Equiptec G20 Mobile User manual

1

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

:

G20 Assembly Manual

www.equiptec.co

1

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

Disclaimer

Recommended safety procedures to be employed by all person assembling their Equiptec Adjustable Height Platform (AHP)

Before proceeding with any assembly operations contained in this manual, you must consult with the designated Safety Professional or other responsible

party within your organization prior to attempting any activities contained herein. Your employer is responsible for your safety at all times and thus all

safety regulations, policies and procedures which have been established by your company take precedence over and supersede any information and

guidance contained herein especially as it relates to your personal safety and that of others in proximity to the work being performed. We highly recommend that you

review this assembly manual with a qualified safety professional such as a CSP or equivalent and/or any other supervisory, union or other staff at your site that are

responsible for safety related matters.

The AHP assembly procedure includes the use of powered and manual hand tools and the equipment being assembled is sometimes large and can be quite heavy. It is

comprised mostly of steel and aluminum, including some heavy-gauge structural pieces such as decks and base frames and also large ‘sheet metal’ panels such as those

found on the front and sides of the units.

Hazards may include (but are not limited to) cuts to fingers, arms etc., from metal edges, accidental contact injuries to all parts of the body such as from contact with hard

metal corners and crushing injuries due to components which are of substantial weight and could drop unexpectedly while being moved or assembled. Other physical

hazards include noise and vibration from powered tools, noise caused by contact of powered or manual tools with metal surfaces by dropping, extraneous bits of metal

from screw threads, threaded holes, etc. that could cause an eye injury, and crush injuries to fingers, hands, or any other part of the body. Therefore it is CRITICALLY

IMPORTANT that you have reviewed this manual with the assigned Safety Professional or authority at your location to ensure you have been given all the necessary PPE

and other tools and appliances needed to safely assemble the Equiptec Adjustable Height Platform.

Working at heights during assembly considerations:

Equiptec AHPs were designed to take the place of other more traditional devices for working at heights.

For the most part , your AHP should be able to be assembled from ground level. However, depending on what accessory you are fitting, or the particular situation you

are in, there may be a need to work at height during the assembly procedure. If that is the case, you will need to ensure you are protected from any potential fall from the

device as it is being assembled. This will require the use of a scissor lift, or ‘wheeled stair ladder’ that meets the ANSI and OSHA requirements for safety.

List of required PPE for persons assembling their Equiptec Adjustable Height Platform:

Note: All PPE and safety related equipment must be approved by ANSI/ASSP/ASTM/NIOSH (or other relevant, recognized and accredited body) in order to effectively

protect the assembler during the assembly process!

• Head Protection: Hardhat or Bump Cap

• Hand Protection: Crush and Cut Resistant Gloves

• Eye Protection: Safety Eyewear

• Hearing Protection: Earplugs / Earmuffs

• Foot Protection: Safety Shoes (steel or composite)

