6

CONTROL UNIT MOUNTING

The Metalarm 3500 control unit is supplied with four

mounting brackets for wall mounting. The dimensions

are shown in Figure 1.

Ideally the control unit should be mounted within 10-15'

(3-5 m) of the sensor coil unit and no more than

66' (20 m).

The control unit must be mounted in a location with

low amounts of vibration, if the area exhibits a high

level of vibration, independent mounting of the control

enclosure must be implemented. Shock mounts for the

control enclosure may be another consideration, based

on the severity of the installation.

The Metalarm 3500 control unit will normally be

mounted by means of four 5/16 inch or M8 bolts

utilizing the four mounting holes.

Adequate clearance must be allowed below the control

unit enclosure to allow for cable entry and exit.

NOTE: Do not replace the HDPE mounting bars, as

these are provided to electrically isolate the control

unit from the metal conveyor framework. Similarly no

metal work should be in contact with the metal control

unit case after mounting on the conveyor.

Failure to comply with the above mounting procedures

will invalidate the ‘CE’ certificate covering the

EMC regulations.

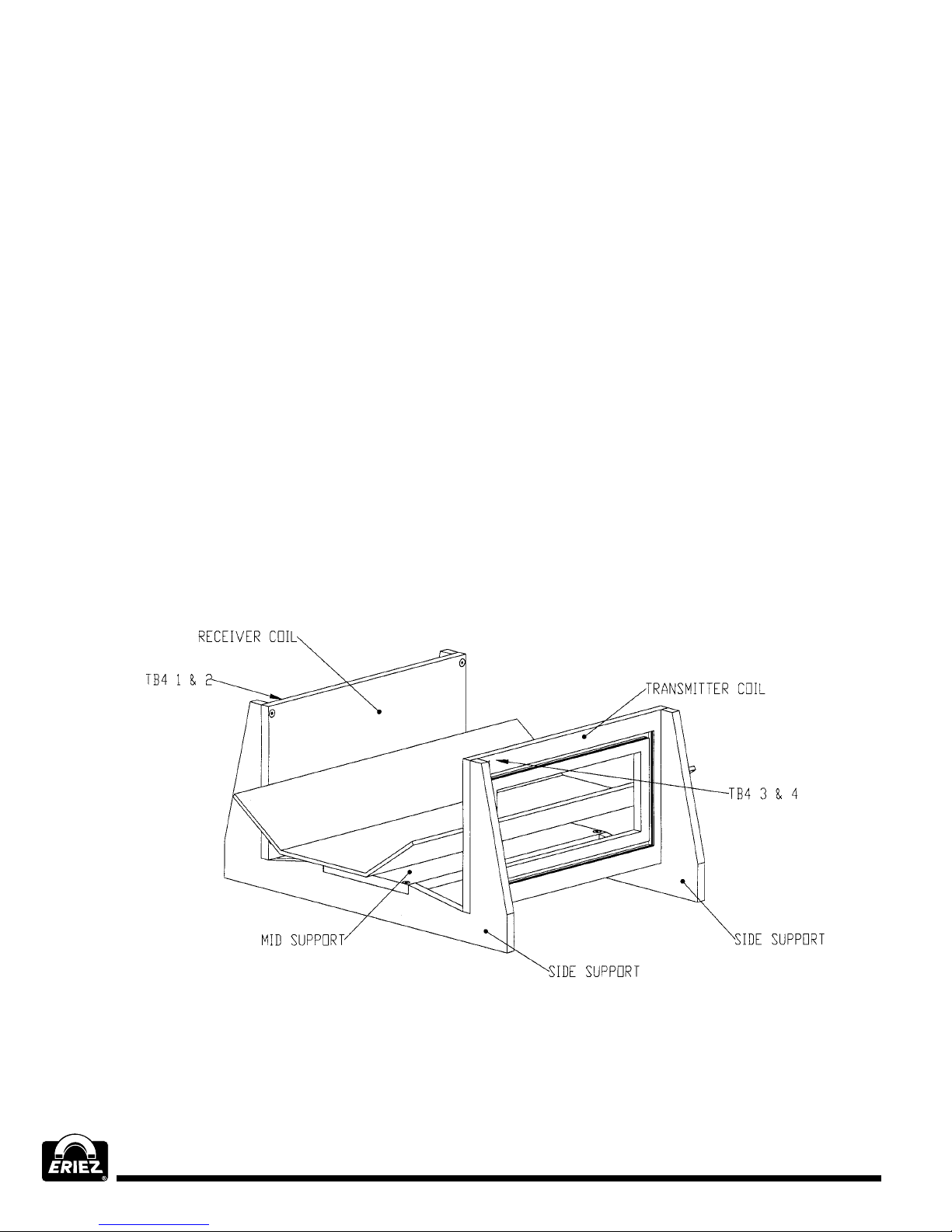

SEARCH COIL MOUNTING

The following instructions give details of how to install

the various types of standard search coils supplied as

part of the Metalarm Metal Detector.

