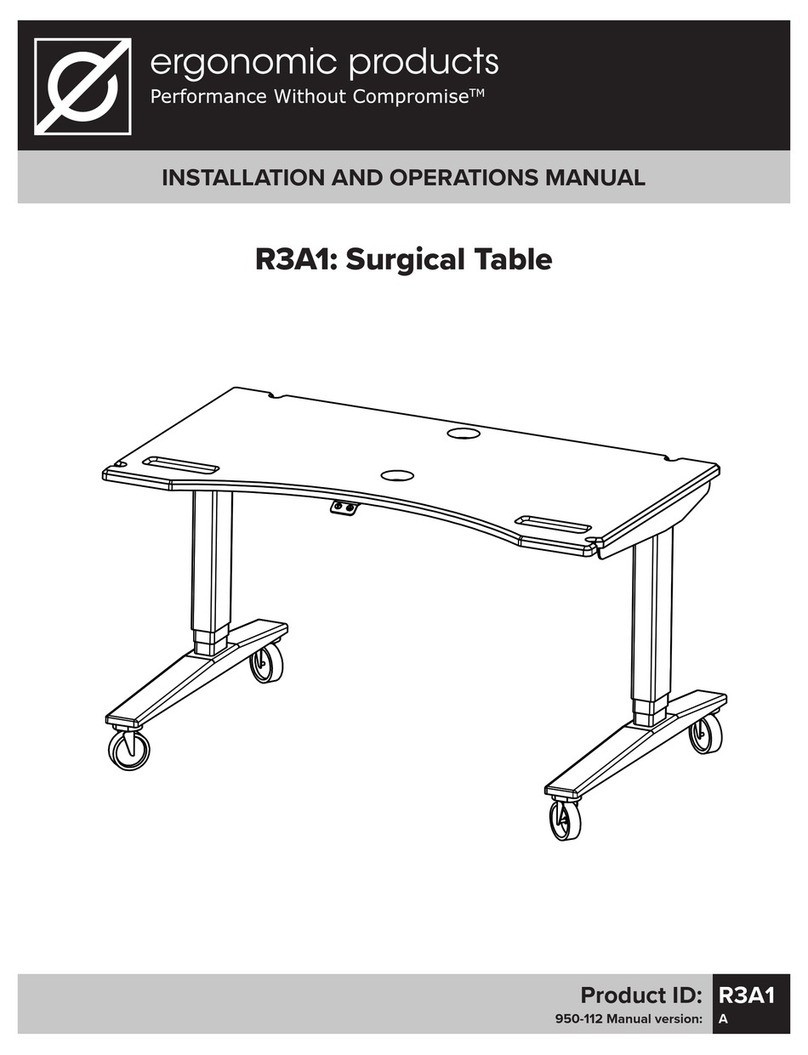

Ergonomic products D1C Series User manual

Installation and Operations Manual

Product ID: D1C1

Manual version: E

D1C series: SRS Compact Cart

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 2

Thank you for purchasing the Ergonomic Products D1C1 SRS Compact Cart.

Years of research by dentists, engineers and designers have made this a uniquely eective

product in the industry. We stand behind our equipment, and genuinely believe it to be the

best available on the market.

Should you have any questions regarding the product’s installation or use, please don’t

hesitate to call our customer service specialists at 1-866-ERGO-4-US. We may also be

reached via email at equip@ergonomic-products.com.

We hope you enjoy the benets and quality of your new equipment and look forward to

handling your future needs as you and your practice continue to grow!

- The Ergonomic Products Team

QUESTIONS?

Call our Customer Service Specialists at:

1-866-ERGO-4-US.

CONTENTS:

