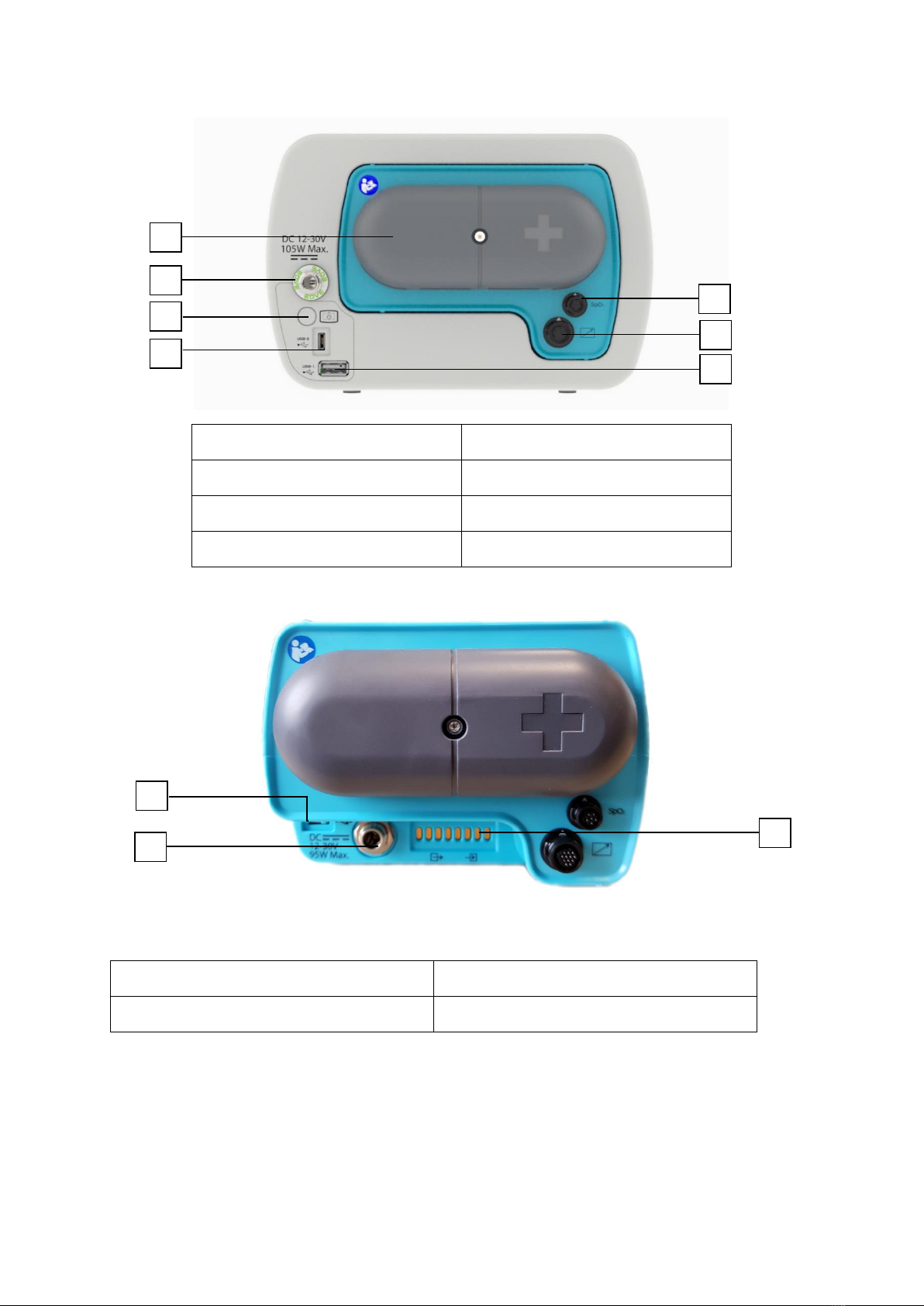

REAR PANEL

1

3

2

4

5

Technical Manual –EOVE-70 MANAGEMENT

12

1. Air inlet/outlet filters cover

2. SpO2 plug

3. DC Power plug

4. Remote control plug

5. Standby button

6. USB port 1

7. USB port 2

REAR VIEW OF DEVICE WITHOUT DOCKING STATION

1. USB port

2. Electrical connection to housing unit

3. DC Car charger connection

1

3

5

2

4

3

2

1

7

6

Technical Manual –EOVE-70 MANAGEMENT

13

VIEW FROM BELOW OF EOVE-70 SMD MODULE

1. Module label with serial number

2. Battery flap

KEYBOARD

1. Power source indicator

2. Alarm indicators

3. Treatment start / stop button

4. Power on/off button

5. Battery level indicator

1

2

1

2

3

4

5

Technical Manual –EOVE-70 MANAGEMENT

14

EO-DISPLAY HOUSING UNIT

The EO-Display housing permits to control the EOVE-70 SMD module when it is inserted inside. The

screen of the unit displays various information from the EOVE-70 SMD module and enables to set the

different parameters.

EO-Display housing unit –Inputs and outputs

1. DC Plug

4. USB connector

2. On/Off button

5. Display screen

3. Micro USB connector

1

2

3

4

5

Technical Manual –EOVE-70 MANAGEMENT

15

2.2 The Technical data

For technical data, refer to the EOVE-70 user guide.

