2000SPe160713.docx

©Copyright by GEDORE Automotive GmbH, Germany 9

1

Instruction Manual EN

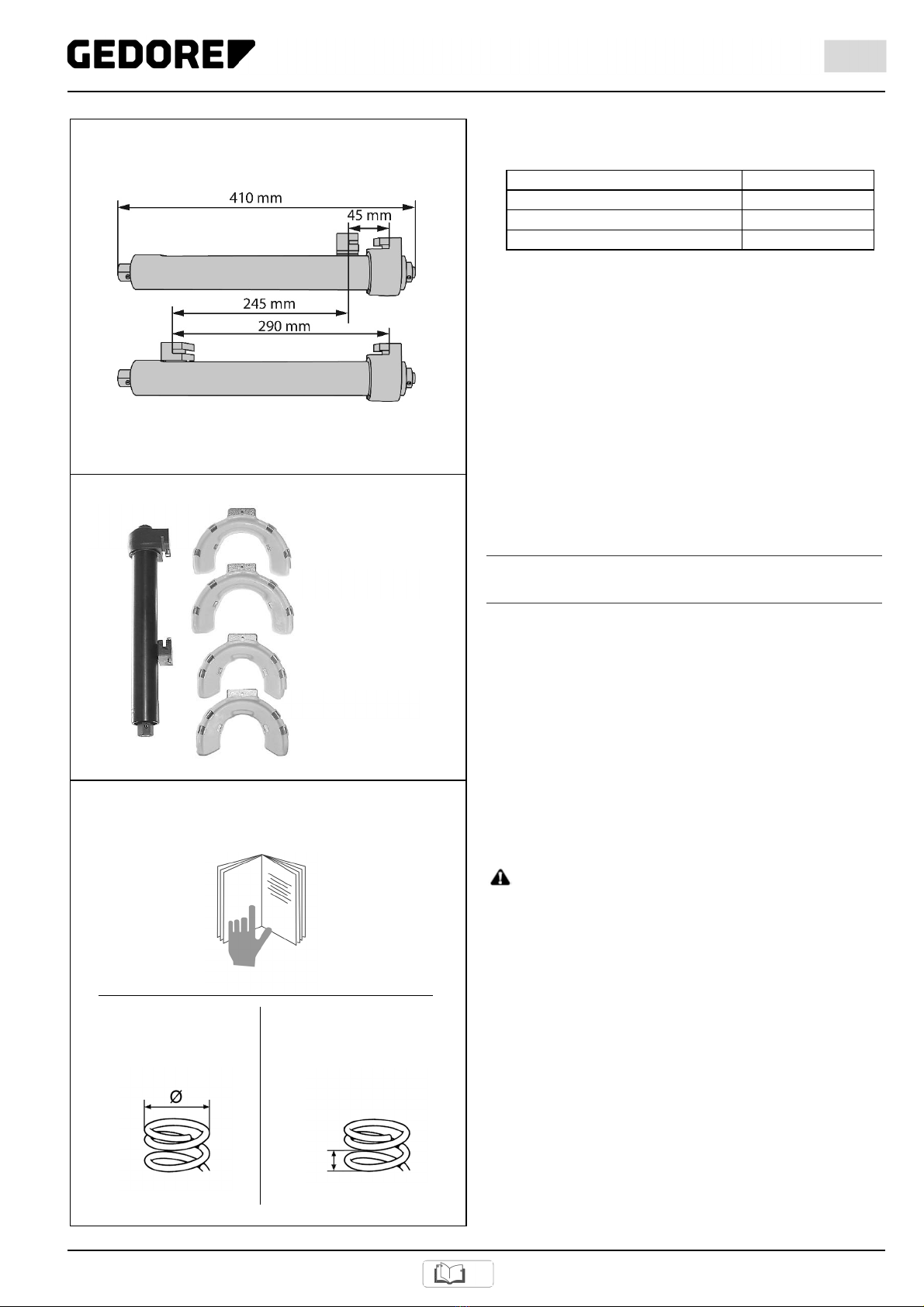

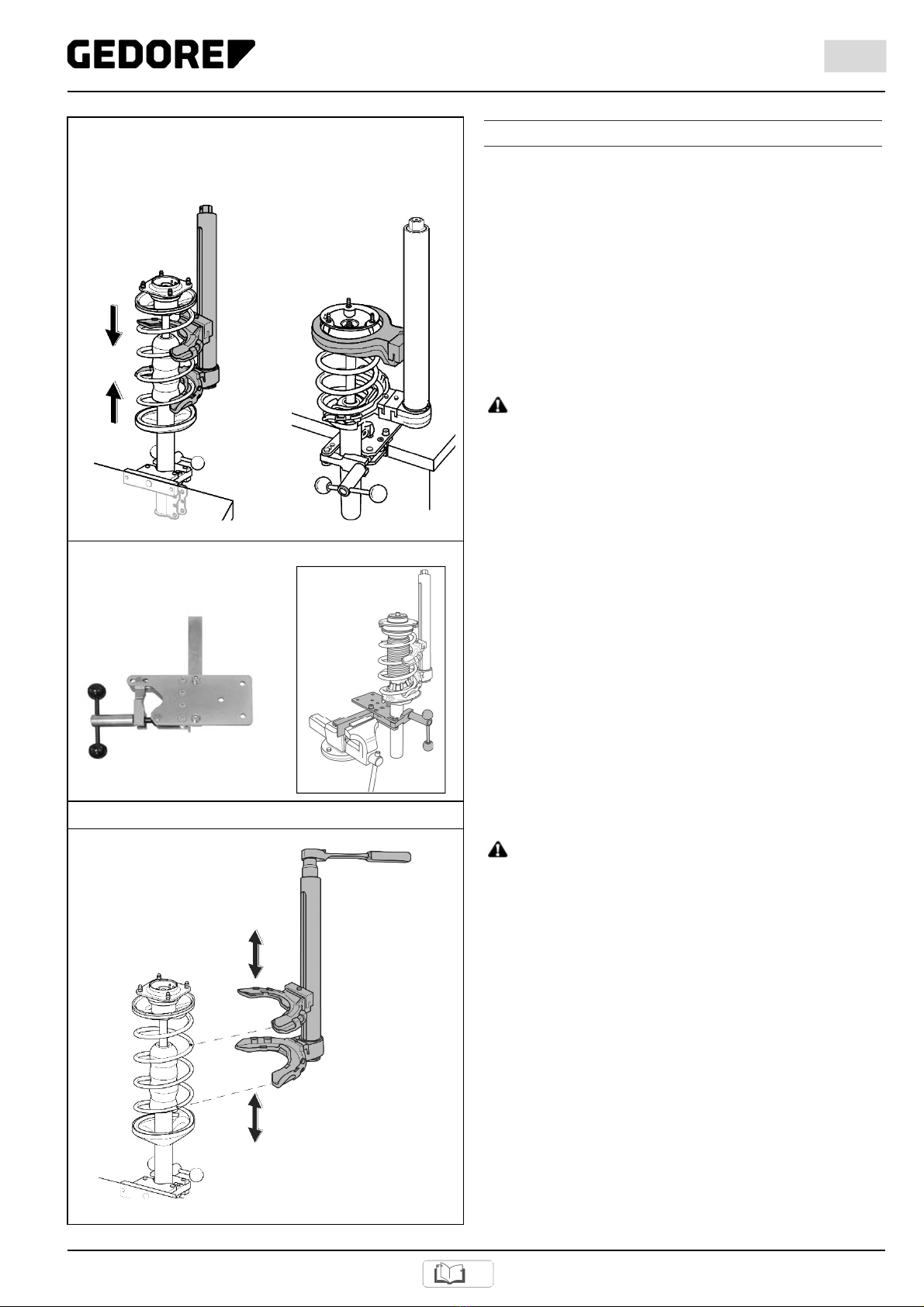

4. Removing and Installing a Spring

The following instructions describe the procedure of removing/installing

a right-hand wound coil spring from/to a suspension-/damper strut.

The examples show two different techniques which are to be applied

depending on the type of jaws used. (Fig. 7)

Technique 1: Removing and installing a spring using the jaws that

engage the spring coils.

Technique 2: Removing and installing a spring using the special jaw

that encompasses the upper spring plate.

Note: Compressing a rear axle spring on the vehicle can be carried out

according to the same principle as described in technique 1. The

procedure is similar, however, with the difference that

dismantling/reassembling the suspension/damper strut is not necessary.

During the whole compression and decompression processes, pay

attention to the space available. Make sure that the base body and the

jaws do not touch the vehicle/car body parts, and that they are not

pushed against these.

DANGER

Considerable forces are exerted when springs are being compressed.

Strictly adhere to the following instructions. Non-observance can lead to

hazardous situations such as breakage of the spring compressor

resulting in debris/parts or the spring becoming projectiles.

Never use the spring compressor if it is damaged or defective.

Never use a hammer on the tool.

Lubricate the spindle with molybdenum disulphide paste, for example

KL-0014-0030.

Only use molybdenum disulphide paste, for example KL-0014-0030,

as lubricant.

Only use Original GEDORE Automotive spare parts.