1. Introduction ....................................................................... 3

2. Basic Anatomy of the Workstation .................................... 5

3. Specications.................................................................... 6

4. Power Channel Face Plate................................................ 7

5. Underside of Channel...............................................................9

6. Foot Pedal.................................................................................. 10

7. Options for Workstation ......................................................... 11

8. Using Your Workstation............................................................12

9. Required Tools / Unpacking and Installation........................ 24

10. Standard Parts List ................................................................ 25

11. Workstation Assembly............................................................ 26

12. Umbilical Connections........................................................... 28

13. Worksurface Height Adjustment........................................... 32

14. Maintenance............................................................................. 33

15. Trobleshooting......................................................................... 34

16. Warrenty Information ............................................................. 35

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 3

1 - INTRODUCTION

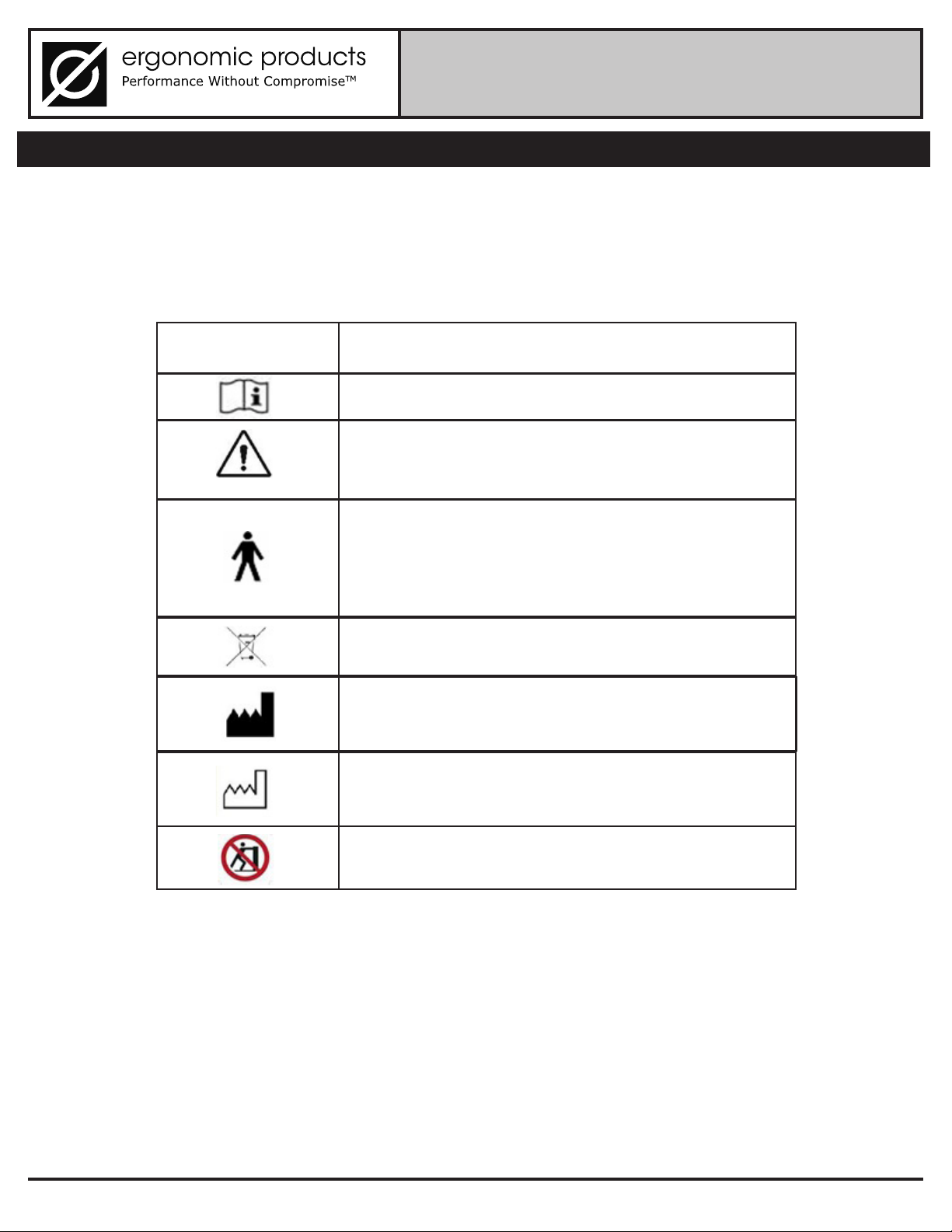

SYMBOLS USED IN THIS MANUAL AND ON PRODUCT LABELS

e following symbols are used in this manual and on product labels.

Symbol Meaning

This symbol means that you must refer to the

documentation that came with your device.

This symbol indicates a Warning. Warnings alert the user

to the possibility of serious injury or death if the equip-

ment is not operated properly.

This symbol indicates that the device is a Type B piece of

equipment and has a certain degree of protection against

electric shock. The B Type refers to applied parts that

are generally not conductive and can be immediately

released from the patient.

This symbol indicates that you must not dispose of any

electronic components along with general waste.

This symbol appears next to the next to the

manufacturer’s contact information.

This symbol appears next to the date of manufacture.

This Symbol Indicates Pushing Prohibited

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 4

INTENDED USE

The Ergonomic Products Workstation is a dental operative unit, which is an AC-powered device that is

intended to supply power to and serve as a base for other dental devices and accessories. The device is to

be operated and used by dentists and other legally qualied professionals.

CONTRAINDICATIONS

There are no known contraindications for the use of this device.

WARNINGS AND PRECAUTIONS

Warnings alert the user to the possibility of serious injury or death if the equipment is not operated properly.

Only properly trained and authorized personnel must use this equipment.

Do not modify this equipment without authorization from Ergonomic Products, Inc.

Read and understand all warnings, precautions, and operating instructions before use.

To avoid risk of electric shock, connect this equipment only to an electrical supply with a protective earth

ground. Do not bypass the grounding circuitry.

The device might cause interference with other electronic devices while in use. Ensure that other medical

devices used in the treatment oce do not receive interference from this device.

A dental unit might include magnets which might aect the function or programming of some implantable

pacemakers or debrillators. People who have devices programmed to respond to a magnet must avoid

dental units with magnets.

Improper installation of the syringe can result in injury or damage. Refer to the syringe manufacturer’s

documentation for instructions on proper installation and use.

Do not position equipment so it is dicult to operate the disconnect device.

Do not use a socket multiplier or an extension cord to connect the Workstation to the electrical supply.

To avoid the risk of electric shock, do not connect equipment that must be connected a multi-socket outlet

with a separating transformer directly to an electrical wall outlet.

Connect only those items that are part of the Workstation or have been approved by Ergonomic Products,

Inc. to be compatible with the Workstation.

It is mandatory that metal reusable syringe tips are sterilized between each patient to prevent cross

contamination. Please follow the manufacturer’s recommended practices for sterilization.

1 - INTRODUCTION CONT’D

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 5

Note: Many of our buyers are right-handed and are purchasing in an eort to accommodate

left-handed associates. Our diagrams are all right-hand biased as this is the most common

conguration. For the sake of continuity, we show all rooms with equal handedness unless

noted.

