Equalizer Express DTE1000 User manual

© 2004 Equalizer Industries, Inc.

18-Volt Battery Powered

Equalizer

® Express

®

Users Guide & Exploded View

DTE1000 • DTA1007

The blade is installed by lifting the quick connect lever, fully

inserting the shaft of the blade into the sheath, and pressing

the quick connect lever back down.

Express® 18-Volt Users Guide

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Volts

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DW9096XR+

Strokes Per Minute . . . . . . . . . . . . . . . . . . . . . . . . . 0-2,800

Proper Use

Begin the cutting pro-

cess by spraying the

entire cutting area and

blade with plenty of

water. Lubrication is

vital for maximum cut-

ting ease. Failure to use

water lubricant increases

cutting friction and will

cause tool damage. Periodically spray the blade with water.

Start cutting from the inside top center of the glass and cut

toward the A-pillars. Keep the blade properly orientated and

flat against the glass. Reverse and cut from the top center of

the glass toward the other A-pillar. Relax and let the tool do

the work.

Next, from the inside (or outside on some vehicle models), cut

the sides from top to bottom. After both sides are cut, insert two

PUMPER™s (Equalizer® LB779) to increase the cutting angle,

thereby improving cutting ease. For an even greater cutting angle,

slightly deflate the PUMPER™s then fold in half & re-insert.

2

The Blade

The blade is

very thin and

flexible, allow-

ing for curved

cutting angles.

It is sharpened

on three sides

and on a single plane. The blade must be properly orientated

(flat side rides against the glass). When properly orientated

the bladeʼs sharpening design causes the blade to cut along the

bottom surface of the glass, thereby protecting headliners and

mouldings from damage.

Caution!

Discard the blade when it has been sharpened down to the line

that says - DO NOT SHARPEN BELOW THIS LINE. Using a

blade that has been sharpened below this line will eliminate the

flexibility of the blade and damage the tool. The blade is extreme-

ly sharp and can cut even when the tool is not in operation!

Rust Prevention

To prevent rust caused by water droplets, every day place

a few drops of oil into the sheath and allow it to run down

into the blade holder.

The Sheath

The sheath provides protection for the dash and interior vehicle

parts. Since the cutting is done by the end of the blade, the

sheath remains free of contaminants. No cleaning is necessary.

To keep the sheath cool we recommend that you periodically

apply a light film of high heat grease to the blade part that is

inside the sheath.

Tool Description

The Equalizer® Express® 18-Volt cordless tool is a multipur-

pose auto glass removal tool, designed primarily for inside

use on bonded auto glass parts. It may be used outside on

A-pillars for windshields of some vehicle models, and on

all broken tempered parts. The blade shaft is enclosed in a

sheath which protects interior car parts. Most of the cutting is

accomplished on the end of the blade, therefore the operator

utilizes upper torso muscles, making the tool easy to operate

and ergonomically friendly. The Equalizer® Express® 18-Volt

cordless toolʼs specific blade stroke length and dynamic two-

way cutting power slices through the toughest urethane adhe-

sive with ease.

Changing the Sheath

IMPORTANT -- PLEASE READ CAREFULLY! General Safety Information

1. Always wear safety glasses and safety gloves when using the

Equalizer® Express® 18-volt tool.

2. Do not activate Equalizer® tools until they are in the cutting position.

Disengage the tool and let it stop before taking it out of the urethane.

3. The blade is sharp and can cut even when the tool is not running.

4. Do not force the tool. Put light forward pressure on the tool.

Let it do the work.

5. Consider your work environment. Do not use or expose power

tools to rain or damp weather.

6. Disconnect the battery from cordless tools before servicing and

when changing accessories.

7. Stay Alert!! Watch what you are doing. Use common sense.

3

Blade Sharpening

A sharp blade is crucial for effective cutting action and tool longev-

ity. A dull blade will destroy the drive mechanism in your Equalizer®

Express® 18-Volt --keep the blade sharp. Sharpen the blade between

each removal with a diamond file (Equalizer® part number BI1038).

Be careful to maintain the original sharpening angle (see Figure 3).