2.3 Structure and operation

2.3.1 EOVE-70 SMD module structure

EOVE-70 SMD module architecture

Pneumatic

subassembly

Electrical

subassembly

Technical Manual –EOVE-70 MANAGEMENT

16

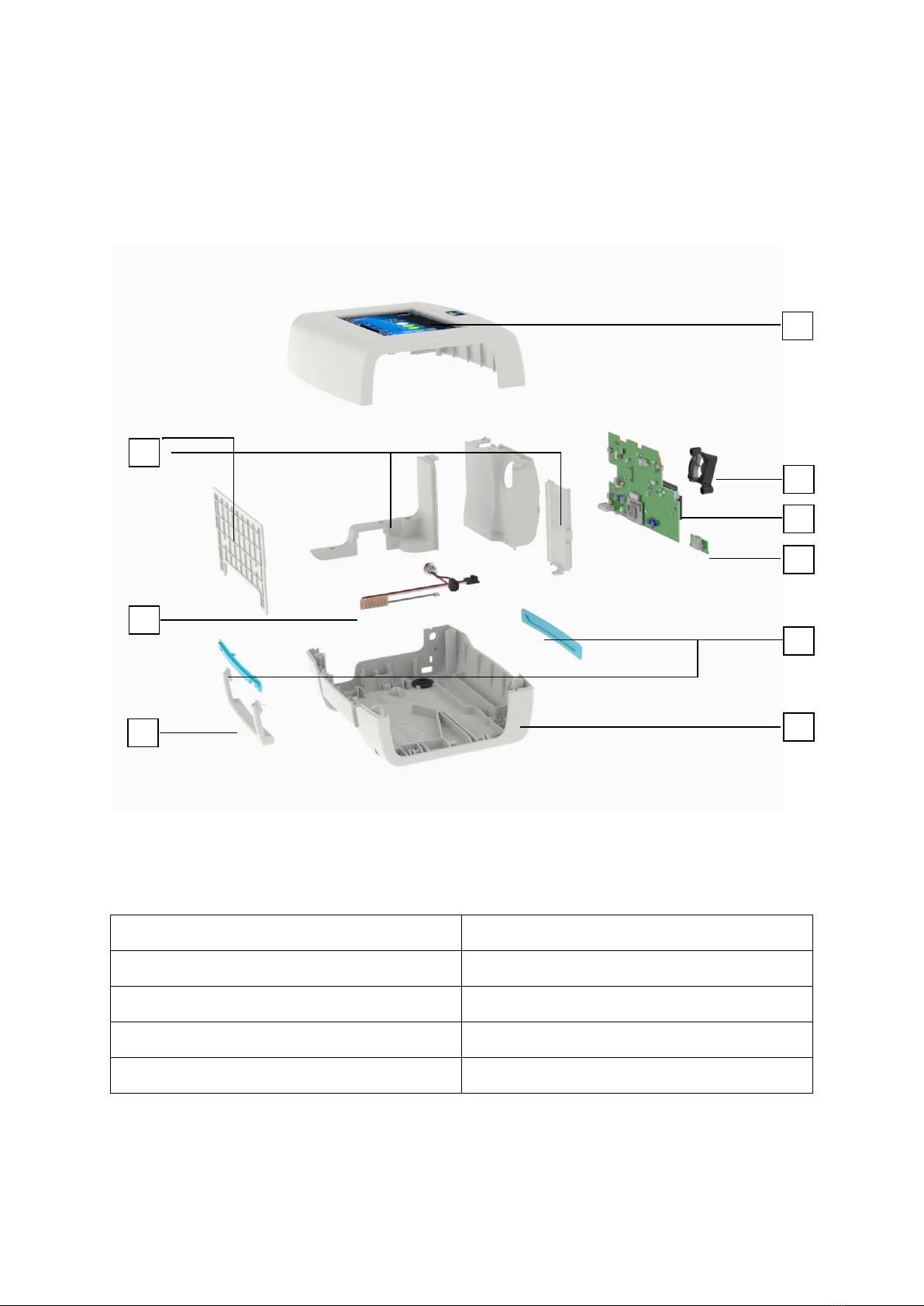

2.3.2 EO-Display housing unit structure

EO-Display Housing unit architecture

1. Upper shell & display screen

6. Lower shell

2. Cooling fan

7. Covers

3. EO-Display CPU board

8. Connection board & DC plug cable

4. USB board

9. Handle

5. Insert

1

2

3

4

7

8

5

9

6

Technical Manual –EOVE-70 MANAGEMENT

17

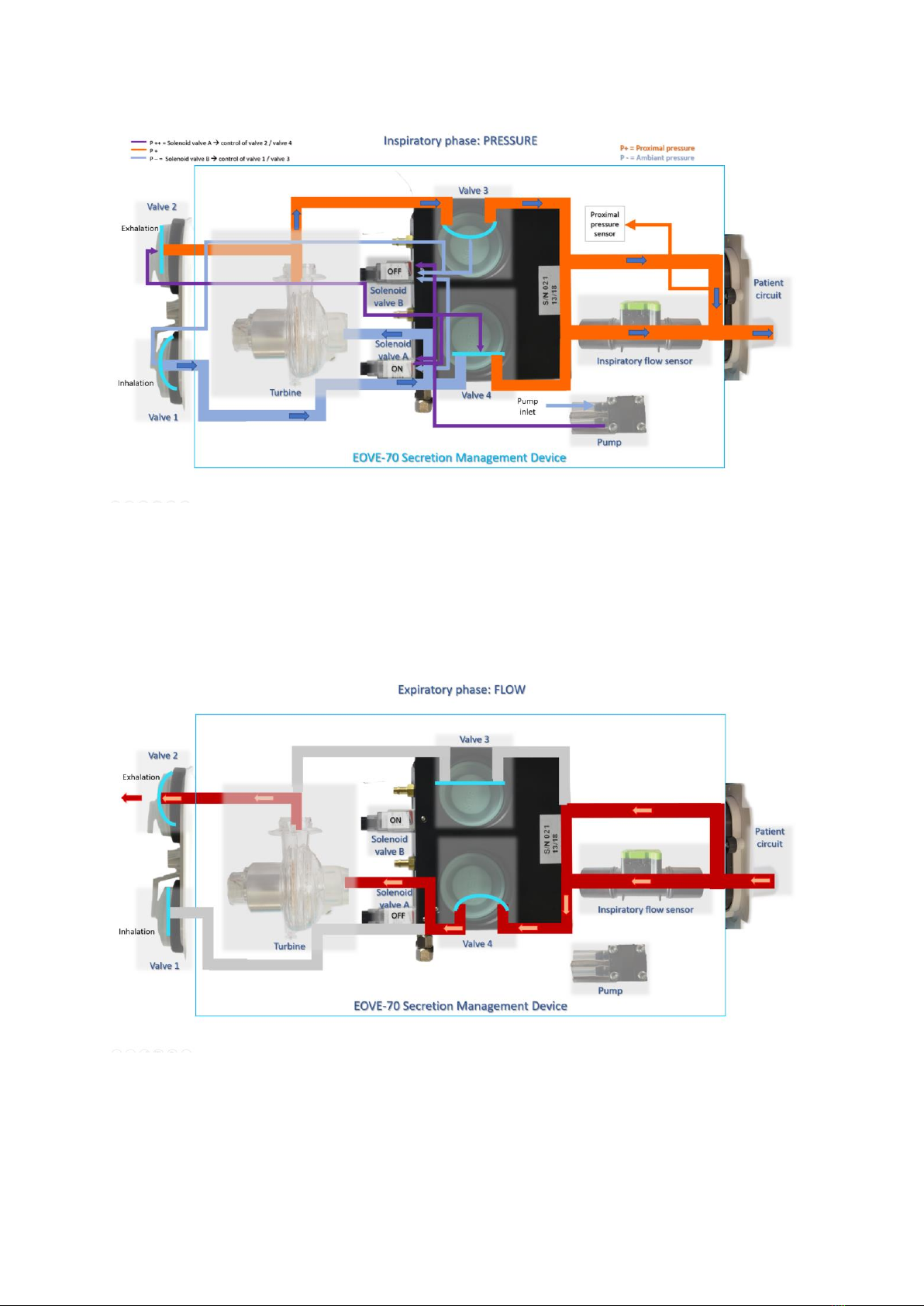

2.3.3 Operation of EOVE-70 SMD module

The operation of the EOVE-70 secretion management device is based on a closed control loop of the

proximal pressure. There are two distribution mode, automatic and manual. In both modes, a pressure

set point is send to the main actuator, the turbine. This pressure set point affectsdirectly turbine speed

which is proportional to pressure evolution. A high pressure set point will increase the turbine speed.

