EPE EPS-2000 Series User manual

EPS-2000” 10 to 40

kVA

Uninterruptible power system

Owner’s manual

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS-This manual contains important instructions for

models

EPS-2010 (10

kVA).

EPS-2015 (15

kVA),

EPS-2020 (20

kVA),

EPS-2030 (30kVA)and EPS-2040

(40

kVA)

that must be followed during installation, operation, and maintenance of the UPS and its

batteries. See page 4-7 for Battery Safety Instructions.

I

f

WARNING

OPENING ENCLOSURES EXPOSES HAZARDOUS

VOLTAGES. ALWAYS REFER SERVICE TO QUALIFIED

.PERSONNEL ONLY. I

f

NOTE

As standards, specifications, and designs change from time to time.

l

please ask for confirmation of the information given in this publication.

I

NOTE

I

f

This equipment generates and uses radio frequency energy, and if not

installed and used in strict accordance with the manufacturer’s instruc-

tions, may cause interference to radio and television reception. It has

0

been type tested and found to comply with the limits for a Class A

computingdeviceinaccordance

with thespecifications in Part 150f FCC

I

Rules, which

aredesignedto

provide reasonable protection against such

interference in a residential installation. However, there is no guarantee

that interference will not occur in

a

particular installation.

EPS-2000” 10 to 40

kVA

Uninterruptible power system

Owner’s manual

for service

call:

1

-

800 -GETS

-

EPE

66-141024-00

NC

4/92

Copyrighl

0

1992 EPE Technologies. Inc.

All rights reserved. Printed in U.S.A.

1660

Scenic Avenue

Costa Mesa. CA 92626

(714) 557

-

1636

1

EPS-2000”

IO

to 40

kVA

Uninterruptible power system

Owner’s manual

Owner’s Manual

ii

iii

vi

vi

l-l

1-2

l-5

l-5

l-6

l-6

I-6

l-7

l-7

l-9

l-8

l-8

l-8

l-9

1-9

1-9

1

-

12

l-12

l-12

l-12

l-13

l-13

l-13

l-13

1.13

l-13

l-13

Saiety

Information

WaMlty

COW3ltS

List of Illustrations

List of Tables

Section I-INTRODUCTION

1.0 Scope

1.1

System Description

1.1

.l

Model Number Format

1 .1.2 Rectifier/Battery Charger

1.1.3

Static

Invwter

1 .1.4 Static Switch

1 .1.5 Maintenance Bypass

1.2 Programmable Controls and Indicators

1.21

System Status and Control Panel

(SSACP)

1.3

Specifications

1.3.1 AC Input Ratings

1.3.2

Bypass AC Input Ratings

1.33

lnwter

AC Output Ratings

1.3.4

Battery

Characteristics

1.3.5 Environmental Characteristics

1.3.6 Other Characteristics

1.4

Options

1.4.1 Sits Distribution Center (SDC)

1.42

Auxiliary Cabinet Assembly (ACA)

1.4.3 BATTERY PAC Assembly (SPA)

1.4.4 Remote Monitor (RM)

1.4.5 Remote Alarm Panel

1.4.6 Remote Communications Link

1.4.7 Modem

1.4.8

Remote Emergency Power Off (REPO)

1.4.9

DC Ground Fault Indication

1.4.10 Smoke/High Temperature Warning (BATTERY PAC)

Conlen,*

Paw

1

EPS-2000”

Uninterruptible Power System

2-1

2-1

2-1

2-2

2-2

2-3

2-4

2-5

2-5

2-5

2-10

2.10

2.10

2-10

2.10

2-11

2-11

2.12

2.15

2-15

2-15

2-16

2.16

2.17

2-17

2-19

2.19

2-19

2-20

2-20

2-20

2

*

21

2-21

2

-

22

Section II -INSTALLATION

2.0 scope

2.1 Receiving

2.2 Handling

2.3 Storage

2.4 Prerequisites to the

InstaffatiOn

2.5 Installation Procedure

2.5.1

Air Fitter Installation

2.52 AC Input Connections

2.53 Bypass AC Input

(MAINS2)

Connection

2.5.4 UPS Output Load Connection

2.5.5 Battery Connections

2.5.6

Controwlntetface

Wiring

2.5.6.1 BPA or External Battery Disconnect Switch

(TBl)

2.5.6.2

Contact Closure Control Wiring

(TBZ)