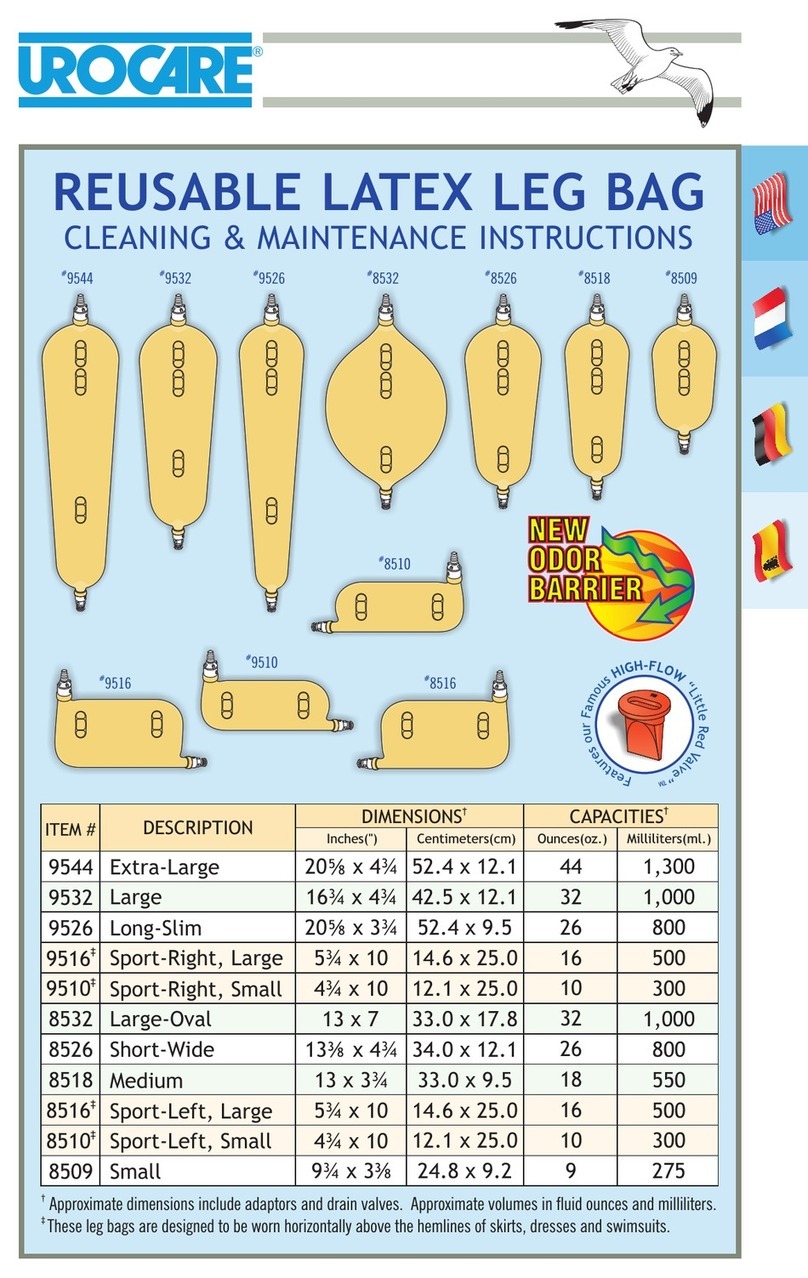

Consumable Bin Med Waste Bin

Vacuum Canister

2L Water Bottle

Corian Worktop

Workstation

Channel

2 - BASIC ANATOMY OF THE WORKSTATION

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 6

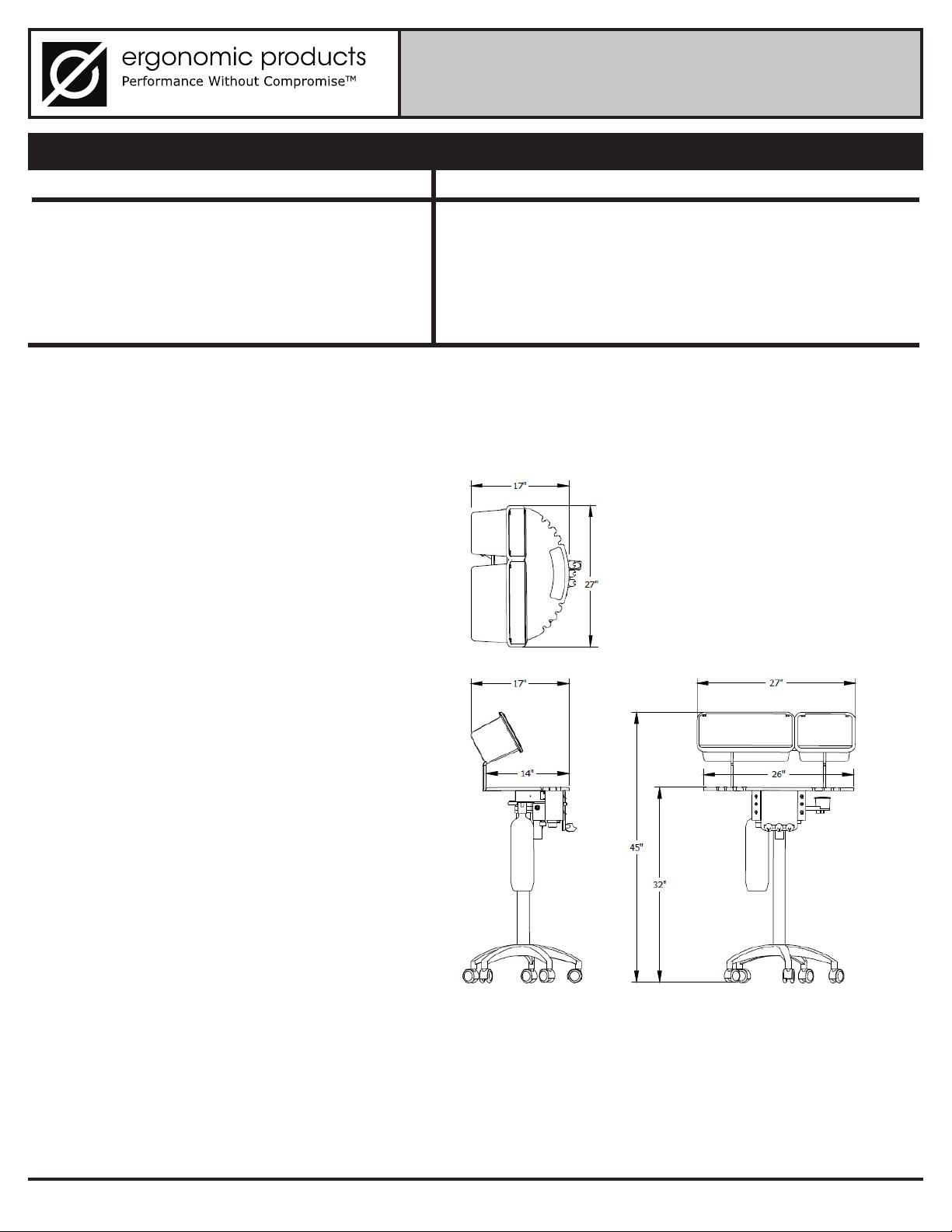

STANDARD FEATURES OPTIONAL FEATURES

- 1 High Speed Air

- 1 A/W Syringe

- 1 Saliva Ejector

- 1 EP Consumable Bin

- 1 Low Speed Air

- 1 HVE

- 1 EP Med Waste Bin

- 2 Liter Water Bottle

- Standard Foot Pedal

- Fiber Optic upgrade includes Light Kit,

and (1 or 2) 5 or 6 pin hose.

- 2nd High Volume Suction

- Cure Light

- Scaler

Electrical Specications*

Electric 120VAC, 60HZ, 8A

Fuse Value Label at Point of Use

Conforms to

US/ANSI/AAMI ES60601-1 2005+C1+A2

CA/CNCSA-C22.2 No. 60601-1

Air, Water, Electric Auxiliary

Air, 1/4 Dental Style Female QD, 80 psi

Water, 1/4 Dental Style Female QD, 30-35 psi

Storage and Transportation Conditions

-30° C to +50 C

10% to 90% Relative Humidity

Standard Atmospheric Pressure

Use Conditions

Typical Dental Oce Environment

Standard Atmospheric Pressure

Materials

Corian Solid Surface, Aluminum, Stainless

Steel, and Powder-Coated Steel

DIMENSION SPECIFICATIONS

3 - SPECIFICATIONS

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 7

1 - Turn master switch on.

2 - Turn bottle pressure o.

3 - Fill water bottle with pottable water

leave 1 inch of air space in the neck.

4 - Turn bottle pressure switch on.

Workstation is now ready to use.

Hand Piece usage

1 - Remove desired hand piece from automatic holder valve.

2 - Turn Wet/Dry switch to postion needed

3 - Push on rheohast (oor pedal) to attain desired RPM

4 - If wet is selected adjust coolant ow knob for proper

water coolant ow

Scaler operation (if applicable)

