ero electronic PKC User manual

rUSER MANUAL PKC

MKC

170.IU0.XKC.0C1 05-02

Xkc-01-C0.P65 5/29/02, 11:58 AM1

Xkc-01-C0.P65 5/29/02, 11:58 AM2

INDEX

MOUNTING REQUIREMENTS ................................................. 1

OUTLINE AND CUT OUT DIMENSIONS ................................. 2

CONNECTION DIAGRAMS ...................................................... 4

PRELIMINARY HARDWARE SETTINGS ............................... 17

SECURITY CODE SETTING MODE ...................................... 22

RUN TIME AND CONFIGURATION MODE ........................... 25

General notes about graphic symbols .............................. 25

Keyboard description ....................................................... 25

CONFIGURATION MODE ...................................................... 27

RUN TIME MODE ................................................................... 62

Display function ................................................................ 62

Indicators ......................................................................... 64

Bargraph description ........................................................ 65

OUT failure detection function (OFD) .............................. 66

Direct access to the set point ........................................... 66

Manual function ................................................................ 67

Serial link ......................................................................... 68

Lamp test ......................................................................... 69

SMART function ............................................................... 69

Hold function .................................................................... 70

Parameter protection ....................................................... 70

RUN TIME PARAMETER MODIFICATION ............................ 71

ERROR MESSAGES .............................................................. 97

GENERAL INFORMATIONS ................................................ 103

MAINTENANCE .................................................................... 112

DEFAULT PARAMETERS .................................................... A.1

ALPHANUMERIC INDEX OF THE

DISPLAY INDICATION ......................................................... B.1

CODING ................................................................................ B.7

Xkc-01-C0.P65 5/29/02, 11:58 AM3

Xkc-01-C0.P65 5/29/02, 11:58 AM4

1

MOUNTING REQUIREMENTS

Select a location, for instrument mounting, where

minimum vibrations are present and the ambient

temperature is within 0 and 50 °C (32 and

122 °F).

The instrument can be mounted on a panel up to

15 mm thick with a cutout of 92 x 45 mm (PKC) or

92 x 92 (MKC).

For outline and cutout dimensions refer to Fig. 2.

The surface texture of the panel must be better

than 6,3 mmm.

The instrument is shipped with rubber panel

gasket (50 to 60 Sh).

To assure the IP65 and NEMA 4 protection, insert

the panel gasket between the instrument and the

panel as shown in fig. 1.

While holding the instrument against the panel

proceed as follows:

1) insert the gasket in the instrument case;

2) insert the instrument in the panel cutout;

3) pushing the instrument against the panel;

4) insert the mounting brackets as shown in fig.1;