Every ten removals, re-sharpen the blade on a bench grinder. Keeping

a sharp blade will help the tool cut faster. A sharp blade will reduce

vibration, increasing the life of the tool and reducing the fatigue of

the operator. Most tool damage is caused because the blade has not

been kept sharp. We will not warranty tools when the blade has not

been kept sharp. Do your part to prolong the life of this tool and

keep the blade sharp!

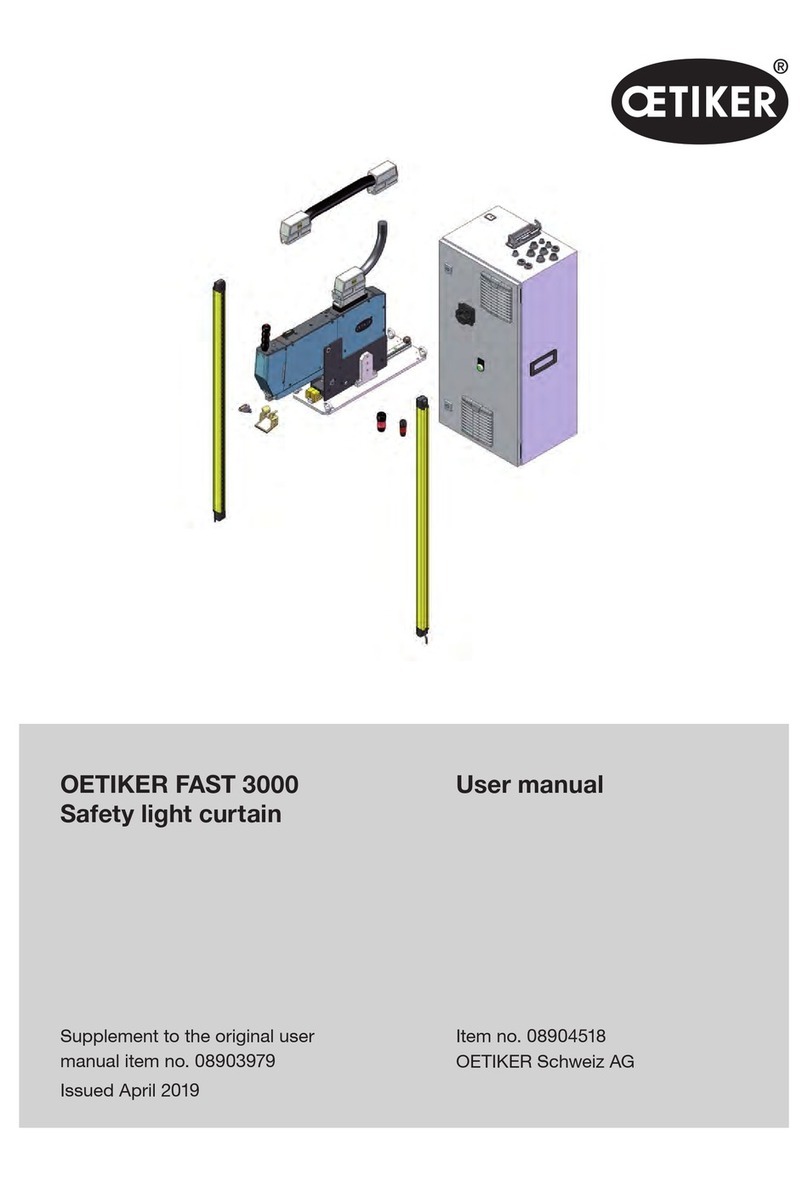

The plunge cut The angle cut

After the sides are loose, cut the bottom of the glass loose, utiliz-

ing one or a combination of two cutting methods.

Figure 1. The plunge cut. Cut straight down, move over three

inches and repeat this process until finished cutting.

Figure 2. The angle cut. Turn the tool at roughly a 45-degree

angle and cut along the bottom until finished.

Figure 1 Figure 2

Pumper™ LB779

Use one on each side.

Pumper™ can be fold-

ed in half to increase

distance of outward

pressure.

