Operating instruction

Spindle lifting system SF 12xx Compact

Document no.: B-00451

Edition 2023 01

Operating instruction EN

Copyright by Ergoswiss AG

Page 3of 25

Table of content

1Safety requirements ................................................................................................................ 4

1.1 Explanations of the symbols and notes ..................................................................................... 4

2System description .................................................................................................................. 5

2.1 General .................................................................................................................................. 5

2.2 Intended purpose use ............................................................................................................. 5

2.2.1 General safety instructions................................................................................................... 5

2.3 Target group and prior knowledge ........................................................................................... 6

2.4 Performance characteristics ..................................................................................................... 7

2.4.1 Lifting column SF 12xx ........................................................................................................ 7

2.4.2 Control box Compact-3-eco ................................................................................................. 8

2.4.3 Hand switch Memory ........................................................................................................... 8

2.4.4 System data ....................................................................................................................... 8

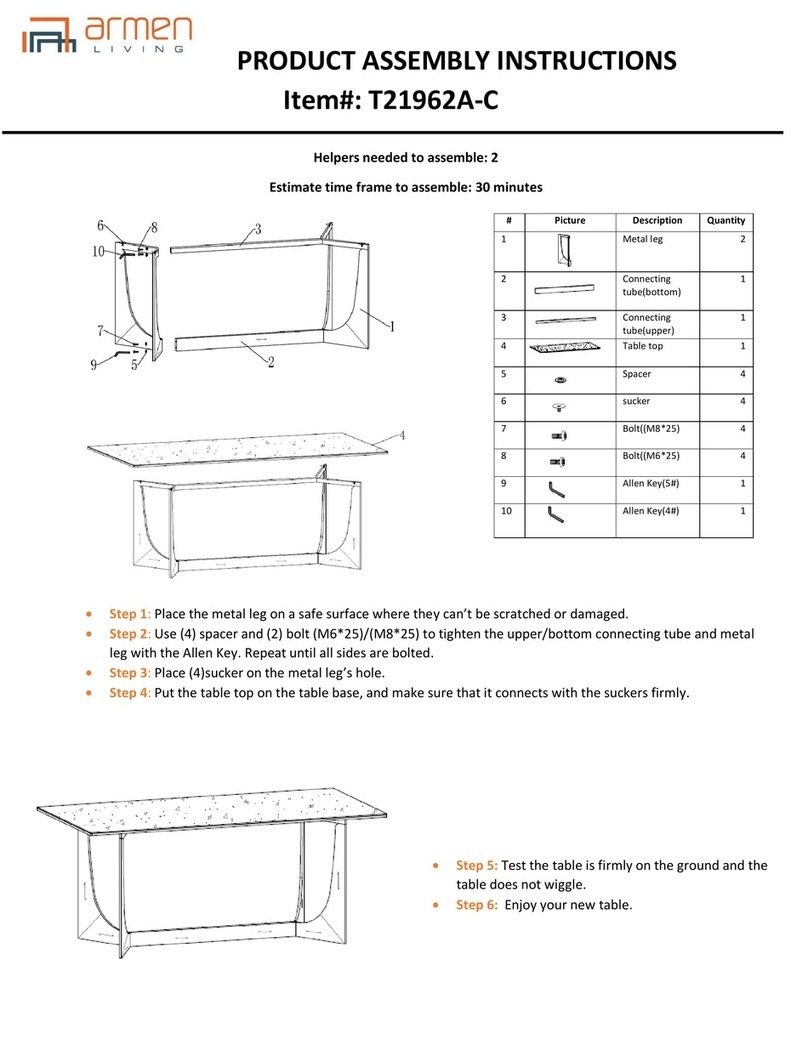

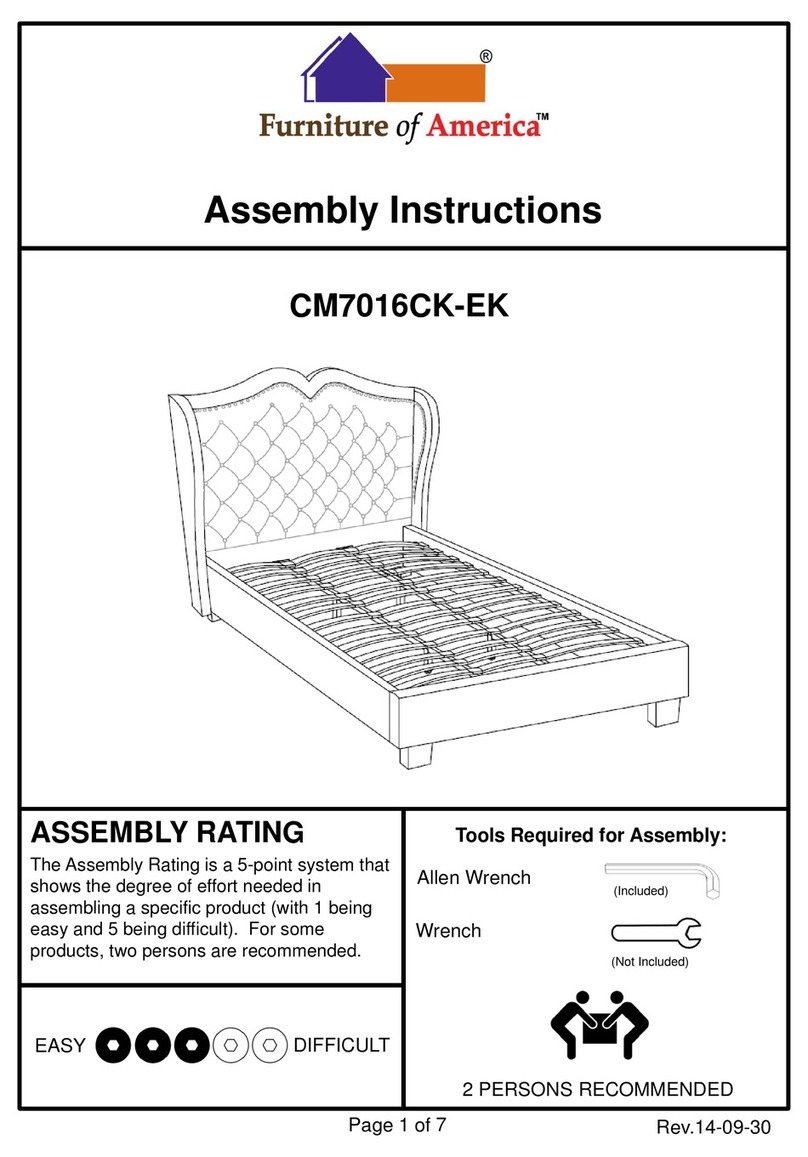

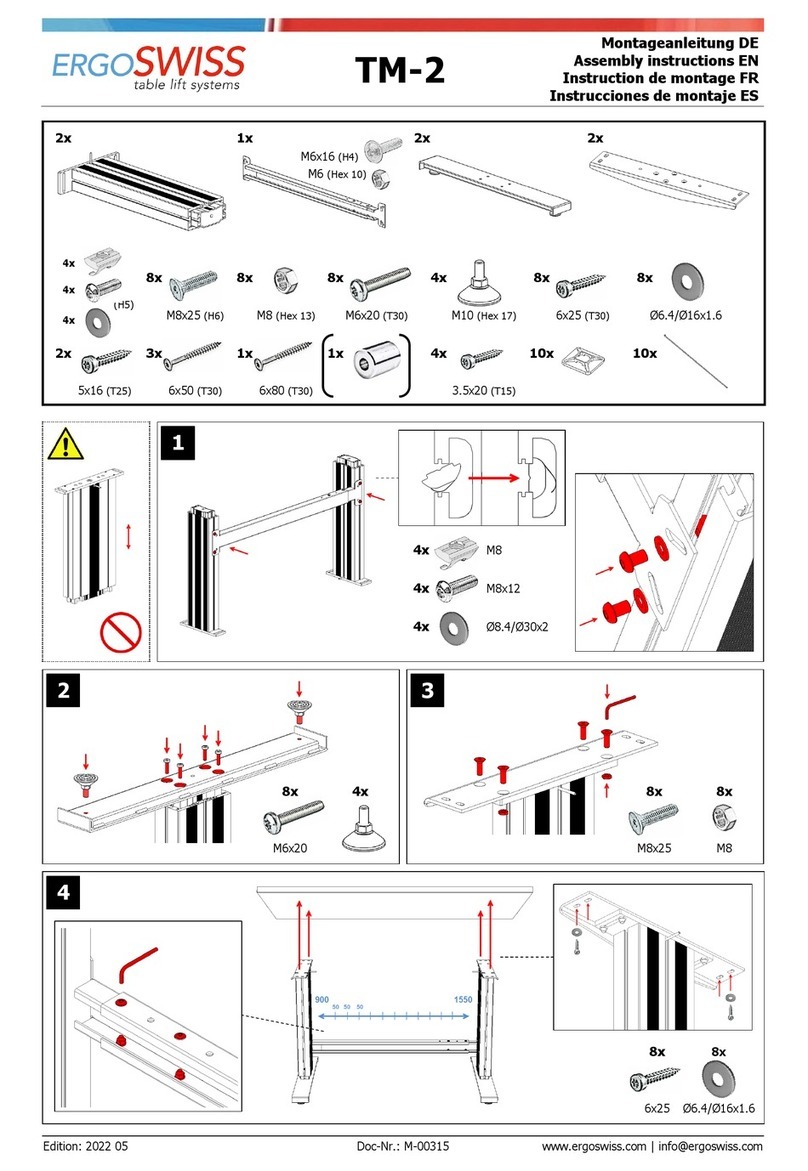

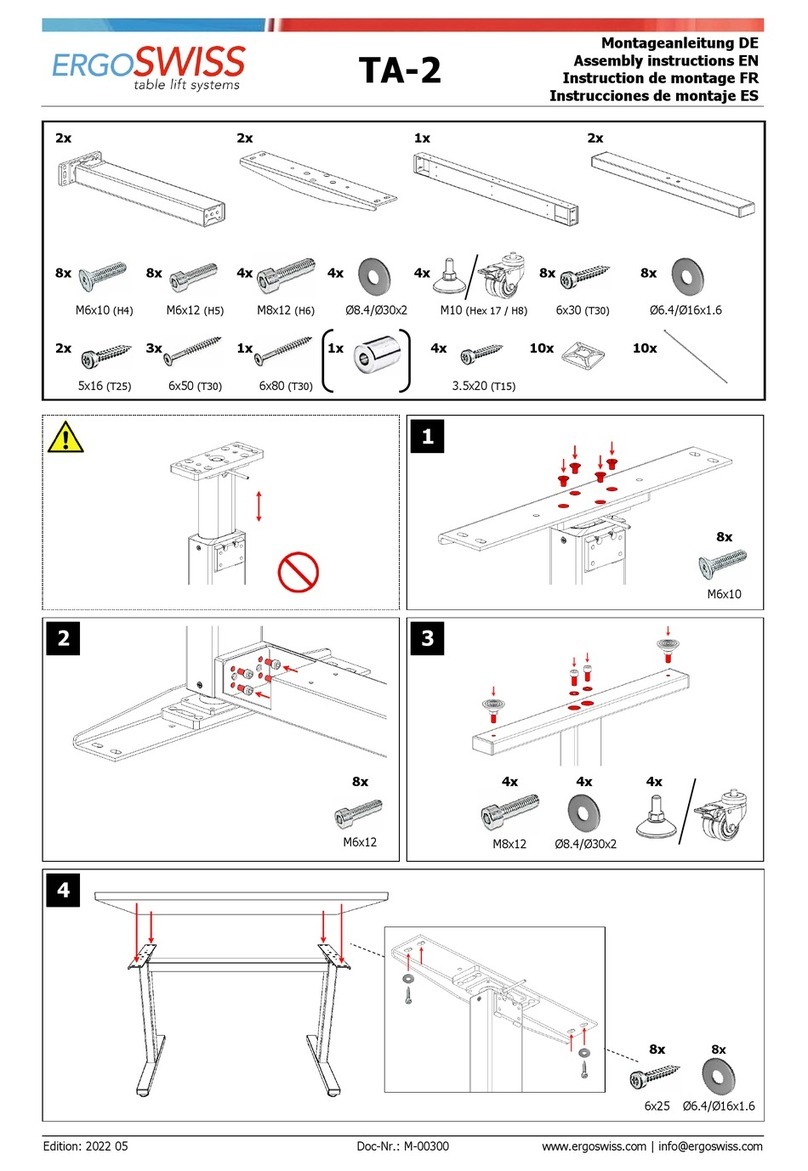

3Mounting instructions.............................................................................................................. 9