5) with a screwdriver, turn the screws with a

torque between 0.3 and 0.4 Nm. Fig. 1

Gasket

bracket

bracket Panel

Screws

Screw

Panel

Screw

brackets

Gasket

Xkc-1-C0.P65 5/29/02, 11:59 AM1

2

OUTLINE AND CUT OUT

DIMENSIONS

Fig. 2.A OUTLINE AND CUT-OUT DIMENSIONS FOR PKC MODEL

Xkc-1-C0.P65 5/29/02, 11:59 AM2

3

Fig. 2.B OUTLINE AND CUT-OUT DIMENSIONS FOR MKC MODEL

Xkc-1-C0.P65 5/29/02, 11:59 AM3

4

CONNECTION DIAGRAMS

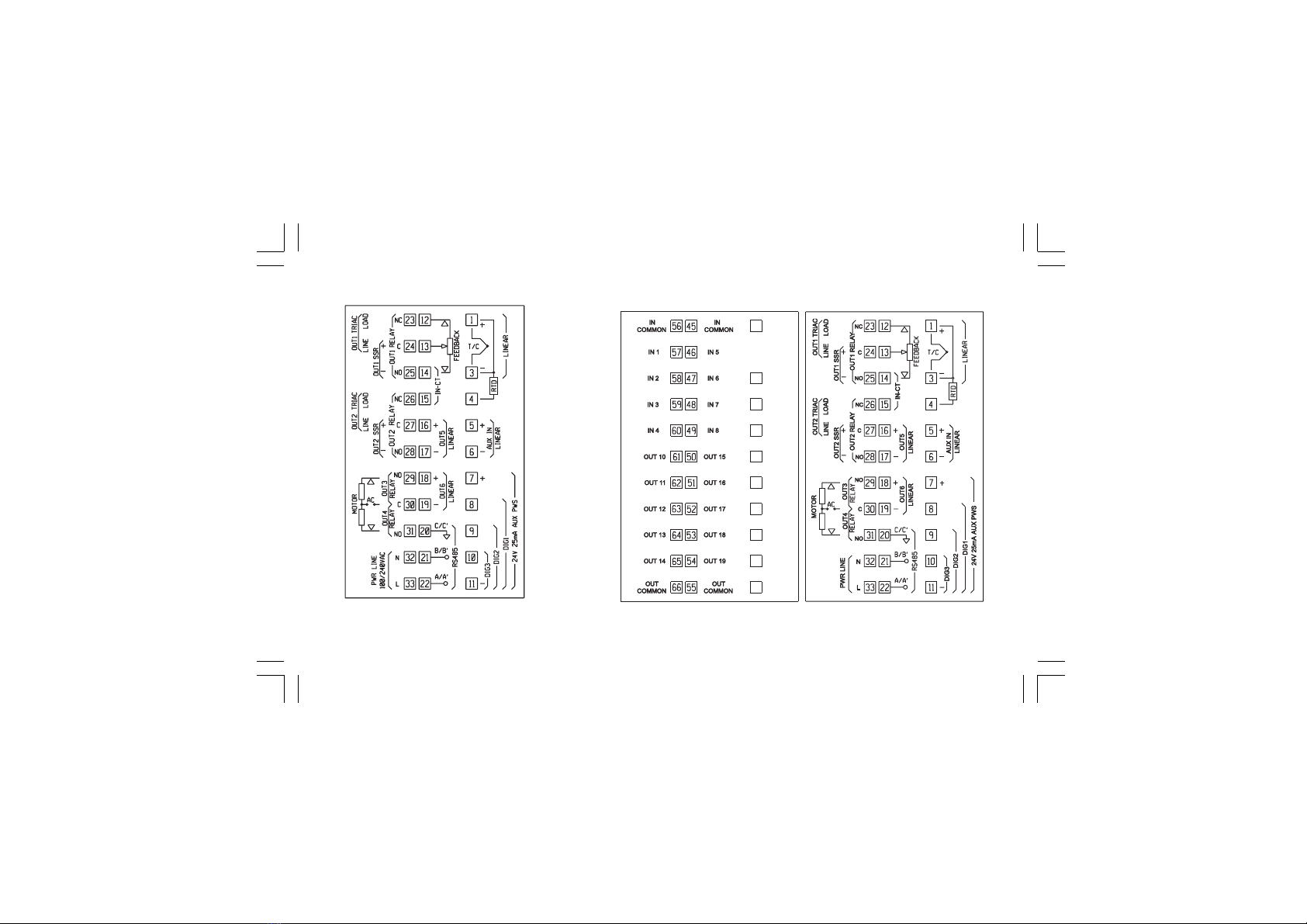

Fig. 3.A PKC -REAR TERMINAL BLOCK Fig. 3.B MKC REAR TERMINAL BLOCK

Xkc-1-C0.P65 5/29/02, 11:59 AM4

5

Connections are to be made with the instrument housing

installed in its proper location.

A) MEASURING INPUTS

NOTE: Any external component (like zener barriers etc.)

connected between sensor and input terminals may cause

errors in measurement due to excessive and/or not balanced

line resistance or possible leakage currents.

A.1) TC INPUT

Fig. 4 THERMOCOUPLE INPUT WIRING

NOTES:

1) Don’t run input wires together with power cables.

2) For TC wiring use proper compensating cable preferable

shielded.

3) When a shielded cable is used, it should be connected at

one point only.