Between each

removal

Every ten removals

Figure 3

BI1038

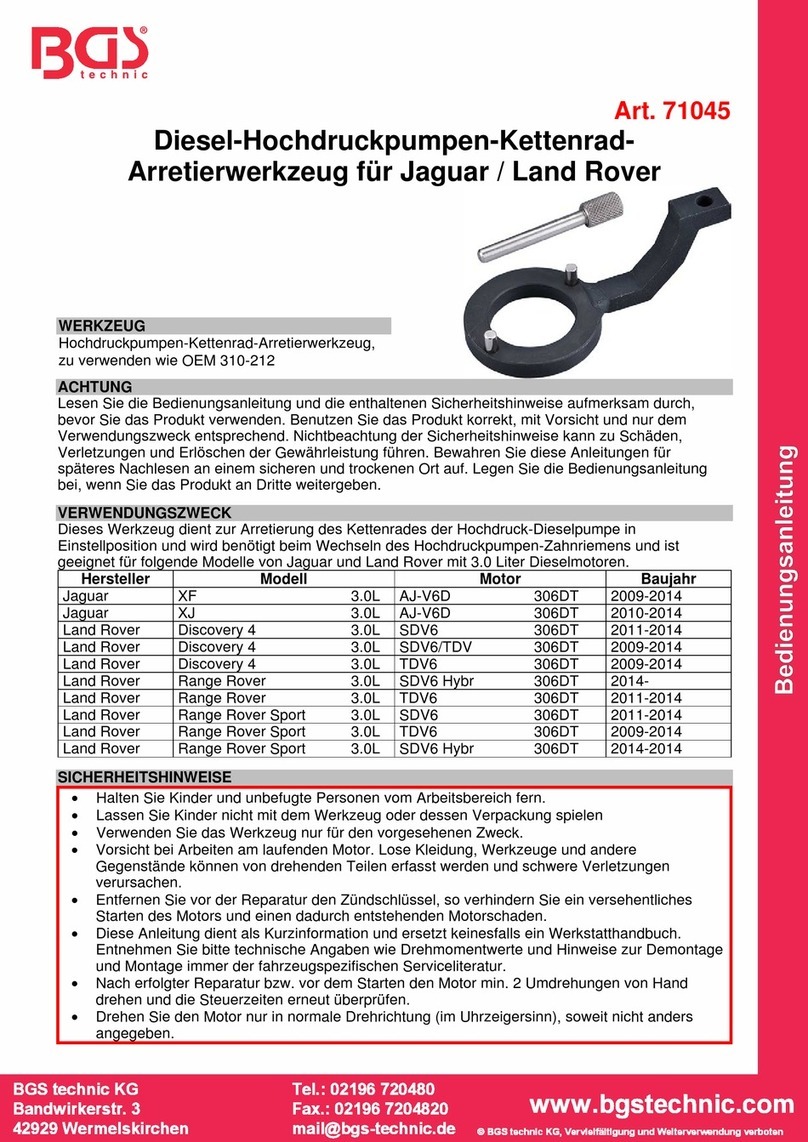

Top view of open

holder

G

Assure gap is even

on both sides.

C

Use a drop of red

Loctite® in each hole.

Loosen screws with

3/16” hex wrench.

Insert new sheath

until it hits stops.

UNDERSIDE view of

holder and sheath stops

D

B

Sheath stops

Remove old sheath.

E

F

ES1406

A

The sheath is not adjustable! The four top screws are secured in place

with Loctite® to prevent loosening from vibration, and are not meant to

be removed unless you are replacing the sheath. Please be aware that

some force may be required to remove these screws. If difficulty is

encountered, to prevent stripping of the screws we recommend warm-

ing the sheath retainer with a heat gun or other warming device. 1.

Loosen the screws with a 3/16” hex wrench (A). 2. Make note of the

built-in sheath stops located at the back of the sheath holder (B). This

is very important! 3. Remove the old sheath (C). 4. Insert the new

sheath until it touches the stops, but do not insert the sheath past

the sheath stops (D,E). 5. Place a drop of red Loctite® in each screw

hole to secure the screws and keep them from loosening from vibration

(F). 6. Reassemble the sheath holder; be sure to install all four screws

so the gap is the same width on both sides of the sheath retainer (G).

CAUTION! Forcing sheath past the stops or overtightening the top

screws will damage your tool. Tools presented for repair with stops

destroyed or removed will not be repaired under warranty.