This pressure is measured by the proximal pressure sensor. Thus, the determination of distribution

parameters, especially the flow ramp rate affects the level of the turbine acceleration at the start of

each phase of respiratory cycle.

At the same time, the two solenoid valves control the four valves to manage phases of respiratory

cycles. A solenoid valve controls two valves during inhalation phase and the other one, the two others

during exhalation phase.

The measurement of inspiratory flow completes the system to calculate the peak flow and the tidal

volume on each respiratory cycle.

NOTE: When the EOVE-70 SMD is switched on but the ventilation is off, the turbine stills operate to

remain cool. There are two speeds for cooling during standby. Below 45°C the turbine speed is low,

and above the temperature threshold, the speed is higher. That is why there is always a low ambient

noise when the device is on.

Technical Manual –EOVE-70 MANAGEMENT

18

Operation of EOVE-70 SMD during inspiratory phase

During inspiratory phase, the EOVE-70 secretion management device provides positive pressure to the

patient. This pressure value depends on the set point configurated by the user and is proportional to

the turbine speed.

The air is inhaled through valve 1, and flows toward the turbine, then the valve 3 and the inspiratory

flow sensor.

During inspiratory phase, the low pressure (blue circuit on the drawing below) is equal to the

atmospheric pressure. The high pressure (orange circuit)provided by the turbine is equal to the

proximal pressure received by the patient. The difference of pressure between the two circuits is

positive.

Meanwhile, the pump enables to provide additional pressure to the two solenoid valves to control the

four valves. The solenoid valve A switches on to close valve 2 and valve 4. The solenoid valve B is turned

off, so the valves 1 and 3 are opened to permit the air to flow toward the patient.