3

+

_

Shield

1

3

+

_

Shield

1

Xkc-1-C0.P65 5/29/02, 11:59 AM5

6

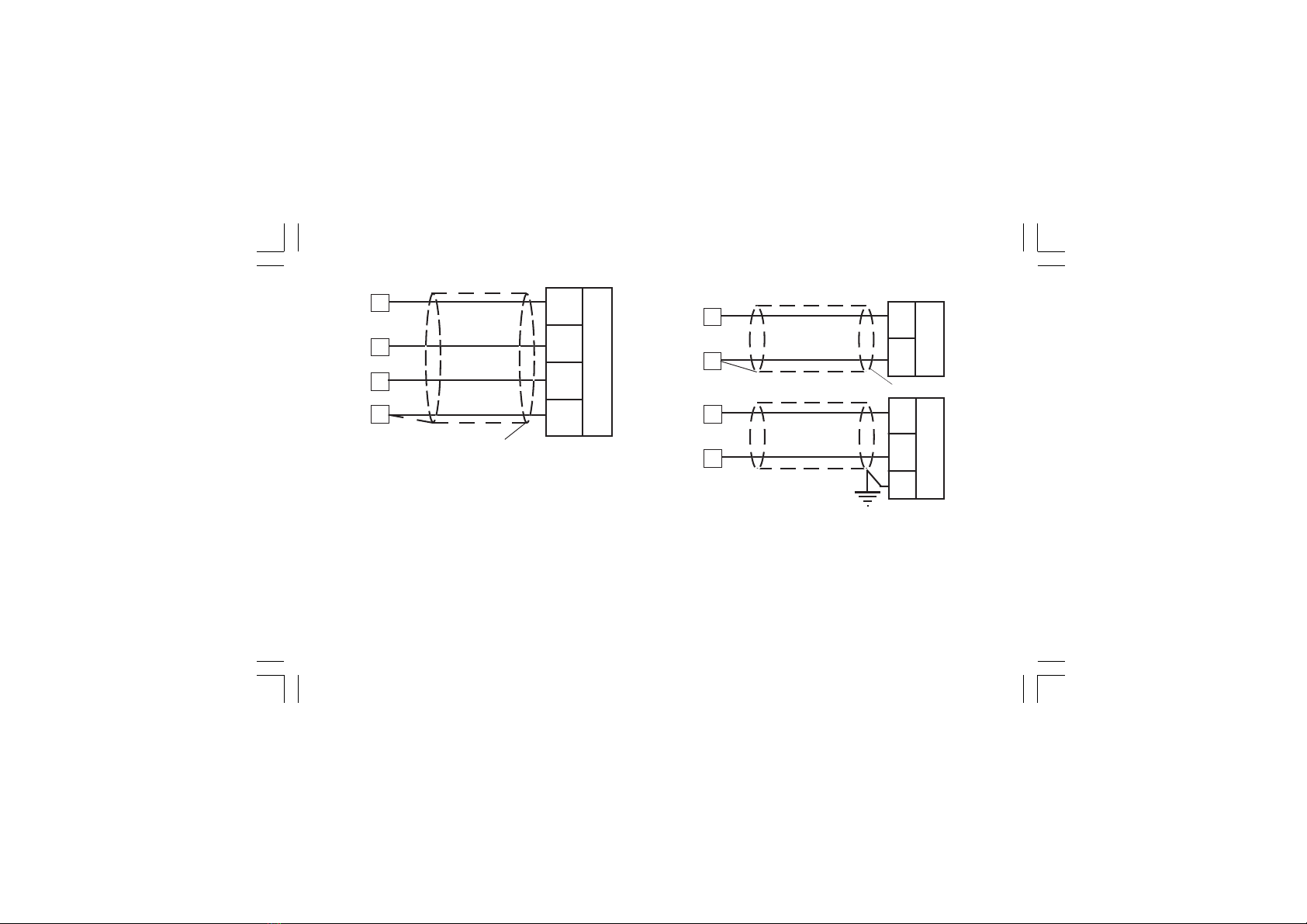

A.3) LINEAR INPUT

Fig. 6 mA, mV AND V INPUTS WIRING

NOTES:

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

Shield

_

+mA,

mV

or

V

3

1

+

_

G

mA

mV

or

V

1

3

4

RTD

13 4

RTD

13

A.2) RTD INPUT

Fig. 5 RTD INPUT WIRING

NOTES:

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The resistance of the 3 wires must be the same.

