Equiptec G20 Mobile User manual

:

G20 Mobile Maintenance

Platform Owner’s Manual

www.equiptec.co

Contents

Disclaimer ..................................................................

Introduction ................................................................

Compliance ................................................................

Assembly ....................................................................

Warranty ......................................................................

Safety Requirements ...............................................

Prior to Use ................................................................

Positioning the Girae G20 ...................................

G20 Use .....................................................................

Girae G20 Stability ................................................

Operation ...................................................................

Maintenance ..............................................................

Six Monthly Service Inspection ............................

Annual Service Inspection .....................................

Biennial Service Inspection ..................................

Girae G20 Parts Diagrams ...................................

Complete Unit Parts Diagram ...............................

Base Unit Parts Diagram ........................................

Roller Panel Parts Diagram ....................................

Hydraulic System ......................................................

Hydraulic Oil ..............................................................

Bleeding the Ram .....................................................

Descent Speed Adjustment ...................................

1

1

2

2

2

3

3

3

4

5

6

7

8

9

10

11

11

12

13

14

14

14

15

Giraffe Owner’s ManualG20 - SB 1.0January 2022

Contents

Hydraulic System Parts Identification ..................

Optional Accessories ...............................................

One Step Extension ..................................................

Two Step Extension ..................................................

Four Step Extension .................................................

Eight Step Extension ................................................

Hammerhead Deck ..................................................

Angle Deck .................................................................

Slide Out Deck ..........................................................

Transport .....................................................................

Contact Details ..........................................................

16

17

17

17

17

17

18

18

18

19

20

Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Recommended Safety Procedures to be employed by all persons using their Equiptec Adjustable Height Platform (AHP):

Before proceeding to use your AHP, you must consult with the designated Safety Professional or

other Responsible Party within your organization prior to attempting any activities contained herein. Your

Employer is responsible for your safety at all times and thus all Safety Regulations, Policies and Procedures which have

been established by your company take precedence over and supersede any information and guidance contained herein

especially as it relates to your personal safety and that of others in proximity to any work being performed. We highly

recommend that you review this Owner’s Manual with a qualified Safety Professional such as a CSP or equivalent and/or

any other supervisory, union or other staff at your site that are responsible for Safety-related matters.

Working at heights considerations:

Equiptec AHP units are designed to make working at height as safe and easy as possible. However, that does not mitigate

the fact that working at height still carries the risk of a fall, no matter how small this may seem. Equiptec strongly

recommends that ALL users familiarize themselves with all safety points in this Manual, and in particular, wish to

emphasize the following:

Users must NOT

• Intentionally rock the device

• Jump off the device

• Step outside the safety cage (unless there is approved and appropriately certified guarding in place)

Users must ALWAYS

• Consult with their designated safety professional or other responsible party within their organization as to the

suitability of the device for the intended work

• Engage 3 points of contact when ascending or descending the stairs on the device

Disclamier

Giraffe Owner’s ManualG20 - SB 1.0Page 1 January 2022

The Equiptec Giraffe G20 (G20) is designed to facilitate easy and simple stair access to a variable height platform. It

incorporates a large cantilever to allow the platform to be positioned over obstacles, and thus provide a deck that is

sturdy, and as ergonomically safe as possible to work from. The G20 has a wide variety of Standard Accessories that can

be added to it, and therefore can be Customised in different ways.

A copy of this manual should remain with the G20 at all times. Prior to using the G20, the user should familiarize his/

herself fully with the contents, paying particular attention to the safety notes included as it is a mandatory requirement

that these are strictly followed.

To avoid confusion, Equiptec stipulates the official orientation of the G20 as follows:

• Front - is the direction you face as you climb the Stairs

• Rear (or Back) - is the opposite to the Front direction

• Left and Right are defined from looking forward

i.e. as you would when you climb the stair

Introduction

Front

Rear

Left

Right

Your G20 is shipped in a consolidated form to facilitate cost efficient freight. Usually, the Assembly of the unit can be

performed by the local Distributor, but if it is more practical, or preferred by the client, it may be done by the end user,

provided there are competent personnel on site to perform the task. To assemble it ready for use is about 2 to 4 hours,

depending on configuration, for two Competent Personnel. Full instructions will come with the Unit for this procedure

and can also be found on Equiptec’s website at www.equiptec.co/instruction-manuals. Equiptec is available to assist via

video conference if required (during regular Business Hours, New Zealand time).

Note: It is a mandatory safety consideration that the G20 is assembled precisely, and when taking on the assembly

procedure, it is the new Owner’s responsibility to ensure all appropriate Equiptec assembly instruction resources are

made fully available and are followed absolutely correctly. If there is any doubt about any aspect, contact Equiptec

for advice before proceeding further. It is also a mandatory requirement to submit the required photos and details of

the assembly via the warranty registration form on the website, www.equiptec.co. This allows Equiptec staff to check

the correct procedure has been followed, and validate the assembly is correct as performed, allowing the terms and

conditions of the standard Warranty to take effect.

Compliance

The G20 units have been tested and confirmed to meet or exceed the strength, stability and all other applicable

requirements for the following standards:

• AS 1657 and AS/NZS 1576 (Australia and New Zealand)

• ANSI-ASC A14.7-2011 (USA)

• CSA Z11-12 (Canada)

Assembly

Page 2Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Introduction

Regular maintenance as per the maintenance schedule in this manual is also a necessary requirement. Details from these

mandatory checks must be submitted to Equiptec via the service checklist form, this can be accessed by scanning the ‘scan

to service me’ QR code located on the stair side support above the hydraulic pump or via the link in the service reminder

E-mail. The G20 comes with a 5 year Warranty which can be extended out to a Lifetime Warranty provided every annual

and biennial service is done at the required time, and a complete service checklist form has been submitted to Equiptec.