2.5.6.3 Remote Interface Panel Wiring (TB3)

2.7 Start-Up Procedure

2.7.1 Checks Prior to UPS Start-Up

2.7.2 UPS Initial Start-Up Procedure

2.7.3 Anomalies

2.8 Tests After Initial Start-Up

2.9.1

Start/Stop Test

2.8.1.1

Rectifier/Battery Charger

2.8.1.2

lnverter

2.9.2

On Battery Operation Test

2.9.3

Manual Bypass Operation

2.9.4 Emergency Power Off (EPO)

2.9.5

Site

Environment

Test/External

Contacts

2.8.5.1

Battery Ventilation Fault

2.8.5.2 Remote Emergency Power Off (REPO)

2.8.5.3

External Contact Closures

2.8.5.4 Auxiliary Cabinet Fault Contact Closure

2.9 Voltage and Current Measurements

2.9.1 Voltage Measurements

2.9.2 Current Measurements

Owner’s Manual

3-1

3-1

3-4

3-4

3-5

3-5

3-6

3-7

3-6

3-6

3-9

3-9

3-10

3-10

3-13

3-15

3-20

3-22

3

-

22

3

-

22

3

-

23

3-24

3-25

3-27

3.27

3

-

27

3

-

27

3

-

28

3-26

3

-

26

3

-

29

3.29

3-30

3.0 scope

3.1 System Status and Control Panel (SS&CP)

3.2

Controls

3.2.1

Eleciro-Mechanical

Controls

3.2.2 Programmable Controls

3.3

EPS Monitor

3.3.1 Instructions

3.3.2 Menus

3.3.2.1 Start-Up

3.3.2.2

Inverter

OrKlff

3.3.2.3 Display Contrast

3.3.2.4 Battery Transfer Test

3.3.2.5 Bypass Procedure

3.3.2.6 Commands

3.3.2.7 Diagnostics

3.3.2.6

Personalizatian

3.3.2.9 Communication

3.4

Operating Modes

3.4.1 Automatic Operating Sequences

3.4.1.1 Normal Operation

3.4.1.2 On

Batiery

Operation

3.4.1.3 Input Power

Restored/Battery

Charging

3.4.1.4 UPS

lnverter

Shut-Down or Major Overload

3.4.2 Manual Operating Sequences

3.4.2.1 Rectifier/Battery Charger Start or Stop

3.4.2.2 UPS

lnvefter

Stat

or Stop

3.4.2.3 UPS Isolation for Maintenance

3.4.2.4 Returning the UPS to Normal Operation

3.5

Alarm Conditions

3.5.1

Minor Alarms

3.5.2 Major Alarms

3.5.2.1 Rectifier/Battery Charger

Major Alarms

3.5.2.2 UPS

lnverter

Major Alarms

Section IV

-

MAfNTENANCE

4-1

4.0

scope

4-t

4.1 Preventive Maintenance

4-2

4.2

General Diagnostic Capability

4-2

4.3

Component Replacement

4-2

4.3.1 Replacing Plug-In Power Modules

4-3

4.32

Replacing Printed Circuit

Assemblies (PCAs)

4-4

4.4

Replacement Parts

4-7

4.5

Battery maintenance

Glossary. 1

Glossary

EPS-2000m

UninterruDtible

Power

SYStefII

List of Illustrations

P=W

Figure

Title

l-l

1

l-2

2

1-3 3A

1-4

38

1-9

4

2-1

5

2-2

6

2-4

6

2-6

9

2-9

10

3-1

11

3.22

12

3-23

13

3

_

24

14

3-25

15

3.26

16

3.27

17

List of Tables

EPS-2000~ Pictorial

EPS-2000M UPS Single Line Diagram

EPS-2000m

UPS Major Internal

Components

-

10. 15. and 20

kVA

Models

EPS-2000” UPS Major Internal

Components

-

30 and 40

kVA

Models

System Status and Control Panel

(SSKP)

Handling

Bottom View. 10 to 40

kVA

Models

Right Side Cable Access

Wiring Area

Wiring Detail

System Status and Control Panel (SSSCP)

Power Flow

-

Normal Operation

Power Flow

-

Emergency Operation

Battery Charge Cycle

Power Flow

-

UPS

lnverter

Shut-Down or Major Overload

Overload Curve

Power Flow

-

UPS Maintenance

l-12

1

Standard Models

2-7

2A

Cable Sizing Data, 60 Hz Models

2-6

26 Cable Sizing Data, 50 Hz Models

4-5 3A Replacement Parts

-

EPS4010,

EPS-2015, EPS-2020

4-6

36 Replacement Parts

-

EPS-2030, EPS-2040

Owner’s Manual

1.0 scope

This manual provides technical information re-

quired for the installation, operation, and main-

tenance of the

EPS-2000m

Uninterruptible Power

Supply (UPS) System. Please read this manual

thoroughly before installing or operating the

EPS-

ZOOOW

equipment. The manual is divided into

four sections:

Section I

-

Introduction

This section serves as an introduction to the

manual and the

EPS-2000~

series

of UPS

products rated 10 to 40

kVA.

The UPS system

is described, followed by specifications for

standard models, an introduction to controls

and indicators, and a description of available

options.

Section II

-

Installation

This section explains procedures for receiving.

handling, and storing the equipment,

prerequisites to the installation procedure, in-

stallation, and equipment start-up procedures.

Introduction

Section

Ill

-

Operation

This section describes the

EPS-2000m

System

Status and Control Panel

(SSKP),

including

programmable controls and indicators. electro-

mechanical controls. UPS operating modes, and

system

alsrm

conditions.

Section IV

-

Maintenance

This section describes preventive maintenance

procedures, diagnostic capabilities of the UPS

system, and includes a listing of replacement

parts for the various UPS models.

In the rear of the manual is a glossary which

provides definitions for terms used within the

text. An Index makes it easy to find topics

of interest.

Door Lock ,

Air Filter

(Behind Screen.

