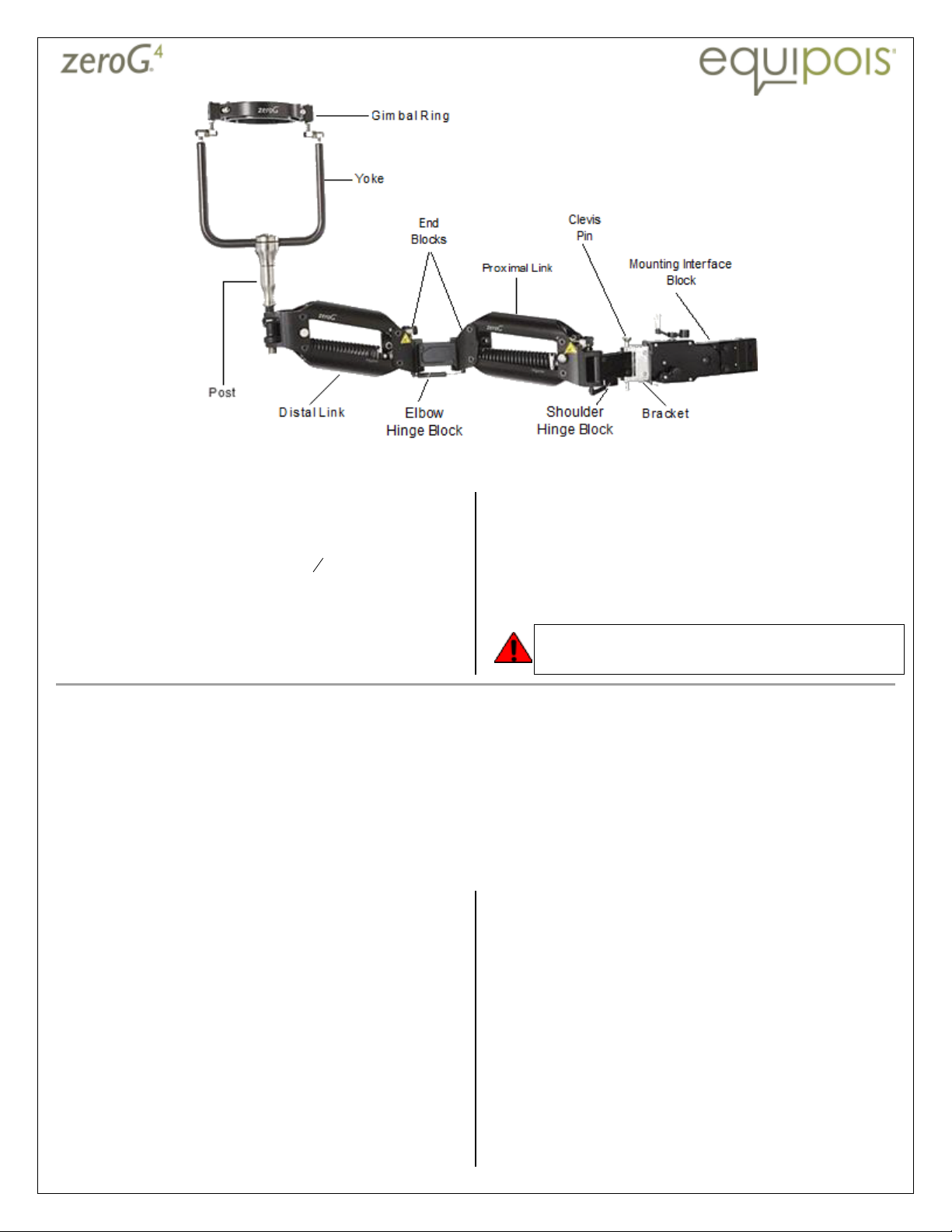

Equipois zeroG Arm User manual

Arm Operator’s Reference

Mounting the payload

1. Extend the arm or dock it securely. Do not mount or

dismount the payload when you are using the built-in

dock, unless there is no alternative.

2.

Loosen the two-piece collar with a

32

3

-inch llen

wrench

.

3. If this is a top-mount (shown), position the collar for the

desired height and tighten it.

4. If this is an underslung mount, remove the collar.

5. Insert the gimbal post into the socket at the end of the

arm.

6. If this is an underslung mount, have an assistant help

you position and tighten the collar.

7. Dress hoses and cables with zip-ties to the gimbal post

and the elbow hinge block.

DO NOT MOUNT ND DISMOUNT THE P YLO D

WHEN THE BUILT

-

IN DOCK IS IN USE

.

Adjusting the rest position

The dynamic and preset mounting interface blocks have different adjustment mechanisms, but the process of adjustment

is the same. Pitch adjustment moves the bracket up and down, in a head-nodding motion. Roll adjustment rotates the

bracket, as viewed from the front.

1. With the tool mounted and the arm undocked, let the arm extend toward the work area and, without letting go com-

pletely, let it move freely.