Should the G20 ever be sold, rented out or handed over to any third party for any reason, it is required that a copy of

this manual should also be passed over at the same time to ensure the new owner and/or operator is aware of the

operational needs, constraints, safety points, and maintenance requirements of the G20 Platform.

Warranty

The standard Warranty for a G20 is 5 years. To ensure this warranty is in place, simply go to the Equiptec website (www.

equiptec.co) and complete the warranty registration form including the required photos of the Assembly process as

stated above. Equiptec will confirm the correct assembly has been achieved (or contact you if they have any questions),

that the Unit is registered for the 5 year warranty and it is good to go! This 5 year warranty can be extended to a “Lifetime

Warranty” by ensuring that every mandatory service in this manual is performed correctly, at the correct time and that the

required photos and information are submitted to Equiptec via the service checklist form (either scan the QR code on the

unit or click the link in the reminder E-mail).

Some situations that a G20 could be used in are extremely demanding of the structure of any machine. Therefore it

needs to be made clear that that the Term “Lifetime Warranty” means the period that the Equipment could reasonably be

expected to operate (in the application(s) and environment(s) it is operating in) without fault in material or workmanship if

used correctly for its intended purpose and maintained according to the Manufacturers recommendations.

Warranty

Prior to Use

1. Check the G20 for any damage and/or missing

components, and that final site assembly has been

correctly completed. Proceed only when the unit is in

good and complete condition. And, if it is the first use

after assembly, this has been confirmed by the Equiptec

team.

2. In addition to the “Hold Valve” (with the Black Plastic knob

on top) the Hydraulic raise/lower system on the G20 is

fitted with 2 safety valves. The first is a “lock valve” (at the

Base of the Cylinder) which will lock the ram in case of any

sudden loss of pressure (hose, burst/cut etc.). The second

one is an adjustable restrictor valve to control the descent

speed of the platform. This is located adjacent to (and

on the right-hand side of) the Reservoir, and should be

checked and adjusted only if necessary, to allow for a safe

lowering speed of the working deck. Refer to instructions

to do this on page 14.

3. Warning: The user must check for all electrical hazards

(and contact all appropriate authorities if necessary) in

the area before positioning or using the G20.

The G20

conducts electricity and offers no electrical protection.

Positioning the G20

1. Check that the ground surface that the G20 is to be used

on is capable of supporting 75% of the combined weight

of the G20 and its intended load (allow approximately

1980lb (900kg)) on any 2 of the wheels.

2. The G20 is heavy. For locatin the unit at the place where

work is to be performed, it is recommended that it is

moved by a minimum of 2 people, for both safe control

and guidance around possible obstacles on all four sides

and above the unit.

3. Check that the path or route to be followed to the work

destination is free from ground or overhead obstructions

eg beams, trusses, mezzanine floors, raised manholes,

electrical cables, gratings, potholes etc. Note: As stated

above the G20 is a metallic object and conducts electicity

so at no time must it come near or into the proximity

of energized power cables due to shock and arc flash

hazards.

Safety Requirements

Giraffe Owner’s ManualG20 - SB 1.0Page 3 January 2022

Positioning the G20

4. The standard issue caster wheels are not designed to roll

over obstacles. If the surface of the area the G20 is to be

moved across is soft, has larger stones, objects or debris

in the G20’s path, or for any reason the G20 cannot be

moved by manual pushing/pulling, it is recommended

to move the G20 with a forklift using the forklift pockets

provided. The G20 should not be towed or pushed by

mechanical means.

5. Under no circumstances must any personnel be allowed

on any part of the G20 while it is either being moved,

repositioned or adjusted for height.

6. Caster swivel directional locks are fitted to at least one of

the 2 front standard issue type casters. This will greatly

assist and control correct tracking, particularly if being

moved longer distances.

7. The G20 has “pinch points” or areas where crushing

could occur. Careful attention must be given to keep

well clear of these areas. It is mandatory to keep all

limbs/heads clear of any part of the G20 that is forward

of the hydraulic pump handle, when the G20 is being

adjusted for height.

8. Always check that the deck will not collide with any object

as it is being raised or lowered. In particular, ensure

all personnel are well clear of the G20 when raising or

lowering the deck. Be absolutely sure all personnel

arewell clear of the G20 when raising or lowering the

deck.

G20 Use

(general points - see also ‘Operation’)

1.

Always ensure

that

all four

caster brakes are effective

and locked on at all times (unless it is being moved),

especially before any personnel use the G20.

2. Always respect the safe operating limits of the G20.

The design load is 660lb (300kg), including a point

load of 295lb (135kg), on the platform OR the stair (not

concurrently). The G20 has a large cantilever, making

this requirement absolutely essential.

Please note that

in the case of the optional ‘angled deck’ , ‘hammerhead

deck ‘ or ‘slide out deck’ options being fitted, the safe

operating limit is reduced

.

3. It is dangerouse and therefore forbidden to jump on or

onto the G20 platform.

4. Temporary means of gaining additional height (eg using a

stepladder or trestle placed on top of the working deck, or

any surface) is strictly prohibited at any time.