Beneath Enclosure) \

System Status and

Control Panel

(SS&CP)

Circuit Breakers

(Behind

Door)

EPS-2000”

Uninterruptible Power System

Figure 2:

EPS-ZOOOTM

UPS Single Line Diagram

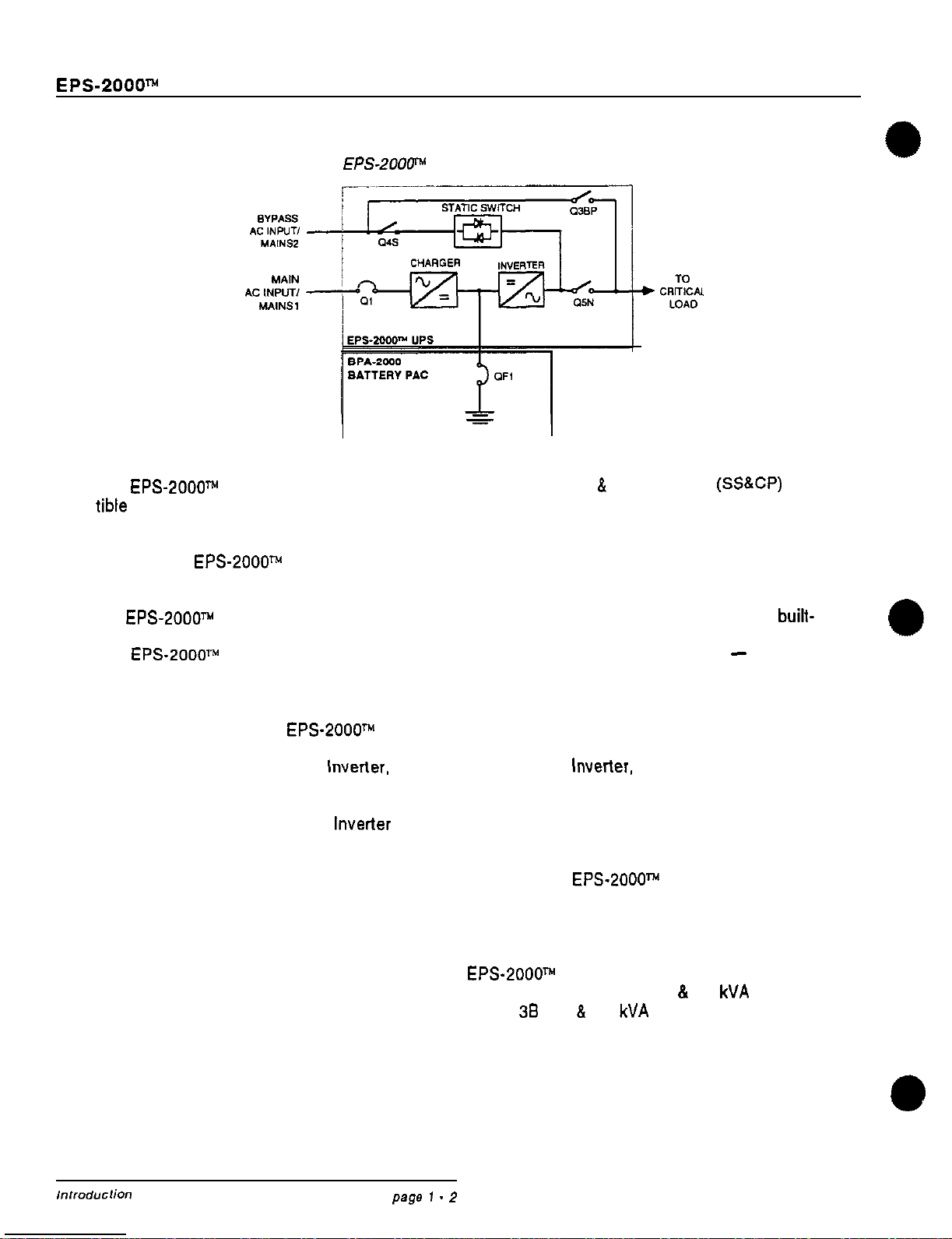

1.1 System Description

The

EPS-2000~

is an on-line static uninterrup

tible

power supply (UPS) system, designed to

protect critical loads from anomalies normally

encountered on a building’s power distribution

system. The

EPS-2000m

UPS and its auxiliary

equipment can be installed in a computer room

or an equipment room. Figure 1 is a pictorial of

the

EPS-2000TH

UPS System.

The

EPS-ZOOOW

UPS and its auxiliary equip-

ment are listed by Underwriter’s Laboratories,

Inc. (UL).

Major components of the

EPS-2000m

include a

Rectifier/Battery Charger, a transistorized pulse

width modulated (PWM) Static

Inverter,

a con-

tinuous duty rated Static Switch which automati-

cally transfers the load to and from the bypass

AC input source and the UPS

lnverter

output,

an internal Maintenance Bypass function which

is comprised of three separate switches that

allows the critical load to be operated from the

utility source while the UPS output is isolated

for service, and a battery system housed in an

external matching enclosure.