• Cut Protection: Cut resistant sleeves and/or heavey duty clothing

2

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

Assembly Instructions for your new Equiptec Giraffe G20

If any instruction is unclear, DO NOT

proceed, contact Equiptec for advice

w. www.equiptec.co

p. 1 888 523 4340

Section Unit / Accessory Kit Page

1 Giraffe G20 Base Unit 5

2 Giraffe G20 Standard Casters 21

3 Giraffe G20 1 Step Extension 25

4 Giraffe G20 2 Step Extension 34

5 Giraffe G20 4 Step Sub Chassis 43

6 Giraffe G20 8 Step Sub Chassis 75

7 Giraffe G20 Slide Out Deck 114

8 Giraffe G20 1.8m Hammerhead Deck 132

9 Contact Details 146

3

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

Configuration Options

Assemblies Section Assemblies Section

Giraffe G20 G20 Base Unit

G20 Standard Casters

1

2

Giraffe G20 + 1 Step

w Slide Out

G20 Base Unit

G20 1 Step Extension

G20 Slide Out Deck

1

3

7

Giraffe G20

w Slide Out

G20 Base Unit

G20 Standard Casters

G20 Slide Out Deck

1

2

7

Giraffe G20 + 1 Step

w Hammerhead

G20 Base Unit

G20 1 Step Extension

G20 1.8m Hammerhead Deck

1

3

8

Giraffe G20

w Hammerhead

G20 Base Unit

G20 Standard Casters

G20 1.8m Hammerhead

Deck

1

2

8

Giraffe G20

+ 2 Step

G20 Base Unit

G20 2 Step Extension

1

4

Giraffe G20

+ 1 Step

G20 Base Unit

G20 1 Step Extension

1

3

Giraffe G20

+ 2 Step w Slide Out

G20 Base Unit

G20 2 Step Extension

G20 Slide Out Deck

1

4

7

4

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

Configuration Options

Assemblies Section Assemblies Section

Giraffe G20

+ 2 Step

w Hammerhead

G20 Base Unit

G20 2 Step Extension

G20 1.8m Hammerhead Deck

1

4

8

Giraffe G20

+ 8 Step

G20 Base Unit

G20 8 Step Sub Chassis

1

6

Giraffe G20

+ 4 Step

G20 Base Unit

G20 4 Step Sub Chassis

1

5

Giraffe G20

+ 8 Step

w Slide Out

G20 Base Unit

G20 8 Step Sub Chassis

G20 Slide Out Deck

1

6

7

Giraffe G20

+ 4 Step

w Slide Out

G20 Base Unit

G20 4 Step Sub Chassis

G20 Slide Out Deck

1

5

7

Giraffe G20

+ 8 Step

w Hammerhead

G20 Base Unit

G20 8 Step Sub Chassis

G20 1.8m Hammerhead Deck

1

6

8

Giraffe G20

+ 4 Step

w Hammerhead

G20 Base Unit

G20 4 Step Sub Chassis

G20 1.8m Hammerhead Deck

1

5

8

5

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Section 1 - Equiptec Giraffe G20 Base Unit

Giraffe G20 as shipped with packaging removed

6

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Note: Heavy duty washers used

everywhere a bolt attaches

to a handrail extrusion

Maximum torque figures

provided to secure bolts

without deforming ‘hollow’

extruded parts

Directions for General Fixing Assembly

Nyloc Nut

Flat Washer

Handrail

Extrusion

Heavy Duty

Washer

Bolt

A

Spring

Washer

Handrail

Extrusion

Heavy Duty

Washer

Bolt

B

Heavy Duty

Washer

Flat

Washer

Bolt

C

M8 Nyloc

Nut

M8 Cap

Screw

Pivot

Joiner

D

Handrail

Extrusion

7

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 1 - Unpack and Identify Parts

1. Remove stair assembly by

removing temporary transport

bolts each side

2. Unpack all parts and check them

against the parts list below

Description Qty

Floating Tread 5

Stair Handrail Assembly 2

Stair Midrail Assembly 2

Platform Handrail Assembly 2

Platform LH Handrail Assembly 1

Platform RH Handrail Assembly 1

Upper Platform Stair Handrail Assembly 2

Left Corner Post + Gate Assembly 1

Right Corner Post + Gates Assembly 1

8

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 1 - Unpack and Identify Parts

Floating Tread

Stair Handrail

Assembly

Stair Midrail

Assembly

Platform Handrail

Assembly

Platform LH Handrail

Assembly

Upper Platform Stair Handrail

Assembly

Left Corner Post + Gate

Assembly

Right Corner Post + Gate

Assembly

Platform RH Handrail

Assembly

9

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 2 - Install Pump Handle

1. Install pump handle – slide into

place as shown and tighten handle

screw into indent at the base of

the handle

Pump

Handle

Grub Screw

to be

tightened

10

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 3 - Install Deck

1. Loosen M12 Bolts on both sides and

rotate deck into position

2. Hold Deck in position

and insert bolts into holes shown.