Safety Requirements

Page 4Giraffe Owner’s Manual G20 - SB 1.0 January 2022

G20 Use (see also ‘Operation’)

5. In its standard configuration, the G20 deck has 3 access

gates to facilitate access to/from a work surface if

required. These gates must remain shut except when

walking through them. Do not use these gates if there

is not a flat surface immediately beyond it that has been

certified to be of sufficient strength to support your

weight and has sufficient, compliant guard railing in

place. Always check with a competent party ie safety

manager, supervisor or other responsible party if in doubt.

The gates must be checked before use. They are spring

loaded to shut automatically. Do not use these gates if

they do not swing freely throughout their full rotation,

and automatically latch securely shut. These gates are

lockable, and it is recommended that they remain shut

and locked unless “walk through” access is required.

6. The G20 is equipped with a Safety Rail at the top of the

stairs. This lifts into place freely and is pushed securely

into the locking position and once in place can be lifted up

and back towards the user to disengage. Ensure this rail is

securely in place before proceeding with any work.

7. It is prohibited for personnel to be under the G20 work

deck when it is loaded and/or elevated.

G20 Stability

1. If the ground surface is not within 5 degrees of level do

not use the G20! Reposition your work piece on flat

ground.

2. The G20 is not designed as a crane.

Do not use the G20

to lift any loads, or as a platform off of which to lower

loads to ground (or an other) level

.

3. The G20 will offer a large area to wind, and so care needs

to be taken when using it in windy conditions. The table

on page 6 gives a good indication of wind conditions the

G20 can and cannot be used in. Due caution must be

given to any circumstances where wind conditions are

magnified, eg in long open-ended buildings, between

buildings where the wind may have a funneling effect,

or where the G20 is positioned close to the corner of a

building. Never attach tarpaulins, flags, banners, signs or

other coverings to the G20 as this may seriously increase

its susceptibility to wind forces.

Safety Requirements

Giraffe Owner’s ManualG20 - SB 1.0Page 5 January 2022

The G20 has a minimum operating temperature and

should

not be used in an environment that is colder than -4°f

(-20°c)

.

The G20 is very simple to operate. In addition to

instructions given in the safety section of this manual,

the following gives a basic guide to what is required.

1. Move the G20 as close as possible to the workpiece

without adjusting the deck height. Being closer allows

you to more accurately gauge the height where you will

require the deck to be positioned.

2. When adjusting the height of the G20, follow this

sequence when moving the Platform UP.

Do not force the Pump handle if it is hard to pump.

Likewise, do not force the Ratchet Lock Lever if it is hard

to disengage.

This could be caused by a deck obstruction

or debri s etc in the mechanism.

Follow this sequence if adjusting the Platform DOWN.

Note that the User must ensure the Ratchet Locks are

engaged on both sides before using the unit.

Operation

Page 6Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Safety Requirements

G20 Stability

Wind

Description

Speed

Visable Indications Action Required

MPH KPH Meters /

Sec

Moderate

Breeze 13 - 18 20 - 29 5.5 - 7.9 Raises dust and

loose paper Safe to work on G20

Fresh Breeze 19 - 24 30 - 38 8.0 - 10.7 Small trees in leaf

begin to sway

Stop all work on the

G20 and secure all

loose items

Strong Breeze 25 + 39 + 10.8 +

Large branches in

motion, overhead

wires whistle

Move G20 indoors

As with all machinery, particularly those used to support working personnel, a regular maintenance system is required.

In the case of the G20, the Manufacturer approved system is very simple, consisting of 6 Monthly, Annual and Biennial

service types.

The responsibility for ensuring these services are done correctly rests with the Owner, however, in conjunction with their

Warranty, Equiptec offers a reminder service to help ensure these services are completed at the required times. Proof

that mandatory servicing has been performed also needs to be submitted to Equiptec via the service checklist form. This

form is accessed either by scanning the service QR code on the unit or via the link in the reminder E-mail. Completing all

mandatory Annual and Biennial Services, and submitting the required information to Equiptec will upgrade the Warranty

to a “Lifetime” Warranty of the Unit (provided that no mandatory services are missed, and that there is no damage etc that

adversley affects operation or structural integrity). Equiptec will vet service reports that are correct and complete only,

and contact the Owner if they see anything that looks like it needs attention.

While these checks are relatively simple, it is recommended that they are carried out by qualified tradespeople. If the

Owner does not wish to carry out any particular service or task themselves, Equiptec may be able to arrange for an

authorized Equiptec Distributor to visit the Site and perform these tasks, however, the Distributor may charge for this

service.

To assist in identifying Parts, refer to the Exploded Parts drawings on page 11.

Operation

3. Move the G20 into the final position. Check it is within 5

degrees of level and on a sufficiently firm base surface.

4. Lock all 4 wheel-brakes

5. You may now climb the base stairs, unlatch the deck

Safety Rail, proceed on to the work deck, making

absolutely sure you position and clise the Safety Rail

behine you.

6. Once your work is finished, descend down the stairs to

ground level and move the G20 out to a clear area to

allow the safe lowering of the deck. See point 2 above

on how to lower the deck. Note that the restrictor valve

described in the safety section (under “Prior to Use”)

should be adjusted if the deck descends too fast or too

slow.

Maintenance

Giraffe Owner’s ManualG20 - SB 1.0Page 7 January 2022

Please note that only genuine Equiptec parts are used if any replacements are required.

