PRELIMINARY SERVICE CHECKS (Continued)

MECHANICAL REMOVAL AND REPLACEMENT

RIBBON CARTRIDGE REPLACEMENT TIMING BELT REPLACEMENT

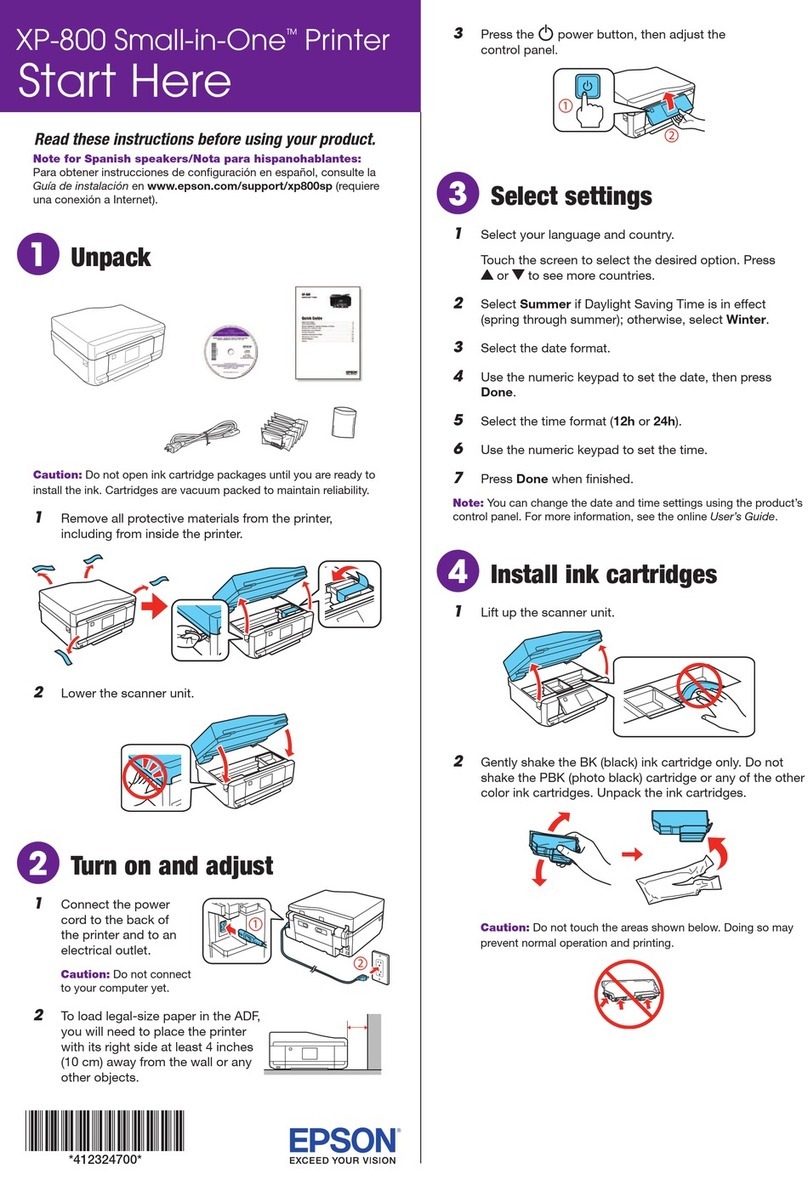

Slide Carriage Assembly to center. Move Scale (5-28) to up-

permost position. Turn knob on replacement Ribbon Car-

tridge counterclockwise to tighten ribbon. Install Ribbon

Cartridge with the two tabs at each end fitting into the two

slots of each side frame and the cartridge seated on the

Ribbon Driving Gear (7-3). Do not force it into place. Care-

fully slide Ribbon between Printhead (5-1) and Ribbon Mask

(5-16). Slide Carriage Assembly back and forth to verify pro-

per Ribbon movement.

PRINTHEAD/RIBBON MASK REMOVAL

Remove Platen Cover, Printer Lid and Ribbon Cartridge. If

Printer has been operating, allow Printhead (5-1) to cool.

Slide Carriage Assembly to the left end of Carriage Shafts

to allow access to Head Cable and Head Cable Connector

on the Terminal Board (8-1), Hold Connector in place and

carefully remove the Head Cable from it by pulling on the

plastic tab beneath the Head Cable.