DW9116 Charger

The DW9116 battery charger is designed to use standard household

120 volt AC 60 Hz power. The use of other power sources like, but

not limited to, those that convert DC to AC is not recommended and

will destroy the internal circuitry of the DW-9116 charger. If you do

not use standard household 120 volt AC, 60 Hz power then only use

a true sine wave inverter.

DW9109 12-Volt Automotive Charger

The DW9109 battery charger is designed to plug into the cigarette

lighter or power point of a vehicle and use 12 volt DC power. Do not

use AC power. The use of any other power source, such as a device

to convert AC to DC power, is not recommended and may cause

serious damage to the circuitry of the DW-9109 charger.

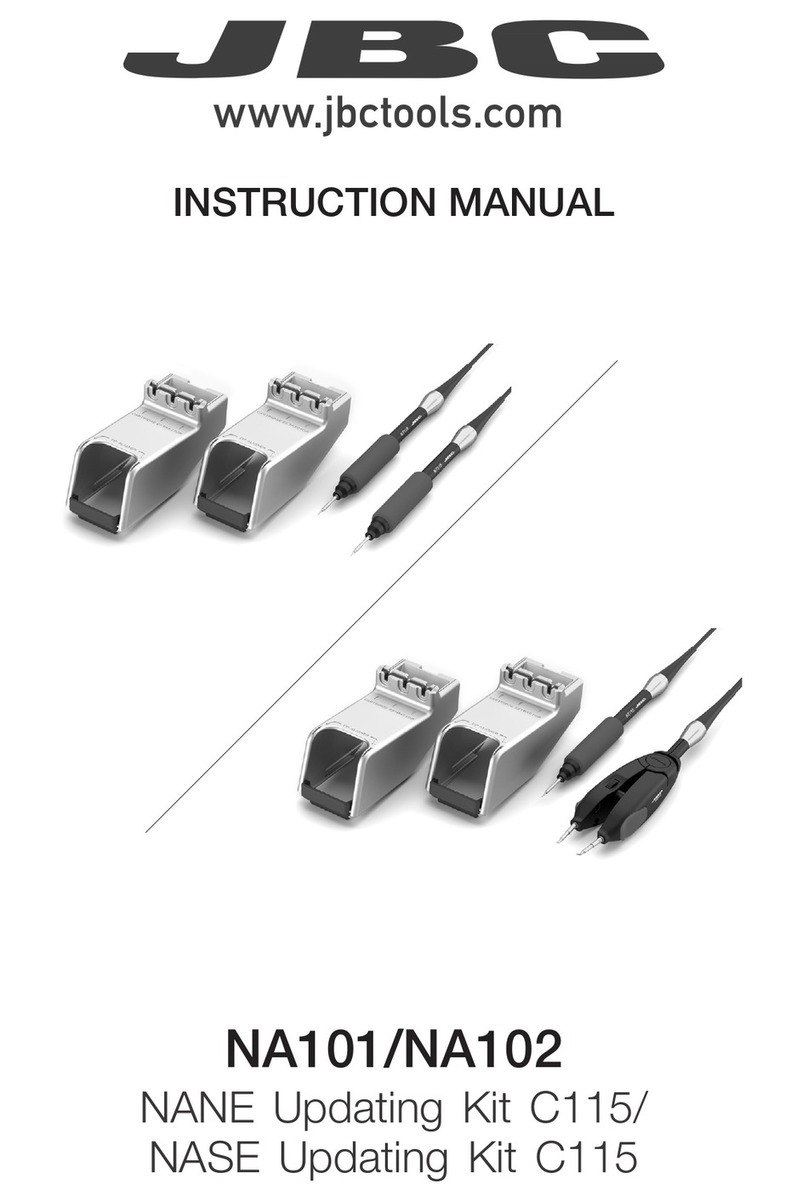

Charging Procedure

1. Plug the charger into an appropriate power outlet.

2.

Insert the battery pack into the charger, as shown in

Fig. 1 and Fig. 2, making sure the pack is fully seated in

the charger. The red (charging) light will blink continously,

indicating that the charging process has started.

3.

The battery pack will be fully charged in about 1

hour. The completion of charge will be indicated by

the red light remaining ON continuously. The pack is

fully charged and may be used at this time or left in the charger.