Six Monthly Service Inspection

(scan the QR code to complete the service checklist form)

1. Conduct a thorough visual check for any damaged/bent components, or loose fastenings.

• Upload any photos of any damage

Note:

Once photos of any damage are uploaded, check with Equiptec before continuing to operate a damaged unit. It

must be ascertained if the damage will compromise safety, strength, or the smooth functioning of the G20.

2. Check all handrails are in place and firm. Ensure any components missing/loose are replaced/tightened (to 7.5 ft/lbs /

10Nm).

3. Check the self-closing gates swing open and shut freely, automatically swing shut and lock, and that the lock is

effective. Adjust the Lock system if required. Instructions for the adjustment of the lock system can be found at the

manufacturers website www.ddtechglobal.com.

4. Check that the caster brake locks and directional locks are functioning correctly. Caster Brakes are occasionally affected

by high wear of the Tires. If this is the case, adjust the Brake system as per the following instructions.

5. Check for any hydraulic leaks, that the hydraulic pump is functioning correctly, and is secure. If any issues come to light,

upload photos and contact Equiptec for advice.

6. Check all floating treads rise/nest correctly and do not catch on anything. Remove/repair any deformation damage that

may cause issues.

7. Check the Ratchet/Trigger system is functioning correctly. This will include checking the following elements.

• Trigger Cable Connections are all intact

• Trigger Cable Lever (by Hand Pump) operates effectively

Note:

If issues are discovered, upload photos/description, and contact Equiptec for advice

Maintenance

1. Loosen Lock Nut under Caster Brake release

lever

2. Adjust Grub Screw to alter brake tension

3. Re-tighten Lock Nut

Grub Screw

Lock Nut

Page 8Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Annual Service Inspection - Mandatory

(scan the QR code to complete the service checklist form)

1. Conduct a thorough clean both inside and out if necessary

2. Attend to all of the 6 Monthly checks plus...

3. Apply the brakes on the front wheels and jack the rear wheels slightly off the ground. Place packing block under Chassis

for safety. Check that the rear wheels spin easily (no roughness) and that the swivel turns freely. Check the rear Caster

mount bolts, and Caster Bracket mounting bolts, are tight (30 ft/lbs / 40Nm) and secure before lowering the rear

wheels and repeating the procedure for the front wheels. (Remember to apply the brakes and chock the rear wheels

and place a timber or other Block under the Chassis when jacking the front ones.) If any issues are identified, contact

Equiptec for advice.

4. Check all handrail and handrail post bolts are tightened to a maximum of 7.5 ft/lbs (10Nm) and any Bolts that attach to

captive nuts are tightened to a maximum of 15 ft/lbs (20Nm).

5. The G20 is not designed for use in corrosive situations. Check all fastenings and all surfaces for any signs of corrosion.

if any is found, photograph this and upload the photos to the service checklist form.

6. Check deck side member bolts (as highlighted in Diagram) are tightened to 30 ft/lbs (40Nm).

7. Pump the machine to full height. Before lowering again, check:

• the Hydraulic Ram, fittings and hoses have no leaks, cracks or chafing. If any issues are identified,

upload photos and contact Equiptec for advice

• whether the Hydraulic Ram needs bleeding (usually causes a soft “spongey” lift that does not go to full

height easily). See Instructions in the Hydraulic System section on page 14

8. Check for any excess movement (either fore/aft or lateral) of the deck when fully elevated. Contact Equiptec for advice

if any issues come to light.

9. Check the Hydraulic Oil level by removing the breather on the top of the tank when the Ram is fully retracted (

be

careful not to allow any contamination of the oil

). The Oil level should be 2.36” (60mm) below the top of the tank.

Add more if necessary but be aware that overfilling will result in spillage via the Tank Breather when the unit is coming

down, and underfilling will result in the Ram not being able to reach full extension.

Note that as per the Hydraulic

section below, the Oil should be changed at least every 2 years

.

10. Check the unit has a smooth raise/lower action throughout its entire range. Adjust the descent speed if required as per

instructions in the “Hydraulic System” section below. If there are any further issues beyond the descent control, contact

Equiptec for advice.

Continued on next page

Maintenance

Giraffe Owner’s ManualG20 - SB 1.0Page 9 January 2022

Annual Service Inspection - Mandatory (continued)

11. As per service checklist form instructions upload photos to show the following details:

• Platform pivot bolts as shown

• Upper deck handrailing

• Upper deck gate(s) including rear safety rail

• Any damage that has been sustained by the unit and

• General views from the 4 elevations with the deck at full height

Biennial Service Inspection- Mandatory

(scan the QR code to complete the service checklist form)

1. All of the Annual Service checks plus...

2. Lift the G20 onto a solid and safe elevated support. Check thoroughly for the following:

• Any damage, denting or any other structural issues around the Fork Pockets

• Check the Caster Bracket bolts under the Chassis are tight (30 ft/lbs / 40Nm)

3. Place unit back on to floor. Raise the Deck to full height. Ensure the Ratchet Locks are locked in place and proceed with

a systematic check of all fastenings on the inside of the Base and Upper Units. Note the following Torque Settings:

• Ram Mount bolts, Ratchet Trigger Guide Mounting bolts and the Roller Panel Bottom Strut bolts are all

tightened to a maximum of 15 ft/lbs (20Nm)

• Base Stair Mount bolts are tightened to a maximum of 7.5 ft/lbs (10Nm)

• Check that the Hydraulic Hoses and Ratchet Cables are tidily routed (away from moving Upper Unit

parts) and tied in place properly. Also check the Ram Hose connection is tight, with no leaks.