2. If the arm consistently drifts to the same side, adjust the pitch down and the roll away from the direction of drift.

3. If the arm drifts to either side, adjust the pitch down. Pitch should be as far up as possible without causing the arm to

be unstable.

Adjust a dynamic mounting interface

block

The block can be adjusted with the arm extended, as you

move around, to compensate for flex in the support or for

uneven floors.

• djust pitch by turning the crank on the top of the

mounting interface block. Cranking clockwise pitches

the bracket down.

• djust roll by turning the crank on the side of the block.

Cranking clockwise rolls the bracket counterclockwise.

Adjust a preset mounting interface

block

djustments are made with pairs of set screws.

1. To adjust pitch, use the screws on the back of the block:

a. If necessary, unload the bottom set screw by moving

the tool toward the back of the mounting interface

block.

b. Back off one of the screws to create slack in the direc-

tion you want to move the bracket

c. Tighten the other screw to move the bracket.

2. djust roll with the side screws, and unload the set

screw by moving the tool to one side or the other.

3. Tighten both screws in each pair snugly.

Arm Operator’s Reference

zeroG and Equipois are registered trademarks of Equipois Inc. of Los Angeles, CA

.

101

-

115 Rev A

Safety notes

The zeroG arm is made to flex effortlessly and follow you as you work, and it uses very strong springs to support the payl-

oad. Because the arm can move very fast and powerfully on its own, you must take care to keep it under control.

L

EANING OR HANGING

Do not lean or hang from the

zeroG

arm.

P

INCH POINTS

• Keep fingers, clothing, tools, work pieces, and other items away from the labeled pinch points on

the zeroG arm.

• During operation, use the tool’s grips and avoid touching the arm, except the adjustment cranks of

the dynamic mounting interface block.

• When the arm is not docked, handle it only by the end blocks and the adjustment knobs.

• Use of protective covers is recommended.

M

AXIMUM

L

OAD

Maximum payload capacity is 36 lbs., including the gimbal-tool-post assembly and cables and hoses.

Do not load more than 36 lbs. on your zeroG arm.

E

NVIRONMENTAL

E

LEMENTS

Keep liquids, gels, dust, paint, and debris away from the

zeroG

arm, or protect arm segments with

disposable or permanent arm covers from Equipois.

D

OCKING

&

POSITIONING

Dock the zeroG arm in a horizontal position when it is not in use. Do not leave the

zeroG

arm free or

floating where it can easily swing or move.

U

NDOCKING AN

UNLOADED

zeroG

ARM

An unloaded

zeroG

arm

RISES FORCEFULLY

and can cause injury if it is released suddenly from its docked

position. Never undock a zeroG arm unless it is loaded with its intended payload or the spring tension

is balanced by restraints or a counter weight.

P

AYLOAD REMOVAL

Do not mount or dismount the payload from the

zeroG

arm when the built-in dock is in use.

Adjust lift

Lift is the force that the links of the arm exert to hold up

the weight of the tool. The usual lift floats the tool with

the links almost level. Some operators prefer to set the

links at a higher angle, to help with the work. To change

the lift:

1. With the payload in place, extend the arm.

2. Move the payload so that the spring of the forearm link

is perpendicular to the adjusting mechanism. The link

should be slanting at about 5° above level and the Lift

knob should turn easily.

3. Turn the Lift knob until the link balances at the 5° slant:

a. Turn the knob clockwise to increase lift, if you lifted

the payload.

b. Turn the knob counterclockwise to decrease lift, if

you pulled the payload down.

4. In the same way, adjust the upper-arm link so it bal-

ances at the 5° slant.

5. When the links are adjusted, carefully move the tool up

and down to the full extent of its range. The links

should track smoothly as you move the tool up and

down.

6. Hold the arm pointed toward the work area and with-

out letting go completely, let it move freely:

a. If the arm drifts consistently to one side, adjust the

pitch down and the roll away from the direction of

drift.

b. If the arm drifts to either side, adjust the pitch down.

7. If a link locks in the full up or down position, adjust the

rate.

Hint: Adjust lift for a lighter tool before you remove the

heavier tool.

Adjust Rate

The arm is isolastic, that is, it requires almost the same

force to move it up and down throughout its vertical

range. As the tool moves, the arm compensates for

changes in the links’ angles. This compensation is called

rate. The usual setting is to have the Rate knob turned ful-

ly counterclockwise for maximum isolasticity. To change

the rate:

1. Raise the link to the full up position.

2. To decrease isolasticity and make it harder for the op-

erator or the arm to raise or lower the tool, turn the

Rate knob clockwise.

3. To increase isolasticity and make it easier to move the

tool through the full range of vertical motion, turn the

Rate knob counterclockwise.

4. When the link no longer locks up, adjust the lift so the

arm floats in the proper attitude.

Lift knob with R te

knob behind

Table of contents

Other Equipois Tools manuals