Scaler is controled by the small button on rheostat (oor pedal)

unit will not operate unless master switch is on

please see manufacturer literature for operation

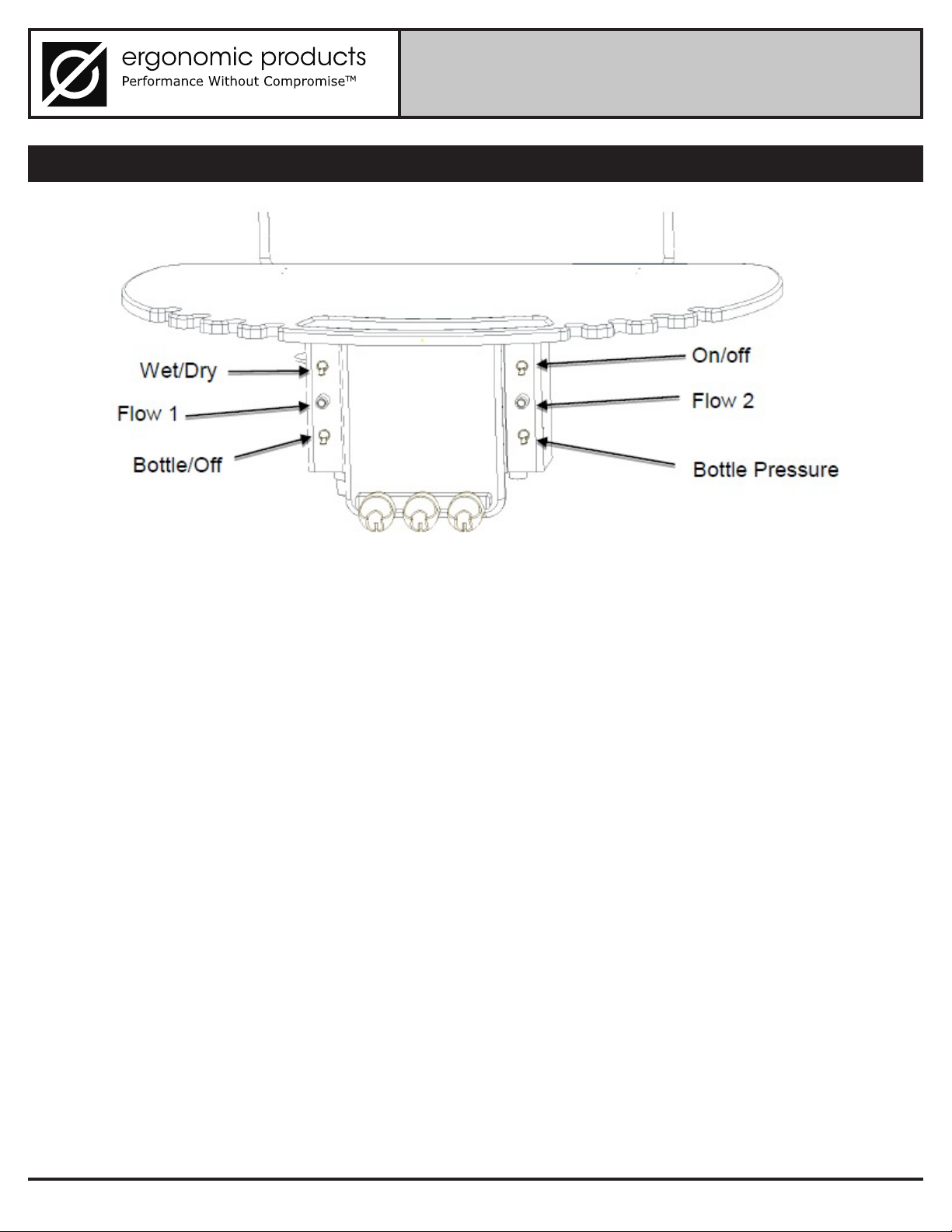

4 - POWER CHANNEL FACE PLATE

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 8

4 - POWER CHANNEL FACE PLATE CONT’D

Function Description

Turning this switch on allows chip air coolant (or water

coolant atomizing air) to spray when the foot pedal is

depressed. When switch is turned o no air is emitted at

head of handpiece.

Pressurizes bottle and routes bottle water to devices.

When turned to o position, relieves bottle pressure and

turns on optional city water, if connected to source.

This adjusts the amount of coolant water that ows through the

left handpiece. Turn the knob counterclockwise to increase the

ow and clockwise to decrease the ow.

This switch turns on and o the air pressure and water

pressure to the workstation.

CAUTION: Turn the master switch O when unit is not in

use to prevent accidental water ow.

This turns on or o the ow of coolant water to the

handpieces. This control must be On to allow water to

ow to either of the Handpiece Coolant Flow controls.

The Chip Air switch should always be on when this

switch is set to the Wet position.

Chip Air

Bottle/O

Flow 1

Master

On/O

Wet/Dry

This adjusts the amount of coolant water that ows

through the right handpiece. Turn the knob counter-

clockwise to increase the ow and clockwise to de-

crease the ow.

Flow 2

Clears lines and hose tubing.Purge

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 9

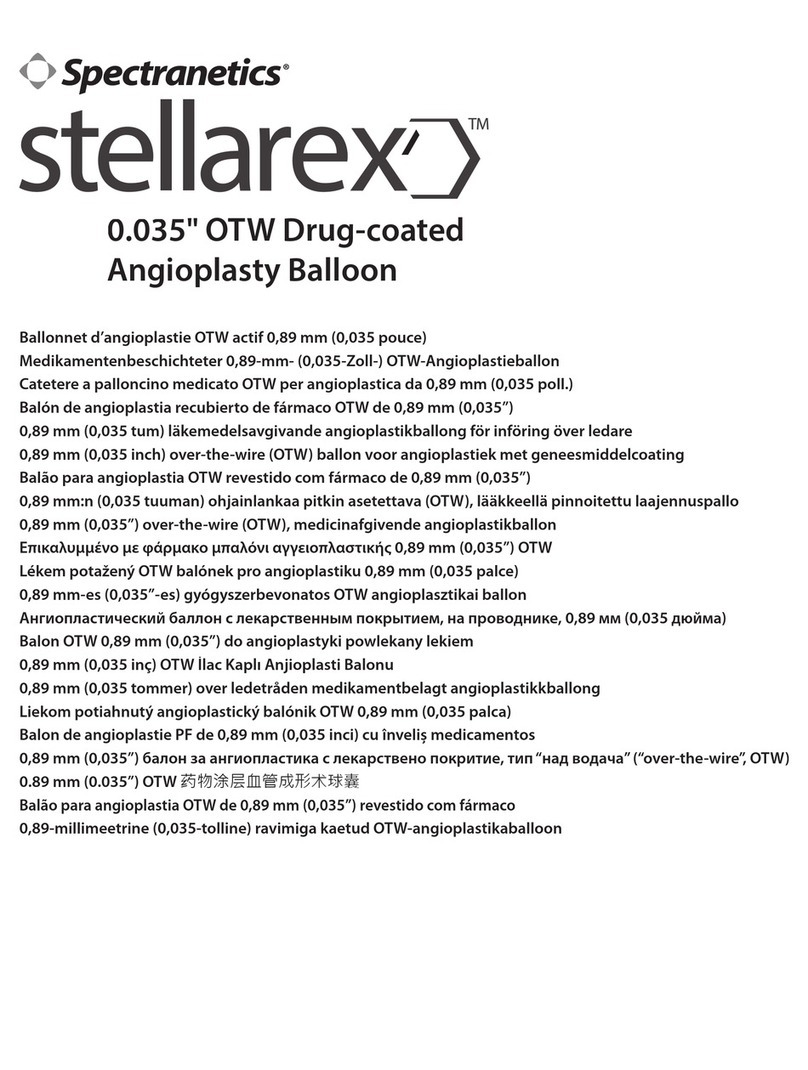

5 - UNDERSIDE OF CHANNEL

e below image shows the underside of the channel and its avaibale functions. (Please note options on your

channel may dier from that shown in the image below.)