• Check the condition of all Rollers*

Note:

Use a safe platform ladder such as an Equiptec Squirrel to access the Side Panel Top Covers and remove them.

* Check Roller condition carefully especially if the environment the G20 is operating in is dusty or abrasive in any

way. Should the Roller surfaces be roughened, they should be replaced. This involves removing of the complete

Upper Unit. Contact Equiptec for instructions on how to perform this procedure

4. Lower the Deck to just above head height (with Ratchet Locks in place), and check the following:

• Ratchet Ladder rivet fasteners are firm

• All fittings and rivet fasteners under the Deck structure are tight (note that the M12 bolt at the Deck

Pivot Point is designed to remain loose and is the only Bolt assembly that is not fully tightened

• Ram Top Mount bolt is firm (do not over tighten)

5. Pull up each Floating Tread and check:

• For any damage, dirt or debris, clean/remove as necessary

• All rivet fastenings are tight

• Rollers spin freely and evenly

6. Do a final run to check the Ratchet Locks function as they should

Remember to upload photos of any issues to the service checklist form

Please note that only genuine Equiptec parts are used if any replacements are required.

Maintenance

Page 10Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Giraffe G20 Parts Diagrams

Complete Unit Parts Diagram

Maintenance

PROJECTION:

9

10

11

14

2

56 6 85

4

117

7

12

13 16

3

15

Item No.

Part No.

Accredo

Description

1

GA A0002

GA Base Unit

1

2

GA A0004

GA Roller Panel Assembly

1

3

GA A0006

GA Upper Platform

1

4

GP0194

Floating Tread

5

5

GA WA0005L

GA Wheel Bracket LH

2

6

GA WA0005R

GA Wheel Bracket RH

2

7

GA A0008

Back Stair

1

8

-

300241

Castor

3

9

GA A0012

GA Handrail Assembly 1

2

10

GA A0013

GA Handrail Assembly 2

2

11

GA A0014

GA Handrail Assembly 3

2

12

GA A0015L

GA Handrail Assembly 4(L)

1

13

GA A0015R

GA Handrail Assembly 4(R)

1

14

GA A0016

GA Handrail Assembly 5

2

15

GA A0020

GA Left Post & Gate

1

16

GA A0021

GA Right Corner Post & Gates

1

17

Grab Handle

2

18

Directional Lock

1

19

-

300241

200mm Castor - VRS G

1

20

GA 0315

GA Rear Gate

1

A3

DO NOT SCALE FROM DRAWING

THE INFORMATION

CONTAINED IN THIS

DRAWING IS THE SOLE

PROPERTY OF EQUIPTEC ANY

REPRODUCTION IN PART OR

WHOLE WITHOUT THE

WRITTEN PERMISSION OF

EQUIPTEC IS PROHIBITED.

DESC.

DRAWN:

PART NO.

G20

13/11/2020

1:30

DIMENSIONS ARE IN MILLIMETERS

UNLESS OTHERWISE SPECIFIED

+64 6 842 0222

www.equiptec.co

SCALE:

SIZE

REV

EQUIPTEC

(C) Copyright

1 OF 2

SHEET

GENERAL NOTES

TOLERANCES

GENERAL

0

0.5

0.0

0.1

0.00

0.01

CUT & FOLDED

FOLD DIM

0.5

FOLD ANGLE

0.5

CUT PROFILE

0.1

PART INFO/NOTES:

BEND RADIUS & ALLOWANCES TO BE CHECKED BY

1.

MANUFACTURER AND PART MODIFIED TO SUIT AS PER FINISHED

DIMENSIONS.

ALL PARTS DEBURRED

2.

VISIBLE SIDE INDICATED BY

A

3.

MATERIAL:

Material <not specified>

A

ACCREDO NO.

USED ON MODELS:

No. Product

Code Description Qty No. Product

Code Description Qty

1n/a G20 Base Unit Assembly 1 10 9840181 - 01 G20 Stair Mid Rail Assembly 2

2n/a G20 Roller Panel Assembly 1 11 9840182 - 01 G20 Platform Handrail Assembly 2

3n/a G20 Upper Platform Assembly 1 12 9840191 - 01 G20 Platform LH Handrail

Assembly 1

4 9840146 G20 Floating Tread 5 13 9840192 - 01 G20 Platform RH Handrail

Assembly 1

5 9840100 - 10 G20 Castor Bracket - LH 2 14 9840194 - 01 G20 Upper Platform Stair Handrail

Assembly 2

6 9840100 - 11 G20 Castor Bracket - RH 2 15 9840198 - 01 G20 Left Corner Post + Gate

Assembly 1

7n/a G20 Stair Assembly 1 16 9840199 - 01 G20 Right Corner Post + Gates Assem-

bly 1

8300241 200mm Castor - Giraffe 4 17 9840211 G20 Guide Handle 2

9 9840180 - 01 G20 Stair Handrail Assembly 2

Giraffe Owner’s ManualG20 - SB 1.0Page 11 January 2022

Giraffe G20 Parts Diagrams

Base Unit Parts Diagram

Maintenance

PROJECTION:

16

13

12

2

4

81 1417

9

5

192520 3

7

6

10

1115 18 23

26

27

24

2122

Item No.

Part No.