Battery Use and Care

Take care when loading the battery into the tool. Do NOT

slam the battery into the Equalizer® Express® tool. Gently

press the battery into place. Depending on cutting conditions

and operator skill, a fully charged battery should remove about

three windshields.

The batteries are the most sensitive part of the Equalizer®

Express® tool. Please, carefully read these detailed instructions

about proper battery charging and care.

Fig. 2

Fig. 1

Battery (DeWalt DW9096XR+)

Read this very carefully! There are sev-

eral off-the-shelf batteries that will fit the

Equalizer® Express®. This toolʼs battery

is a DeWalt DW9096XR+ and it feeds

electricity to the motor and runs it back-

wards so it will stop quickly. Other batter-

ies will feed too much electricity into the switch and can cause

the drive mechanism to unwind. Some do not send enough and

can cause the switch to be destroyed. The threads are clockwise

and when too much counterclockwise force is applied the threads

can unscrew, freeze the tool and cause permanent damage. Use

only DeWalt DW9096XR+ batteries.

Important Safety Instructions About the

Battery and Chargers

Warning: When using the Equalizer® Express® there are basic

safety precautions that should be followed to reduce risk of

fire, electric shock and personal injury, including the following:

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire.

• A small leakage of liquid from the battery pack cells may

occur under extreme usage or temperature conditions. This

does not indicate a failure. However, if the outer seal is broken

and this leakage gets on your skin--

A. Wash quickly with soap and water.

B. Neutralize with mild acid such as lemon juice or vinegar.

C. If battery liquid gets into your eyes, flush them with

clean water for a minimum of 10 minutes and seek

immediate medical attention.

(Medical Note: The liquid is a 25%-30% solution of potassium

hydroxide.)

• Never attempt to open the battery pack for any reason. If the

plastic housing of the battery pack breaks or cracks, immedi

ately discontinue use and do not recharge.

• Do not carry extra, charged battery packs in aprons, pockets, or

tool boxes along with other metal objects. Battery pack could

be short circuited, causing damage to the battery pack and pos

sibly causing severe burn or fire.

Tune-Up Procedure

At the end of every two weeks, completely discharge your bat-

tery. Batteries can develop a memory which will shorten the

working time they can be used. The tune-up procedure will

eliminate the memory build-up.

1. Hold or tie down the trigger & let the tool run until it stops.

2. Wait 20 minutes then repeat (tool will only run a

short time the second time).

3. Allow the battery to cool completely, then

recharge.