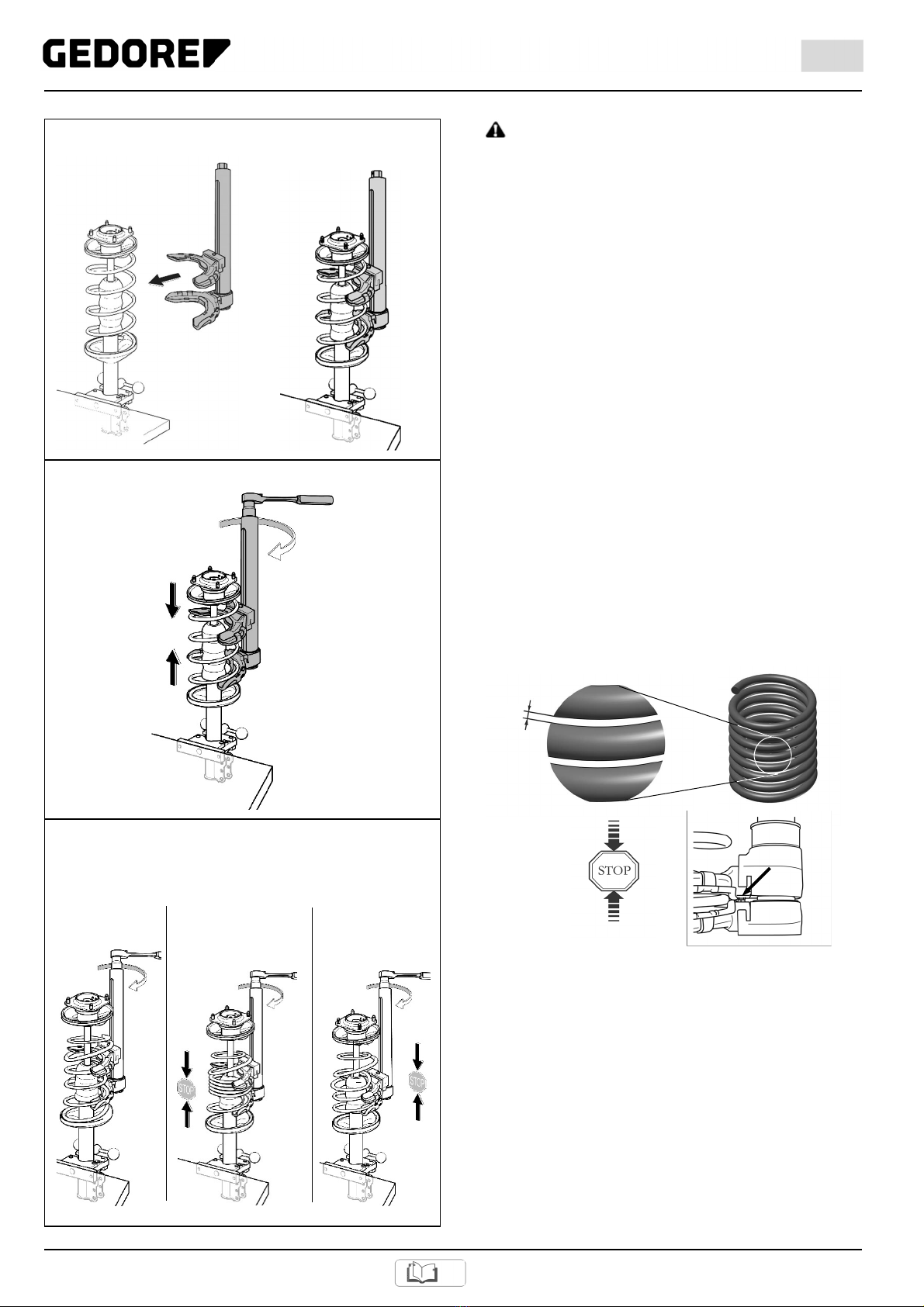

ATTENTION

Stop turning the drive nut once the spring compressor has reached its

limit stop (that is when the mobile jaw mount has been slid against the

fixed one until limit stop). Failure to do so will result in damage to the

spring compressor.

Once the spring compressor has reached its limit stop, that is when

the mobile jaw mount has been slid against the fixed one until limit

stop, make sure that the drive nut is rotated only in the opposite

direction.

Note: Always perform all work on the vehicle/vehicle components in

strict compliance with the directions, provisions, and safety regulations

specified by the vehicle manufacturer.