Accredo

Description

1

GA A0001

GA Chassis

1

2

GA 0007R

9840209

GA Front Side Panel RH

1

3

GA 0007L

9840208

GA Front Side Panel LH

1

4

GA 0008

9840212

GA Roller Mast

2

5

GA 0009

9840207

GA Front Panel

1

6

GA 0010R

9840211

GA Rear Side Panel RH

1

7

GA 0010L

9840210

GA Rear Side Panel LH

1

8

GA 0011R

9840214

GA Rear Mast RH

1

9

GA 0011L

9840213

GA Rear Mast LH

1

10

GA 0012

9840219

GA Top Fixed Tread

1

11

GA WA0003

9840220

GA Landing Rail

1

12

GA 0015

9840215

GA Mid Horizontal Strut

2

13

GA 0016

9840216

GA Top Horizontal Strut

2

14

GA 0017

9840285

GA Pump Moutn Bracket

1

15

GA 0031

9840231

GA Floating Tread Guide

10

16

GA 0032R

GA Top Cover RH

1

17

5L Tank

1

18

GA 0056

9840217

GA Tube mount bracket

2

19

GA 0054

9840240

GA Ram

1

20

GA 0095

GA Front Panel Crush Tube

2

21

GA 0275

GA Landing Rail Cross

Member

1

22

GA0032L

GA Top Cover LH

1

23

GA 0302

GA Front Panel Corner

Support 2

24

GA 0065

GA Pump Handle

1

25

GA A0051

GA Trigger Fully Assembly

2

26

GA A0052

GA Lever Assembly

1

27

GA 0066

9840239

GA Pump Handle Bracket

1

A3

DO NOT SCALE FROM DRAWING

THE INFORMATION

CONTAINED IN THIS

DRAWING IS THE SOLE

PROPERTY OF EQUIPTEC ANY

REPRODUCTION IN PART OR

WHOLE WITHOUT THE

WRITTEN PERMISSION OF

EQUIPTEC IS PROHIBITED.

DESC.

DRAWN:

PART NO.

GA Base Unit

13/11/2020

1:17

GA A0002

DIMENSIONS ARE IN MILLIMETERS

UNLESS OTHERWISE SPECIFIED

+64 6 842 0222

www.equiptec.co

SCALE:

SIZE

REV

EQUIPTEC

(C) Copyright

1 OF 1

SHEET

GENERAL NOTES

TOLERANCES

GENERAL

0

0.5

0.0

0.1

0.00

0.01

CUT & FOLDED

FOLD DIM

0.5

FOLD ANGLE

0.5

CUT PROFILE

0.1

PART INFO/NOTES:

BEND RADIUS & ALLOWANCES TO BE CHECKED BY

1.

MANUFACTURER AND PART MODIFIED TO SUIT AS PER FINISHED

DIMENSIONS.

ALL PARTS DEBURRED

2.

VISIBLE SIDE INDICATED BY

A

3.

MATERIAL:

Material <not specified>

B

ACCREDO NO.

USED ON MODELS:

No. Product

Code Description Qty No. Product

Code Description Qty

1 9840101 - 01 G20 Chassis Assembly 1 15 9840143 G20 Floating Tread Guide 10

2 9840117 G20 Front Side Panel RH 1 16 9840163 G20 Top Cover RH 1

3 9840116 G20 Front Side Panel LH 1 17 9840111 - 01 G20 Hydraulic Tank 1

4 9840112 G20 Roller Mast 2 18 9840129 G20 Tube Mount Bracket 2

5 9840120 G20 Front Panel 1 19 9840110 G20 Ram 1

6 9840119 G20 Rear Side Panel RH 1 20 9840122 G20 Front Panel Crush Tube 2

7 9840118 G20 Rear Side Panel LH 1 21 9840142 G20 Landing Rail Cross Member 1

8 9840114 G20 Rear Mast RH 1 22 9840162 G20 Top Cover LH 1

9 9840113 G20 Rear Mast LH 1 23 9840121 G20 Front Panel Corner Support 2

10 9840126 G20 Top Fixed Tread 1 24 9840111 - 01 Hydraulic Pump Handle 1

11 9840141 G20 Landing Rail 1 25 9840155 - 01 G20 Trigger Wire Guide Assembly 2

12 9840127 G20 Mid Horizontal Strut 2 26 9840152 - 01 G20 Trigger Lever Assembly 1

13 9840128 G20 Top Horizontal Strut 2 27 9840109 - 01 G20 Trigger Wire Bracket Assembly 1

14 9840108 G20 Pump Mount Bracket 1 G20

Page 12Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Giraffe G20 Parts Diagrams

Roller Panel Parts Diagram

Maintenance

PROJECTION:

2

1

4

10

7

3

5

9

6

8

Item No.

Part No.

Accredo

Description

Qty.

1

GP0288R

Roller Panel RH

1

2

GP0288L

Roller Panel LH

1

3

GA 0022

9840229

Roller Panel Bottom Strut

2

4

GA WA0004

9840228

GA Roller Panel Upper Strut

1

5

GP0283

Side Support Roller

8

6

GA 0029

9840251

GA Nylon Mast Roller

8

7

GA 0030

9840232

GA Floating Tread Support

10

8

GA WA0019R

GA WA0019 Ratchet Ladder RH

1

9

GA 0062

9840249

GA Roller Bush

8

10

GA WA0019L

GA Ratchet Ladder LH

1

A3

DO NOT SCALE FROM DRAWING

THE INFORMATION

CONTAINED IN THIS

DRAWING IS THE SOLE

PROPERTY OF EQUIPTEC ANY

REPRODUCTION IN PART OR

WHOLE WITHOUT THE

WRITTEN PERMISSION OF

EQUIPTEC IS PROHIBITED.