A System Status

&

Control Panel

(SS&CP)

pro-

vides controls to select system operation, and

indicators which allow system performance to

be monitored. A liquid crystal display (LCD) is

used to display system operating parameters,

provide step-by-step operating instructions to

the system operator, and provide a diagnostic

capability to assist in troubleshooting. The

built-

in EPS Monitor software is programmed to dis-

play messages in five languages

-

English,

French, German, Spanish, and Italian.

The EPS-2000” uses microprocessors to pre-

cisely control operation of the Rectifier/Battery

Charger, transistorized pulse width modulated

(PWM) Static

Inverter,

and Static Switch to in-

sure optimum performance for all line, load, and

operating conditions. In addition, a micropro-

cessor-based diagnostic system assists in trouble-

shooting faulty assemblies for replacement, to

minimize service time. Modular construction

throughout the

EPS-2000m

UPS facilitates main-

tenance of the system.

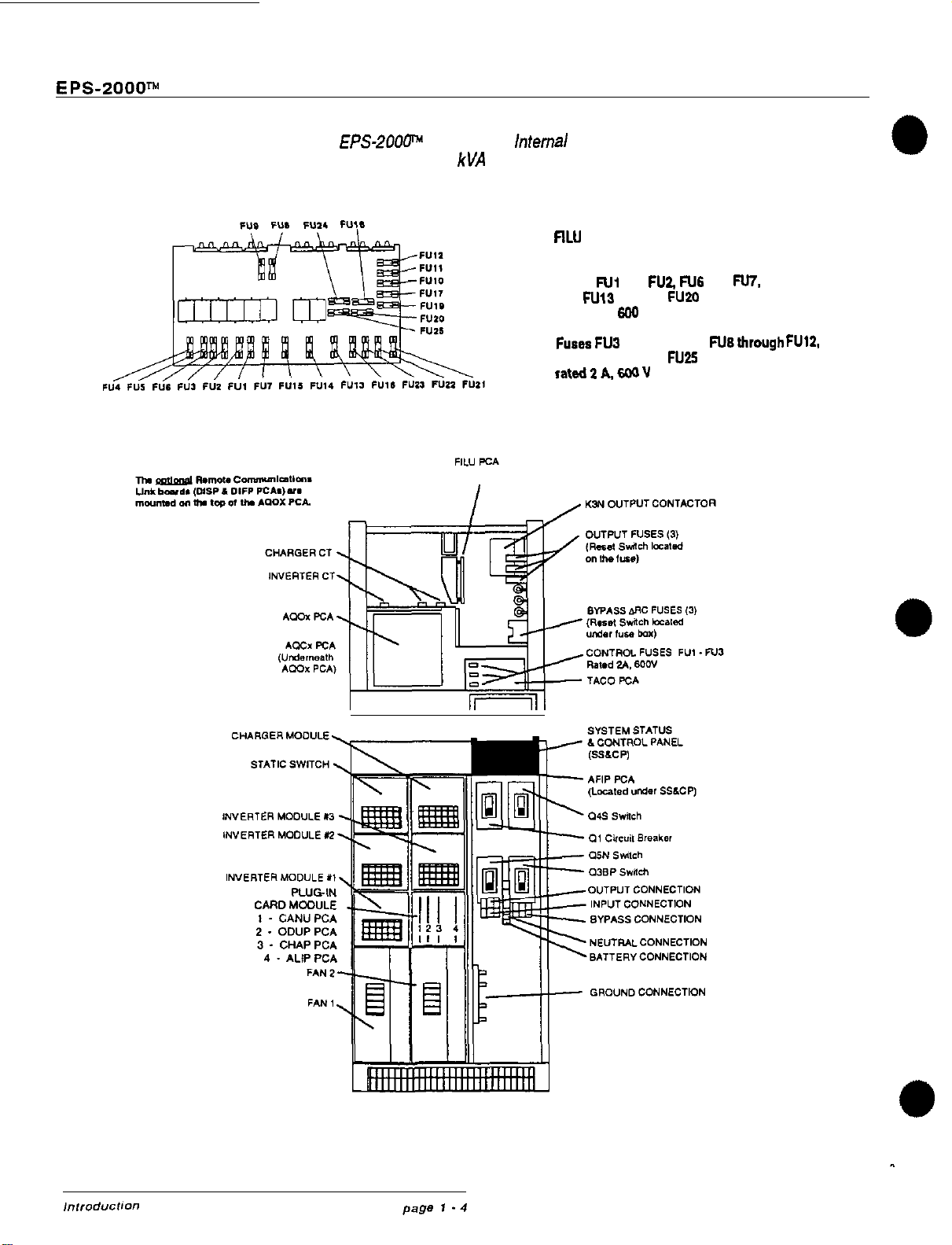

A single-line diagram of the EPS-2000”” UPS

system is shown in Figure 2. The location of the

EPS-2000m

UPS major internal elements is

shown in Figure 3A (10. 15.

&

20

kVA

Models),

Figure

38

(30

8

40

kVA

Models).