Slide Carriage Assembly to the center position for access

to the Head Lock Lever (5-13). Rotate the lever to the left to

release the Printhead. Lift Printhead straight up to remove

from Carriage Assembly.

Remove the two positioning screws holding Ribbon Mask

(5-16) and lift mask from Carriage Assembly.

Reverse the procedure for replacement. See Printhead Ad-

justment in Miscellaneous Adjustments.

CARRIAGE MOTOR/POSITION-TIME (PTS) SENSOR

REMOVAL

Remove upper case. See Disassembly Instructions. Dis-

connect Connector CN4 from FMBD Board. Remove left-

front screw and right-rear screw from base of Carriage

Motor (2-1). Lift motor assembly out of Printer base. Free

the motor wire harness and separate the Carriage Motor

and Position-Time Sensor wires.

Remove Printer mechanism from case. See Disassembly In-

structions. Press downward on the Timing Belt (4-1) at each

side of the point where belt is attached to Carriage

Assembly. CAUTION: Belt may be held in place with

adhesive cement. If removal is difficult, slide the Carriage

Assembly to the right and over the access hole in the

chassis base. Turn the chassis over. Carefully cut the

adhesive seal with arazor blade and remove the belt from

the Carriage Assembly with needle-nose pliers.

Loosen the screw securing the Belt Tension Plate (4-5) and

remove the Timing Belt from the belt-driven pulley. Remove

the left-front screw and right-rear screw from the Carriage

Motor (2-1). Lift the motor assembly from the Printer base

for access to the belt drive pulley. Remove belt from pulley.

Push belt through opening in right frame and remove belt

from Printer.

Install replacement by reversing the removal procedure. Be-

fore adjusting tension, apply adrop of adhesive cement I

where Timing Belt is attached to Carriage Assembly and

allow to dry. See Timing Belt Adjustment in Miscellaneous |

Adjustments.

BELT TENSION PLATE REMOVAL

Remove upper case. See Disassembly Instructions. Slide

Carriage Assembly all the way to the right. Loosen the nut

on each end of the front Carriage Shaft (5-17). Remove the

left end of the Carriage Shaft from the side frame. Remove

the adjustment screw from the Belt Tension Plate (4-5) and

lift the Timing Belt (4-1) from the belt-driven pulley. Lift the

Tension Plate up and out of the Printer base with ribbon

driving gears intact.

Reverse the procedure for replacement. See Timing Belt |

Adjustment in Miscellaneous Adjustments.

PAPER FEED MOTOR/TRANSMISSION GEAR

REMOVAL

Remove the screw holding the Position-Time Sensor Board

(3-7) to the motor base and remove Sensor Board from Car-

riage Motor heat sink. Remove right-front screw and left-

rear screw from the motor base to remove the Carriage

Motor and Sensor Disk from the heat sink.

Reverse the procedure for replacement. See PTS Sensor

Board Adjustment in Miscellaneous Adjustments.

HOME POSITION SENSOR REMOVAL

Remove Platen Cover, Printer Lid and Ribbon Cartridge.

Slide Carriage Assembly to the right end of Carriage Shaft

to access the Home Position Sensor Connector on the Ter-

minal Board (8-1). Disconnect Connector and remove screw

holding Sensor Board. Lift Sensor Assembly out of Printer

base.

Reverse the procedure for replacement. See Home Position

Sensor Adjustment in Miscellaneous Adjustments.

Remove upper case. See Disassembly Instructions. Dis-

connect Connector CN4 from FMBD Board. Remove three

screws from base of Paper Feed Motor (2-3). Remove motor

from chassis side frame. Free the motor wire harness and

separate Paper Feed Motor wires from harness. Pull Trans-

mission Gear (5-3) straight out from side frame and off of

gear shaft pin. Retain thrust washer used on inner side of

gear.

Reverse the procedure for replacement. Slide motor up to

minimize gear lash but do not lock up gears. Perform self-

test to check proper paper advancement.

SCALBPAPER HOLDING LEVERS REMOVAL

Remove upper case. See Disassembly Instructions. Re-

move two screws holding Platen Cover (6-2). Carefully lift

cover backward and upward to clear the lever on the Paper

Empty Sensor. Loosen the screws at the end of the Scale

(5-28). Remove the E-rings and Springs (5-23) from the Paper

III