Handpiece

Hanger Valves

Handpiece

Connectors

Handpiece Drive

Air Adjusment

Screws

Cure Light

Connection.

(Optional)

Muer/Oil

Collector

Water Bottle

Base/Connector

Umbilical Outlets

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 10

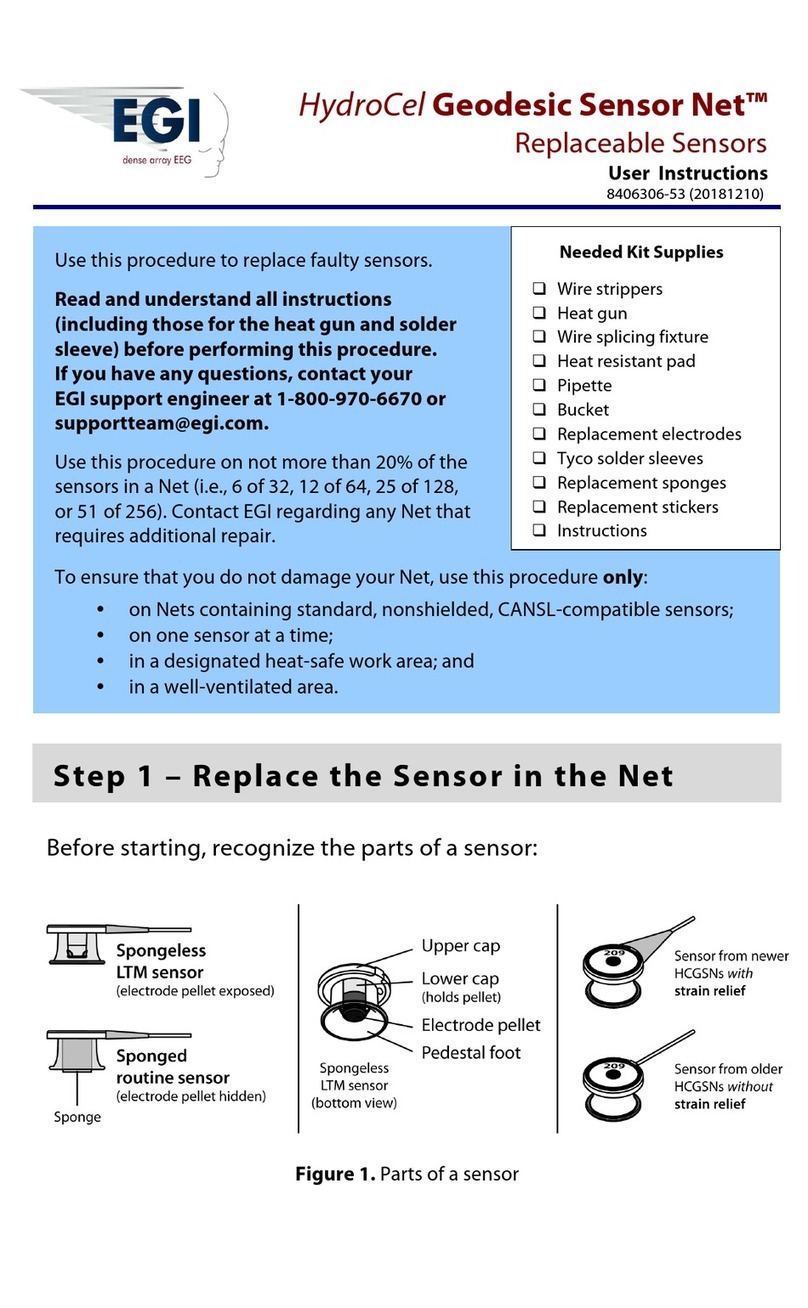

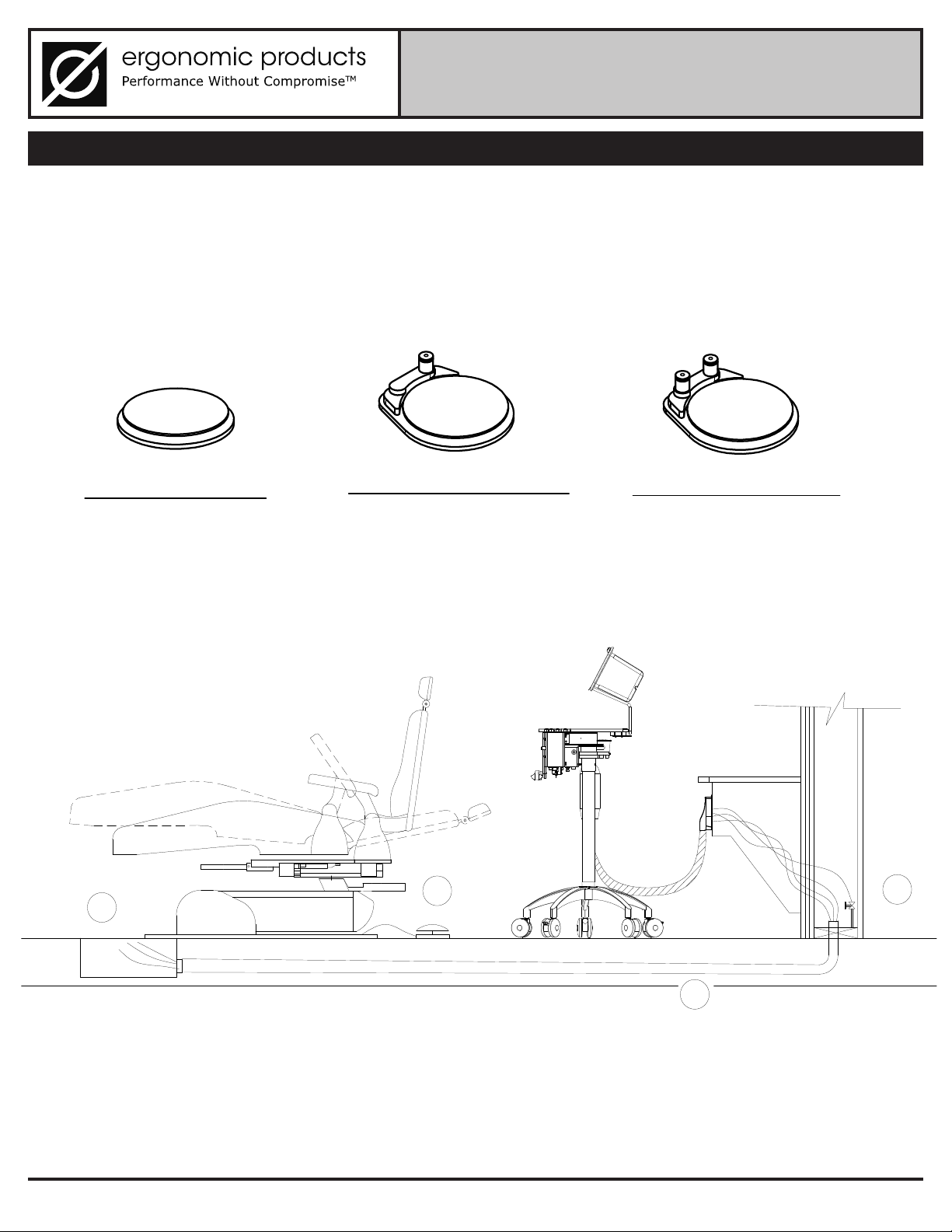

6 - FOOT PEDAL

1

2

3

4

Foot pedal tubing (1) is connected to the (2) oor box. Tubing is fed under the oor through

conduit (3) abd then is connected to the Air Regulator (4).