DESC.

DRAWN:

PART NO.

GA Roller Panel Assembly

13/11/2020

1:12

GA A0004

DIMENSIONS ARE IN MILLIMETERS

UNLESS OTHERWISE SPECIFIED

+64 6 842 0222

www.equiptec.co

SCALE:

SIZE

REV

EQUIPTEC

(C) Copyright

1 OF 1

SHEET

GENERAL NOTES

TOLERANCES

GENERAL

0

0.5

0.0

0.1

0.00

0.01

CUT & FOLDED

FOLD DIM

0.5

FOLD ANGLE

0.5

CUT PROFILE

0.1

PART INFO/NOTES:

BEND RADIUS & ALLOWANCES TO BE CHECKED BY

1.

MANUFACTURER AND PART MODIFIED TO SUIT AS PER FINISHED

DIMENSIONS.

ALL PARTS DEBURRED

2.

VISIBLE SIDE INDICATED BY

A

3.

MATERIAL:

Material <not specified>

A

ACCREDO NO.

USED ON MODELS:

No. Product

Code Description Qty No. Product

Code Description Qty

1 9840132 - 01 G20 Roller Inner Panel Assembly LH 1 6 9840115 AHP Nylon Mast Roller 8

2 9840133 - 01 G20 Roller Inner Panel Assembly RH 1 7 9840144 G20 Floating Tread Support 10

3 9840137 G20 Roller Panel Bottom Strut 2 8 9840149 - 01 G20 Ratchet Ladder LH 1

4 9840136 G20 Roller Panel Upper Strut 1 9 9840175 AHP Roller Bush 8

5 9840140 G20 Side Support Roller Bracket 8 10 9840149 - 02 G20 Ratchet Ladder RH 1

Giraffe Owner’s ManualG20 - SB 1.0Page 13 January 2022

Hydraulic System

Hydraulic Oil

The Oil used in the G20 hydraulic system is standard ISO 46 hydraulic oil. Brand equivalents are shown here.

The recommended interval of change is 2 years. It may require changing sooner in certain circumstances. Factors that

would affect this include being used in a dusty or high humidity environment or high humidity. Cracked seals or Oil

contamination will also necessitate an Oil change. NOTE that when changing the Oil, it is also recommended to replace

the Tank Breather fitting at the same time.

Bleeding the Ram

If the Ram movement becomes inconsistent, “spongey” or does not lift to the full height, it is likely that air has gotton into

the system and needs to be bled out. To bleed the Ram, follow these simple steps…

1. Pump the Ram up as high as it will go. Then pump the handle

slightly

more to ensure the oil is under pressure.

2. Make sure the Platform is supported by engaged triggers, or some other external support system.

3. Move to the Front of the unit and locate the Bleed Valve that is near the top of the Ram, just above the Landing rail

“apron” as illustrated.

4. Have a rag ready to absorb any excess Oil. Place the rag under the Bleed Valve, covering the immediate surrounding

area, but leaving the Valve plug nut accessible.

5. Using a 3/4” (19mm) Wrench, “crack” open the nut very slowly. As you gradually unwind the nut, you should hear air

escaping, or may see frothy Oil coming out. There may also be some “spatters” of Oil/Air but keep unwinding slowly till

you see just Oil coming through.

6. Close the Valve nut immediately and tighten.

7. Check again to see if the Operation of the Ram has improved. If there are still some issues, repeat the procedure untill

all air has been bled from the system, and the Ram is performing normally.

Maintenance

Supplier Product Name Supplier Product Name

Atlantic Hy Lube Hydraulic Fluid ISO 46 Mobil DTE 25

BP Batran 46 Penrite Indus Pro Hydraulic 46

Caltex Rando HD 46 Prolube Hyplex 46

Castrol Hyspin H46 Shell Tellus 52 M 46, Tellus 52 MX 46

Fuchs Renolin B Plus 46 Total Azolla ZS 46

Gulf Western Superdraulic 46 Valvoline Ultramax 46

Hitec Hydraulic 46

Page 14Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Hydraulic System

Descent Speed Adjustment

The Hydraulic system has a valve to control the speed of the descent of the Platform. This will be factory set at an optimal

speed that is both practical and safe. This should not need any alteration, but if for any reason further adjustment is

required, the procedure is as follows…

1. Pump the Ram up to full height.

2. Make sure the Platform is supported by engaged triggers, or some other external support system.

3. Unlock the small Allen Key Set Screw in the side of the Valve Knob.

4. Turn this Valve completely shut (as far as it will go in the clockwise direction).

5. Activate the Trigger Rods by pushing the Lever against the Rear Panel as shown.

6. Release the Main Hold valve to lower the Ram. The Ram should not move if the Speed Control Valve is completely

shut.

7. Slowly open the Speed Control Valve and the deck will start to come down. The further you open the Speed Control

Valve, the faster the deck will lower.

8. When the desired speed is reached, shut of the Main Hold Valve, and lock the Speed Control Valve position using the

small Allen Key Set Screw in the side of the Valve Knob.

Maintenance

Giraffe Owner’s ManualG20 - SB 1.0Page 15 January 2022

Hydraulic System

Hydraulic System Parts Identification

The system is relatively simple. See hydraulic system general assembly below.

Maintenance

8

3

14

3

8

12

1

13

2

4

3356

10

9

7

11 3

ITEM NO.