Important Instructions For Your Equalizer® Express® 18-Volt Battery& Charger

Equalizer® Express®

4

I-1001

I-3451

2712

2501

I-3452

2502

2504

2505

2506 2507

2508

2509

2510

2511

I-1105

2513 2514

2515

I-1101

ES1406

2516

2503

2512

Detach and return

www.equalizer.com

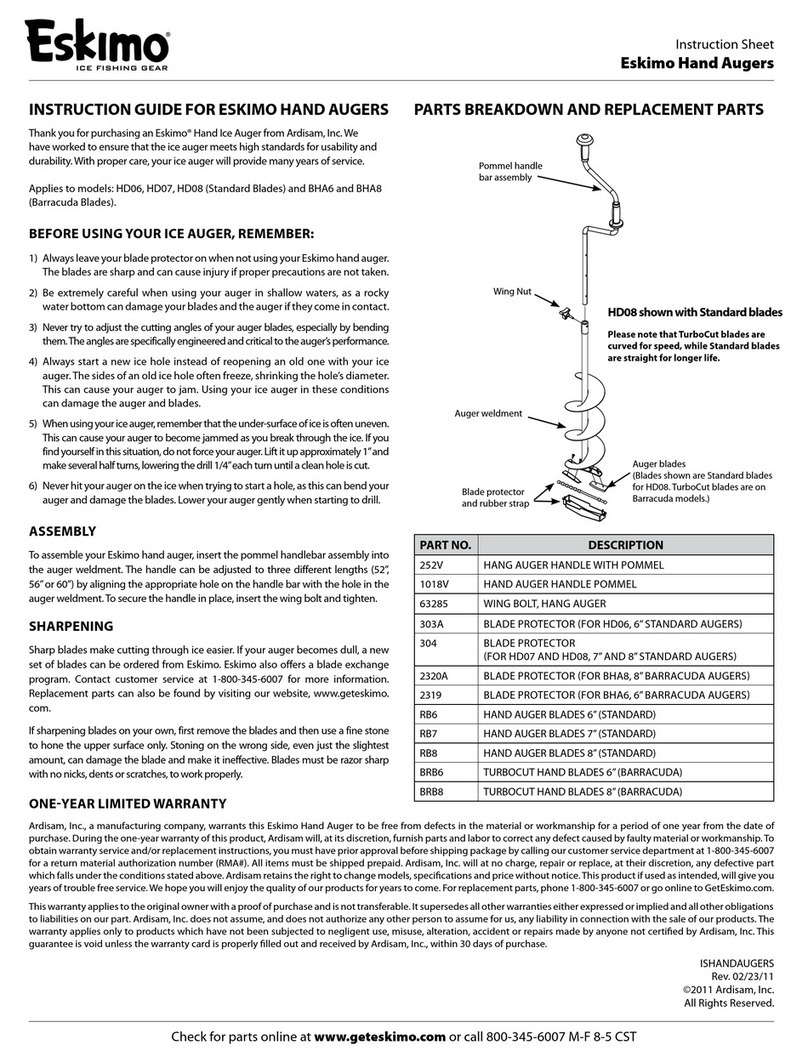

Part No. Description Required

2500 18V Express replacement handle set

(includes gear case & 2 handles) 1

2501 Lead wires (set of 2) 1 set

2502 Rear armature bearing 1

2503 Gear case cover 1

2504 Brushes (set of 2) 1 set

2505 Armature assembly 1

2506 Armature retaining screws (set of 2) 1 set

2507 Gear case cover screws (set of 2) 1 set

2508 Output shaft with blade retainer 1

2509 Rear wobble drive assembly bearing 1

2510 Wobble drive assembly (with gear) 1

2511 Front wobble drive assembly bearing 1

2512 Gear case cover screws (set of 4) 1 set

Part No. Description Required

2513 Wobble drive retainer nut & cover (set) 1

2514 Gear case cover boot 1

2515 Blade release latch 1

2516 Front armature bearing 1

2712 Housing screws (6 large, 1 small) 1 set

ES1406 Sheath 1

I-1001 Switch, 18 volt 1

I-1101 Complete sheath clamp assembly

(includes two-piece sheath clamp,

all screws and a sheath) 1

I-1105 Gear case 1

I-3451

1

I-3452 Field case

1

Model DTE1000

I-1101

2500

2500

Switch lock

WARRANTY REGISTRATION

Please PRINT clearly and fill in all of the blanks.

TOOL SERIAL #_____________________________________________________________

TOOL TYPE________________________________________________________________

DATE YOU PURCHASED THIS TOOL______________________________

YOUR COMPANY___________________________________________________________

ADDRESS________________________________________________________________

CITY________________________________STATE______________ZIP CODE________

TELEPHONE NUMBER ( )____________________________________________

YOUR NAME_________________________

YOUR POSITION______________________

PURCHASED FROM_________________________________________________________

THEIR ADDRESS______________________________________________________

CITY, STATE, ZIP___________________________________________________

TOOL SERIAL NUMBER

KEEP THIS FOR YOUR RECORDS

All Equalizer® Express® tools are warrantied for one year to be free of factory defects. Warranty does not apply to abuse,

misuse, or normal wear and tear. We will repair or replace, at our option, any defective part. Tools are repaired and sent

back the same day they are received.

If you feel your tool is covered under warranty, the entire tool, including all blades, must be returned to:

EQUALIZER INDUSTRIES, INC.

1304 WEST INDUSTRIAL BOULEVARD

ROUND ROCK, TEXAS 78681

If you want a tool repaired, but are not seeking to have it repaired under warranty we would still like for you to

return the complete tool including the blades.

Equalizer Industries, Inc., reserves the right to refuse to repair, at our expense, any tool which has not been prop-

erly maintained as specified in the Users Guide. Particularly important are the following:

1. KEEP THE BLADES SHARP!!!!! This is the one thing most technicians WILL NOT do and it WILL damage the tool.

2. Use a cutting lubricant. If you are using the short cut method (not recommended by anyone anymore) use only clean

water as a cutting lubricant.