Standard Foot Pedal

Drive Air

Single Button Foot Pedal

Auto/Manual Scaler

Internal Scaler (D840)

Dual Button Foot Pedal

Turbo Sensor

Turbo Piezo

Refer to Fig 6.1 to review your foot pedal type.

Refer to Fig 6.2 for a detailed view of the rheostat running

through the oor to the toe of the chair.

Fig 6.1

Fig 6.2

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 11

Curing Light

If Curing Light provided, refer to manufacturer’s documentation for proper operation of the curing

light for the workstation.

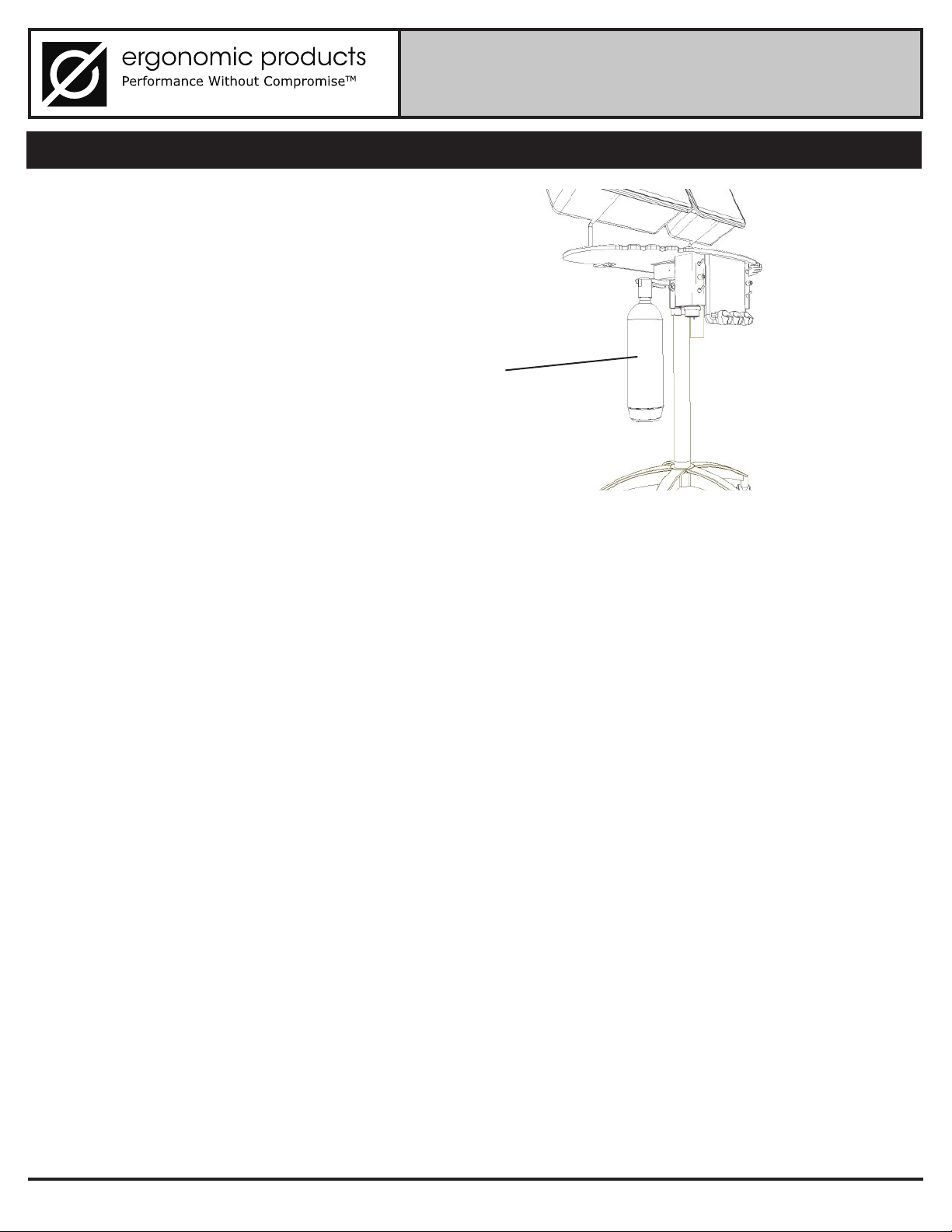

Umbilical quick disconnect

The umbilical quick disconnect is typically installed in the cabinet behind the workstation. It allows

for easy removal of mechanicals for repairs or upgrades, or for wheeling the entire workstation out

of the room for building maintenance such as oor work.

Handpiece Compatibility

The delivery system of the Ergonomics Products Workstation has been designed to be compatible

with air driven handpieces that conform to ISO 13294.

Tubing for air driven handpieces is available in 4-5 hole ISO B tubing or 6-hole ISO C tubing. The

end user has responsibility to acquire appropriate handpieces for use with the Workstation. Your

country might have certain regulations in regards to what handpieces are acceptable to use. Refer

to your local dealer for more information.

For instructions and details about accessories provided from other manufacturers, refer to their

product documentation.

7 - OPTIONS FOR YOUR WORKSTATION

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 12

8 - USING YOUR WORKSTATION

Water Bottle

Waterline Disinfection Recommendations

The bottle mounted under the rear of the power channel is a .75L (750ml) or 2L (2000ml) bottle water

bottle.

Its use is selected via the “Bottle” position on the Bottle/O switch mounted on the power channel face. The

“O” position on the Bottle/O switch relieves bottle pressure for bottle service and selects water from your

piped water supply (if this option is purchased).

The correct water to use in the Ergonomic Products Workstation equipped with self-contained water

depends on the quality of your municipal water.

Tap Water – If you have condence in the quality of your municipal water supply, consider using tap water

in your self contained water bottle.

Softened Water – Water hardness that is greater than 200mg/L, Ergonomic Products recommends use of

a water softener to prevent build up of mineral deposits that may impact Workstation performance. Water

pH should be compliant with local drinking water regulations.

Ergonomic Products does not recommend the use of distilled or reverse osmosis water in self-contained

dental units.