Technical Manual –EOVE-70 MANAGEMENT

19

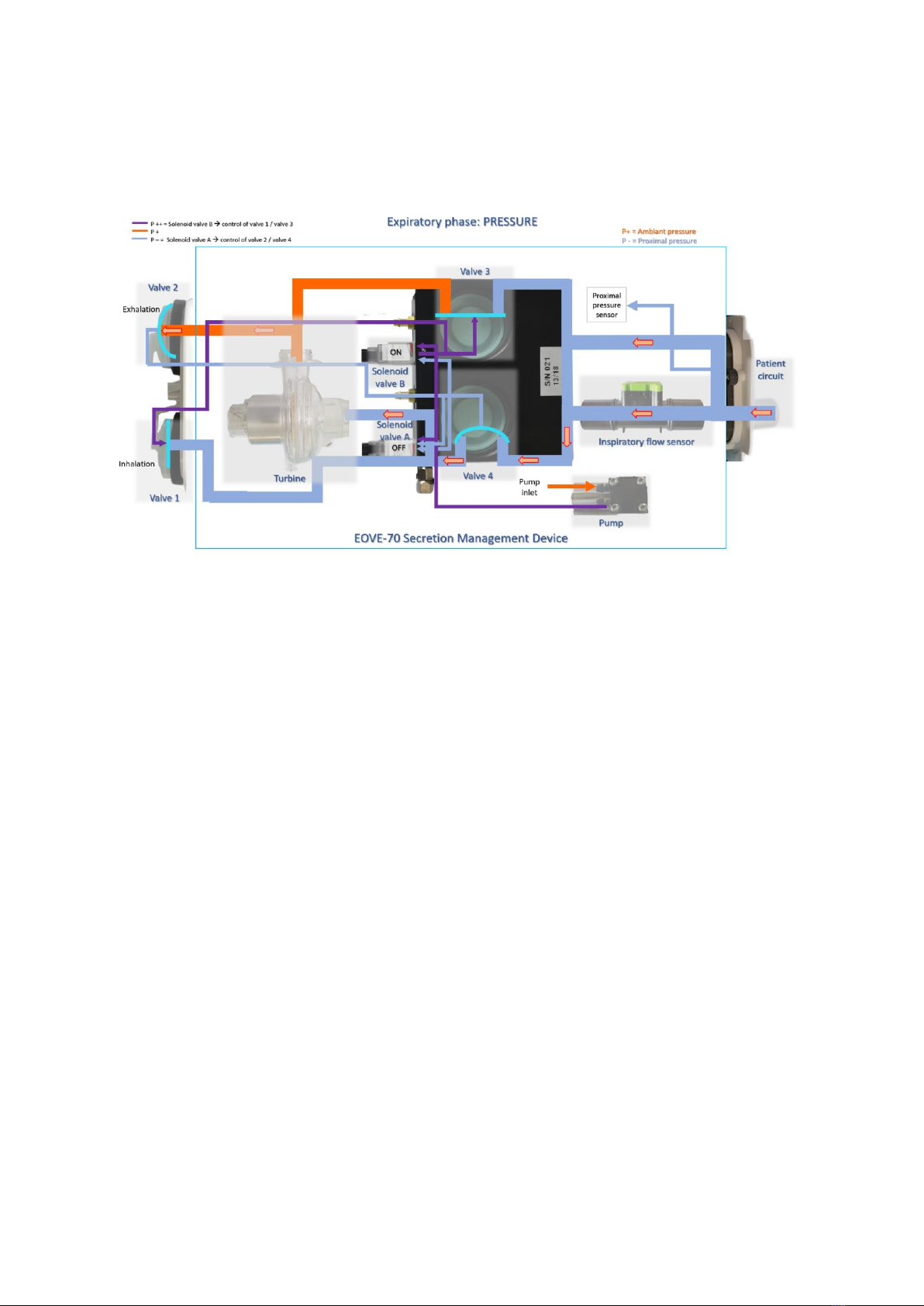

Operation of EOVE-70 SMD during expiratory phase

During the expiratory phase, the EOVE-70 secretion management device creates a suction to assist the

patient when he coughs. The air flows through the inspiratory flow sensor, the valve 4, then the turbine

and is exhaled by the valve 2.

During the expiratory phase, the low pressure is equal to the proximal pressure and the high pressure

is equal to atmospheric pressure. The difference of pressure between the two circuits is negative.

Technical Manual –EOVE-70 MANAGEMENT

20

The pump still provides additional pressure to the two solenoid valves to control the four valves.

However, during the expiratory phase, the solenoid valve B turns on to close the valve 1 and the valve

3 and the solenoid valve A switches off to open the valve 4 and the valve 2 to permit the exhalation.

Table of contents

Other eove Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual