ERGONOMIC EHL User manual

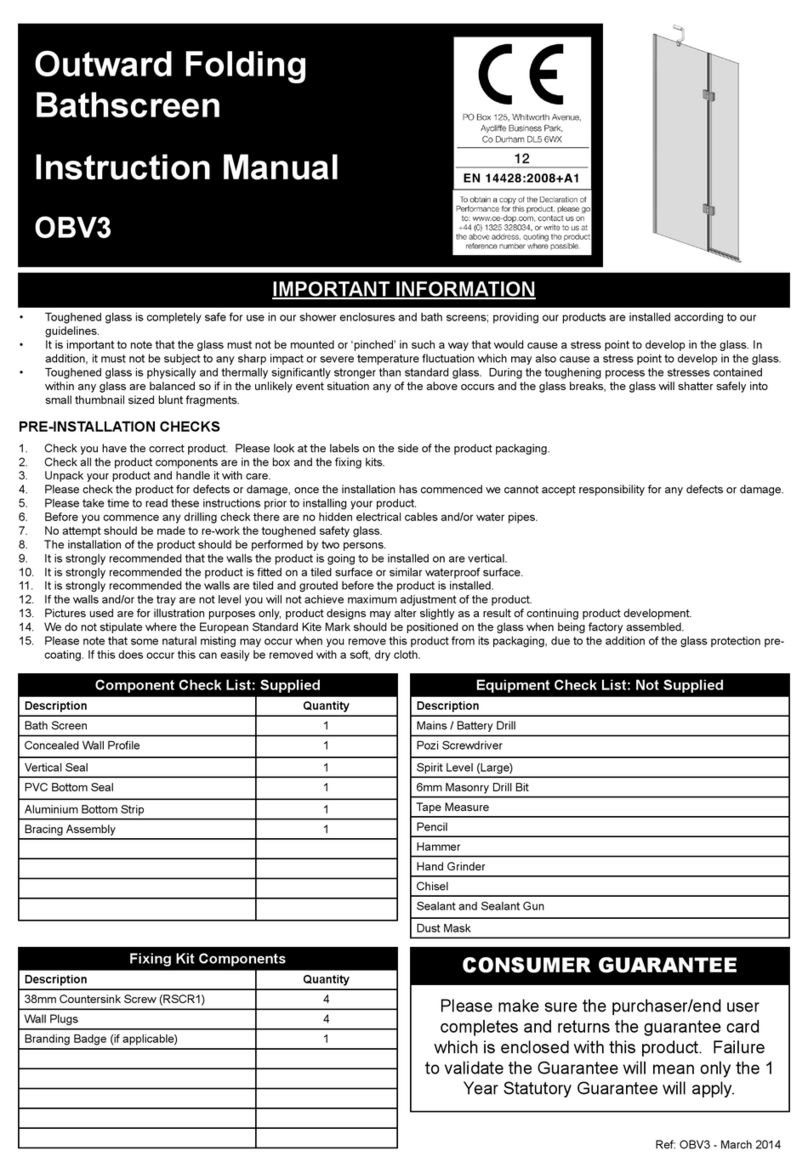

In-Line Panel

Instruction Manual

EHL

IMPORTANT INFORMATION

• Toughenedglassiscompletelysafeforuseinourshowerenclosuresandbathscreens;providingourproductsareinstalledaccordingtoour

guidelines.

• Itisimportanttonotethattheglassmustnotbemountedor‘pinched’insuchawaythatwouldcauseastresspointtodevelopintheglass.In

addition,itmustnotbesubjecttoanysharpimpactorseveretemperatureuctuationwhichmayalsocauseastresspointtodevelopintheglass.

• Toughenedglassisphysicallyandthermallysignicantlystrongerthanstandardglass.Duringthetougheningprocessthestressescontained

withinanyglassarebalancedsoifintheunlikelyeventsituationanyoftheaboveoccursandtheglassbreaks,theglasswillshattersafelyinto

smallthumbnailsizedbluntfragments.

Component Check List: Supplied

Description Quantity

EndCap 1

InlinePanel 1

LowLevelBracingAssembly 1

ScrewCoverTrim 1

Fixing Kit Components

Description Quantity

No4x1/4”PanHeadScrews 3

2.5mmDrillBit 1

BrandingBadge(ifapplicable) 1

5mmAllenKey 1

Equipment Check List: Not Supplied

Description

Electric/Batterydrill

6mmMasonryDrill

SpiritLevel

Screwdriver

PipeCutters

Hacksaw

Pliers

SealantGun

BathroomSealant

TapeMeasure

Pencil

Pleasemakesurethepurchaser/enduser

completesandreturnstheguaranteecard

whichisenclosedwiththisproduct.Failure

tovalidatetheGuaranteewillmeanonlythe1

YearStatutoryGuaranteewillapply.

CONSUMER GUARANTEE

PRE-INSTALLATION CHECKS

1. Checkyouhavethecorrectproduct.Pleaselookatthelabelsonthesideoftheproductpackaging.

2. Checkalltheproductcomponentsareintheboxandthexingkits.

3. Unpackyourproductandhandleitwithcare.

4. Pleasechecktheproductfordefectsordamage,oncetheinstallationhascommencedwecannotacceptresponsibilityforanydefectsordamage.

5. Pleasetaketimetoreadtheseinstructionspriortoinstallingyourproduct.

6. Beforeyoucommenceanydrillingchecktherearenohiddenelectricalcablesand/orwaterpipes.

7. Noattemptshouldbemadetore-workthetoughenedsafetyglass.

8. Theinstallationoftheproductshouldbeperformedbytwopersons.

9. Itisstronglyrecommendedthatthewallstheproductisgoingtobeinstalledonarevertical.

10. Itisstronglyrecommendedtheproductisttedonatiledsurfaceorsimilarwaterproofsurface.

11. Itisstronglyrecommendedthewallsaretiledandgroutedbeforetheproductisinstalled.

12. Ifthewallsand/orthetrayarenotlevelyouwillnotachievemaximumadjustmentoftheproduct.

13. Picturesusedareforillustrationpurposesonly,productdesignsmayalterslightlyasaresultofcontinuingproductdevelopment.

14. WedonotstipulatewheretheEuropeanStandardKiteMarkshouldbepositionedontheglasswhenbeingfactoryassembled.

15. Pleasenotethatsomenaturalmistingmayoccurwhenyouremovethisproductfromitspackaging,duetotheadditionoftheglassprotectionpre-

coating.Ifthisdoesoccurthiscaneasilyberemovedwithasoft,drycloth.

Ref:EHL-July2012

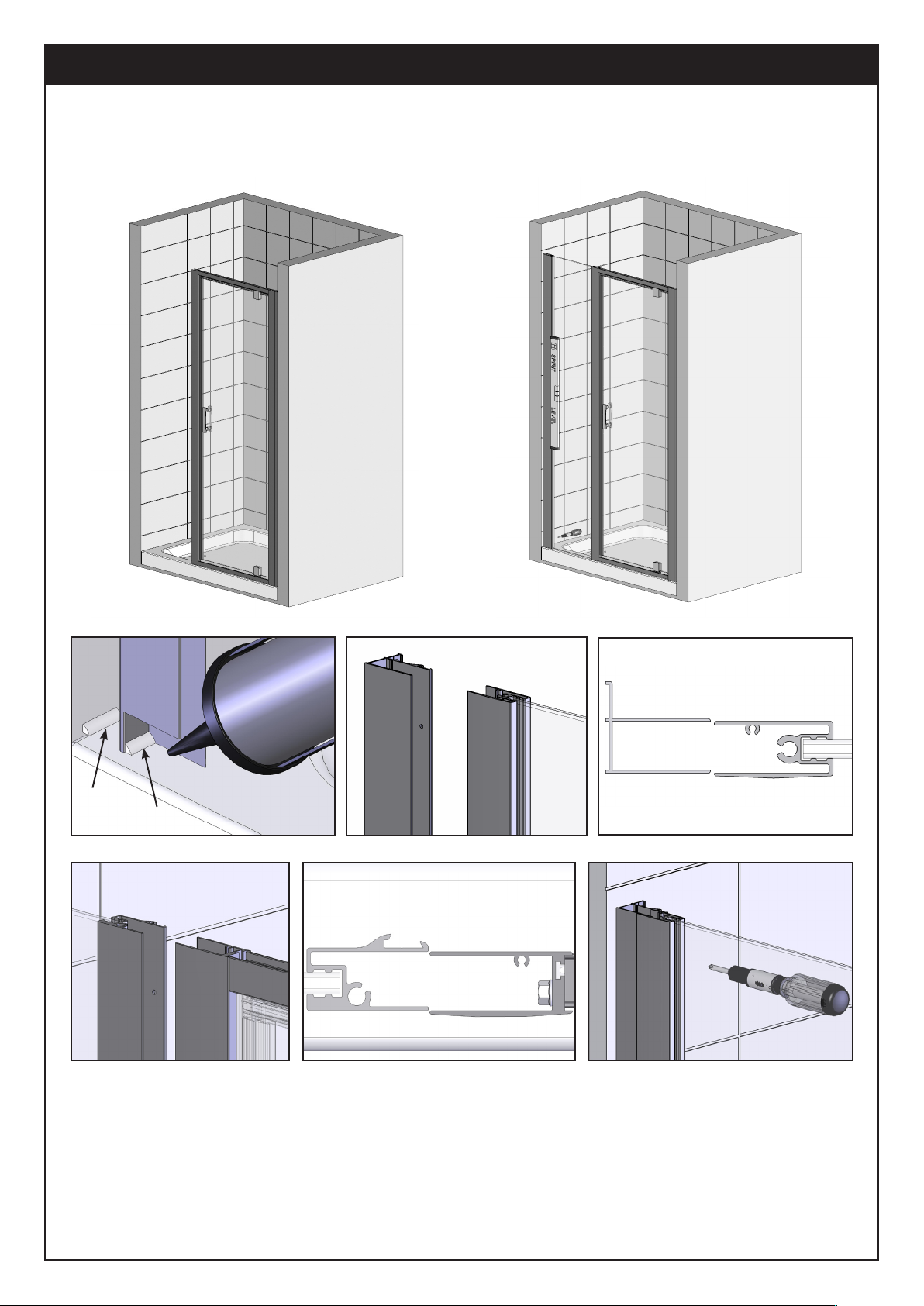

Step 1 - Inserting Door and Panel

1. LiftthedoorontothetrayandlocateintotheWallProle.

2. ApplyabeadofsealantthewidthoftheWallProlewherethe2ndprolewillmeetthetiledwallandtray.

3. Locatethe2ndWallProleontotheendoftheInlinePanel.

4. LifttheInlinePanelontothetrayandlocatefullyintotheverticalaluminiumofthedoor.

5. Screwxthe2ndWallProletothewall(makesuretheproleiscompletelyverticalusingaspiritlevel).

6. LifttheInlinePaneluptobeabletoaddabeadofsealanttotheinsideoftheWallProle

• You will need the assistance of someone when doing this procedure.

• Failure to carry out Stages 2 and 6 can result in serious water damage and will not be covered under the

terms of the guarantee.

IMPORTANT:Makesuresteps1to4oftheDoorInstallationGuidearecompletedbeforettingyourInline

Panel(Thedoorimageusedintheseinstructionsisanexampleonly).BesuretoremovetheblackTransit

Capsbeforeproceeding.

↓

①

②

③

④ ⑤

⑥

↓

③

↓

↓

④

⑥

↓

②

Step 2 - Fixing Panel and Door

1. MakesuretheDoorandInlinePanelprolesarelocatedcorrectlyandarelevelatthetopandbottom.

2. Drillthroughthepre-drilledholeswiththe2.5mmdrillbit(supplied).

3. ScrewttheDoorandInlinePaneltogetherusingtheNo4x1/4”screws.

②

③ ③

Step3-FixingPanelandDoortoWallProles

1. CentretheDoorandInlinepanelbetweentheWallProles.

• NOTE:Aminimumof10mmisrequiredbetweentheInlinePanel/DoorandWallProlesforxing.

2. MakesuretheInlinePanelandDoorarecompletelyverticalusingaspiritlevel.

• Prior to drilling/screwing the Inline Panel and Door refer to the Door installation guide to understand the

Doorttingandadjustmentrequirements.

3. DrillthroughtheWallProleintothePanelverticalwiththe2.5mmdrillbit(supplied),makesurethatthe

InlinePanelandDoorremaincompletelyverticalduringthisprocedure.

• You will need the assistance of someone when doing this procedure.

4. FitthebasesonthescrewsandfastentheWallProleandInlinePaneltogether,pushttheCoverCaps.

• ItmaybebenecialtoapplysomepressuretotheDoorandInlinePanelassemblyandcheckthedoor

operationpriortoxingthedoorside.

③

③

①

Equal Equal

10mm

minimum

④CoverCap

Screw

Base

⑥

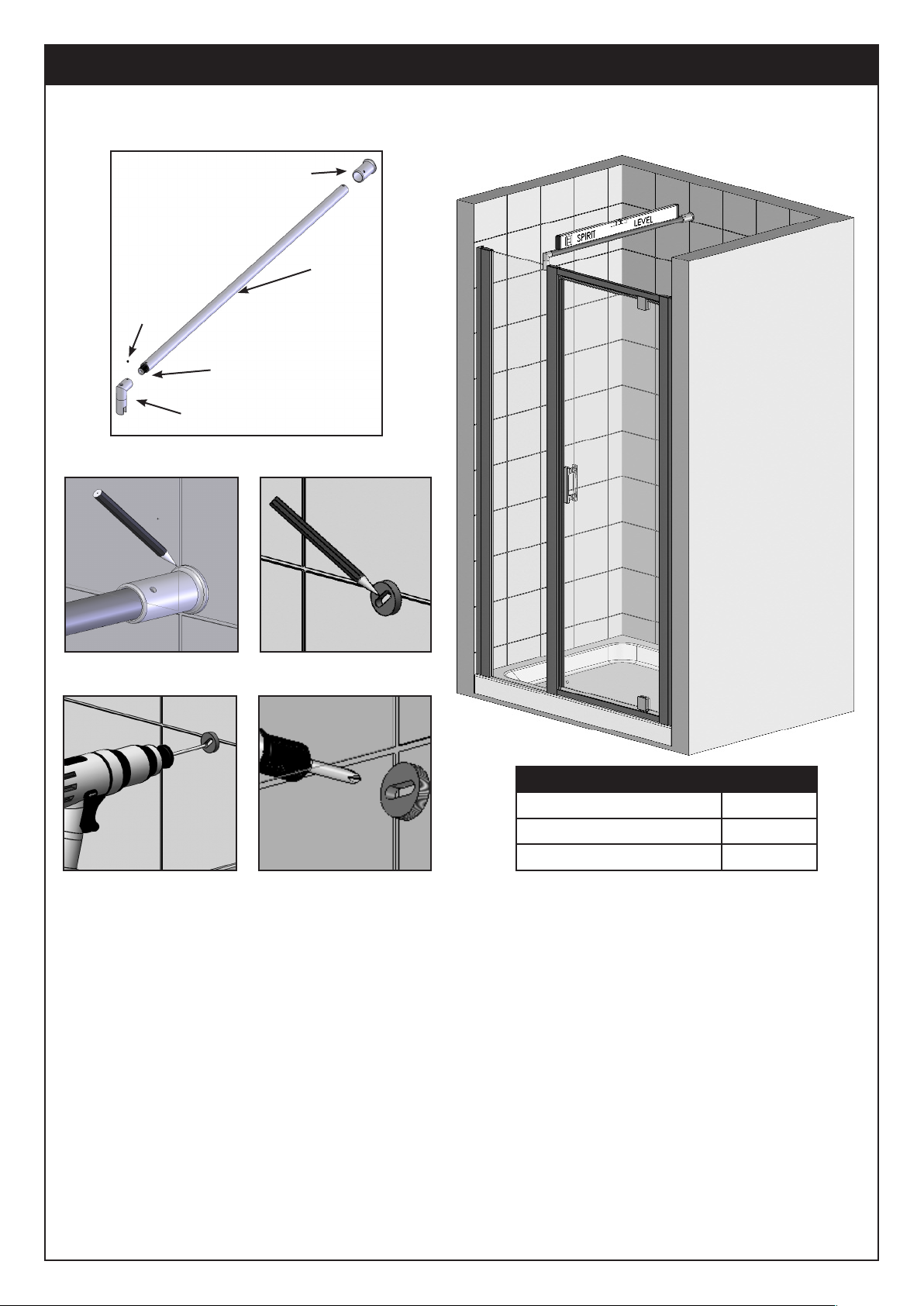

Step 4 - Bracing

1. MeasurethedistancefromthebackwalltotheoutsidefaceoftheInlinePanelGlass.

2. Deductthatmeasurementfrom1038mm,shortentheBraceBarbythenewamount(see*Exampleabove)

3. PlacetheserratedendofthestraightsectionintotheLowLevelbraceassemblyandfastentogetherby

tighteningtheSetScrew,slidetheWallCupontheoppositeendtocompletetheBraceBarassembly.

4. PositionthefullbracingassemblyontotheInlinePanelGlass,donotxatthisstage.LoosentheAllen

screwintheLowLevelbraceassemblysothatitcanbeturnedtoachievethecorrectangle.

• There should be no metal parts touching the glass, the spacers must be used.

5. SlidethewholeassemblyuptothetiledwalltodeterminethepositionoftheWallCup,markusingapencil.

6. UnscrewtheinsertfromtheWallCupandpositionitcentrallyonthepencilmark.Markthroughtheslotfor

thepositionofthescrewholethatistobedrilled.

7. Drilltheholeusinga6mmMasonryDrill(notsupplied)andttheWallPlug.

8. Fixtheinserttothewallusinga40mmscrew(supplied).ScrewtheWallCupontotheinsertuptothewall.

9. PlacetherestoftheBraceBarassemblyontothepanelandintotheWallCup,checkthateverythingis

placedcorrectly(includingspacersbeingtted)thentightenallthescrewswiththeAllenKeys(supplied).

• Thereis35mmofadjustmentintheBraceBarassemblytoallowforcorrectadjustment.

• The Brace Bar must be level, use a Spirit Level and ensure the bubble is in the middle of the two lines.