Ensure bolts are installed from the

inside (so bolt heads are facing the

deck, nuts are on the outside)

Fastening List

12 x M10 x 30mm Bolt

12 x M10 Nyloc Nut

24 x M10 Flat Washer

Rotate Deck up into position

11

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 4 - Install Stair Assembly

1. Lift Stair assembly into position

(two people required for this)

2. Insert Bolts on both sides as shown

3. Tighten to maximum of 7.5 ft/lbs

(10Nm) torque

Fastening List

4 x M10 x 80mm Bolt

4 x M10 Nyloc Nut

8 x M10 Flat Washer

M10 x 80mm Bolt

DO NOT OVERTIGHTEN

7.5 ft/lbs (10Nm) maximum

12

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 5 - Install Floating Treads

1. Install the five floating treads as

shown

2. Ensure orientation is correct

Floating

Treads

13

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 6 - Install Stair Handrail Assembly

1. Install the Stair Handrail assembly on

both sides as shown

Fastening List

4 x M10 x 65mm Bolt

4 x M10 Spring Washer

4 x M10 Heavy Duty Washer

Leave this cap

screw loose

M10 x 65mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See directions for

general fixing assembly

detail B on page 2

14

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 7 - Install Stair Midrail Assembly

1. Install the Stair Midrail assembly on

both sides as shown

Fastening List

4 x M8 x 35mm Cap Screw

4 x M8 Nyloc Nut

4 x M10 x 65mm Bolt

4 x M10 Nyloc Nut

4 x M10 Flat Washer

4 x M10 Heavy Duty Washer

Leave these cap

screws loose

See directions for

general fixing

assembly detail D

on page 2

M10 x 65mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See directions for

general fixing

assembly detail A

on page 2

15

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 8 - Install Platform Handrail Assembly

1. Install the Platform Handrail assembly

on both sides as shown

2. Once in position tighten all M8 Cap

Screws on all installed assemblies

Fastening List

2 x M8 x 35mm Cap Screw

2 x M8 Nyloc Nut

4 x M10 x 65mm Bolt

4 x M10 Nyloc Nut

4 x M10 Flat Washer

4 x M10 Heavy Duty Washer

M10 x 60mm Bolt with

Heavy Washer on inside

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See directions for

general fixing assembly

detail C on page 2

See directions for general fixing

assembly detail D

on page 2

16

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 9 - Install Left + Right Platform Handrail Assemblies

1. Install the left and right Platform

Handrail assemblies as shown

Fastening List

6 x M10 x 65mm Bolt

4 x M10 x 70mm Bolt

10 x M10 Nyloc Nut

10 x M10 Flat Washer

10 x M10 Heavy Duty Washer

M10 x 70mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See direction for general

fixing assembly detail A

on page 2

M10 x 65mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

17

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 10 - Install Upper Stair Handrail Assembly

1. Note: Ensure the G20 platform is lifted up

two steps before installing these handrail

assemblies

2. Install the Upper Platform Stair Handrail

assembly on both sides as shown

Fastening List

4 x M8 x 35mm Cap Screw

4 x M8 Nyloc Nut

2 x M10 x 75mm Bolt

2 x M10 Nyloc Nut

2 x M10 Flat Washer

2 x M10 Heavy Duty Washer

M10 x 75mm Bolt

M8 x 35mm Cap Screw

See direction for general

fixing assembly detail D

on page 2

Ensure bolt heads are

on inside (facing treads)

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See direction for general fixing assembly

detail A on page 2

18

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 11 - Install Left Corner Post + Gate Assembly