It is important to regularly monitor the water in your dental equipment. The frequency depends on your test

results and water quality goals. Although the ADA has established a target of less than 200 colony forming

units per milliliter (cfu/ml) of heterotrophic, mesophilic organisms, acceptable water quality, according to

The Center’s For Disease Control (CDC), suggest less than 500CFU/mL. https://www.cdc.gov/oralhealth/

infectioncontrol/faqs/dental-unit-water-quality.html

Shocking you dental unit waterlines is required for every water treatment protocol followed up with a daily

or continuous maintenance.

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 13

8 - USING YOUR WORKSTATION CONT’D

When you should shock:

• Before using your EP Workstation for the rst time, shock your dental unit waterlines.

• At least every quarter (There are yearly continuous products, please refer to manufacturer)

• When your waterline test results reveal contamination of 500CFU/mL

• Any time you change up your daily waterline maintenance protocol

Daily Maintenance:

• Fill water bottles with use of daily and a water treatment (For example; BluTab; EPA registration

#84020-1).

• Flush waterlines at the beginning of the day for 30 seconds

• Flush waterlines for 30 seconds between patients

• Empty water bottles nightly

It is important to test the water in your self-contained dental unit once per month. If monthly results meet

water quality requirements for all treatment rooms for three consecutive months, reduce testing to once

every three months. Check with your dental supplier or local municipality for testing kits.

Treatment During periods of inactivity

Shut Down:

1. Remove and empty water bottle

2. Purge water from all waterlines including handpieces, ultrasonic scalers, and A/W Syringe.

3. Place empty water bottle back on unit.

Start up:

1. Shock dental unit

2. Test waterlines

3. Resume daily maintenance and ll water bottle.

Caution: Ergonomic Products self-contained water systems are not designed to deliver sterile

solution. A separate means for administering sterile coolant and irrigant is required if you use the

Ergonomic Products Workstations for surgical procedures.

Caution: Do not use saline solutions, mouth rinses or any chemical solutions not specied in this

guide in your Ergonomic Products Self- Contained water system. These may damage the system

components and cause equipment failure.

Check water lines periodically for deterioration and replace if necessary prior to patient use. If wa-

ter line tubing needs to be replaced, please contact Ergonomic Products.

Ergonomic Products does not assume responsibility for you waterline treatment decisions. Always

choose a waterlines maintenance protocol that ts your practice needs and in your practice budget.

All microbials used for dental waterline maintenance must be registered with the EPA. NOTE: De-

pending on the cleaning/shock product used, you may need up to 3 days to complete the cleaning/

shocking protocol. Always follow manufacturer instructions for cleaning/shocking procedures

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 14

8 - USING YOUR WORKSTATION CONT’D

VACUUM USE AND MAINTENANCE

CAUTION: Always wear gloves when servicing dental workstations.

System description

Your workstation is equipped with a 5/8” main vacuum tube connecting to a 3-port vacuum canister (2

HVE and 1 Saliva Ejector) mounted in the forward part of the power channel, with the lid protruding

through the cover for easy access. Units come standard with one saliva ejector valve and one HVE

valve. Both valves are a quick-disconnect and autoclaveble type. Tips for both valves are industry

standard and you can order these from your dental equipment supplier.

System maintenance Vacuum Canister

Check the vacuum canister and screen (part #409-155) weekly. Replace them as soon as lower than

normal vacuum is detected. To facilitate cap removal, turn o the vacuum pump before servicing. Call

Ergonomic Products, Inc. at 1-800-ERGO-4-US to order new components.

Valves

Valves can be autoclaved after each use or wiped down using any of the commercially available disin-

fecting wipes. Daily, draw clean water through the valves while working the valve handle to help pre-

vent the buildup of debris. Brush the internal bore once a week with a sti brush of proper size. Disas-

semble valves periodically (2-3 months) to clean internal parts and lubricate the O-rings.

Muer and Oil Collector Maintenance

A combination muer and oil collector quiets the spent drive and traps excess handpiece lubrication.

Unscrew the lower portion of the canister to access the piece of gauze that acts as an absorbing pad.

Check the gauze every couple of weeks and replace it as necessary.

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 15

CLEANING AND DISINFECTING DENTAL UNITS AND ENVIRONMENTAL SURFACES

GENERAL GUIDELINES

After treatment of each patient and at the completion of daily work activities, countertops and dental unit

surfaces that might have been contaminated with patient material or when the surface is contaminated

with biological material must be cleaned with disposable toweling (for example PDI Super Sani Cloth)

and water as necessary. Then disinfect surfaces with a suitable chemical germicide (for example DisCide

Ultra Disinfectant Spray).

The CDC recommends using a chemical germicide registered with the EPA as a “hospital disinfectant”

and labeled for “tuberculocidal” (i.e., mycobactericidal) activity to disinfect surfaces that have been soiled

with patient material. These intermediate-level disinfectants include phenolics, iodophors, and chlo-

rine-containing compounds. Because mycobacteria are among the most resistant groups of microorgan-

isms, germicides eective against mycobacteria should be eective against many other bacterial and viral

pathogens.

Low-level disinfectants—EPA-registered “hospital disinfectants” that are not labeled for “tuberculocidal”

activity (e.g., quaternary ammonium compounds)—are appropriate for general housekeeping purposes

such as cleaning oors, walls, and other housekeeping surfaces. The CDC does not recommend using

intermediate- and low-level disinfectants to reprocess critical or semi critical dental instruments.

CDC Guideline for Disinfection and Sterilization in Healthcare Facilities, 2008; Centers for Disease Con-

trol and Prevention. Guidelines for Infection Control in Dental Health-Care Settings— 2003. MMWR

2003;52(No. RR-17):[inclusive page numbers]. FDA Processing/Reprocessing Medical Devices in Health

Care Settings: Validation Methods and Labeling DRAFT GUIDANCE May 2, 2011.

8 - USING YOUR WORKSTATION CONT’D

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 16

CLEANING

Metal Components

Use mild detergent and water or any of the commercially available sprays, such as 409, Fantastic, or oth-

ers, with a soft cloth or sponge. DO NOT USE ABRASIVES as these will permanently scratch the nish.

Plastic, Rubber and Painted Surfaces

Use mild detergent and water or any of the commercially available sprays, such as 409, Fantastic, or oth-

ers, with a soft cloth or sponge. DO NOT USE ABRASIVES as these will permanently scratch the nish.

Corian

Your Corian surfaces are delivered with a matte/satin nish and any of the above cleaners are accept-

able. Minor surface blemishes can be brought back to a like-new nish with the use of a mild abrasive

cleaner such as Comet on their own or in conjunction with a green or white Scotch-Brite Pad.

Dried composites can be scraped o using a single-edged razor blade or equivalent, being cautious not

to dig into the surface.

If the surface becomes too scarred to be renewed with the above procedures, a resurfacing can be done.

Please contact us or any Corian-certied installer for the correct procedure.

The FDA recommends that Items contaminated with blood or body uids, which might contain blood

borne pathogens, must receive intermediate level disinfection with a product having an EPA-registered

claim for activity against hepatitis B after cleaning.