Xkc-1-C0.P65 5/29/02, 11:59 AM6

7

Shield

+

_

TX

3

1

11

7

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is equal to:

< 5 Wfor 20 mA input

> 1 MWfor 60 mV input

> 200 kWfor 5 V input

> 400 kWfor 10 V input

A.4) 2, 3 AND 4-WIRE TRANSMITTER INPUT

Fig. 7.A INPUTS WIRING FOR 2-WIRE TRANSMITTER

Fig. 7.B INPUTS WIRING FOR 3-WIRE TRANSMITTER

Shield

3

1

11

7

PWR

+

Out

TX

GND

Xkc-1-C0.P65 5/29/02, 11:59 AM7

8

B) AUXILIARY INPUT

Fig. 8 AUXILIARY INPUT WIRING

NOTES:

1) This input is not isolated from measuring input. A double or

reinforced insulation between instrument output and power

supply must be assured by the external instrument.

2) Don’t run input wires together with power cables.

3) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

Shield

_

+mA

or

V

6

5

+

_

G

mA

or

V

5

6

Fig. 7.C INPUTS WIRING FOR 4-WIRE TRANSMITTER

NOTES:

1) Don’t run input wires together with power cables.

2) Pay attention to the line resistance; a high line resistance may

cause measurement errors.

3) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

4) The input impedance is lower than 5 W(20 mA input)

Shield

3

1

11

7PWR

+

Out

+

TX

PWR

_

Out

_

Xkc-1-C0.P65 5/29/02, 11:59 AM8

9

8

9

10

11

DIG. 1

DIG. 2

DIG. 3

4) When shielded cable is used, it should be grounded at one

side only to avoid ground loop currents.

5) The input impedance is equal to:

< 5 Wfor 20 mA input

> 200 kWfor 5 V input

> 400 kWfor 10 V input

C) LOGIC INPUT

Fig. 9.A - LOGIC INPUTS DIG.1, 2 and 3 WIRING

Fig. 9.B - LOGIC INPUTS IN 1, 2, 3 and 4 WIRING

58

59

IN 2

IN 3

56

57

IN 1

60

IN 4

Xkc-1-C0.P65 5/29/02, 11:59 AM9

10

14

15

Load

Current

transformer

D) CURRENT TRANSFORMER INPUT

Fig. 10 CURRENT TRANSFORMER INPUT WIRING

This input allows you to measure and display the current running

in the load, driven by a time proportional control output, during

the ON and OFF periods of the output cycle time. By this feature

it is also available the "Output failure detection" function (see

page 66).

Fig. 9.c - LOGIC INPUTS IN 5, 6, 7 and 8 WIRING

NOTES:

1) Do not run logic input wiring together with power cables.

2) Use an external dry contact capable of switching 0.5 mA,

5 V DC.

3) The instrument needs 110 ms to recognize a contact status

variation.

4) The logic inputs are NOT isolated by the measuring input. A

double or reinforced insulation between instrument output and

power supply must be assured by the external element.

47

48

IN 6

IN 7

45

46

IN 5

49

IN 8

Xkc-1-C0.P65 5/29/02, 11:59 AM10

11

NOTES:

1) This input is not isolated from measuring input. A double or

reinforced insulation between instrument output and power

supply must be assured by the external element.

2) Do not run current transformer input wiring together with AC

power cables.

3) The minimum active period to perform this measurement is

equal to 120 ms.

4) The input impedance is equal to 20 W.

E.1) RELAY OUTPUTS

Fig. 11.A RELAY OUTPUTS 1,2,3 and 4 WIRING

OUT 1

23 NC

24 C

25 NO

OUT 2 27 C

NO

28

OUT 3

29 NO - OUT 3

OUT 4

30 C - OUT 3/4

31 NO - OUT 4

26 NC

Xkc-1-C0.P65 5/29/02, 11:59 AM11

12

OUT 10 61 NO OUT 10

62 NO OUT 11

NO OUT 12

63

64 NO OUT 13

65 NO OUT 14

66 COMMON

OUT 11

OUT 12

OUT 13

OUT 14

COMMON

OUT 15 50 NO OUT 15

51 NO OUT 16

NO OUT 17

52

53 NO OUT 18

54 NO OUT 19

55 COMMON

OUT 16

OUT 17

OUT 18

OUT 19

COMMON

The outputs from OUT 1 to OUT 4 are equipped with relays

having contact rating equal to 3A/250V AC on resistive load.