,“,,od”crio”

page

1

-

2

Owner’s, Manual

Figure 3A:

EPS-2OOp

UPS Major

lnfemal

Components

IO,

15.

and 20

kVA

Models

FILU PC Assembly

Conbol

Fuse

Locations

Fuass

FUI

and

FUZZ,

FU6

and

FE’,

and

N13

through FUZO

rated 5

4 600 v

Fuses FU3 through FU5, FU6 through

FUIZ,

and

FUZI

through FU25

rated2 A. 600 V

F”3

I

I,

EPS-2000m

Uninterruptible Power System

Figure 38:

EPS-2OOF

UPS Major

lntemal

Components

30 and 40

kVA

Models

flLU

PC Assembly

Control Fuse Locations

Fuses

Ni

and

FU2

FlJ6

and

M.

and

FM3

through FUZO

rated 5 A,

600

V

Fuses

F”2

through FU5,

FU8through

FU12.

end FU21 through FU25

rated21/wJV

Owner’s

Manuai

1.1.1 Model Number Format

The Model Number Format used for the EPS- Standard Models and characteristics are listed in

2000TM

series of UPS follows: Table

1.

EPS

-

2 XXX

/

Vi

V,,

5

F,

output Power

Ratina

in

kVA

010

I10

015

=

15

020

= 20

030

=

30

040

=

40

FW.WenC~

m

2

.208

5=50

3

=380

6

=

60

4

=4so

6

=6W’

M

=220

D

=240’

A

=4o0

E

=415

‘Not available as an

output voltage

1.1.2 Rectifier/Battery Charger

The Rectifier/Battery Charger consists of:

l AC Input Circuit Breaker

(al):

The AC

*

Input Circuit Breaker provides mechanical

isolation and electrical protection for the in-

put of the UPS.

-

Input Autotransformer: The Input Autotrans-

former is used to match the external AC

input source to that internally required for

the UPS. .

Power Module: The Power Module is a

plug-in unit which converts incoming AC power

lo

a regulated DC output voltage. The regu-

lation is carried out by controlling the

SW

conduction angles, allowing the Rectifier/

Battery Charger to supply a stable DC volt-

age

(2

1%). The DC voltage is filtered by a

capacitor bank.

DC Shunt: The DC Shunt is used to moni-

tor the battery charge current and provide

data for regulating the DC voltage at the

desired level. Battery current is normally

limited to 10% of the Ampere-Hour (Ah) rat-

ing of the battery siring.

EPS-2000~~

Uninterruptible Power System

1.1.3 Static lnverter

The Static lnverler consists of:

Power Module: The Power Module is a

plug-in unit, used

lo

chop the DC voltage to

obtain the PWM waveform at the primary of

the output transformer. A single power module

is used for UPS systems having an output

rating of 20

kVA

or lower. UPS systems

rated above 20

kVA

use three power mod-

ules, one module per phase.

lnverter Transformer: The lnverter Trans-

former is a full isolation transformer which

provides input/output electrical isolation for

the UPS, provides the required output volt-

age, and provides the required inductance

for the AC output filter.

AC Output Filter: The output filler is used

to achieve a computer grade sine wave

output voltage waveform, with a Total

Harmonic Distortion (THD) of 4% maximum

(3% typical).

1.1.4 Static Switch

The Static Switch transfers the load from the

UPS lnverter

output

to the bypass AC input source,

or from the bypass AC input source to the UPS

lnverter Output, without any interruption to the

load (provided that the UPS lnverter output is

synchronized lo the Bypass AC Input source).

These transfers take place automatically upon

lnverter start-up or shut-down. The Static Switch

is rated for continuous duty, and is of plug-in

construction for ease of maintenance.

The ARC circuit network protects the Static Switch

against high voltage spikes and surges by

absorbing the excess

enerov.

The ARC circuit

network

ib

protected by

fus&.

and any failure

of

these fuses will be displayed on the

SS&CP

LCD.

1.1.5 Maintenance Bypass

The internal Maintenance Bypass function con-

sists of three switches which, when operated

as specified, provide a make-before-break transfer

of the load from the UPS lnverler output to the

bypass AC input source, or from the bypass AC

input source to the UPS lnverler output. This

feature allows the critical load to be operated

from the utility power source while the UPS

lnverter output is isolated for maintenance.

The three internal Maintenance Bypass non-auto-

matic switches are designated as:

A. Bypass (MAINS2) Input

(04s)

B. UPS Output Isolation

(Q5N)

C. Maintenance Bypass

(Q3BP)

Correct operation of the three switches is shown

on the Liquid Crystal Display (LCD), located on

the System Status

&

Control Panel

(SS&CP)

as

part

of the procedure for

star+up

or shut-down

of the equipment.