1. Lower the G20 platform back to the

lowest position

2. Install left corner post and gate assembly

as shown

3. Align gate and lock/latch before

tightening bolts

Fastening List

3 x M10 x 70mm Bolt

3 x M10 Nyloc Nut

3 x M10 Flat Washer

3 x M10 Heavy Duty Washer

M10 x 70mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See direction for general fixing assembly

detail A on page 2

19

www.equiptec.co May 2022

Giraffe Assembly Instructions G20 - SB 2.1

1

Step 12 - Install Right Corner Post + Gates Assembly

1. Install the right corner post and gates

assembly as shown

2. Align gate and lock/latch before

tightening bolts

Fastening List

3 x M10 x 70mm Bolt

3 x M10 Nyloc Nut

3 x M10 Flat Washer

3 x M10 Heavy Duty Washer

M10 x 70mm Bolt

DO NOT OVERTIGHTEN

Max tightening torque

7.5 ft/lbs (10Nm)

See direction for general fixing assembly

detail A on page 2

Other manuals for G20 Mobile

4

Table of contents

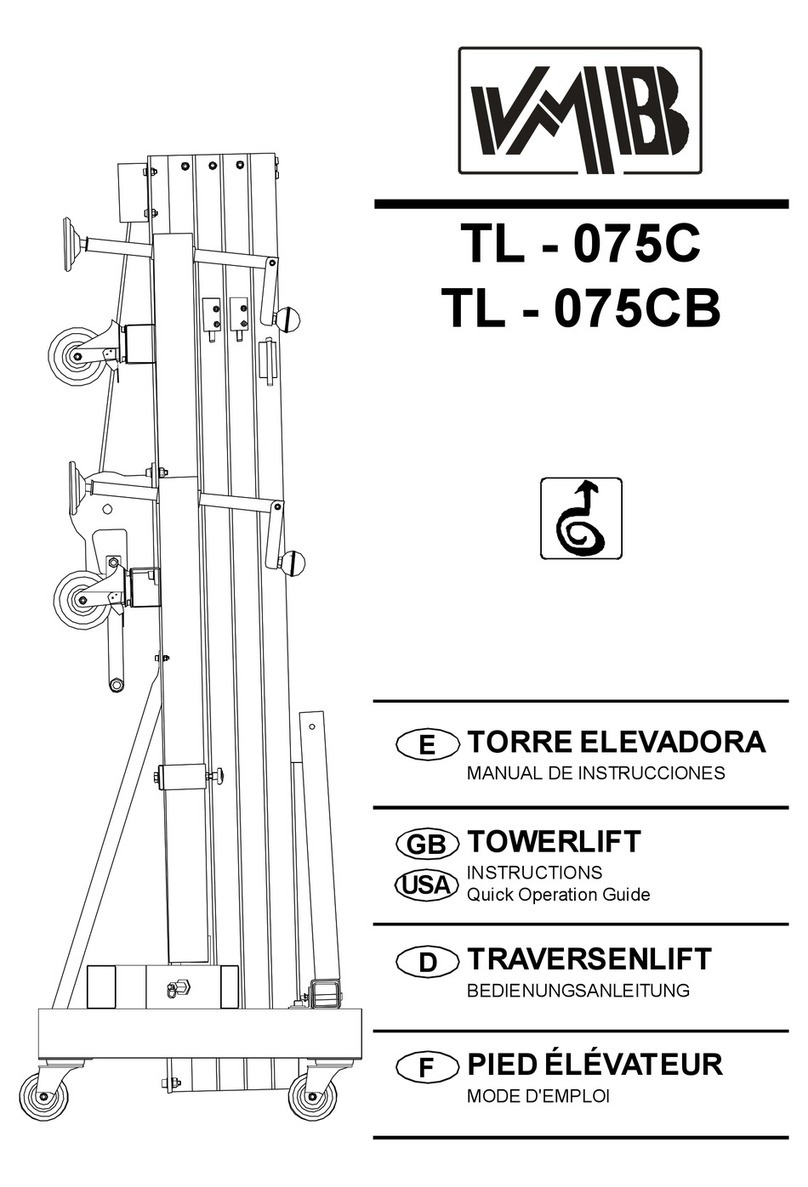

Other Equiptec Lifting System manuals

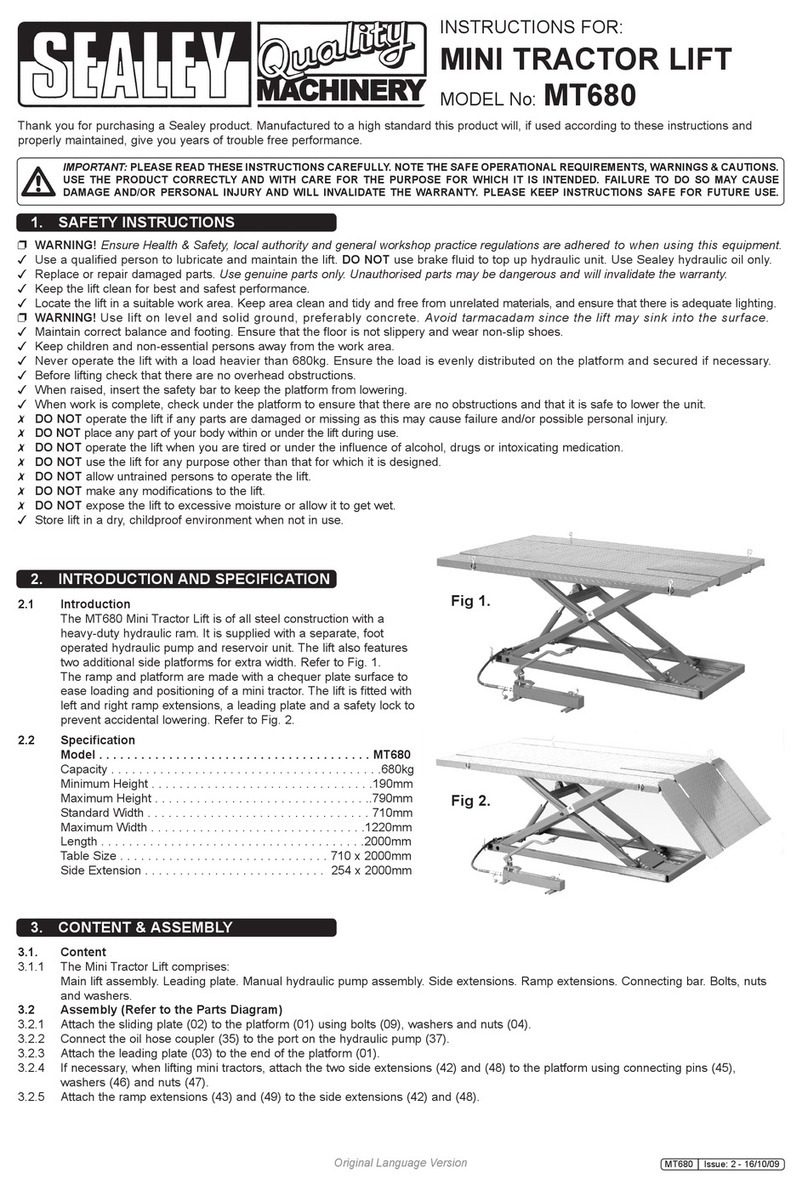

Popular Lifting System manuals by other brands

Cub Cadet

Cub Cadet 39A-212-100 Operator's manual

Ergoswiss

Ergoswiss TL-2 Assembly instructions

WOOD'S POWR-GRIP

WOOD'S POWR-GRIP POWR-FRAME Series instructions

Euroscreen

Euroscreen SI-100 Installation and maintenance manual

Atlas Escalateurs

Atlas Escalateurs VISTA installation manual

Direct-Lift

Direct-Lift Pro Cycle XLT Installation-safety-operation-maintenance