DESCRIPTION

PART NO.

Default/QTY.

1

PM 25 s PUMP

1

2

1/4"-3/8" ADAPTOR

AC-0406

1

3

DOWTY WASHER 1/4" DO4

2002600

5

4

1/4" FLOW CONTROL VALVE WITH CHECK

VRFU9001

1

5

1/4"-1/4" ADAPTOR

BB-0404

1

6

HOSE

HH-ETECH

1

7

1/2" VELOCITY FUSE

9009480

1

8

1/4" BUNG

B-04

2

9

DOWTY WASHER 1/2" DO8

2002602

1

10

1/4"-1/2" ADAPTOR

BB-0408

1

11

1/4" BREATHER

2002646

1

12

Handle

1

13

5L Tank 5L Tank

1

14

G20 Ram

GA 0054

1

Page 16Giraffe Owner’s Manual G20 - SB 1.0 January 2022

Many optional extras are available for the G20. They can all be retrofitted relatively simply, but Equiptec recommends

these tasks are undertaken by an Engineering based or otherwise qualified Tradesperson. The instructions for installing

each type are all downloadable from the Equiptec website, and Equiptec remains available to assist via Video Conference

if required. If in doubt, do not hesitate to contact Equiptec for advice.

Installation/Operation instructions for optional equipment is supplied with the said equipment.

Options available include...

One Step Extension

Taller Single Step height caster brackets paired with the

additional Single Step module on the base stair gives

the standard G20 a single step (8.85” / 225mm) addition to

all platform heights.

Two Step Extension

Similar to the One Step Extension, taller Double Step height

caster brackets paired with additional Double Step module

on the base stair gives the standard G20 a double step

(17.7” / 450mm) addition to all platform heights.

Four Step Sub Chassis

This is a full sub chassis giving the standard G20 a four-step

(35.4” / 900m) addition to all platform heights.

Eight Step Sub Chassis

This is a full sub chassis, including a landing (to meet the AS/NZS

standards requirements) give the standard G20 an eight-step

(70.86” / 1800mm) addition to all platform heights.

Optional Accessories

Giraffe Owner’s ManualG20 - SB 1.0Page 17 January 2022

Other manuals for G20 Mobile

4

Table of contents

Other Equiptec Lifting System manuals

Popular Lifting System manuals by other brands

EAE

EAE EE-6215E Installation, operation, parts and service manual

WMH Tool Group

WMH Tool Group JET TSLT-770 Operating instructions and parts manual

BorMann

BorMann BWR5218 user manual

Atlas

Atlas BP12000 Installation & operation manual

Garage Smart

Garage Smart Universal XL HD Lifter user guide

Wayne-Dalton

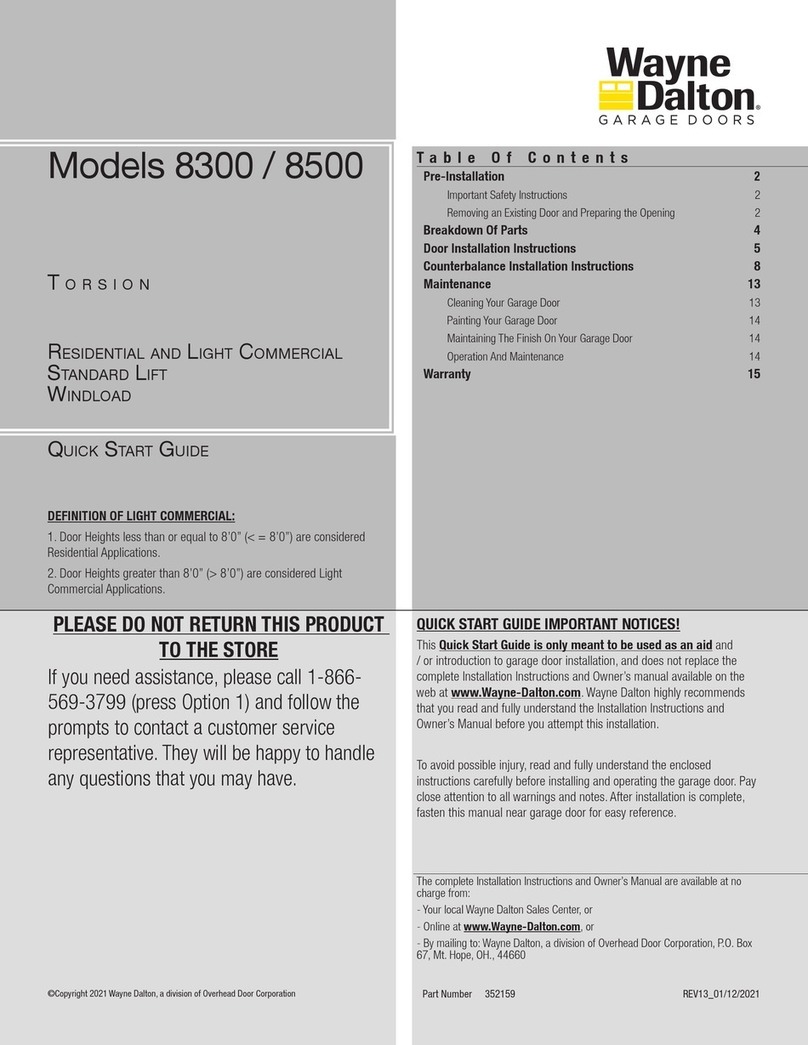

Wayne-Dalton 8300 quick start guide