WARNING: When OUT 3 and 4 are used as independent relay

outputs the addition of the two currents must not exceed 3 A.

Fig. 11.B RELAY OUTPUTS 10 to 14 WIRING

Fig. 11.C RELAY OUTPUTS 15 to 19 WIRING

The outputs from OUT 10 to 19 are equipped with relays having

contact rating equal to 0.5A/250V AC on resistive load.

Xkc-1-C0.P65 5/29/02, 11:59 AM12

13

Fig. 12 EXTERNAL SWITCH IN SERIES WITH THE INTER-

NAL CONTACT

In this case it is recommended to install an additional RC

network across the external contact as show in Fig. 12

The value of capacitor (C) and resistor (R) are shown in the

following table.

Anyway the cable involved in relay output wiring must be as far

away as possible from input or communication cables.

NOTES 1) To avoid electrical shock, connect power line at

the end of the wiring procedure.

2) For power connections use No 16 AWG or larger

wires rated for at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

All relay contacts are protected by varistor against inductive load

with inductive component up to 0.5 A.

The following recommendations avoid serious problems which

may occur, when using relay output for driving inductive loads.

INDUCTIVE LOADS

High voltage transients may occur switching inductive loads.

Through the internal contacts these transients may introduce

disturbances which can affect the performance of the instru-

ment.

For all the outputs, the internal protection (varistor) assures a

correct protection up to 0.5 A of inductive component.

The same problem may occur when a switch is used in series

with the internal contacts as shown in Fig. 12.

R

C

LOAD

LINE

LOAD

(mA)

<40 mA

<150 mA

<0.5 A

C

(mF)

0.047

0.1

0.33

R

(W)

100

22

47

P.

(W)

1/2

2

2

OPERATING

VOLTAGE

260 V AC

260 V AC

260 V AC

Xkc-1-C0.P65 5/29/02, 11:59 AM13

14

NOTE: This output is not isolated.

A double or reinforced insulation between instrument output and

power supply must be assured by the external solid state relay.

E.3) TRIAC OUTPUTS

Fig. 14 TRIAC OUTPUT WIRING

23 Load

24 Line

26 Load

27 Line

OUT 1

OUT 2

E.2) VOLTAGE OUTPUTS FOR SSR DRIVE

Fig. 13 SSR DRIVE OUTPUT WIRING

Logic level 0: Vout < 0.5 V DC.

Logic level 1:

- 14 V + 20 % @ 20 mA

- 24 V + 20 % @ 1 mA.

Maximum current = 20 mA.

+

__

+

24

25

OUT 1

SOLID STATE

RELAY

+

__

+

27

28

OUT 2

SOLID STATE

RELAY

Xkc-1-C0.P65 5/29/02, 11:59 AM14

15

E.4) SERVOMOTOR OUTPUT

Fig. 15 SERVOMOTOR OUTPUT WIRING

Switching mode: isolated zero crossing type.

Rated current: from 50 mA to 1 A.

Rated voltage: from 24 VRMS to 240 VRMS -10 % +15 % (50/

60Hz)

Load type: resistive load only

NOTES 1) To avoid electrical shock, connect power line at

the end of the wiring procedure.

2) For power connections use No 16 AWG or larger

wires rated for at last 75 °C.

3) Use copper conductors only.

4) Don’t run input wires together with power cables.

5) This output is not fuse protected. Please, provide it

externally using a fuse with a I2t equal to128.

29

30

31

Servo-

motor

Power

line

12

13

14

s(Open the valve)

t(Close the valve)

Feedback

potentiometer

Shield

s(Open)

t(Close)

Xkc-1-C0.P65 5/29/02, 11:59 AM15

16

The two relay output must be interlocked (see chapter

"Preliminary hardware setting" paragraph "Out 3 and 4

selection").

NOTES:

1) Before connecting the instrument to the power line, make sure

that line voltage and the load current are in accordance with the

contact rating (3A/250V AC on resistive load).