Owner’s Manual

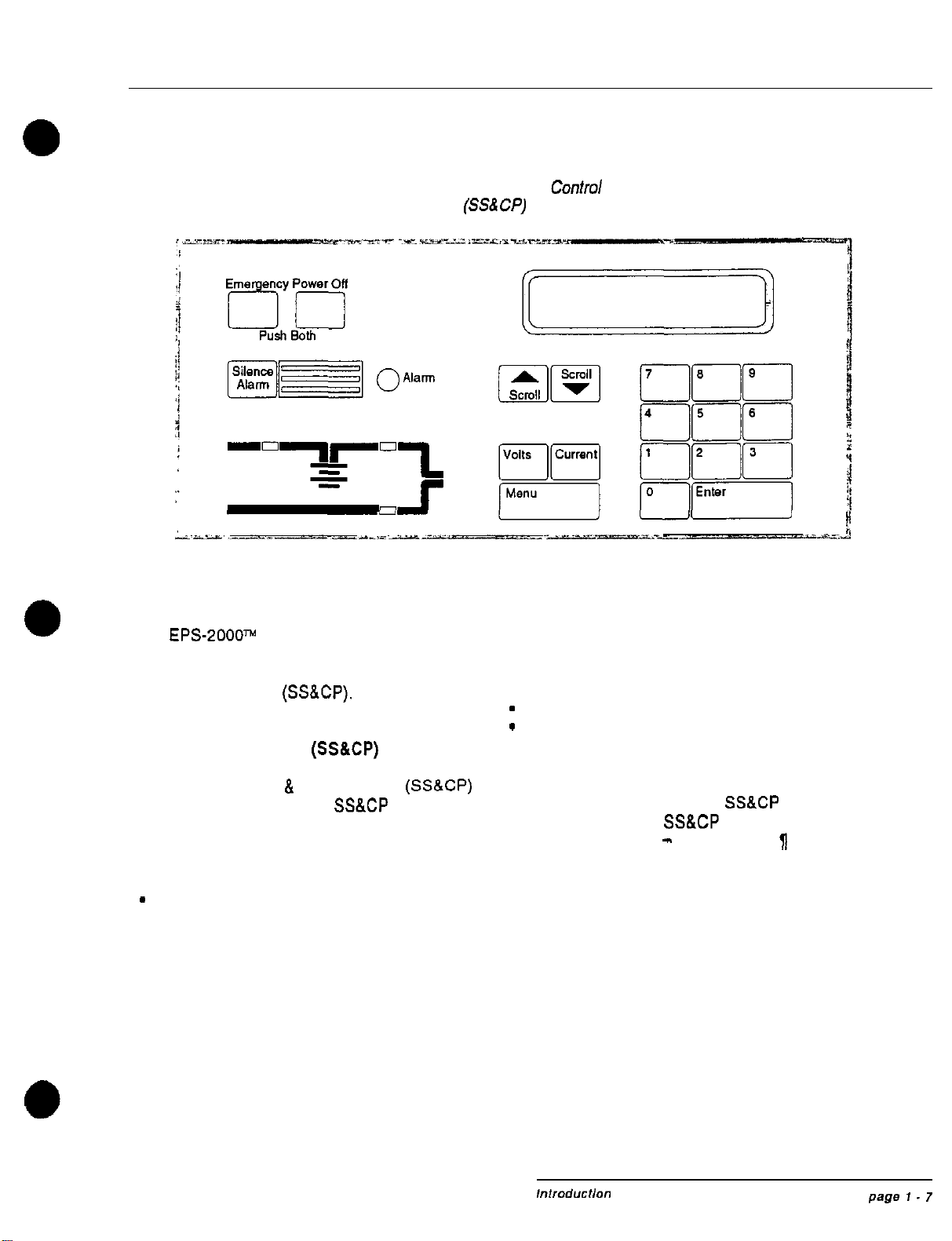

figure 4: System Status and

Confro/

Panel

(SSS CP)

1.2 Programmable Controls and Indicators

All

EPS-2000w

Programmable Controls (exclud-

ing circuit breakers and non-automatic switches)

and Indicators are located on the System Status

and Control Panel

(SS&CP).

1.2.1 System Status and

Control Panel

(SS&CP)

The System Status

&

Control Panel

(SS&CP)

is

shown in Figure 4. The

SS&CP

contains the

elements listed below:

l Liquid Crystal Display (LCD)

l Audible Alarm Silence keypad

-

Alarm Indication

l Scroll Up keypad

l Scroll Down keypad

l Ten Digit (0 to 9) keypads

l Rectifier/Battery Charger Status Indicator

l lnverter Status Indicator

l Load on Bypass Indicator

l Voltage Measurement keypad

l Current Measurement keypad

-

Main Menu Call keypad

-

Entry Validation or Return To Menu

keypad

l Emergency Power Off (EPO) keypads

Detailed descriptions of the

SS&CP

indicators

and the use of the

SS&CP

keypads are pro-

vided in Section Ill

-

OPERATION,

g

3.1.

EPS-2000”

Uninterrupttble

Power System

1.3 Specifications

1.3.1 AC Input Ratings

Refer to

1

1

.I

.I

for nominal Voltage (VAC)

values available.

Voltage:

Frequency:

Phases:

Wires:

Current:

As specified, nominal

plus (+)

lO%/minus

(-)

15%

Nominal, plus (+) or

minus

(-)

5%

Three, phase rotation A,

B,

C

Three plus equipment ground

See Table 2 (page 2

-

7).

Nominal AC Input Current

Power Factor: 0.82 lagging minimum at full

load output, nominal input voltage, and normal

float voltage on battery

1.3.2 Bypass AC Input Ratings

Voltage: Must match UPS nominal

output voltage

*

10%

Frequency Window: Nominal plus

(t)

or

minus

(-)

0.25, 0.5, 0.75, or 1.0 Hz. Standard

setting for bypass input frequency window is

+

0.5 Hz unless otherwise specified when or-

dered. The Frequency Window can be changed

after the unit is installed, but requires a visit by

an EPE authorized Customer Support Services

(CSS) representative to modify the equipment,

Contact

EPE’s

Customer Support Services or-

ganization for further information.