3.1 Mounting instructions Lifting column ........................................................................................ 9

3.2 Montage instructions Control box ........................................................................................... 11

3.3 Montage instructions Hand switch .......................................................................................... 13

3.3.1 Hand switch Memory ......................................................................................................... 13

3.3.2 Hand switch Up-Down ....................................................................................................... 13

4Initial operation..................................................................................................................... 14

4.1 Plug detection....................................................................................................................... 14

4.2 Duty cycle monitoring............................................................................................................ 14

5Operation with Hand switch Type Memory ........................................................................... 15

5.1 Drive Up / Down ................................................................................................................... 15

5.2 Saving and approaching a memory position ............................................................................ 15

5.3 Limit the stroke length (Container-Stop/Shelf-Stop)................................................................. 16

5.4 Setting the shown height on the display ................................................................................. 16

5.5 Changing the display unit of measurement (mm/inch) – Reset «S 5» ....................................... 17

5.6 Restore to factory settings – Factory reset «S 0» .................................................................... 17

5.7 Reference drive – Referencing the end positions – «Long Key Down» ...................................... 18

6Operation with Hand switch Type Up-Down ......................................................................... 18

6.1 Drive Up / Down ................................................................................................................... 18

7Synchronous operation of 2, 3 or 4 control boxes................................................................. 19

7.1 Cable connections ................................................................................................................. 19

7.2 Commissioning the synchronized systems............................................................................... 20

7.3 Operation scenarios – FAQ .................................................................................................... 20

8Safety strip – Squeezing protection ...................................................................................... 21

8.1 Commissioning...................................................................................................................... 21

9Maintenance and disposal ..................................................................................................... 22

9.1 Maintenance and cleaning ..................................................................................................... 22

9.2 Repairs and spare parts......................................................................................................... 22

9.3 Disassembly and disposal ...................................................................................................... 22

9.4 Electrical and Electronic Equipment Act .................................................................................. 22

9.5 Error codes on the display ..................................................................................................... 23

9.6 Click codes ........................................................................................................................... 24

9.7 Trouble-shooting................................................................................................................... 24

10 Declaration of Incorporation ................................................................................................. 25