The search coil should be assembled using the

instructions supplied with the search coil.

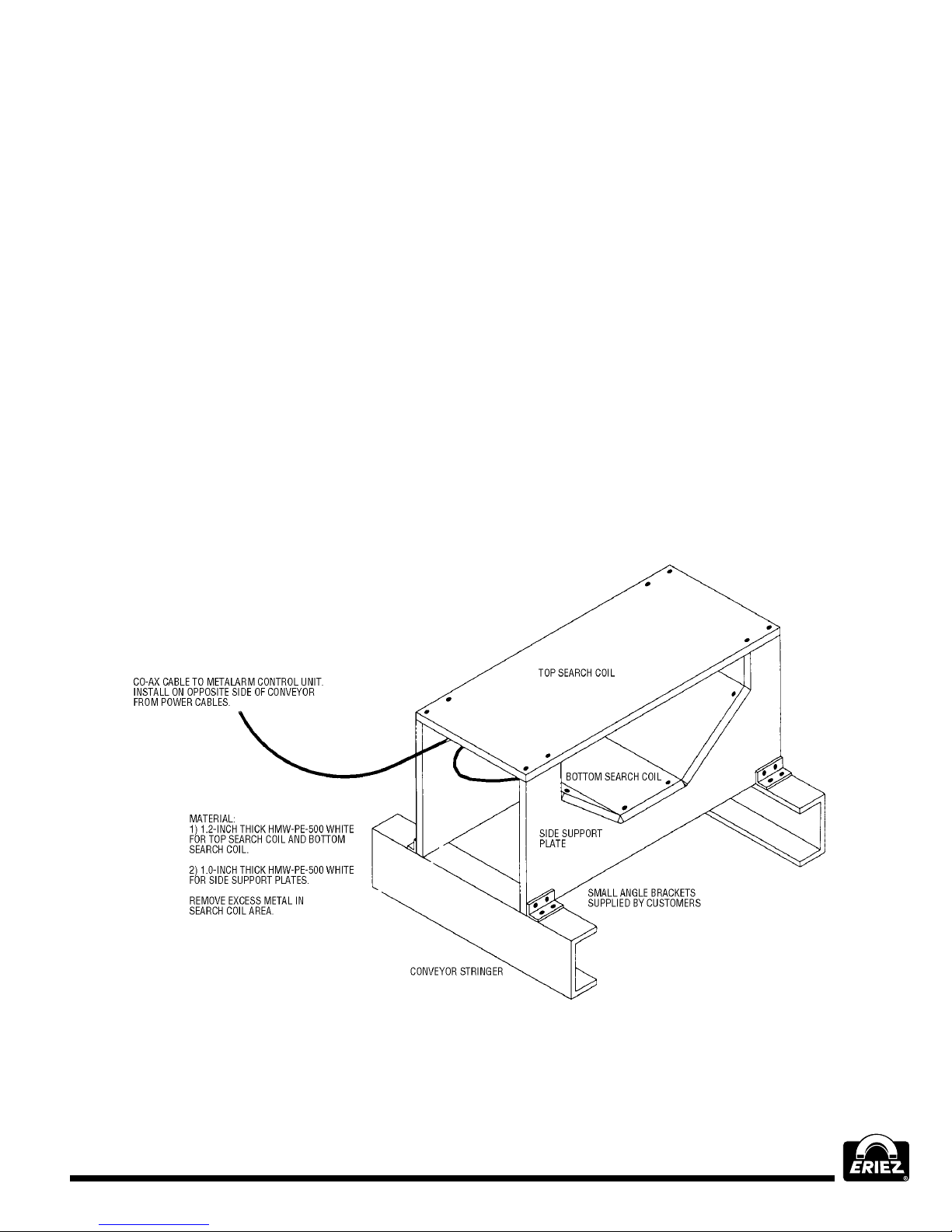

UNDERBELT COIL (MODEL TR) ‑

IDLER CONVEYORS

Locate a suitable position in the conveyor mid way

between two idlers where:

• There will not be a return idler or cross piece

beneath the search coil.

• There is not a joint in the conveyor frame.

Installation • Metal, when detected, can easily be removed from

the conveyor belt.

• There is no moving metal in the vicinity.

• Any metal base plate present can be removed or

replaced by non-metallic material.

• Any metal covers over the belt can be removed or

replaced by non-metallic material.