Phase: Three, phase rotation A, B, C

Wires: Four wire WYE

Current: See Table 2 (page’2

-

7). UPS

Output and Bypass AC Input Current at speci-

fied nominal output voltage.

Power Factor: load dependent

1.3.3 lnverter AC Output Ratings

Refer to

j)

1

.l.l

for nominal Voltage (VAC)

values available.

Voltage: Nominal value

f

1% for all

conditions of line, load, and temperature

Frequency: Normally synchronized to the by-

pass AC input source (when available); other-

wise the output frequency is the nominal value

*

0.1%.

Phase: Three, phase rotation A,

8,

C

Wires: Three or four. The UPS lnverter

output is a WYE configuration with the neutral

grounded. A three wire DELTA load can be

connected to the UPS lnverter output. but the

phase connections cannot be grounded.

Current: See Table 2 (page 2

-

7),

UPS

Output and Bypass AC Input Current at speci-

fied nominal input voltage.

Power Factor: The UPS lnverter output is rated

at full

kVA.

0.8 power factor lagging load.

Slew Rate: The rate of change of the UPS

Inverter

output frequency, (a) while tracking within

the frequency window (see Bypass AC Input

Ratings

-

Frequency Window), (b) when syn-

chronizing to the bypass AC input source, or(c)

when going to a free running condition after

losing AC input power, is 1

Hz/secmaximum.

Owner’s Manual

1.3.5 Environmental Characteristics

Overload Characteristics: Applies to the UPS Temperature:

Output when operating from either the bypass

AC input source or the UPS lnverter output: Operating Range: 0” c. to

+40”

c.

(Excluding battery)

125% for 10 minutes

150% for 1 minute Non-Operating and Storage:

Overloads in excess of 150% or exceeding the -25” C. lo

+70”

C

overload time periods previously indicated will

cause the load lo be transferred from the UPS

lnverler

output to the bypass AC input source, NOTE

provided the sources are synchronized. Once

the load is transferred to the bypass AC input

f

Batteries should only be stored

source after exceeding the time periods

previ-

in a fully charged condition at

ously

indicated, the timed periods will

start

again temperatures less than

80”

F.

for operation on the UPS Static Switch. If the

0

(26.7” C.)

load does not return to less than the unit’s full

load rating prior to completing the timed over-

load periods, the load will be disconnected. Relative Humidity: 0 to

95%,

non-condensing

Dynamic Characteristics: Peak voltage devia-

tion on the UPS

Inverter

output is listed below Recommended Environment: Computer Room

for the conditions indicated: or other temperature controlled environment.

50% step load change Recommended Temperature: 20 to 30” C.

*

3% maximum (Battery protection time is based on a 25°C.

ambient temperature)

100% step load change

2

5% maximum Recommended Relative Humidity: 50%

Dynamic Response: The UPS

lnverter

output 1.3.6 Other Characteristics

voltage returns lo

k

1% of nominal within one

cycle after experiencing a 100% step load change Audible Noise Level:

1.3.4 Battery Characteristics 10 to 40

kVA

ratings:

5

60

dBA

DC Voltage Range: Physical Dimensions:

325 Vdc minimum Height:

55.16”/1,402

mm

436 Vdc maximum Depth:

32.10”1017

mm

Width: See Table

1

DC Current Required: Weight: See Table 1

See Table 2 (page 2

-

7),

Maximum

Battery Current.