8 - USING YOUR WORKSTATION CONT’D

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 17

8 - USING YOUR WORKSTATION CONT’D

DISINFECTING

Instruments and Workstation

Infection Control in the dental environment is always a high priority for both the user and the patient. It is

the responsibility of the practitioner to be familiar with best practices and protocols for disinfecting of instru-

ments and surfaces as recommended by CDC, ADA and OSHA.

In addition to the General Guidelines, the CDC recommends general cleaning and disinfecting of clinical

contact surfaces, dental unit surfaces, and countertops at the end of daily work activities. Cleaning and

disinfection are required if surfaces have become contaminated since their last cleaning. To facilitate daily

cleaning, keep treatment areas free of unnecessary equipment and supplies.

To disinfect Corian surfaces, use a suitable chemical germicide (for example DisCide Ultra Disinfectant

Spray). Dental devices that are connected to the dental water system and that enter the patient’s mouth

(for example; handpieces, ultrasonic scalers, or air/water syringes) must be operated to discharge water

and air for a minimum of 20–30 seconds after each patient.

Most of the surfaces are compatible with commonly used disinfectants, however if discoloration is no-

ticed (especially hoses) it would be advisable to change cleaning products. If using a spray, use sparingly

around electrical devices and components.

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 18

8 - USING YOUR WORKSTATION CONT’D

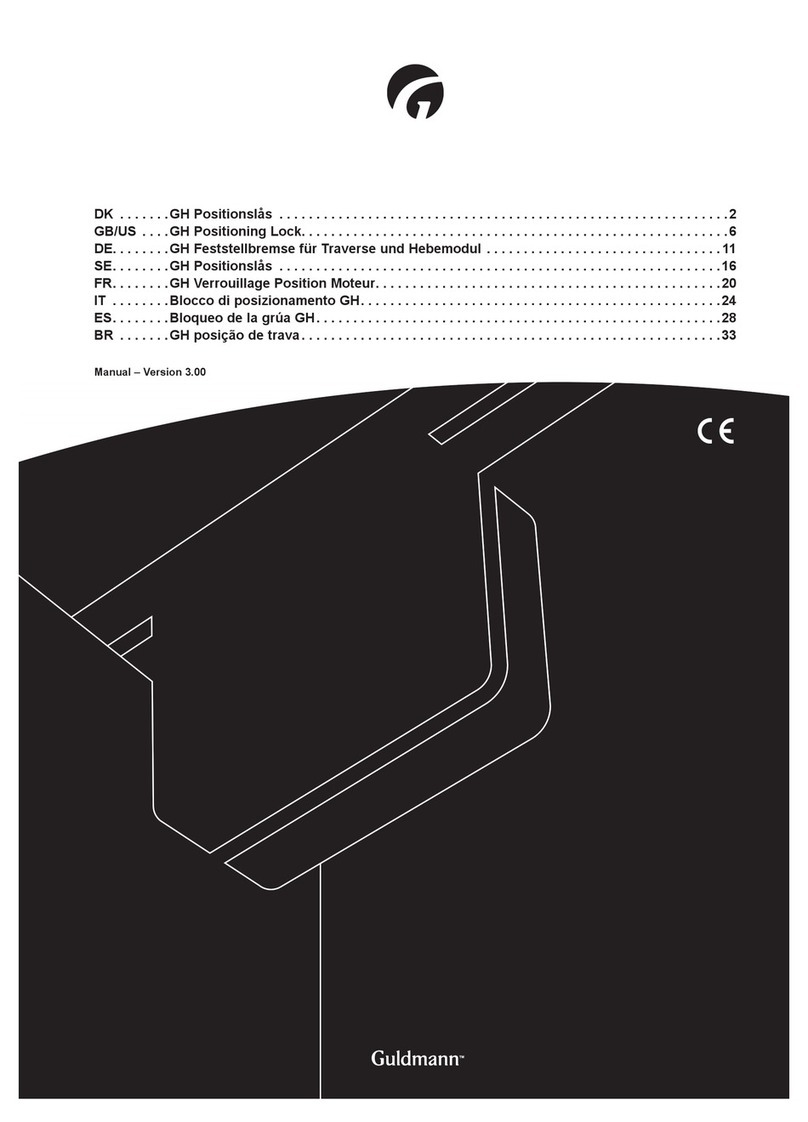

BASIC PLACEMENT FOR CLINICAL DENTISTRY

Your Workstation is designed to be more exible then other delivery systems. The Workstation’s

placement is also critical.

Ideal placement of the Ergonomic Products Delivery

System creates both an assistant’s “Control Panel”

and allows full access to supplies by the doctor.

In this position, hoses are able to comfortably reach

the patient without dangling to the oor while not in

use.

This is the most productive position for the Ergonomic

Products Workstation.

Correct Positioning

If individuals unfamiliar with the possibility of

ngertip supplies push the delivery system

back to a more familiar position, it may be less

productive.

This placement prevents ngertip access,

inhibits proper hose function, and markedly

slows treatment progress.

If handpiece hoses appear to be shorter than

needed for treatment, you will probably nd

that the Workstation is not ideally placed.

In-Correct Positioning

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 19

8 - USING YOUR WORKSTATION CONT’D

WORKING WITH AN ASSISTANT

The Ergonomic Products doctor Workstations can be successfully used in both two- and

four-handed mode. In addition, delivery is possible with both seated and standing dental

assistants. Its exibility permits side-saddle, leg overlap, and European 3 and 9 o’clock

seating as desired.

Oces in the U.S. that have been practicing with a side-saddle operating position do so

simply because supplies have always been out of reach for the seated assistant. This is

now changed with your new system that reduces wasted motions.

950-032 D1C1 manual ver. Eergonomic products • 198 Airport Rd • Fall River, MA 02720 • 866-374-6487

SRS Compact Cart

Model: D1C1

PAGE 20

4-Handed Layout

Workstation perpendicular to the long axis of the pa-

tient chair.

Assistant positioned with the ability to obtain all sup-

plies without torso rotation.

WORKING 2 AND 4-HANDED

The Workstation may be moved and positioned for a doctor or assistant working alone. Oces may

choose to equip all rooms equally and, therefore, rooms used for hygiene maintain two-handed posi-

tioning as their basic conguration.

Traditional delivery systems may force solo operators to stand up and stretch for supplies. Two-hand

can be accomplished by simply turning the Workstation to face the operator, while rotating the power

channel back toward the patient’s head.

2-Handed Layout

Reposition light curing unit closer to operator.

Rotate the work surface.

Swivel power channel into position.

8 - USING YOUR WORKSTATION CONT’D

Table of contents

Other Ergonomic products Medical Equipment manuals

Ergonomic products

Ergonomic products Safe-T-Shield User manual

Ergonomic products

Ergonomic products R3A1 User manual

Ergonomic products

Ergonomic products C1A1 User manual

Ergonomic products

Ergonomic products Safe-T-Shield VacTrac User manual

Ergonomic products

Ergonomic products 32 INWALL COMFORT MEDIA User manual

Ergonomic products

Ergonomic products R3A1 User manual