• Thepanelmustbeverticallylevel,useaSpiritLevelandadjustthebracingtoachievethis.

③

⑧ ⑦

LowLevelBrace

WallCup

SerratedEnd

Straight

Section

Set

Screw

⑤

NOTE:TheStraightSectionoftheBraceBarassemblymayneedshortening,ifsouseahacksaworsimilar.

ItisIMPORTANTthatitisshortenedattheWallCupend-besuretoremoveallburrsandsharpedges.

BraceBar(*Exampleonly)

GivenDimension 1038mm

Walltooutsideofglass *878mm

ReduceBraceBarby *160mm

②

Step 5 - Fitting Screw Cover, Caps and Sealing

1. FittheScrewCoverTrim(ifyouhaveroomthiscanbesliddownfromthetop).

• CuttheCovertrimsushwiththetopoftheverticalprolesusingaStanleyknifeorsimilar,pleasetake

care when cutting.

2. FittheTopCapstothetopoftheDoor/Panel.

• On the vertical between the Panel and Door it may be necessary to remove a front leg on the Panel side.

3. UsingagoodqualitysealantsealbothsidesoftheWallProlesverticallyinsideandoutsidewherethey

meetthetiledwalls.

4. Sealtheenclosurehorizontallythefulllengthtothetray/wetroomoorontheoutsideonly.

• IMPORTANT: Failure to follow Stages 3 and 4 may result in serious water damage and will not be covered

under the terms of the guarantee.

• Do not seal the inside of the enclosure horizontally.

• Please allow 24 hours for the sealant to fully cure before using the enclosure.

5. PlacetheBrandingBadge(ifapplicable)onaprominentnonemovingpartofaluminium..

②

↓

①

①

③

Spare Parts

Part No. Description Q’ty Part No. Description Q’ty Part No. Description Q’ty

1EndCap 111 21

2WallCupAssembly 112 22

325mmBraceBar 113 23

4ExpandableJoint 114 24

5LowLevelBracing 115 25

6InlinePanel 116

7ScrewCoverTrim 117

8 18

9 19

10 20

If you need to replace any damaged parts please see illustration below for parts list then

call Customer Relations on 01325 328033/328034

TROUBLE SHOOTING GUIDE

Problem Solution

Leaking 1. Checkthetrayhasbeensealedcorrectlypriortoinstallationoftheenclosure(Step1in

theDoorInstructions).