EPS-2000” Uninterruptible Power System

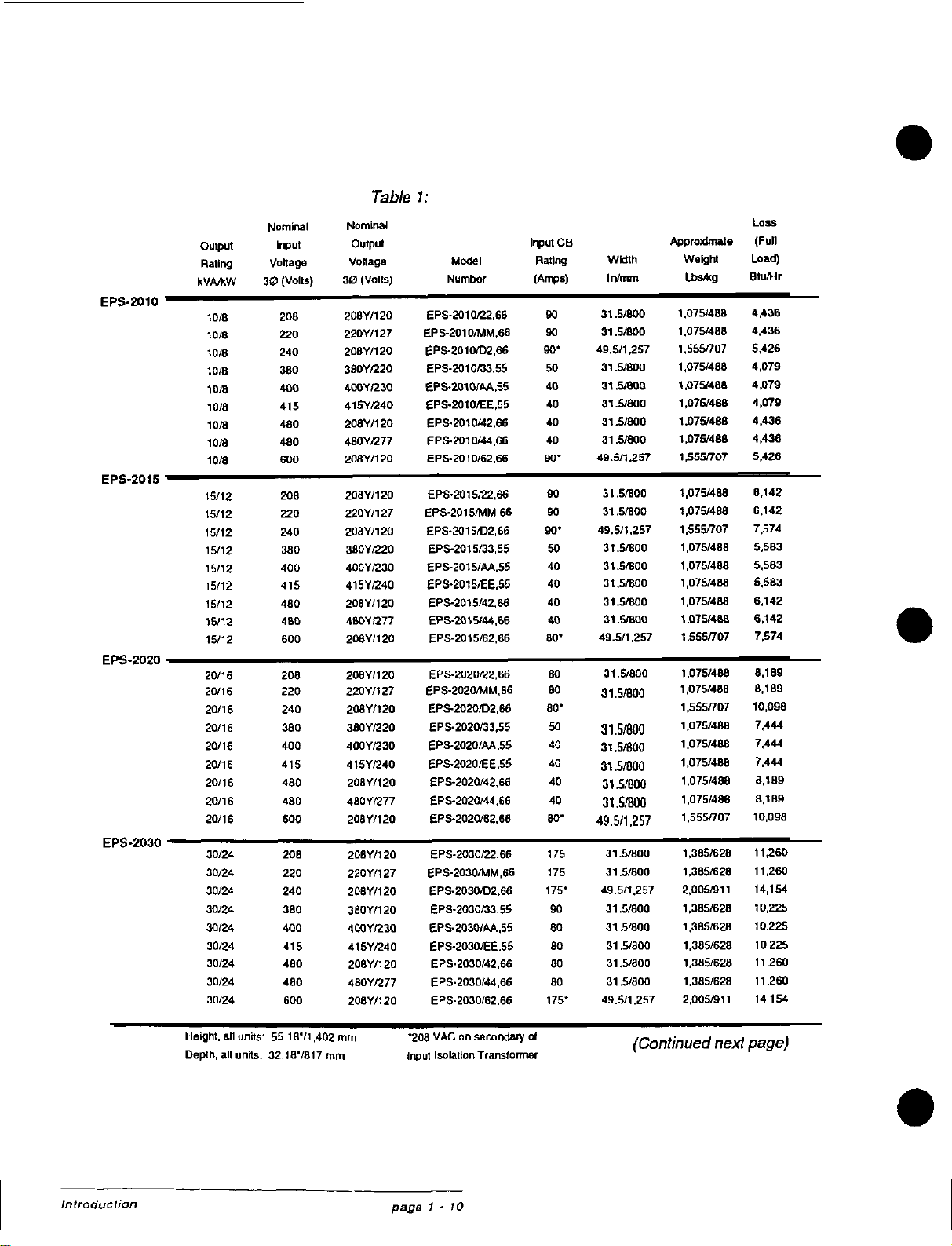

Table

I:

Standard Models

31

s/800

49.5n.257

31

.moo

31.5moo

31.5moo

31.5moo

31.5moo

49.511257

Owner’s Manual

Table

1:

Standard Mode/s (continued)

EPS-2000~

Uninterruptible Power System

1.4 Options

1.4.1 Site Distribution Center (SDC)

The Site Distribution Center (SDC) provides the

means of distributing powerfrom the EPS-2000”

UPS

svstem

to the user’s intended equipment.

The

S&Z

is furnished in an enclosure matching

the other

EPS-2000N

series equipment. The

SDC attaches to the right side of the

EPS-2000TM

UPS enclosure, or the right side of the Auxiliary

Cabinet Assembly (ACA). EPE provides all the

necessary hardware, power and control cables.

and the instructions for the task. The customer

is responsible for installation of the equipment

in the field.

1.4.2 Auxiliary Cabinet Assembly

(ACA)

The Auxiliary Cabinet Assembly (ACA) provides

the means for incorporating three optional el-

ements into the

EPS-2000N

UPS system. The

ACA attaches to the right side of the EPS-2000”

UPS enclosure. EPE provides all the necessary

hardware, power and control cables, and in-

structions for the task. The customer is respon-

sible for installation of the equipment in the field.

The empty ACA enclosure alone will accommo-

date top cable entry when required, which may

occur if the UPS is installed in an equipment

room with limited space available. Alternately,

the ACA may include an input isolation trans-

former, or an input harmonic current filter or

both depending on which options are purchased.

The input isolation transformer provides com-

plete electrical isolation between the utility line

and the input of the UPS (Rectifier/Battery Charger

and Battery), providing extra protection against

electrical noise and ground faults. The input

harmonic current filter limits the amount of har-

monic current fed back on to the input AC power

source to less than 10% when the

EPS-2000m

UPS is operating at full load.

a

isolation transformer as

I

standard equipment.

I

1.43

BATTERY PAC Assembly (BPA)

Each EPS-2000” UPS is furnished with a

BATTERY PAC Assembly (BPA), which contains

a battery having sufficient ampere-hour (A-H)

capacity to

suppori

the UPS and its intended

load for the protection time specified.

An EPE BPA features the use of sealed,

maintenance-free, lead-calcium, recombination

type batteries. The batteries are

maintenance-

free from the standpoint that they do not require

the electrolyte level nor the density of the elec-

trolyte to be checked periodically. However, the

BPAs

do require that the interior of the assem-

bly, including the exterior surfaces of the indi-

vidual batteries, be kept clean and free of all

foreign matter including dust. The integrity (torque)

of the individual battery connections inside the

BPA must be verified annually.

The EPA-2000 series BATTERY

PACs

provide

ready access to the batteries, as they are mounted

on pull-out rack assemblies.

Other manuals for EPS-2000 Series

2

This manual suits for next models

5

Other EPE UPS manuals