2) To avoid electric shock, connect power line at the end of the

wiring procedure.

3) For servomotor connections use No 16 AWG or larger wires

rated for at last 75 °C.

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For feedback potentiometer, use shielded cable with the shield

connected to the earth at one point only.

7) The relay outputs are protected by varistor against inductive

load with inductive component up to 0.5 A.

E.5) ANALOG OUTPUTS

Fig. 16.A OUTPUT 5 WIRING

+

_

Shield

_

+

17

+

_

G

16

17

16

OUT 5

OUT 5

20 mA20 mA

+

_

Xkc-1-C0.P65 5/29/02, 11:59 AM16

This manual suits for next models

1

Table of contents

Other ero electronic Controllers manuals

Popular Controllers manuals by other brands

AUMA

AUMA SA 25.1 operating instructions

Nordson EFD

Nordson EFD ValveMate 7197PCP operating manual

ActronAir

ActronAir QTW-1000 Installation and commissioning manual

Vaillant

Vaillant sensoCOMFORT VRC 720 Operating and installation instructions

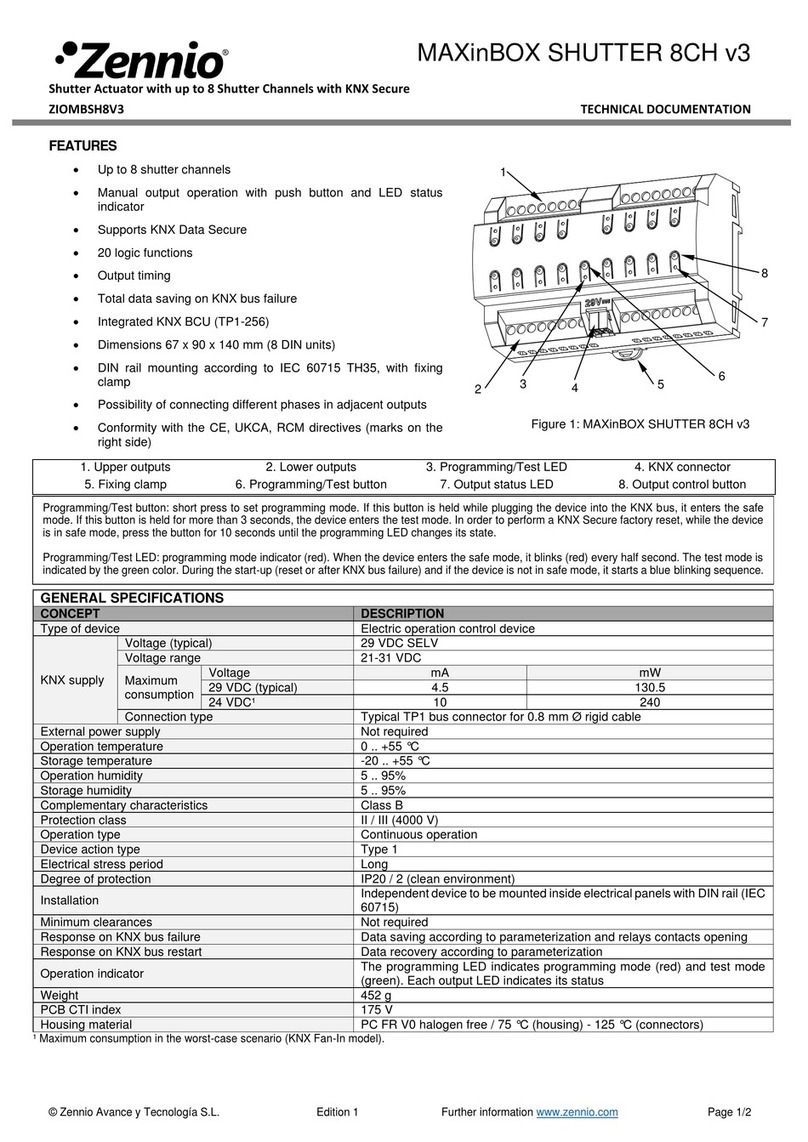

Zennio

Zennio MAXinBOX SHUTTER 8CH v3 Technical documentation

opto engineering

opto engineering LTDVE8CH-20 instruction manual