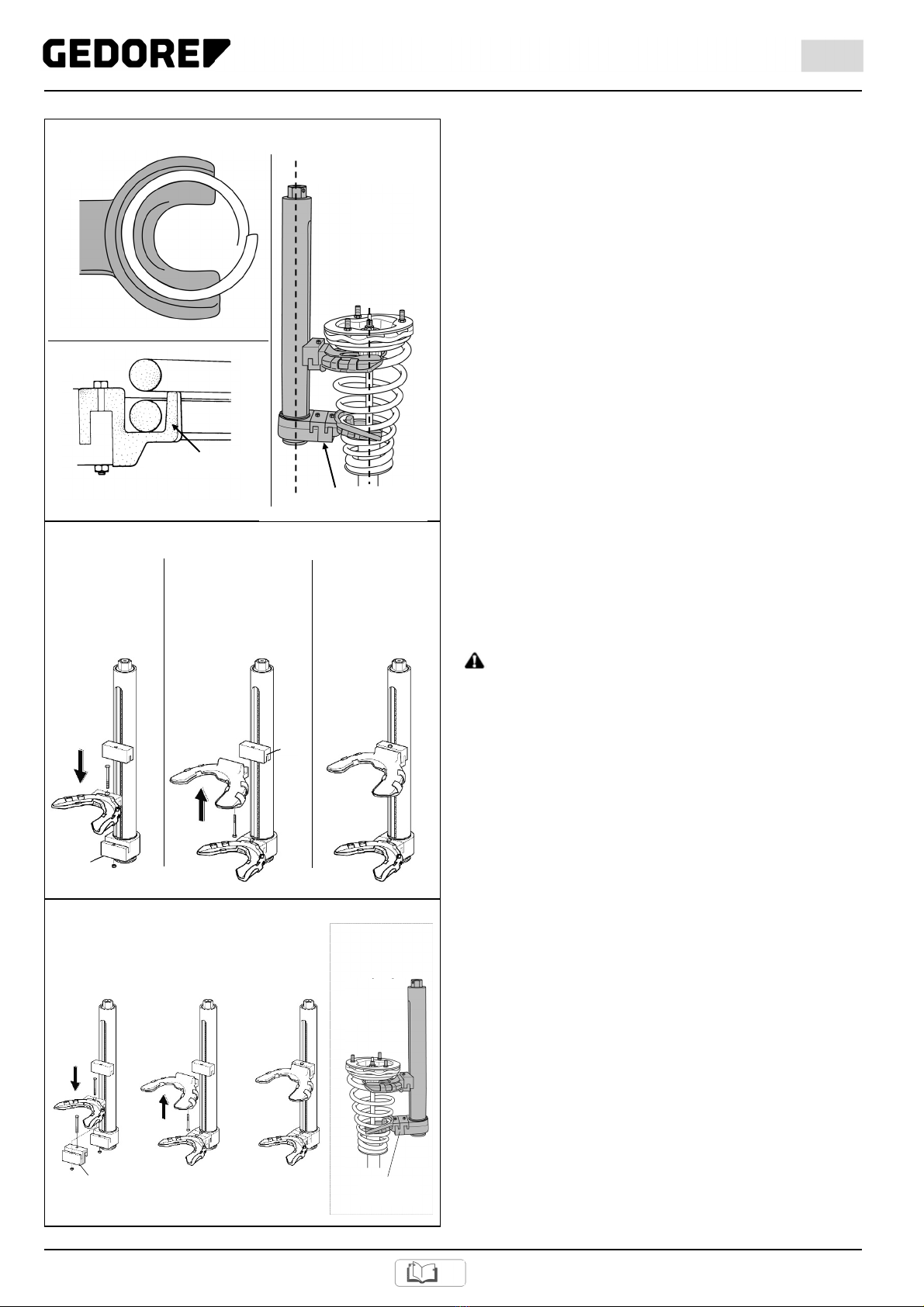

4.1 Clamping a Suspension-/Damper Strut

into the holding fixture.

DANGER

Suspension-/damper struts that are not properly fixed can come

loose and fall off the spring compressor while the spring is being

compressed.

Do not clamp neither the suspension-/damper strut nor the spring

compressor into a vice.

Clamp the removed suspension-/damper strut into holding fixture

KL-0055-60 (accessory). (See Fig. 8)

4.2 Removing a Spring

Technique 1: Removing a spring using the jaws that

engage the spring coils.

1.

ATTENTION

When opening the jaws, there is a risk of damage to the base body.

When opening the jaws on the base body, make sure that there is

no pressure being exerted on the limit stop once the maximum

opening distance has been reached.

(Stop turning the drive nut counter-clockwise.)

Using a 1/2" reversible ratchet with a 24mm (waf) socket, turn the

drive nut and adjust the spring compressor so as to enable it to grasp

and compress as many coils as possible. (Fig. 9)

Fig. 7: Compressing a spring.

Technique 1: Technique 2:

Compressing a spring Compressing a spring via

via the spring coils. the upper spring plate.

Fig. 8: Clamping the suspension-/damper strut into

holding fixture.

Removing a Spring (Technique 1)

Fig. 9: Preadjusting the spring compressor.

(see Fig. 16)

KL-0055-60

Holding Fixture (Accessory)