2. Checktheinsidegaphasbeensealedcorrectlybetweenthetrayandwallproles(Step

2intheDoorInstructionsandStep1intheseInstructions).

3. Checkthatthebaseoftheenclosureissealedtothetrayontheoutsideonly(Step5).

4. Checktoseeifbothwallproleshavebeensealedverticallyinsideandoutsidewhere

theymeetthetiledwall(Step5).

5. Checkthatthebaseoftheenclosurehasn’tbeensealedtothetopofthetrayonthe

insideofthecubicle.(Step5).

Important: This enclosure should be water tested conforming to BS EN 14428

Enclosure Alignment 1. Checkthattheenclosureisttedontoatiledwallorasimilarsealedsurface(Step1in

theDoorInstructions).

2. Checkthatthewallproleshavebeentted15mmfromthefrontoutsideedgeofthe

tray(Step2intheDoorInstructions).

3. Checkthatthewallproleshavebeenttedcompletelyvertical(thebubblemustbein

thecentreofthetwolinesonaspiritlevel-Step2intheDoorInstructions).

4. Checktheenclosureiscompletelyverticalandlevel(Step1intheDoorInstructions).

Door not Operating

Smoothly

1. Checkthatthetrayiscompletelylevel(thebubblemustbeinthecentreofthetwolines

onaspiritlevel).

2. Checkthatthewallproleshavebeenttedcompletelyvertical(thebubblemustbein

thecentreofthetwolinesonaspiritlevel).

Some important information to help you Maintain your product.

Thefollowinginformationisallyouneedtokeepyourproductlookingnew.

Cleanyourproductusingamilddetergentdilutedinwaterandthenpolishedoffusingasoftcloth.

Ifyouliveinahardwaterarea,periodicallycleanyourproductusinga50/50solutionofwhitevinegarandwater.The

solutionshouldbeleftontheenclosureforapproximately5minutesthenrinsedoffusingwarmwater.Thismethodof

cleaningshouldremovelimescaleresidue.

Simple Maintenance

Ourproductsaregenerallymaintenancefree,howeveritmaybenecessarytolubricatewheelassembliesandother

movingpartsfromtimetotime.

Itisstronglyrecommendedthataqualitysiliconesprayisused.

A list of Don’t’s:

1. Don’tuseacidicbasedproductswhichareunsuitableforcleaningenamelsurfaces.

2. Don’tuseabrasivecleanersorcleanersusingbleachorsolvents,theseproductswilladverselyaffectthenishof

thealuminiumproles.

3. Don’tusescouringpads,powderoranysharpinstrumentswhencleaningtheenclosure.

Shouldyouexperienceanyproblemsduringinstallationpleaserefertothe

TroubleShootingGuideorcontactCustomerRelationson:

+44 (0) 1325 328033/328034

Toenablecustomerrelationstoprovideyouwithanexcellentlevelofserviceitisimportantthatyou

quoteyourproductCodeandReferenceNumber-thesecanbefoundontheGuaranteecard.

Table of contents

Other ERGONOMIC Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

VADO

VADO WG-81389-C Installation & maintenance instructions

INR

INR LINC 20 installation instructions

Spectrum Brands

Spectrum Brands Pfister Kenzo 016-DF0 Quick installation guide

Triton

Triton Michelle TSHUMICH3 manual

Ronbow

Ronbow AMORA VANITY 054030 Installation and care guide

Purmo

Purmo Amirante E manual

Vaunn Medical

Vaunn Medical M725N-AAWH-CHVM user manual

Kohler

Kohler ENGLEFIELD EXCLUSIVE Series installation instructions

Kohler

Kohler NEW PURIST K-701574T installation instructions

Helvex

Helvex Vertika 16104 installation guide

Voda Plumbingware

Voda Plumbingware Olympia VOP63RBG quick start guide

Booth & Co

Booth & Co AXBRIDGE BC-AXB-183-CP installation guide