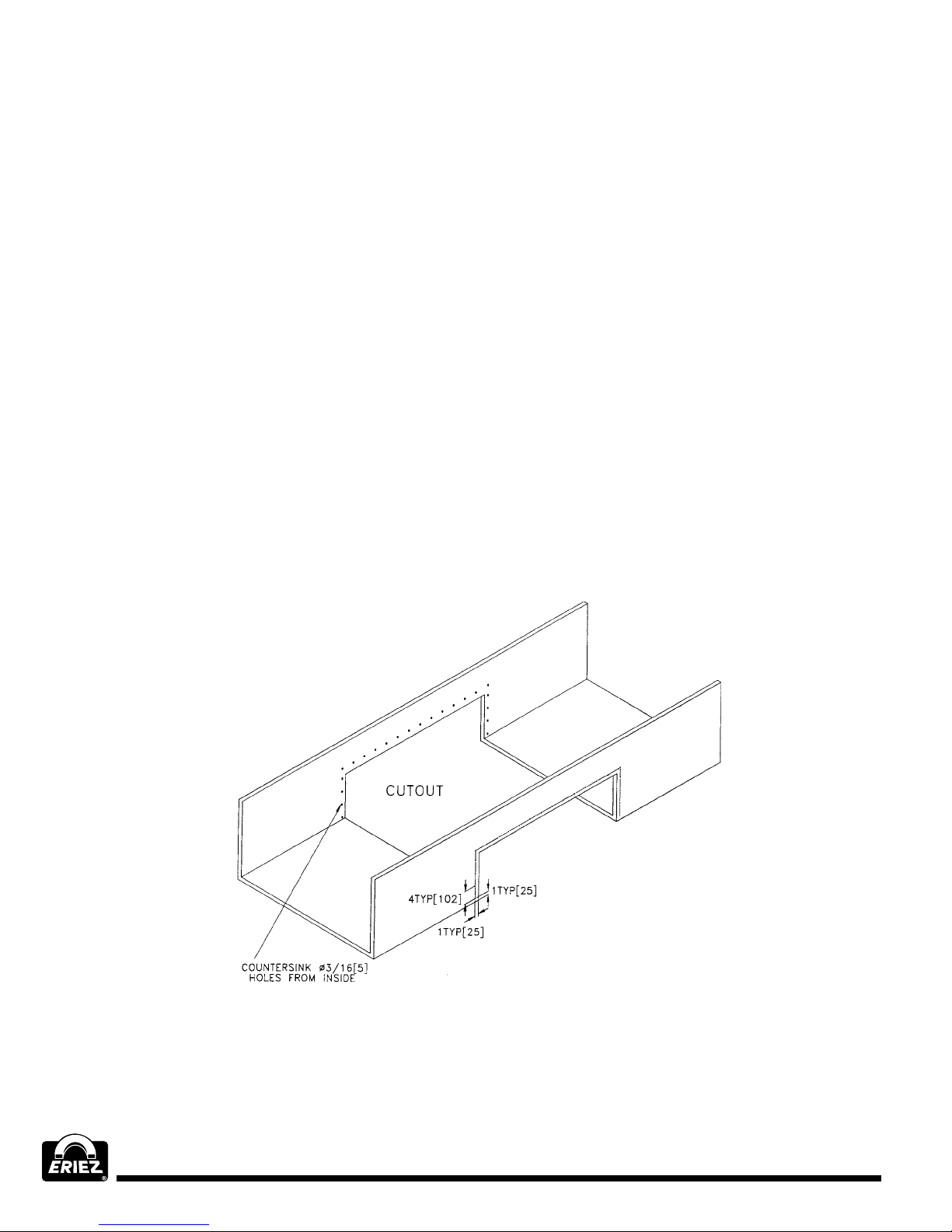

Place the search coil on the conveyor frame at the

chosen position. There should be at least a 1' (25mm)

gap between the underside of the conveyor belt and

the top of the search coil. If not cut out notches in the

bottom of the search coil at all four corners so as to

lower the search coil within the conveyor frame.

User supplied stainless steel “L” brackets are

suggested for securing the search coil assembly to the

conveyor. Brackets should be fitted to the coil, in the

area marked for such purposes, as shown on the coil

assembly drawing. (See Figure 2)

The search coil should then be bolted to the conveyor

frame with the coil electrical connection on the

opposite side of the conveyor frame to any heavy-duty

cables or wiring.

A recommended idler spacing of 48"- 60" should apply

to the infeed and outfeed idlers adjacent to the search

coil. An idler isolation kit is recommended and may

be purchased from the factory. The idler isolation kit

provides suitable materials to electrically insulate the

idlers from the conveyor frame. Insulating the idlers

directly adjacent to each side of the search coil will help

to alleviate any possible false tripping. Electrical loops

can be created from the metal detectors field in relation

to the surrounding metal. The idlers on each side of

the search coil should be checked to see that all nuts

and bolts have been securely tightened.

The cable connecting the search coil to the control

unit should then be attached to the connector on the

underside of the search coil and to the control unit. The

cable should be secured and protected from damage.