3. DO NOT HIT THE PINCHWELD. THIS WILL DESTROY THE DRIVE MECHANISM OF YOUR TOOL.

If you have any questions about your tool, call us toll free at 1-800-334-1334 or fax us at (512) 388-4188.

Detach and return

WARRANTY

This manual suits for next models

1

Table of contents

Other Equalizer Tools manuals

Equalizer

Equalizer Terminator TSK710 User manual

Equalizer

Equalizer ECT113 User manual

Equalizer

Equalizer FA1TM Assembly instructions

Equalizer

Equalizer MG7TM Assembly instructions

Equalizer

Equalizer Express 360 SR1418360 User manual

Equalizer

Equalizer SWi12TMEX Assembly instructions

Equalizer

Equalizer NS12TI Assembly instructions

Equalizer

Equalizer ELPTP50 Assembly instructions

Equalizer

Equalizer TRANSFORMER TFM50 User manual

Equalizer

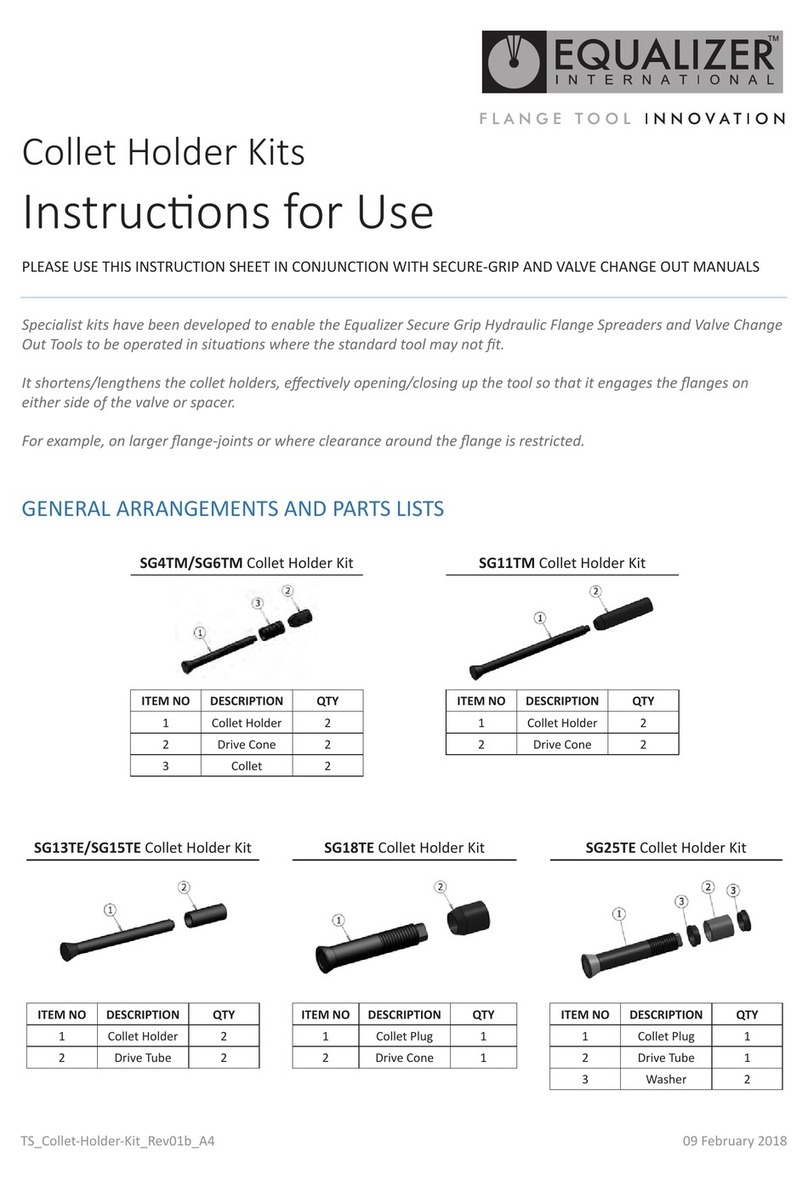

Equalizer SG4TM User manual